Method for increasing gas extraction rate by permeability increasing of single thick coal seam

A technology for gas drainage and thick coal seam, which is applied in the fields of gas emission, mining equipment, earthwork drilling, etc. It can solve the problems of poor drainage effect, difficulty in controlling the direction of fracturing, and general gas drainage rate effect, etc. A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: A method for enhancing gas drainage rate in a single thick coal seam area, including the following steps:

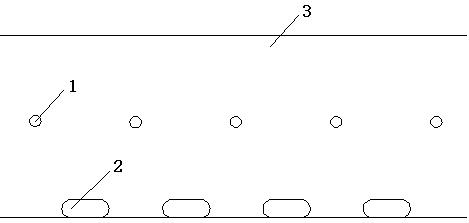

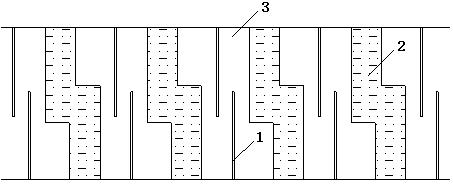

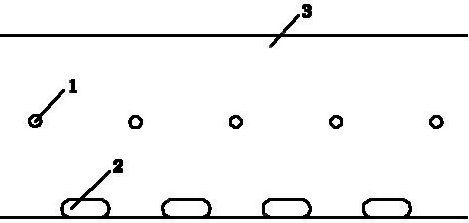

[0018] a. During the roadway excavation of the coal seam working face, construct the bedding gas drainage borehole 1;

[0019] b. After the construction of the gas drainage borehole 1 is completed, the hole protection pipe is sent into the gas drainage borehole 1;

[0020] c. Seal the gas drainage borehole 1 and connect it to the mine gas drainage system to extract gas from the coal body 3 in the working face;

[0021] d. When the roadway excavation length is greater than 50m, along with the progress of the roadway excavation, use the auger shearer to drill along the inclination at the bottom of the coal seam in the excavated roadway to form the drilling hole 2;

[0022] e. Continue to drill with the auger shearer to form the next drilling hole 2 every other section of the coal pillar until the drilling hole 2 operation of the entire roadway is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com