Reusable anti-hole collapse drilling apparatus and drilling method thereof

A drilling device and anti-slump hole technology, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve the problem of damage to casing, increase in cost, and reuse of drill pipe jacket without mentioning hole protection pipe and other problems, to achieve the effect of repeated use and reduction of drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a reusable anti-collapse hole drilling device and drilling method. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. illustrate.

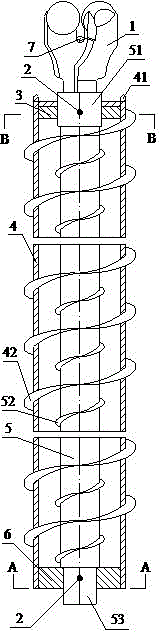

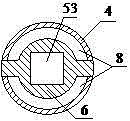

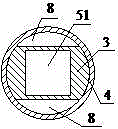

[0021] like Figure 1~5 As shown, a reusable anti-collapse hole drilling device and drilling method, the device includes a drill bit 1, an auger rod 5, an auger barrel 4, a plug 3, a rotor 6 and a latch 2; the auger rod 5 The rod body part is a cylinder, and the head and tail are square handles 51, 53. The rod body is welded with spiral patterns 52, and the head square handle 51 is provided with a cylindrical threaded hole, which is identical with the diameter of the drill bit 1 tail bolt. The auger barrel 4 is a steel pipe, the top of which is welded with alloy drill teeth 41, and the outside of the auger barrel 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com