Method for forming easy-to-collapse drilled hole

A hole-collapse and hole-sealing technology, applied in drilling equipment and methods, drilling equipment, earth-moving drilling, etc., can solve the problems of large workload, hole-collapse, and high cost, and achieves easy operation, wide practicability, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

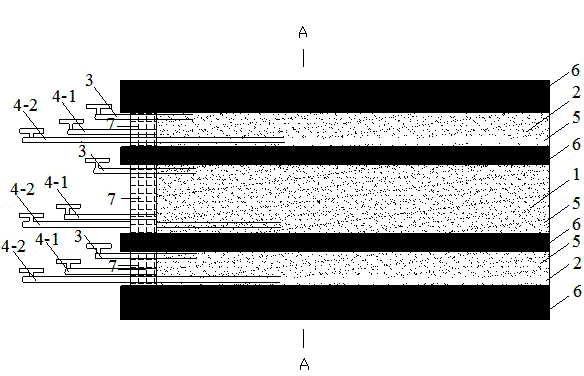

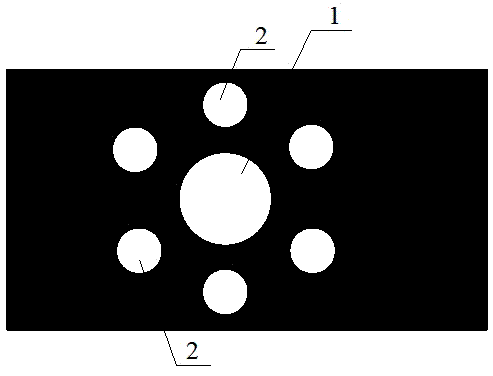

[0027] Embodiment one, as figure 1 , figure 2 In the drilling and forming method of easy-to-collapse holes, a large-diameter main curing hole 1 with a diameter of 113 mm and a depth of 70-90 m is pre-constructed in the coal seam 6, and then a radius of 200 m is constructed around the large-diameter main curing hole 1. 3~6 small-diameter auxiliary curing holes 2 evenly distributed ~250mm; the diameter of the small-diameter auxiliary curing holes 2 is 70mm and the depth is 70-90m, the drilling construction is the same as the existing technology, and the auger drill rod is selected according to the needs of the site , round drill pipe or triangular drill pipe; after the drilling construction is completed, first seal the large-diameter main curing hole 1, and put a polyurethane grouting pipe with a length of 3 to 5m into the large-diameter main curing hole 1 4-1. The cement grouting pipe 4-2 with a length of 11-13m and the grouting pipe 3 with a length of 3-5m; inject it into th...

Embodiment 2

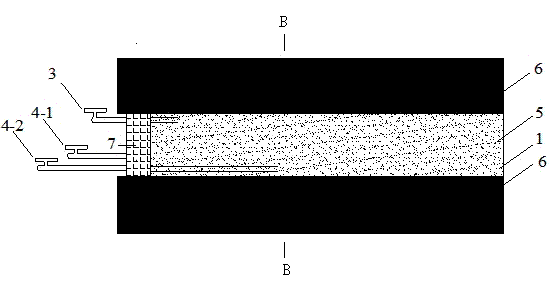

[0028] Embodiment two, such as image 3 , Figure 4 In the drilling method for easy-to-collapse holes shown, a large-diameter main curing hole 1 with a diameter of 113mm and a depth of 70-90m is pre-constructed in the coal seam 6. The drilling construction is the same as the existing technology, and the auger drill can be selected according to the needs. rod, round drill rod or triangular drill rod. After the drilling construction is completed, the large-diameter main curing hole 1 is sealed, and a polyurethane grouting pipe 4-1 with a length of 3 to 5 m and cement with a length of 11 to 13 m are put into the large-diameter main curing hole 1. The grouting pipe 4-2 and the grouting pipe 3 with a length of 3-5m; the polyurethane layer 7 with a thickness of 1-2m is injected into the orifice of the large-diameter main curing hole 1 through the polyurethane grouting pipe 4-1. During the polyurethane process, the grouting pipe 3 should be kept close to the upper inner wall of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com