Gas pumping-exhaust directional drilling tool and drilling method

A technology of gas drainage and drilling method, which is applied in the direction of gas drainage, directional drilling, earthwork drilling, etc., and can solve the problems of gas drainage channel collapse, large drilling spacing, and drill bit hysteresis, so as to reduce hole collapse The probability of improving work efficiency and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

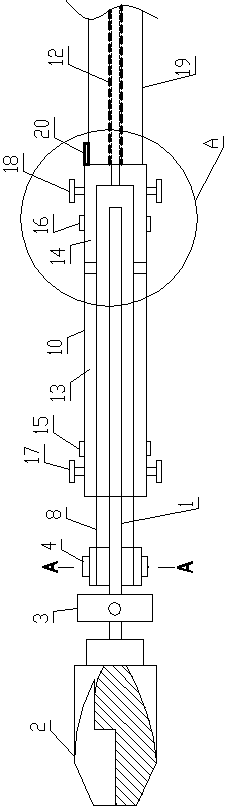

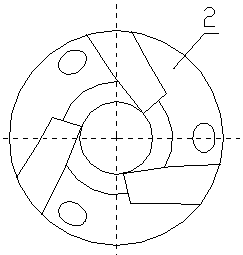

[0052] Such as Figure 1 to Figure 6 As shown, the gas extraction directional drilling tool of the present invention includes a hollow drill rod 1 and a drill bit 2, with the drilling direction as the forward direction, the hollow drill rod 1 is connected with a high-pressure gas circuit in the rear, and the front end of the hollow drill rod 1 is connected with a pneumatic Motor 3, the output shaft of the air motor 3 is forwardly connected to the drill bit 2;

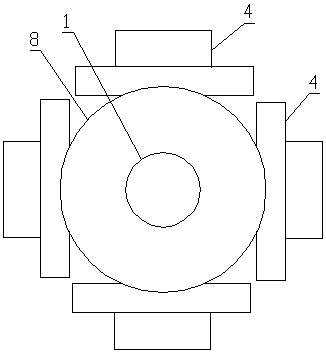

[0053] The hollow drill pipe at the rear of the air motor 3 is uniformly provided with more than three (preferably four) front air pressure tops 4 along the circumferential direction, and each front air pressure top 4 is connected with the high-pressure air circuit respectively, and each front air pressure top 4 is connected to the high-pressure air circuit. The joints of the roads are respectively provided with front solenoid valves 5 for controlling the working state of the corresponding front air pressure jacks 4; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com