Method for draining gas of mining layer of mine

A gas drainage and mining layer technology, which is applied in the fields of gas discharge, mining equipment, earthwork drilling, etc., can solve the problem of not exceeding the limit of gas gushing, and achieve the effect of improving the gas drainage rate and increasing the gas permeability coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

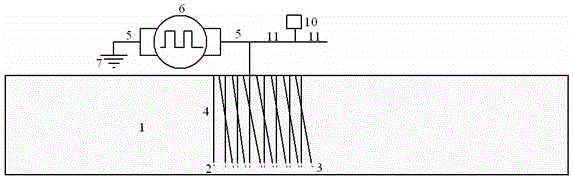

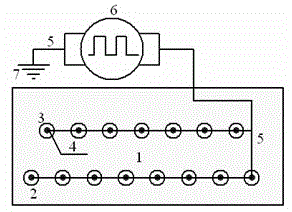

[0020] Such as figure 1 , 2 As shown, a mine 2 # The gas in the coal seam working face mainly comes from mining layer 1, which is a coal seam that is difficult to drain. Originally, the coal seam gas drainage was mainly used, and goaf drainage was supplemented, and the pre-drainage was combined with extraction while mining. Arrange cross-drilled high-negative-pressure drainage along the air return trough of the mining face. The vertical drilling 2 for gas drainage has a hole height of 1.5m, and the oblique cross-drilled hole 3 for gas drainage has a height of 1.8m. The drilling depth is 90m, the actual drainage rate is 20%. On this basis, adopting the method of the present invention to carry out the gas drainage of the working face of the mining layer, the steps are:

[0021] I. In 2 # Iron insulated electrodes 4 are arranged in the gas drainage vertical boreholes 2 and gas drainage oblique cross boreholes 3 of the coal mining layer 1. The iron insulated electrodes 4 have...

Embodiment 2

[0026] A mine 15 # The gas in the coal seam mining face mainly comes from mining layer 1, which is a coal seam that is difficult to drain. Originally, the coal seam gas drainage was mainly used, and the gob drainage was supplemented, and the pre-drainage was combined with extraction while mining and extraction while digging. Arrange cross-drilled high-negative-pressure drainage in the return air trough of the mining face. Vertical drilling 2 for gas drainage is located 1.4m away from the bottom plate. The hole depth is 170m, and the drainage effect is poor. according to figure 1 The shown arrangement of pulsed high-voltage electric field for gas drainage in the mining layer drains the gas in the mining layer. The output power of the intrinsically safe pulsed high-voltage power supply is 1000kW, and the output voltages are 660V, 1000V, 1600V, 7800V, 12kV, 20kV and 40kV. , the actual drainage effect is good, and the drainage rate is increased by 23%. Others are with embodime...

Embodiment 3

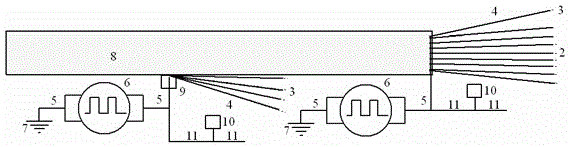

[0028] A mine 3 # The coal seam is a high-gas coal seam, and the roadway is excavated in a single lane. Vertical drilling 2 for gas drainage and oblique cross drilling 3 for gas drainage are arranged in the stepping drill field 9 where two sides of roadway 8 are excavated at the front of the excavation working face and behind the front of the excavation working face. The lengths of the drilling holes are 130 m and 150 m respectively. , the actual pumping effect is not good. according to image 3 The shown arrangement of pulsed high-voltage electric field for gas drainage in the mining layer is used to drain the gas in the excavation face. The iron insulated electrode 4 has a diameter of 16mm and a length of 130m and 150m respectively. The actual drainage effect is good, and the drainage rate Increased by 21%. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com