Soft rock and soil layer jet flow guiding hole forming-chamfering-hole collapse preventing integrated drilling method

A technology for rock and soil layers and anti-collapse holes, applied in drilling equipment and methods, directional drilling, earthwork drilling and mining, etc., can solve problems such as hole collapse in soft strata, reduce trajectory deviation, and improve drilling efficiency , Improve the effect of hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The integrated drilling method of the soft rock-soil layer with jet-guided hole formation, hole expansion and collapse prevention of the present invention includes the following steps:

[0057] (1) Processing and testing the integrated drilling device for jet-guided hole formation in soft rock and soil-jet reaming-shotcrete anti-collapse hole.

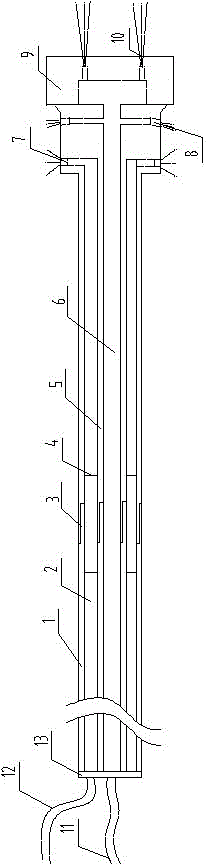

[0058] An integrated drilling device for jet-guided hole-forming-jet reaming-spraying anti-collapse hole in soft rock and soil layers such as figure 1 Shown. 1 is the outer drill pipe, 2 is the slurry inlet channel, 3 is the drill pipe joint, 4 is the support piece, 5 is the inner drill pipe, 6 is the high-pressure water channel, 7 is the slurry nozzle, 8 is the jet reaming cutting nozzle, 9 is the front section of the drill bit, 10 is the jet-guided cutting nozzle, 11 is the high-pressure water inlet pipe, 12 is the slurry inlet pipe, and 13 is the rotary seal joint. During the drilling process, the drill rod is connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com