A method for pressure relief and permeability enhancement of coal seam area slices based on the principle of "mining protective layer"

A technology for protecting seams and coal seams, applied in the direction of mining fluids, ground mining, mining equipment, etc., can solve problems such as poor pre-drainage of coal seam gas, reduce the amount of drilling engineering, shorten the extraction time, and solve technical and economic problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. The present invention can also be implemented or applied through other different specific embodiments, and various details in this specification can also be modified or changed based on different viewpoints and applications without departing from the spirit of the present invention.

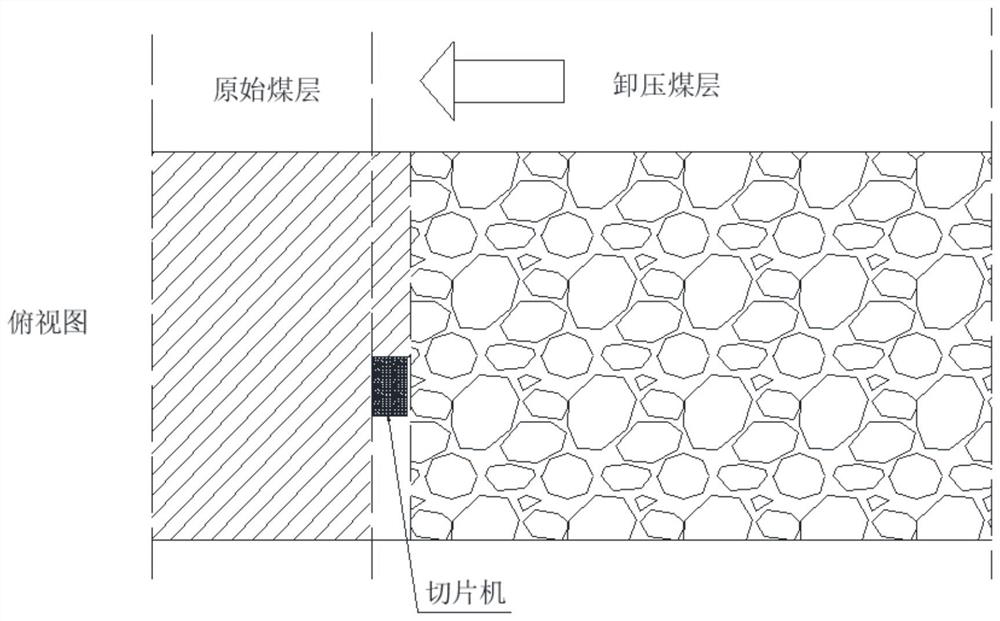

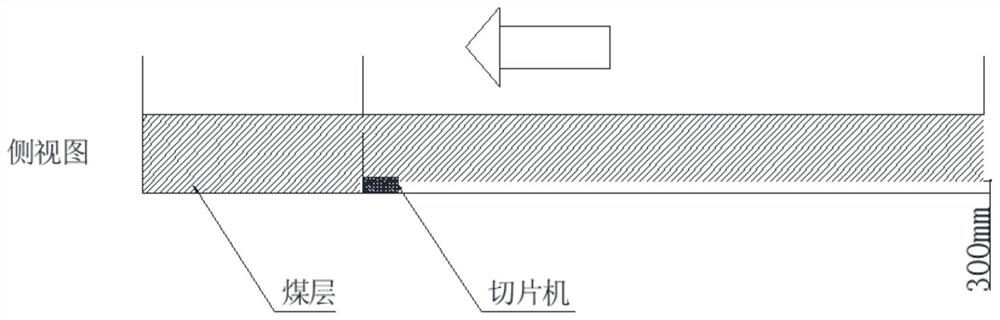

[0030] like Figures 1 to 2 A method of slicing pressure relief and permeability enhancement in the coal seam area based on the principle of "mining protective layer" is shown. A slicer can sweep across the entire mining face, freeing 200-300 mm of pressure relief space for the coal seam in the thickness direction of the coal seam. It is fully decompressed. Now, taking a mining face that is being driven along the groove as an example, the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com