Hole forming process of dual-purpose hole of anchoring hole and drainage hole in muck side slope

A technology for drainage holes and slag, which is used in soil protection, infrastructure engineering, sheet pile walls, etc., can solve the problems of weak and loose soil collapse, difficulty, stuck drilling, etc., to strengthen the anchoring effect and improve the construction. Efficiency, the effect of enhancing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

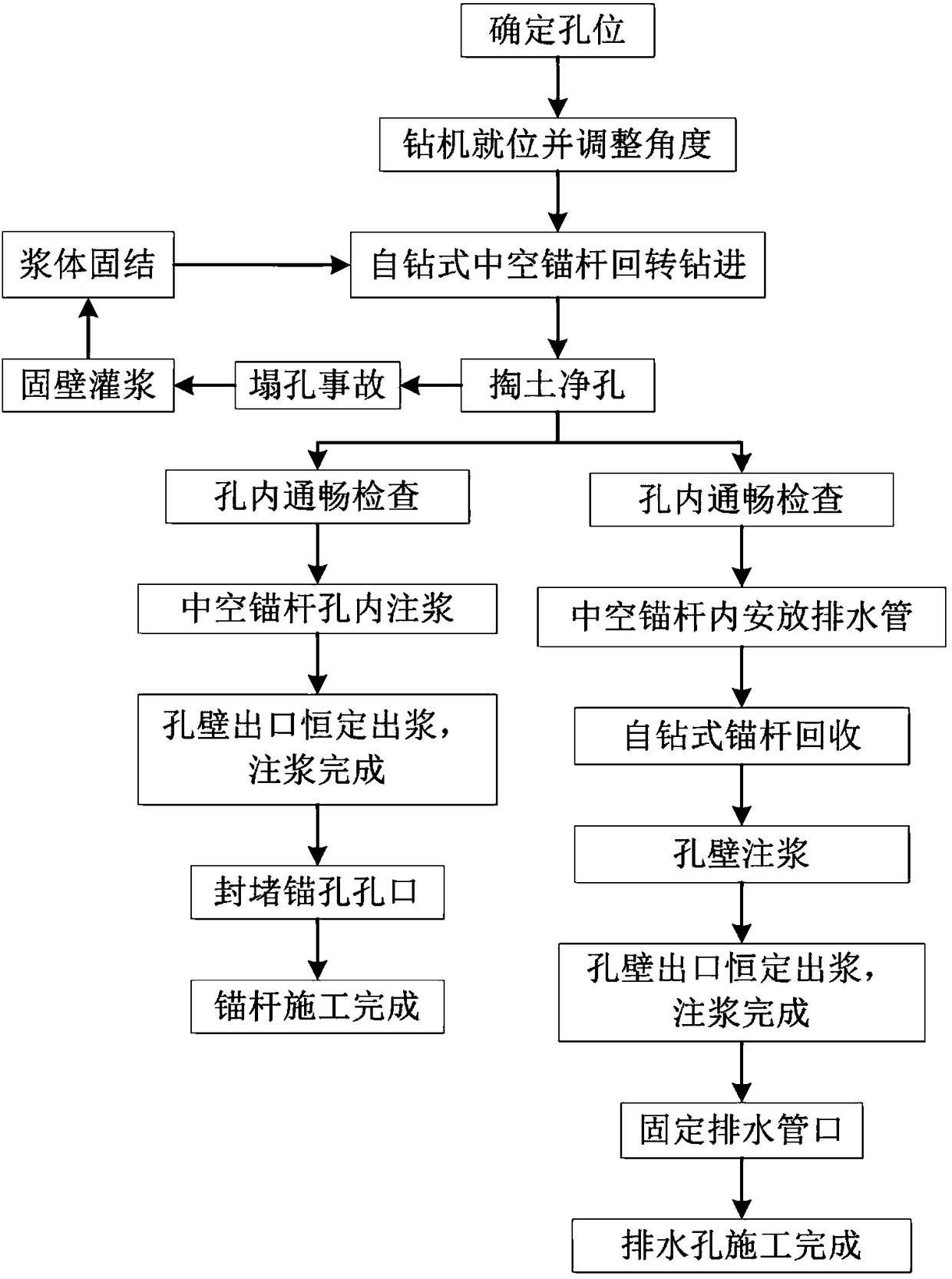

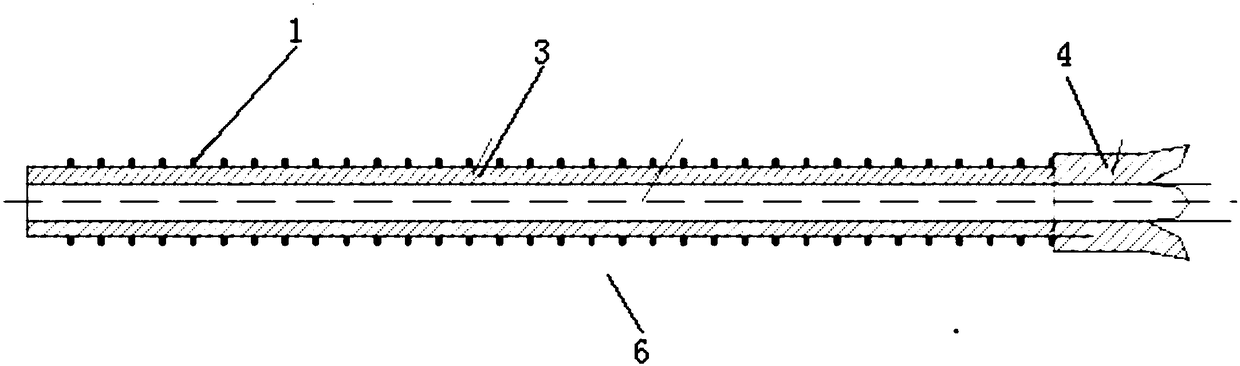

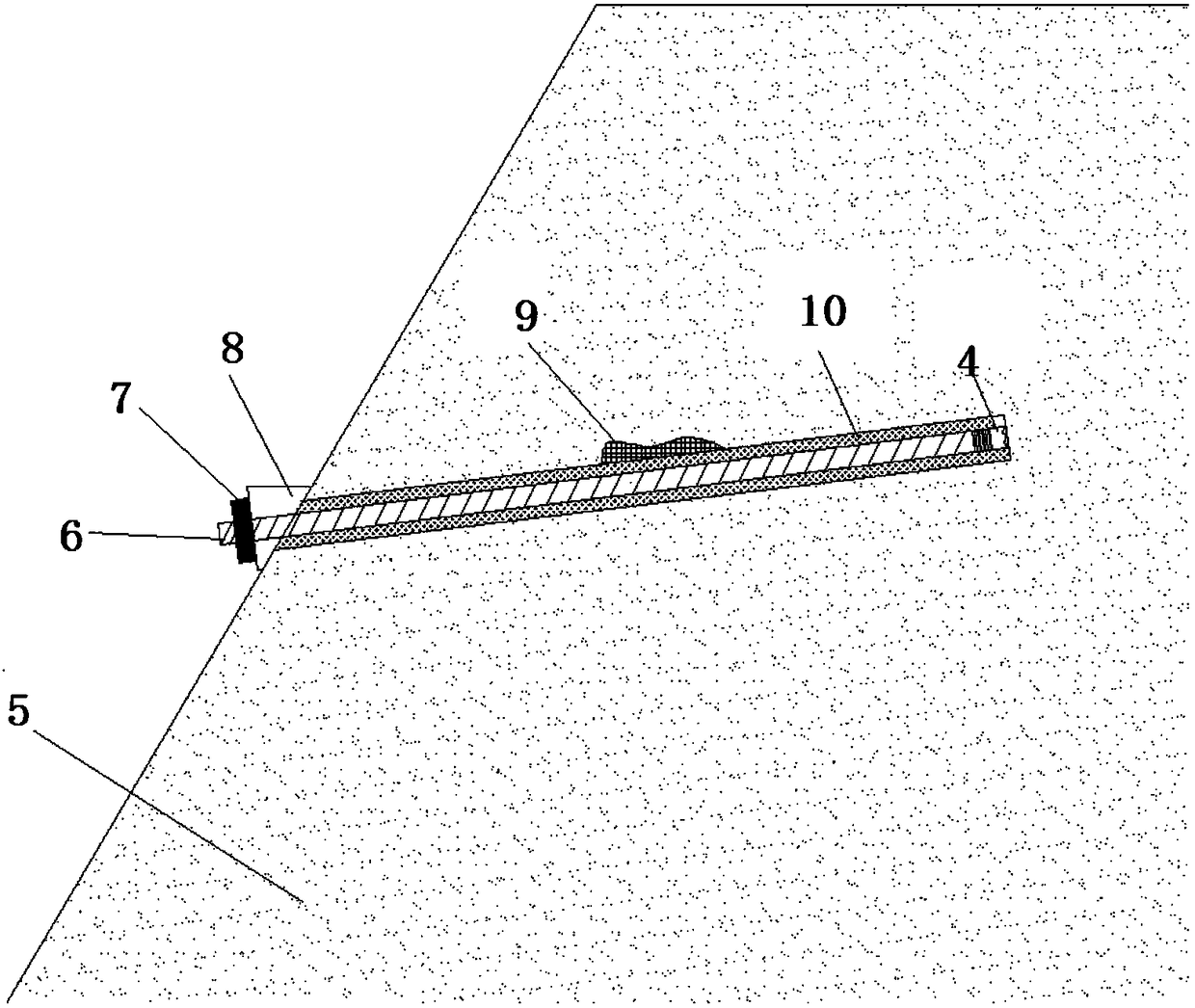

[0040] Such as Figure 1-4 As shown, the present invention will be described in detail below in conjunction with specific examples. The following examples and descriptions are only used to explain the present invention, but not as a limitation to the present invention.

[0041] A hole-forming process for an anchor hole and a drainage hole in a muck slope, comprising the following steps:

[0042] a. According to the analysis of the internal structure of the muck body 5, determine the position and depth of the hollow anchor body 6 and the drainage pipe 11; mark the corresponding position;

[0043] b. After installing the hollow bolt body 6 on the rotary drilling rig, at the position determined in step a, the on-site technicians use a protractor to adjust the turning angle of the hollow bolt body 6, and then drill the hollow bolt into the muck body 5 body 6; when drilling the hollow bolt body 6, it is necessary to dig out soil and discharge slag. During the drilling process, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com