A telescopic floating pipe bridge applied to floating pumping stations

A technology of floating and pipe bridges, applied in floating bridges, bridge applications, bridges, etc., can solve the problems of large investment, difficult maintenance, increased water intake costs, etc., and achieve the effect of convenient construction and low erection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

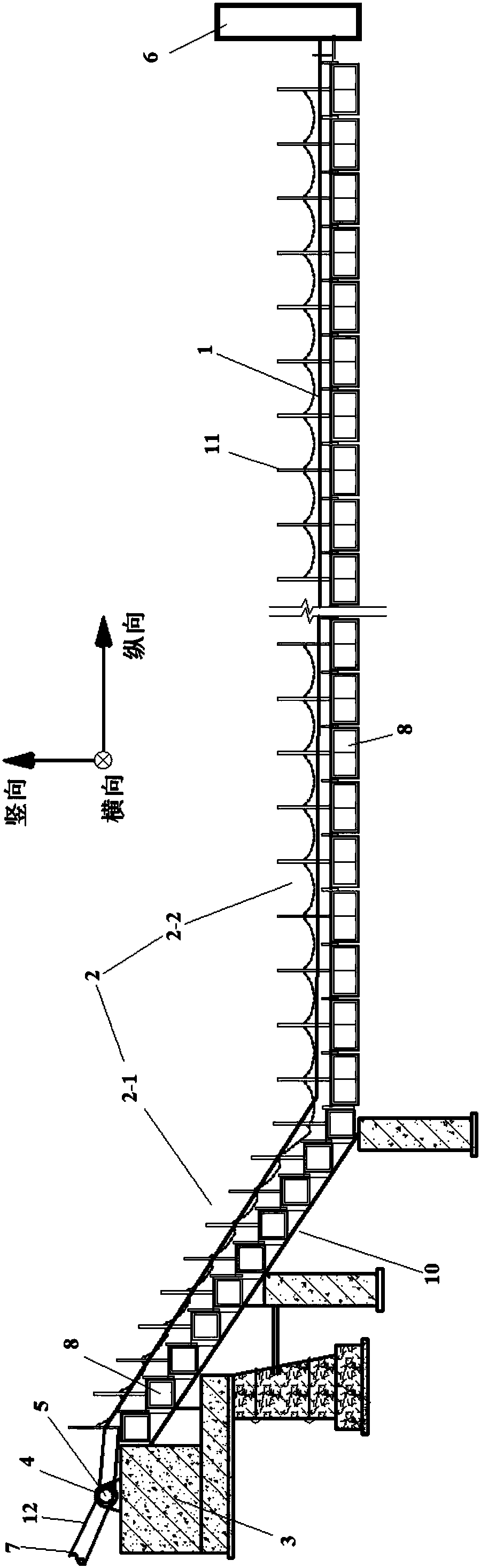

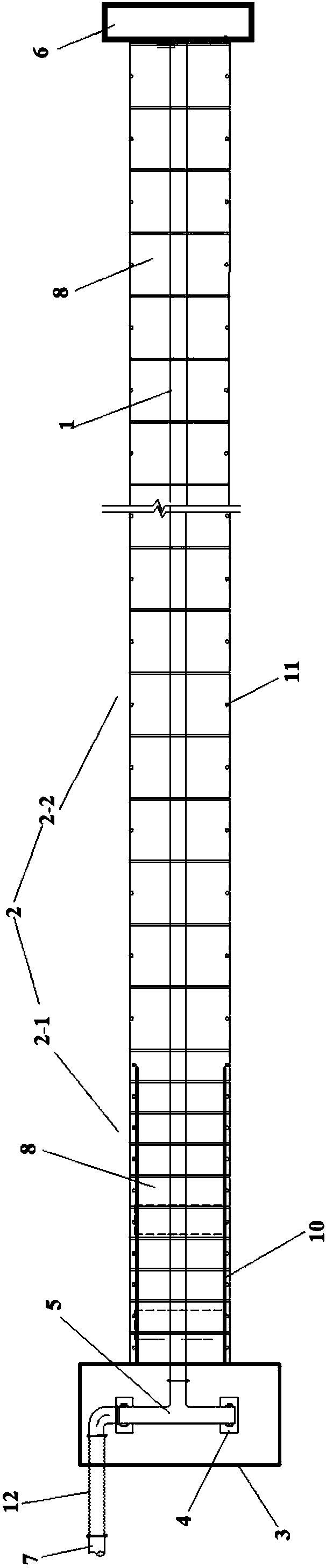

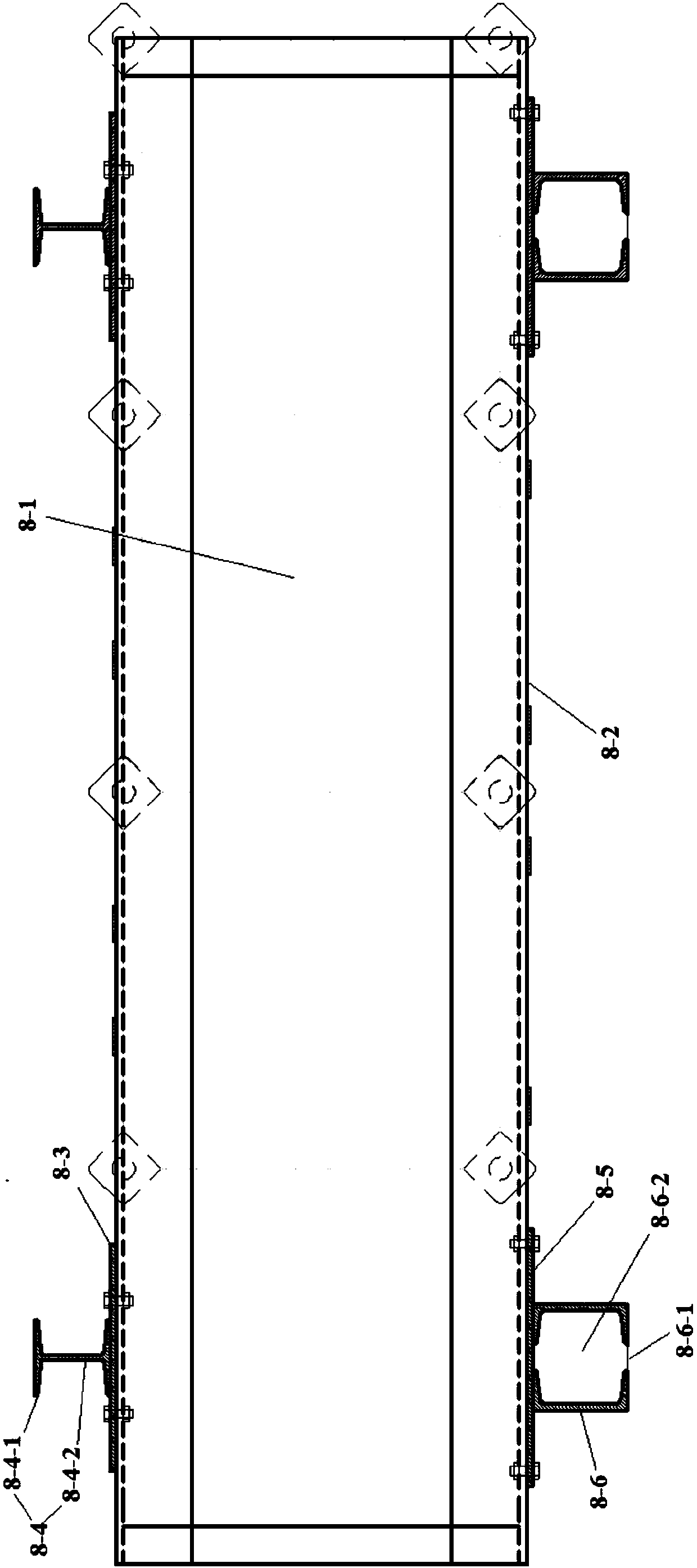

[0055] Comply with the above technical solutions, such as Figure 1 to Figure 13 As shown, this embodiment provides a telescopic floating pipe bridge applied to floating pumping stations, including a water delivery pipe 1, the water delivery pipe 1 is an inextensible hose, and a floating pipe bridge 2 and installed on A pair of rotating bearings 4 on the embankment foundation 3, a pair of rotating bearings 4 are equipped with a three-way pipe 5 that can rotate on the rotating bearings 4, the tee pipe 5 between a pair of rotating bearings 4 The end is connected with the head end of the water delivery pipe 1, and the tail end of the water delivery pipe 1 is connected with the floating pump station 6; the end of the tee pipe 5 on one side of the pair of rotating support bases 4 communicates with the upper water delivery pipe 7; The ends of the tee pipe 5 on the other side of a pair of rotating support bases 4 are closed for standby use;

[0056] The floating pipe bridge 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com