High-low-speed shear emulsifying mixer

A stirring device, high and low speed technology, applied in mixers with rotating stirring devices, transportation and packaging, chemical instruments and methods, etc., can solve problems such as uneven stirring, bottom material discharge deposition, backward stirring methods, etc., to achieve Stir evenly and fully, emulsify evenly and fully, and have good emulsifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

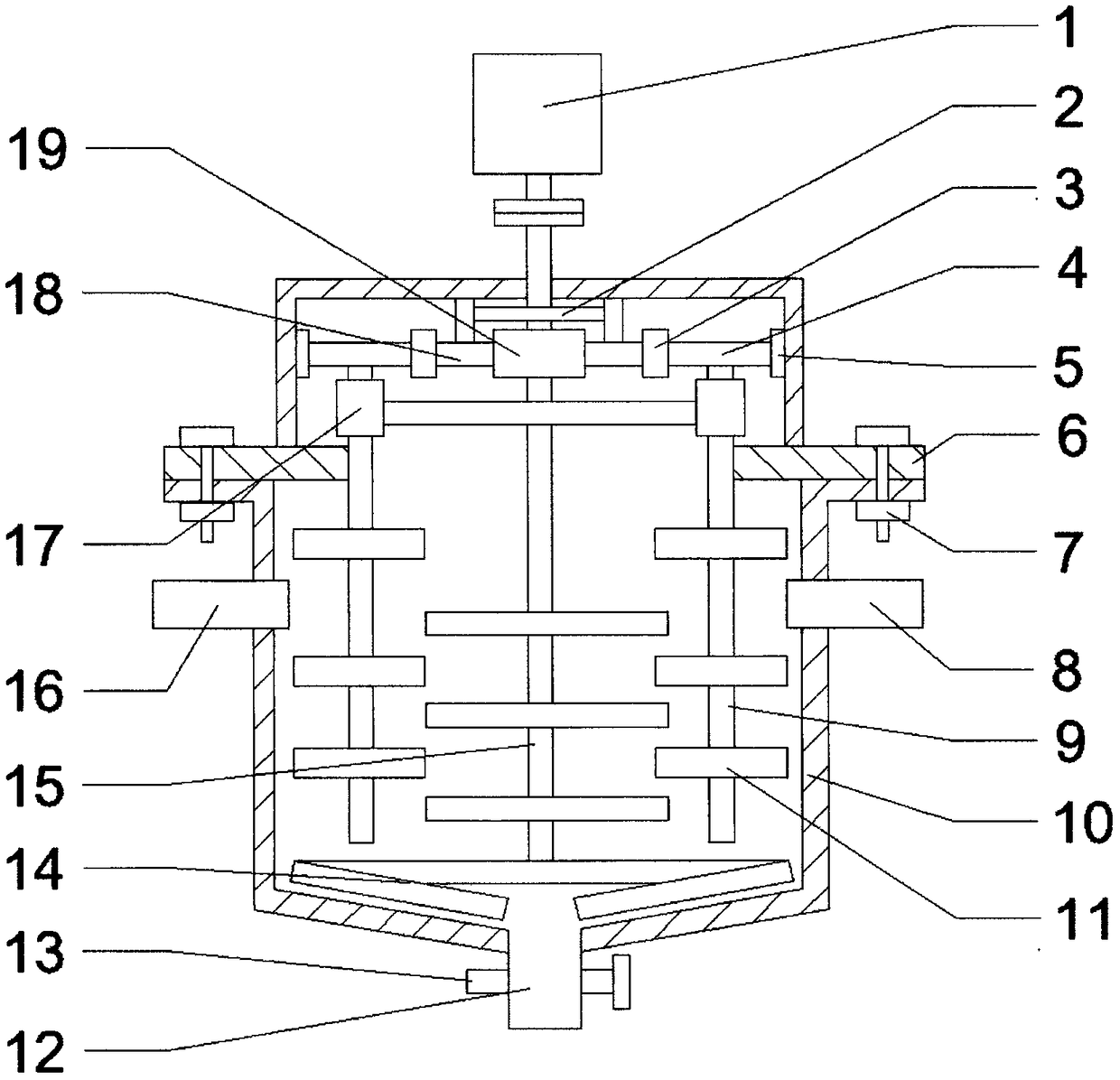

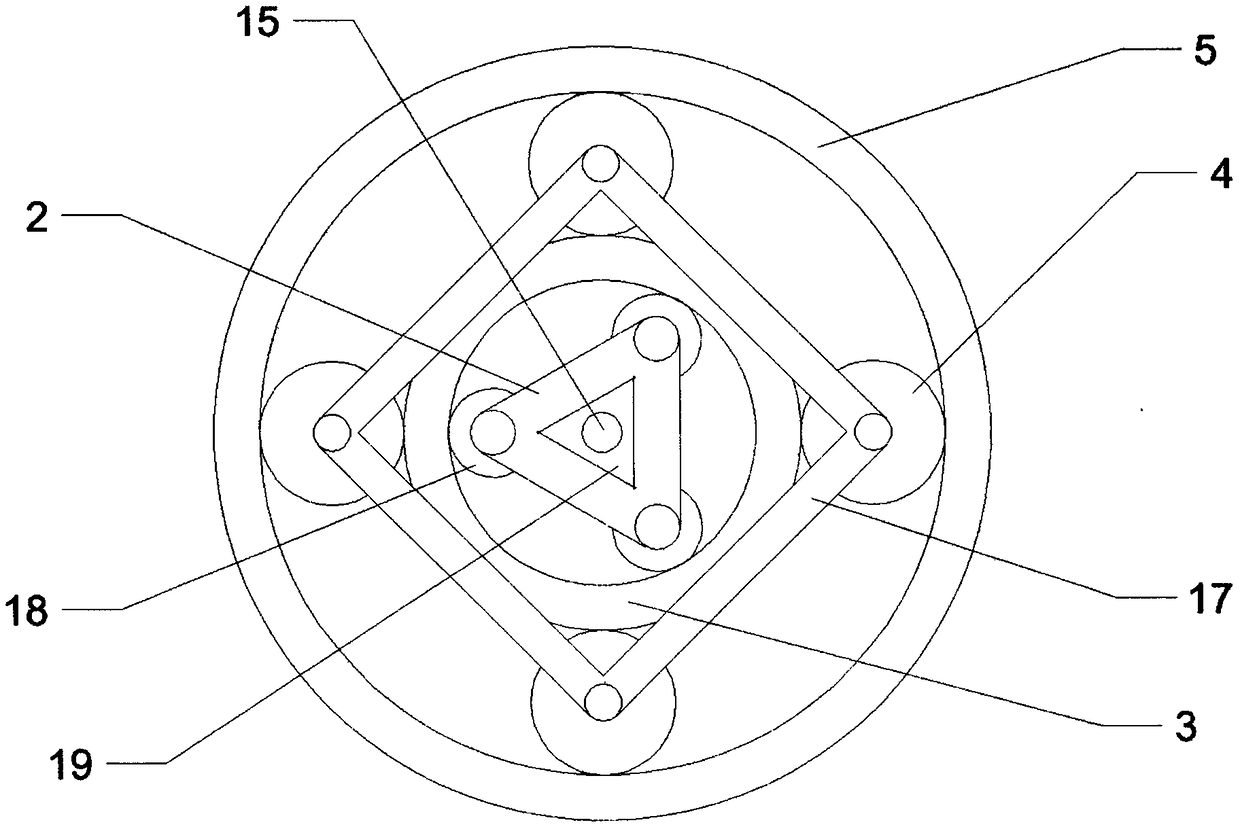

[0016] see Figure 1-2 , a high and low speed shear emulsification stirring device, including a tank body 10 and a cover body 6; the tank body 10 is a cylindrical structure with an open cavity, and the bottom is conical; the center position of the bottom of the tank body 10 is provided with a discharge port 12; the discharge port 12 is equipped with a shut-off valve 13; the upper part of the side of the tank body 12 is provided with a first feed port 8 and a second feed port 16; the first feed port 8 and the second feed port 16 Symmetrically distributed; the tank body 10 is connected and fixed with the cover body 6 by bolts 7; the cover body 6 is a cylindrical structure with an open cavity, and the opening is downward; the inner wall of the cover body 6 is fixed with a large ring gear 5; The large ring gear 5 meshes with the second planetary gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com