Spiral high-pressure jetting wing-enlarged stirring bottom-expanded stiff composite pile, construction method thereof and drilling machine

A composite pile and screw technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of insufficient bearing capacity of pile foundation and high pile layout density, and achieve the improvement of pile bearing capacity, increase of pile end resistance, The effect of reducing the layout density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

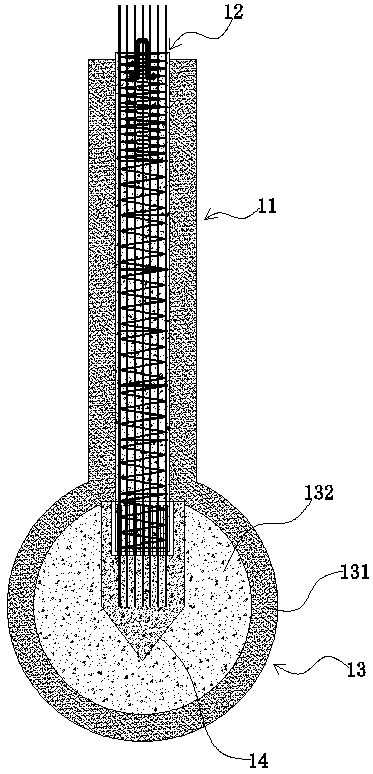

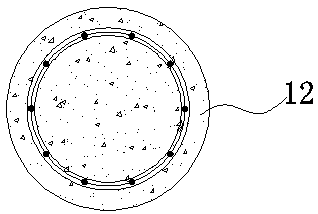

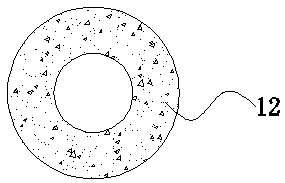

[0053] Please also refer to Figure 1 to Figure 6 .

[0054] Such as figure 1 As shown, the spiral high-spraying-spreading-wing-stirring and bottom-expanding composite pile provided in this embodiment includes an outer pile body 11, an inner core pile 12 and an expansion base 13, the lower end of the outer pile body 11 is combined with the expansion base 13, and the inner core The lower end of the pile 12 is equipped with a prefabricated pile tip 14 , and the inner core pile 12 and the prefabricated pile tip 14 are pressed and implanted into the outer pile body 11 . By installing the prefabricated pile point 14 at the lower end of the inner core pile 12, it is convenient to penetrate the inner core pile 12 into the outer pile body 11 during actual construction. The expansion base 13 includes a peripheral portion 131 made of cement and soil and a central portion 132 made of concrete, and the central portion 132 accounts for 80%-90% of the volume of the entire expansion base 1...

Embodiment 2

[0062] see Figure 7 .

[0063] The difference from Example 1 is that the outer pile body 11 of the spiral high-spray-spreading wing-stirring and bottom-expanding stiff composite pile provided in this embodiment is provided with three diameter-expanding pile body parts 111, and the diameter-expanding pile body parts 111 expand outwards. , by changing the diameter, the contact area between the entire composite pile and the surrounding soil is increased, the side friction resistance is improved, and the settlement of the pile is reduced.

Embodiment 3

[0065] Please also refer to Figure 8 to Figure 15 .

[0066] The difference from Example 1 is that the inner core pile 12 of the spiral high-sprayed wing-stirred and bottom-expanded stiff composite pile provided in this example can also be Figure 8 Polygonal reinforced concrete prefabricated solid core piles in Figure 9 Polygonal reinforced concrete prefabricated hollow core piles in Figure 10 cast-in-place reinforced concrete core piles, Figure 11 The finished pipe piles in Figure 12 The finished solid square pile in Figure 13 The finished hollow square pile core pile, Figure 14 Concrete-filled steel pipe piles in or Figure 15 The H-shaped steel piles in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com