Patents

Literature

37results about How to "Increase speed difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

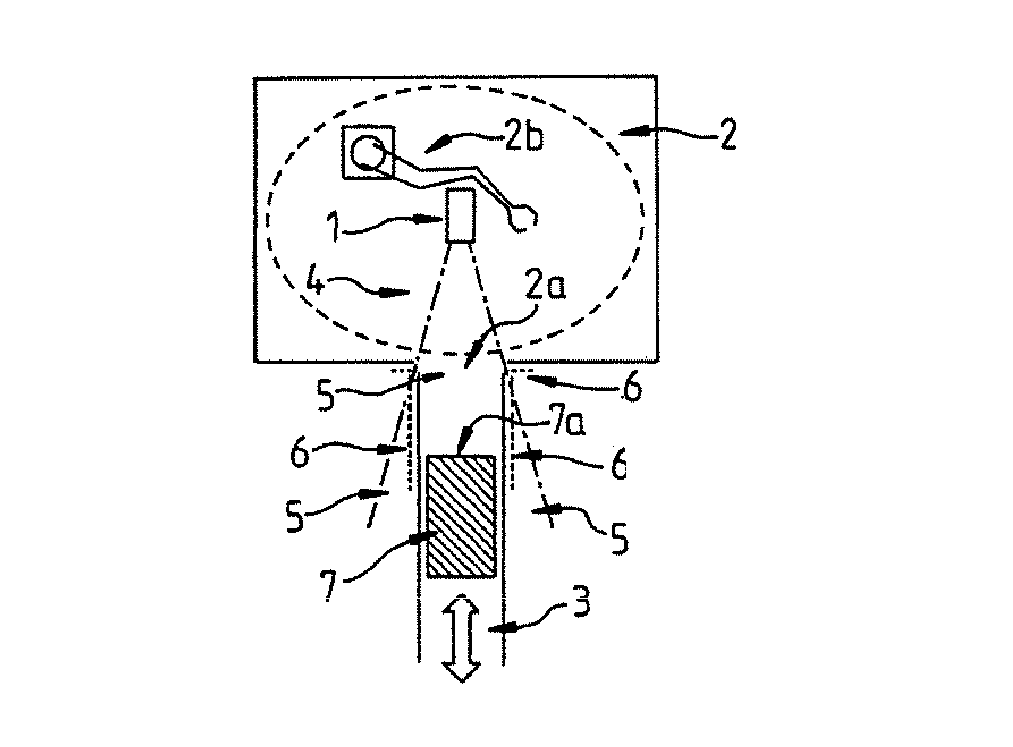

Sensor device and system having a conveyor and a sensor device

ActiveUS20090316135A1Easy to monitorMutual disturbanceProgramme controlProgramme-controlled manipulatorEngineeringAcceleration Unit

A sensor device having a sensor arrangement for detecting moving objects that includes a sensor and an electronic unit. The sensor arrangement is designed to detect an object and to subsequently investigate whether there are present within the surface of the object regions that move at a different speed and / or acceleration. The sensor arrangement can also investigate whether the object is accelerating.

Owner:ROCKWELL AUTOMATION SWITZERLAND

Sensor device and system having a conveyor and a sensor device

ActiveUS8107058B2Easy to monitorMutual disturbanceProgramme controlProgramme-controlled manipulatorEngineeringElectronic unit

A sensor device having a sensor arrangement for detecting moving objects that includes a sensor and an electronic unit. The sensor arrangement is designed to detect an object and to subsequently investigate whether there are present within the surface of the object regions that move at a different speed and / or acceleration. The sensor arrangement can also investigate whether the object is accelerating.

Owner:ROCKWELL AUTOMATION SWITZERLAND

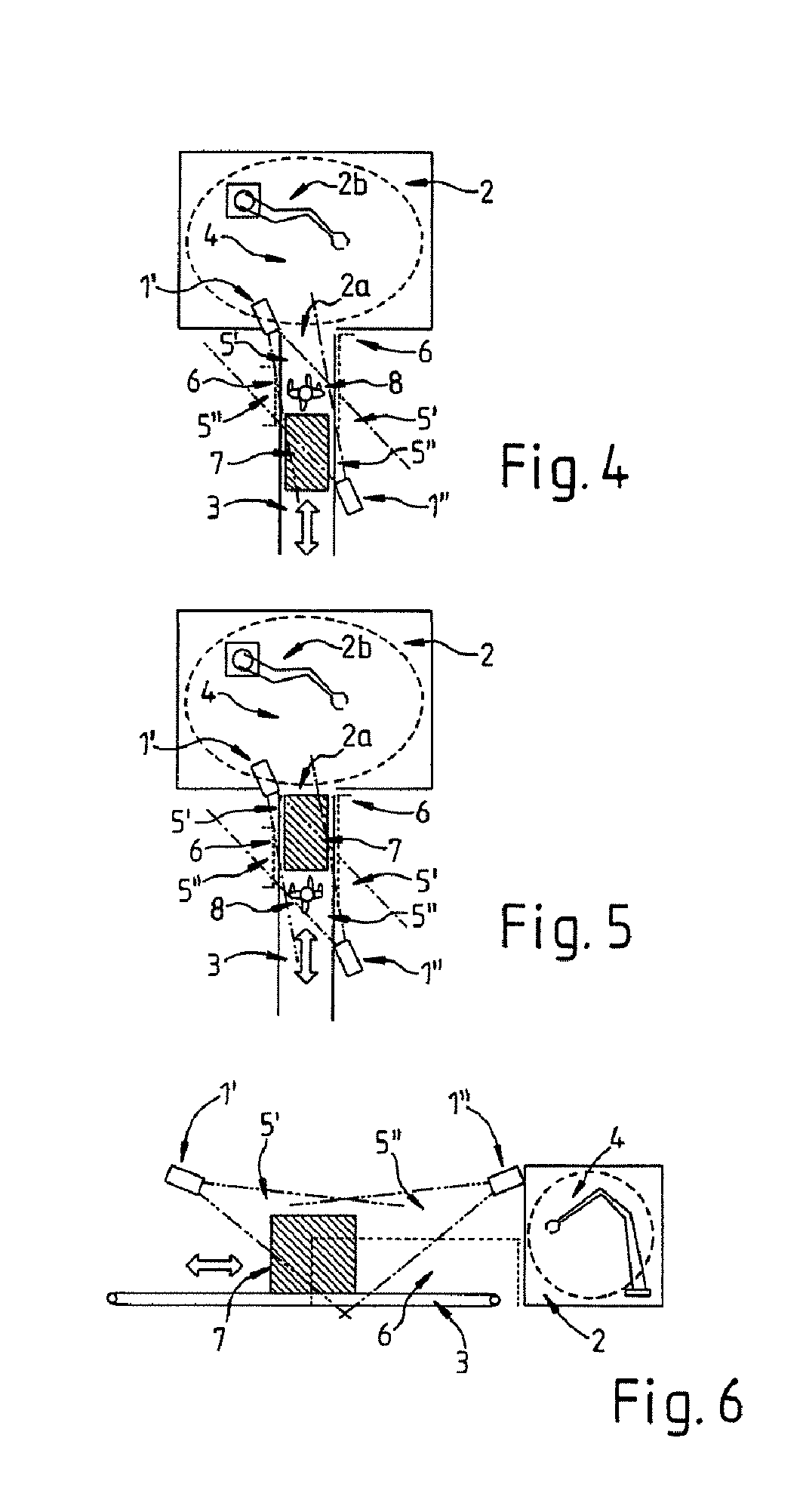

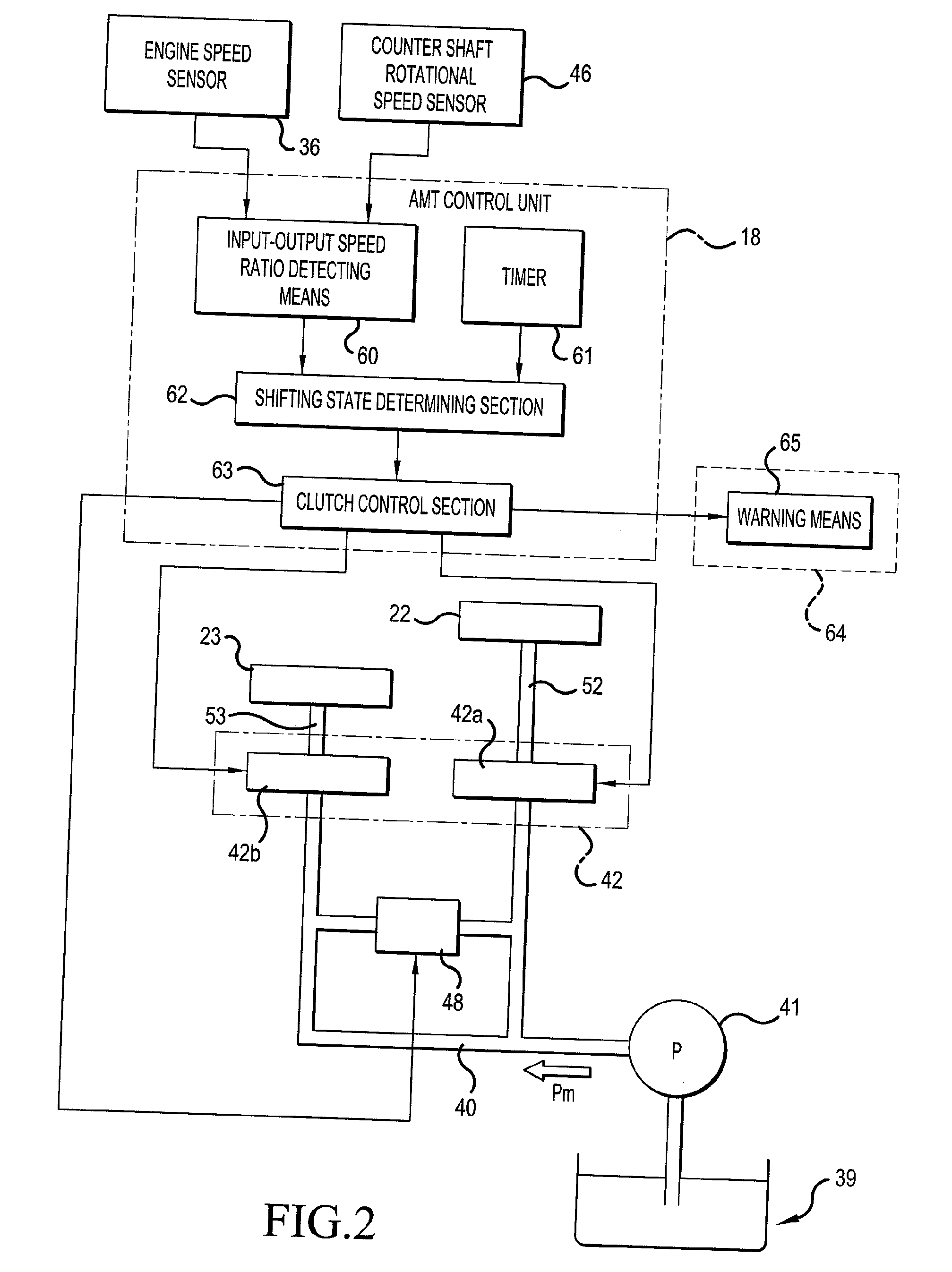

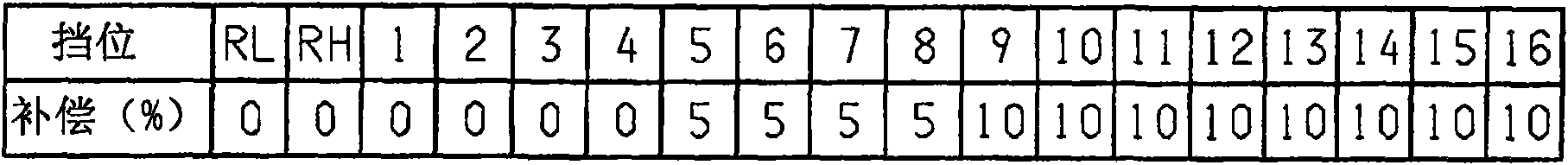

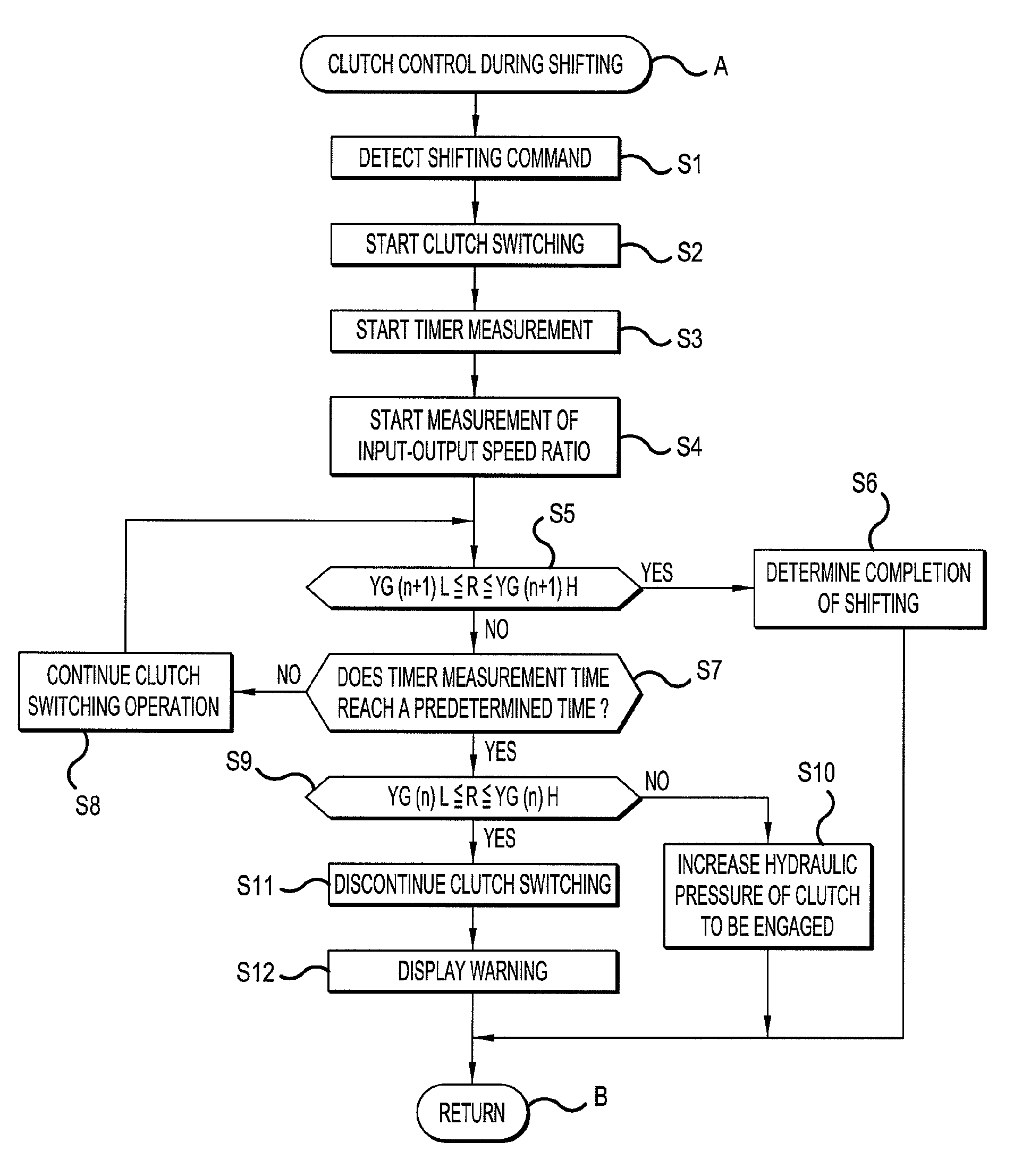

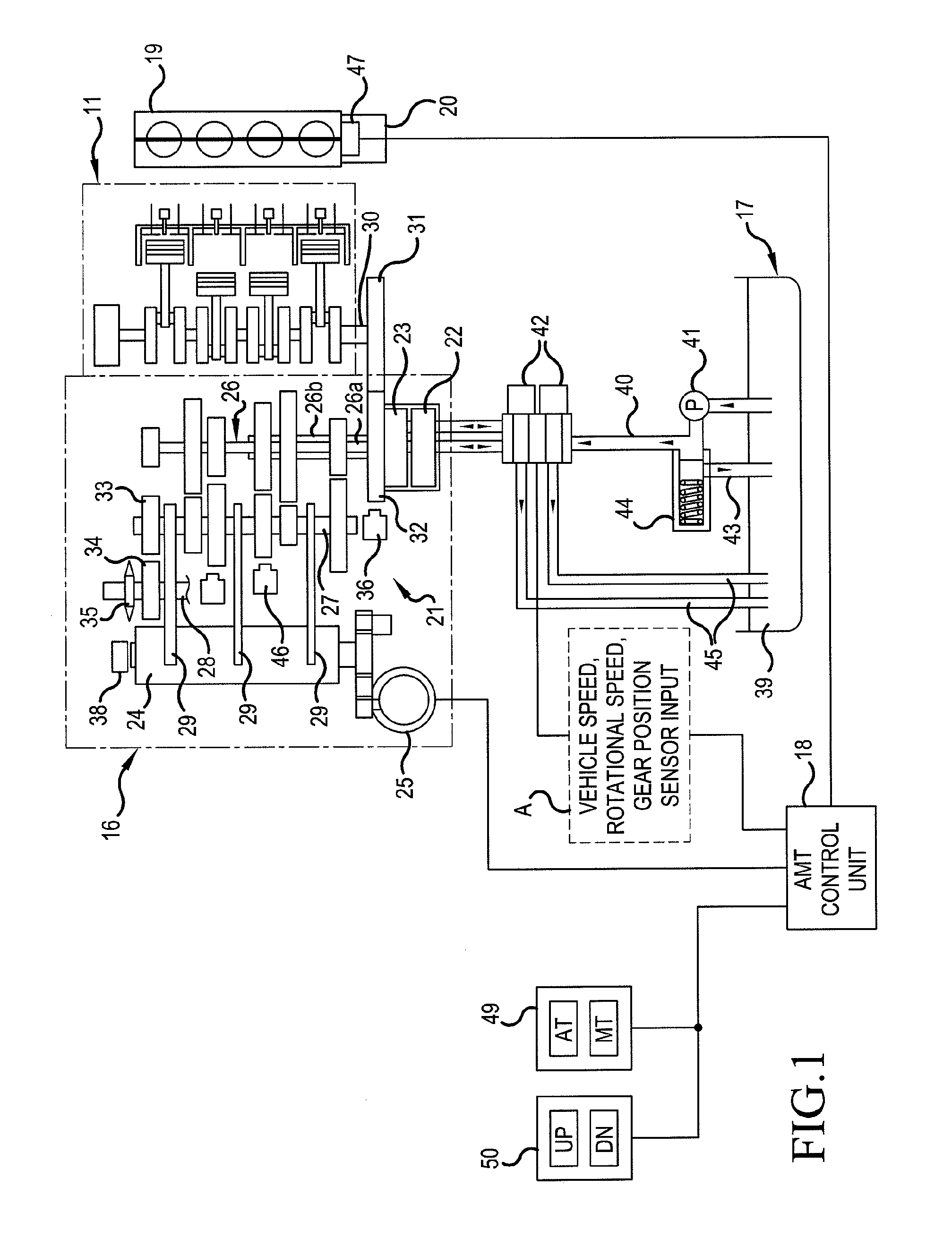

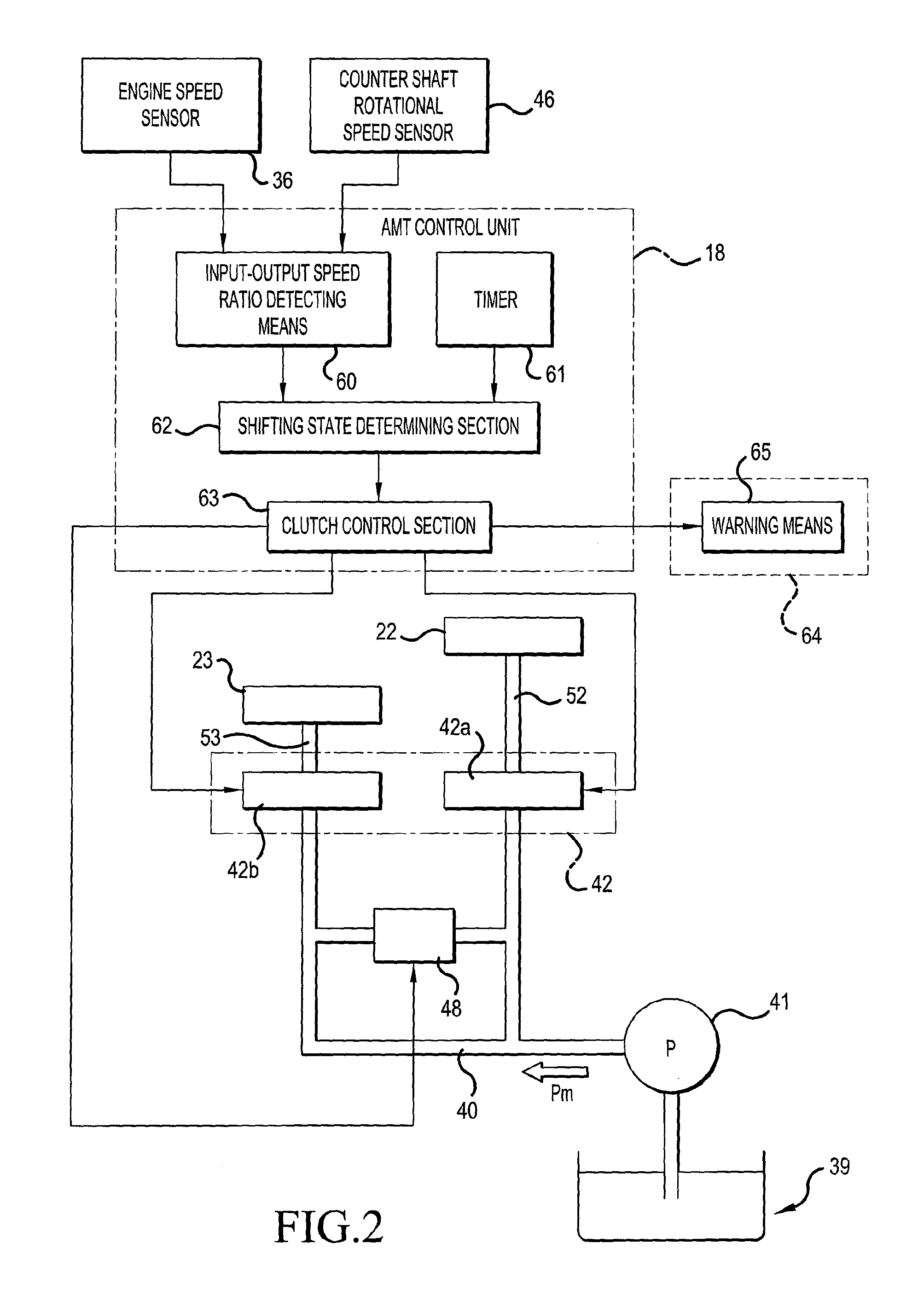

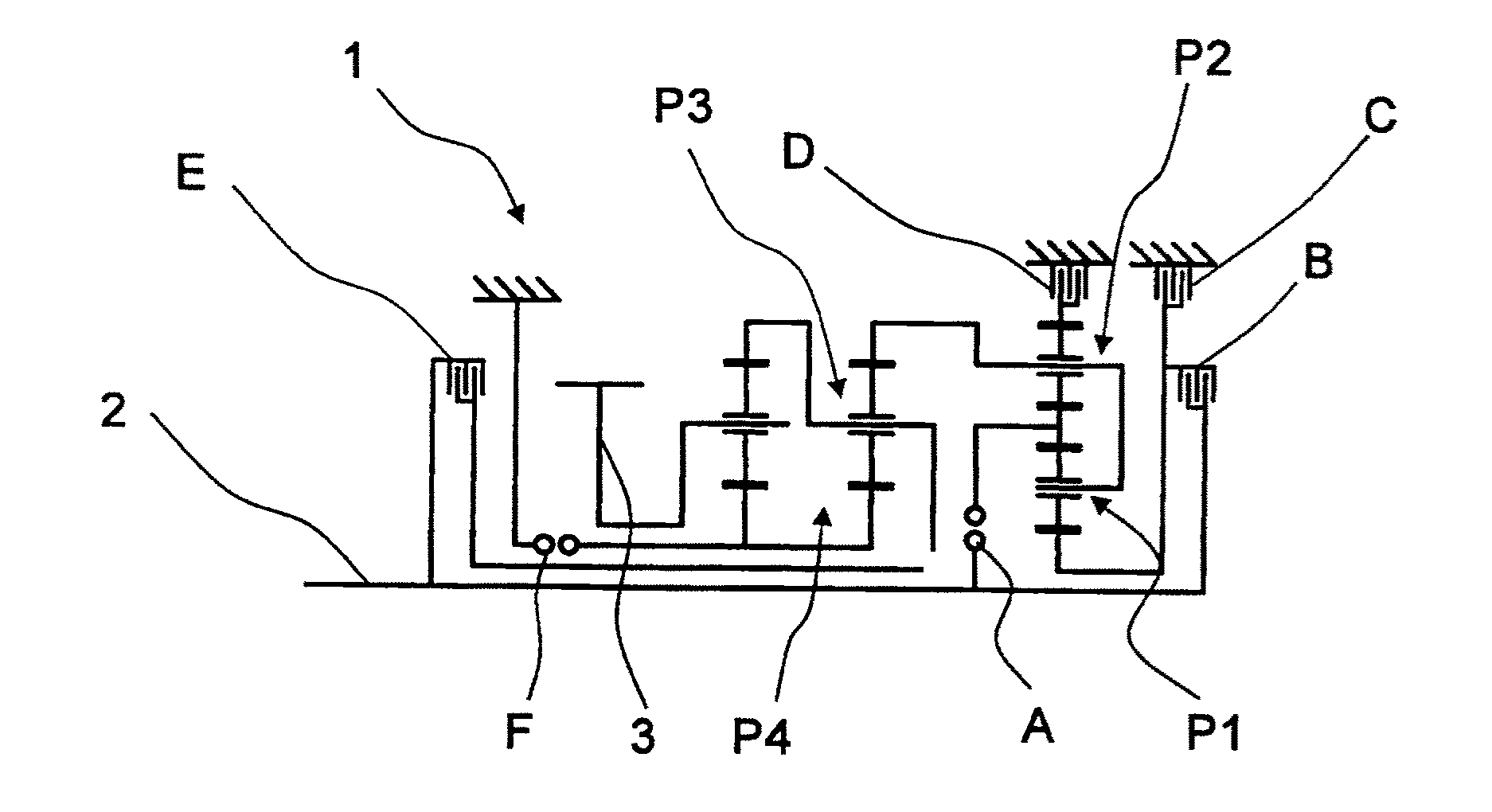

Clutch control system for transmission

ActiveUS20090132133A1Discontinue switching operationQuick identificationDigital data processing detailsGearing controlVariatorEngineering

A clutch control system for a transmission for detecting if hydraulic control during shifting is not executed. A first clutch and a second clutch are switched from a disengagement state to an engagement state by receiving a predetermined pressure generated by a hydraulic pump. A transmission executes shifting to an adjacent gear step by operation of switching the engagement state of the first clutch and of the second clutch from one side to the other side. If an elapse time t from the start of clutch switching operation reaches a predetermined time and an input-output speed ratio which is a ratio between engine speed and counter shaft rotational number falls within a predetermined range corresponding to a gear step before shifting, the transmission control unit discontinues the clutch switching operation by stopping the supply of hydraulic pressure to the other side clutch to bring it into the disengagement state.

Owner:HONDA MOTOR CO LTD

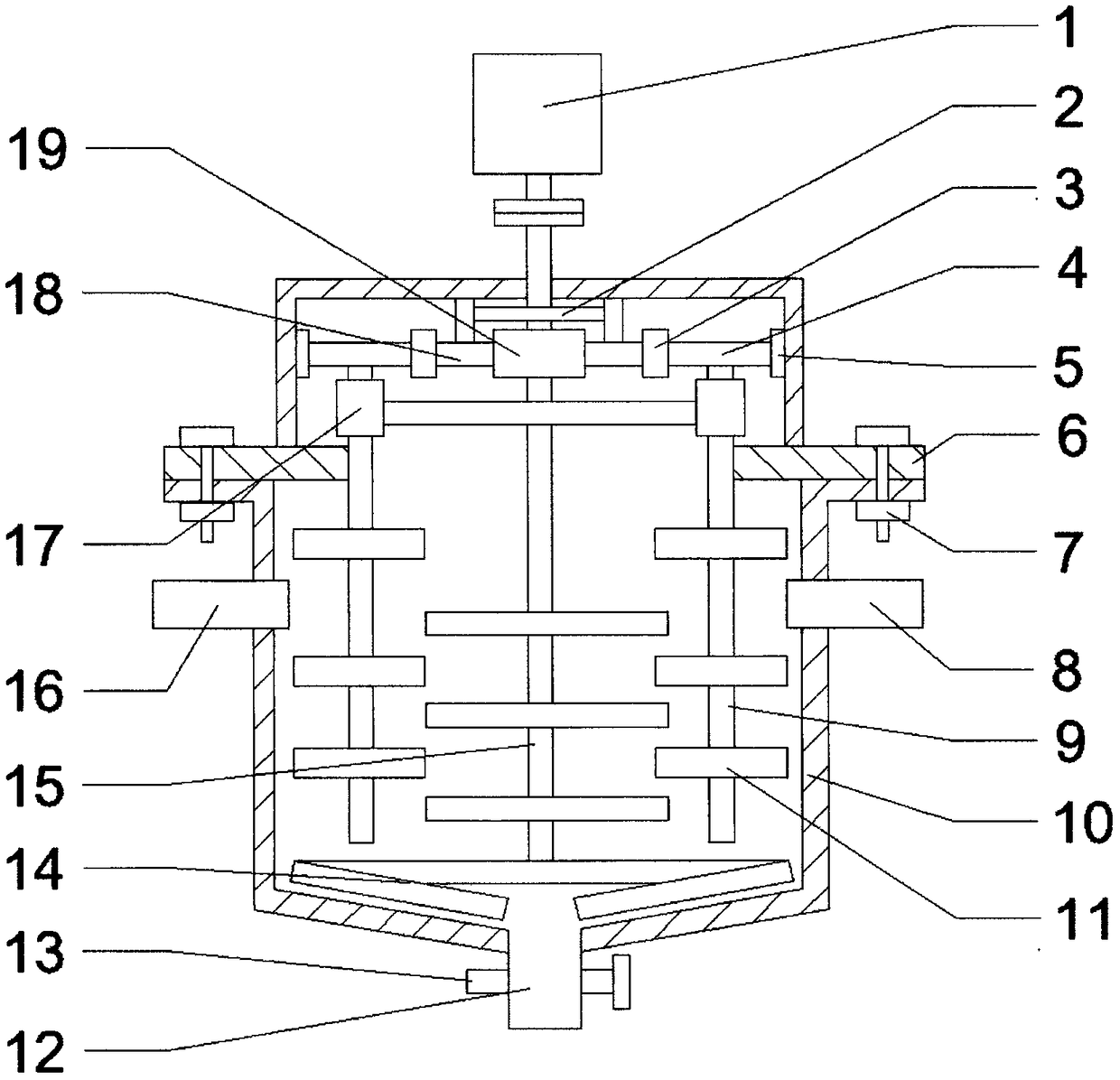

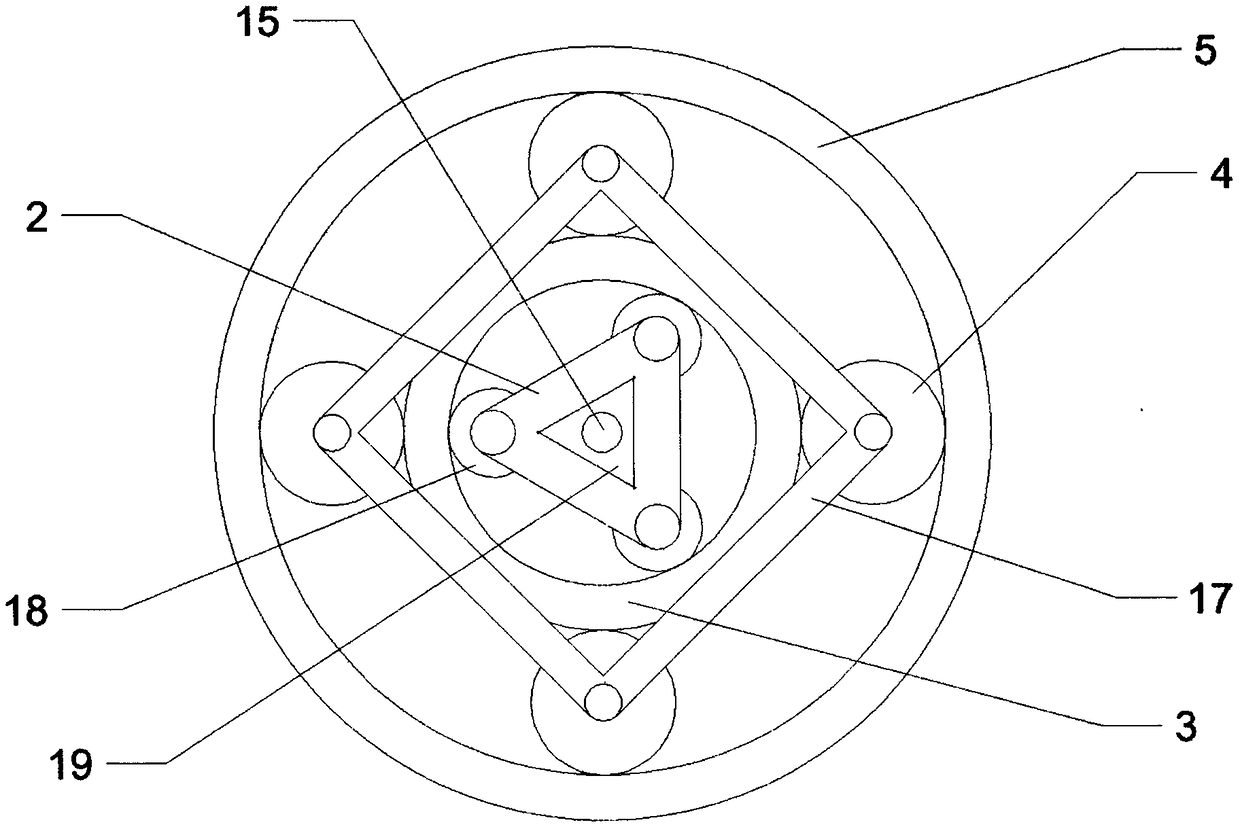

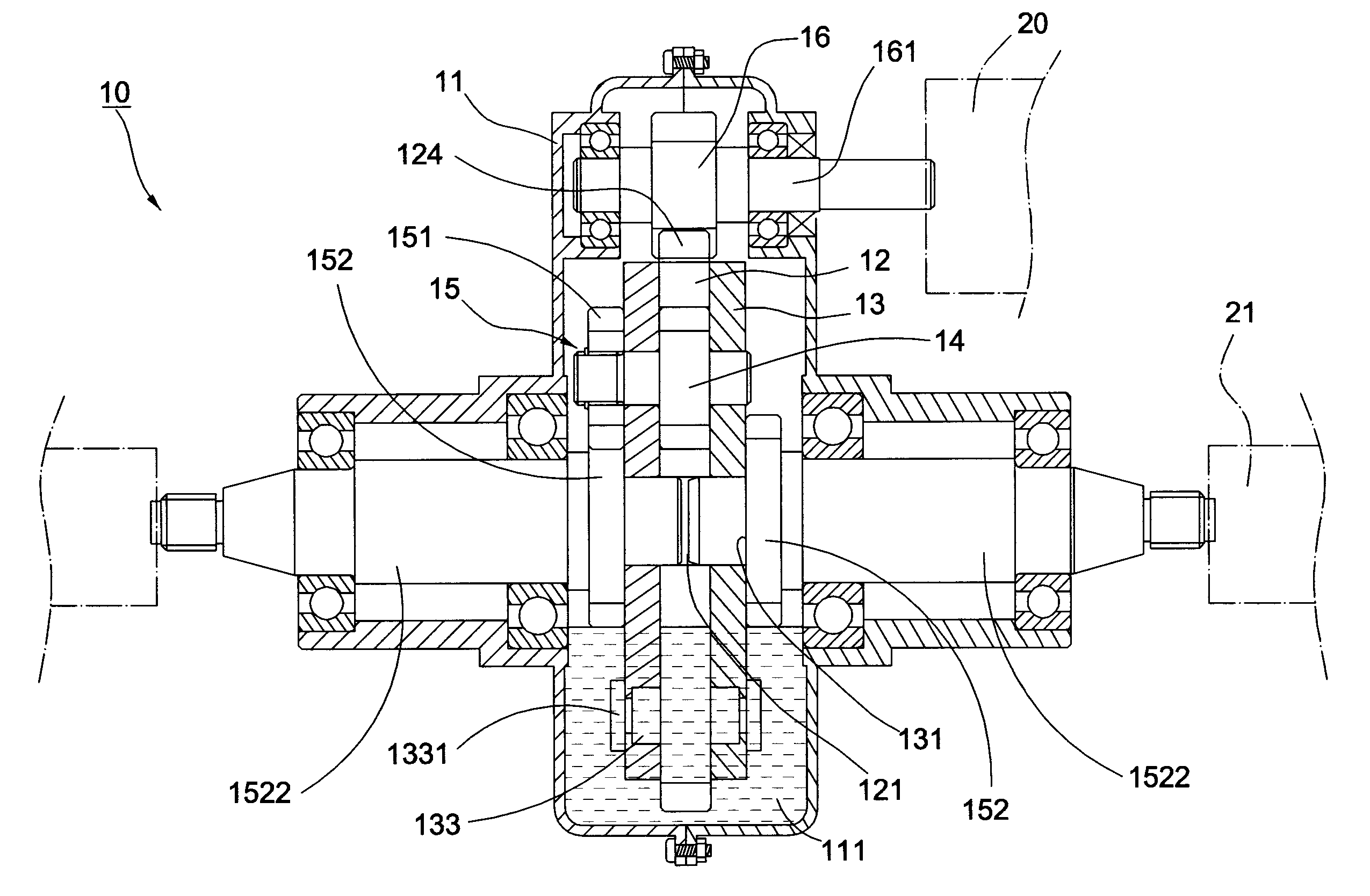

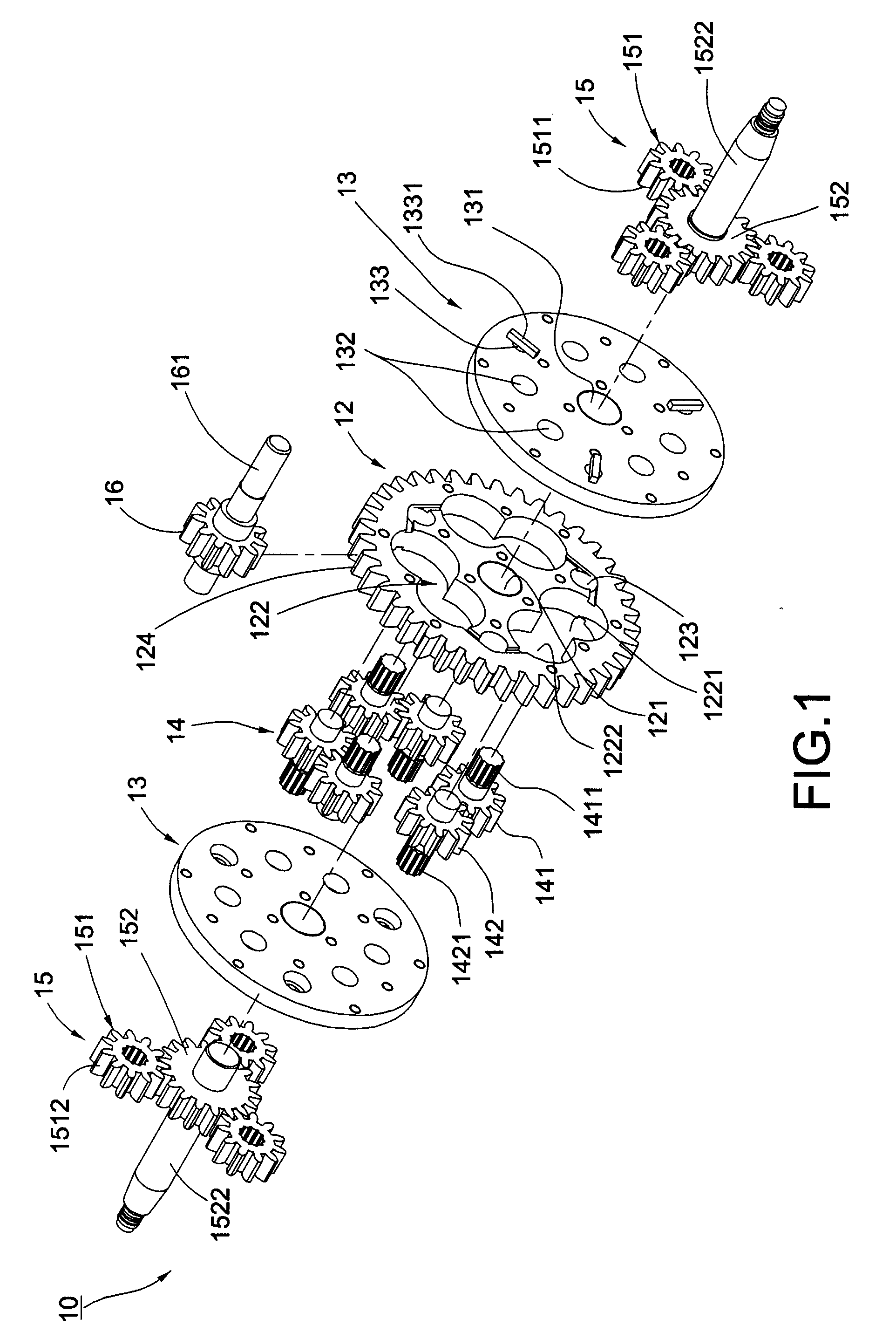

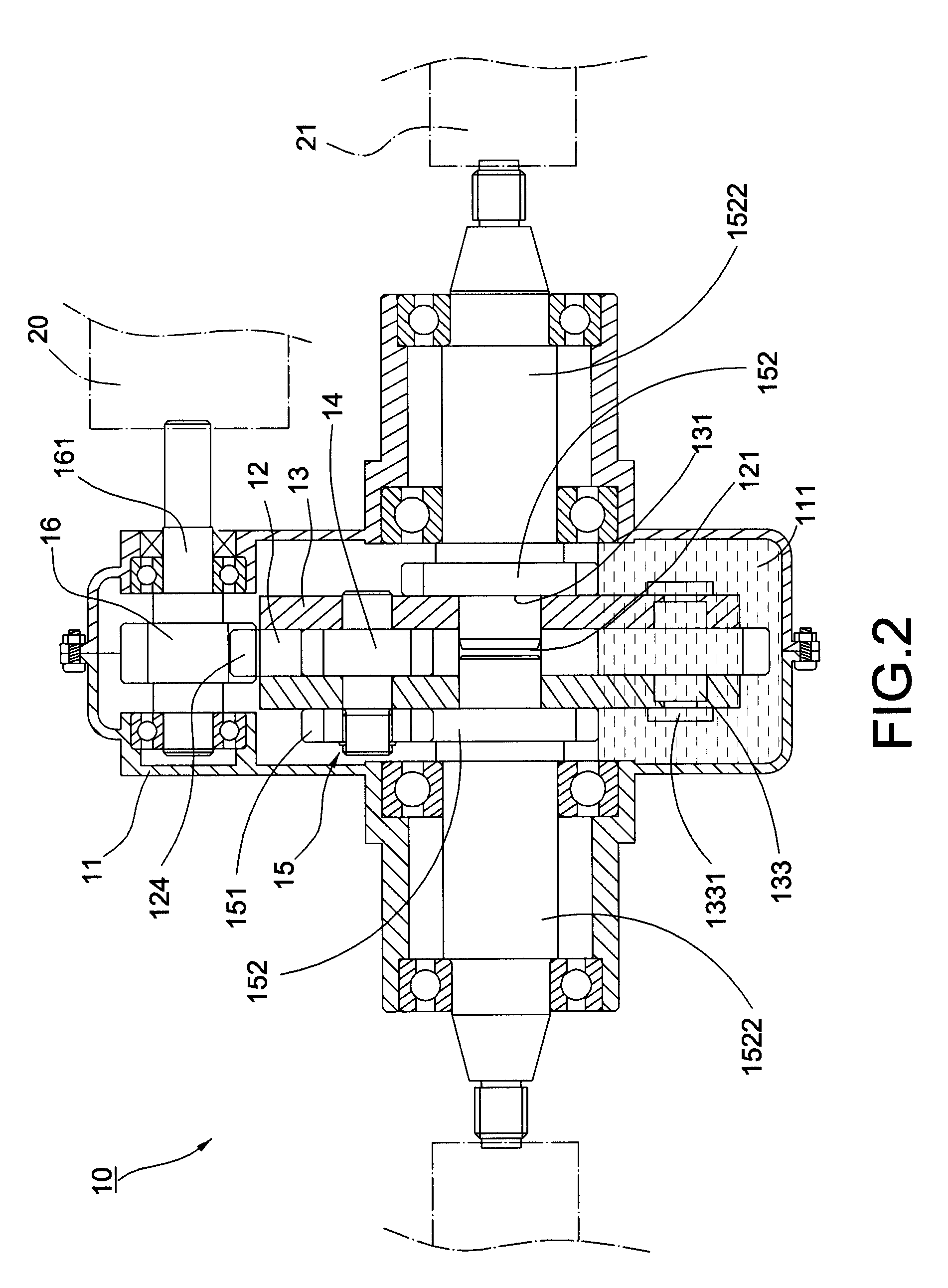

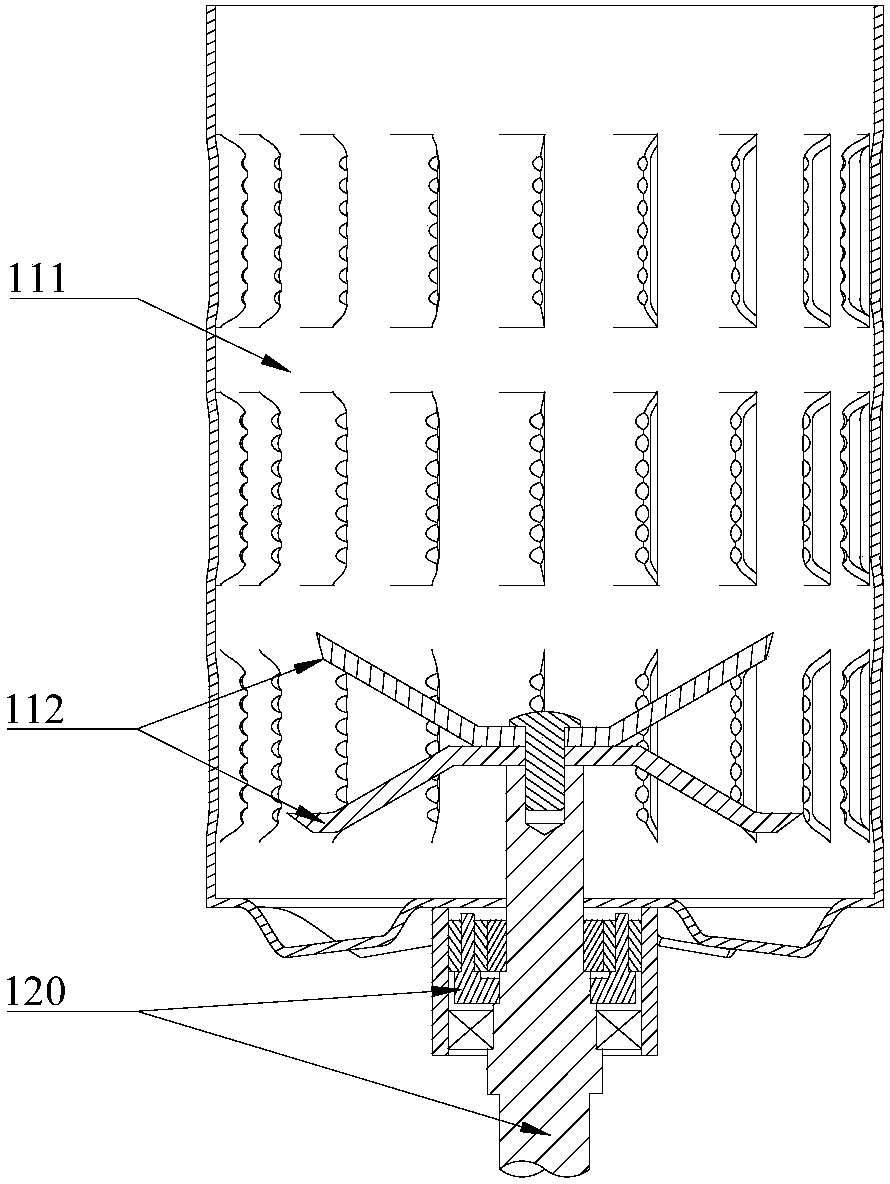

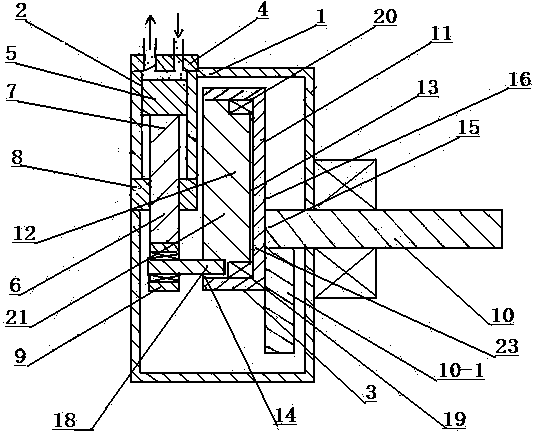

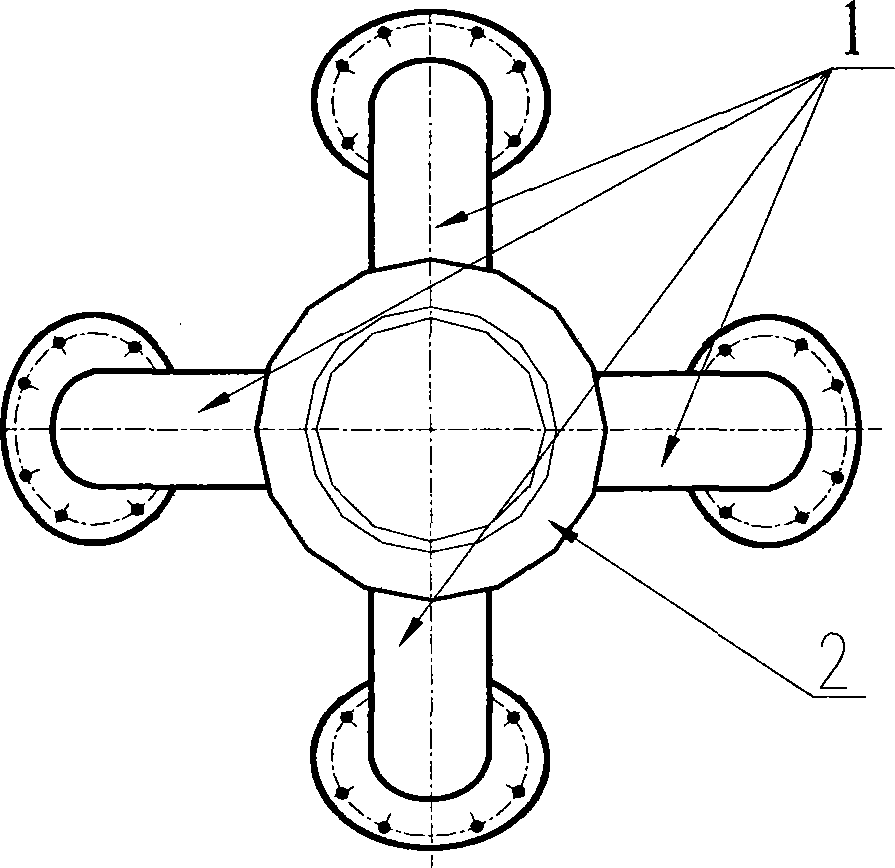

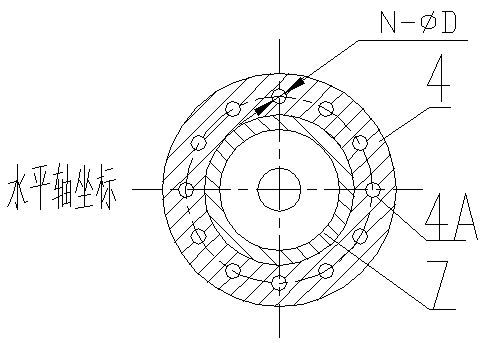

High-low-speed shear emulsifying mixer

InactiveCN108211875APrevent precipitationSimple structureTransportation and packagingMixing methodsLow speedDrive shaft

The invention discloses a high-low-speed shear emulsifying mixer. The high-low-speed shear emulsifying mixer comprises a tank body and a cover body, wherein a discharge opening is formed in the bottomcentral position of the tank body; a first feed opening and a second feed opening are formed in the upper part of the side face of the tank body; a big gear ring is fixed on the inner wall of the cover body and is meshed with a second planet gear inside the big gear ring; a driven shaft is arranged on the second planet gear; the second planet gear is meshed with a small gear ring at the central position of the big gear ring; the small gear ring is meshed with a first planet gear inside the small gear ring; the first planet gear is meshed with a sun gear at the central position of the small gear ring; a driving shaft is arranged on the sun gear; a scraper is arranged at the bottom of the driving shaft. By gear train transmission, the driven shaft rotates and revolves around the driving shaft, so that uniformity and sufficiency in mixing are realized; by transmission of two gear trains, opposite rotating directions of the driving shaft and the driven shaft are realized; meanwhile, the speed difference between the driving shaft and the driven shaft is increased, and uniformity and sufficiency in emulsifying are realized; the scraper arranged at the bottom of the driving shaft can effectively prevent the settlement of materials.

Owner:余姚市滨腾电器有限公司

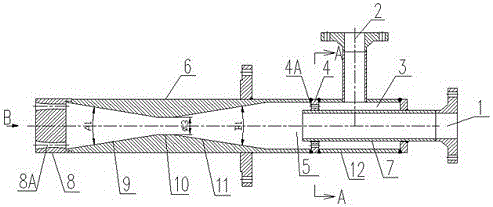

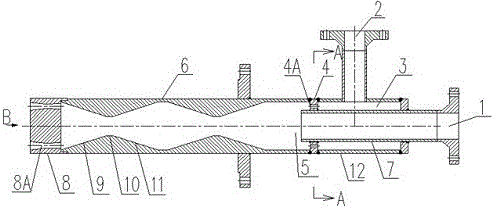

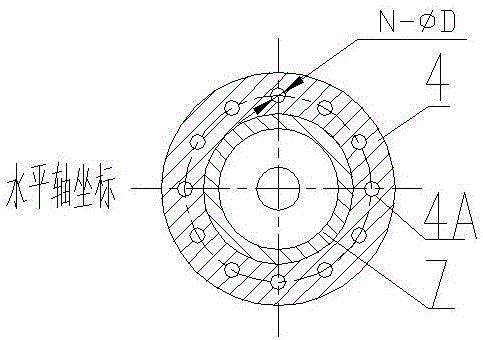

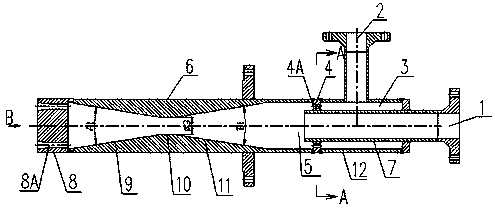

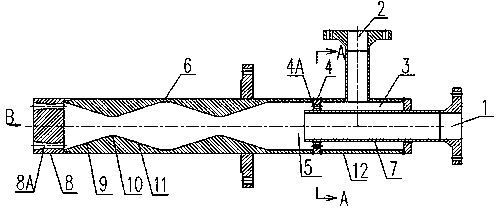

Feed atomizing nozzle for catalytic cracking

ActiveCN106010630AAtomized particle sizeFully contactedCatalytic crackingLiquid spraying apparatusPetroleum engineeringRaw material

The invention discloses a novel atomizing feed nozzle for catalytic cracking. The nozzle comprises a spray head, a venturi, an outer tube, an inner tube, a raw material oil inlet, a steam inlet and a steam hole plate. Steam atomizes raw material oil in a mixed atomization chamber for the first time, steam carrying raw material oil enters the venturi and passes through a contraction section, the circulation area is contracted, then steam carrying raw material oil passes through a throat section and is sprayed out of an expansion section, and therefore steam atomizes raw material oil for the second time; steam carrying out raw material oil enters a nozzle outlet of the spray head for atomization for the third time. The nozzle outlet of the spray head has multiple arrangement forms, a wide screen is formed when steam carrying raw material oil is sprayed out, sufficient contact and reaction of raw material oil and a catalyst are promoted, and meanwhile catalyst cracking is effectively lowered.

Owner:石宝珍 +1

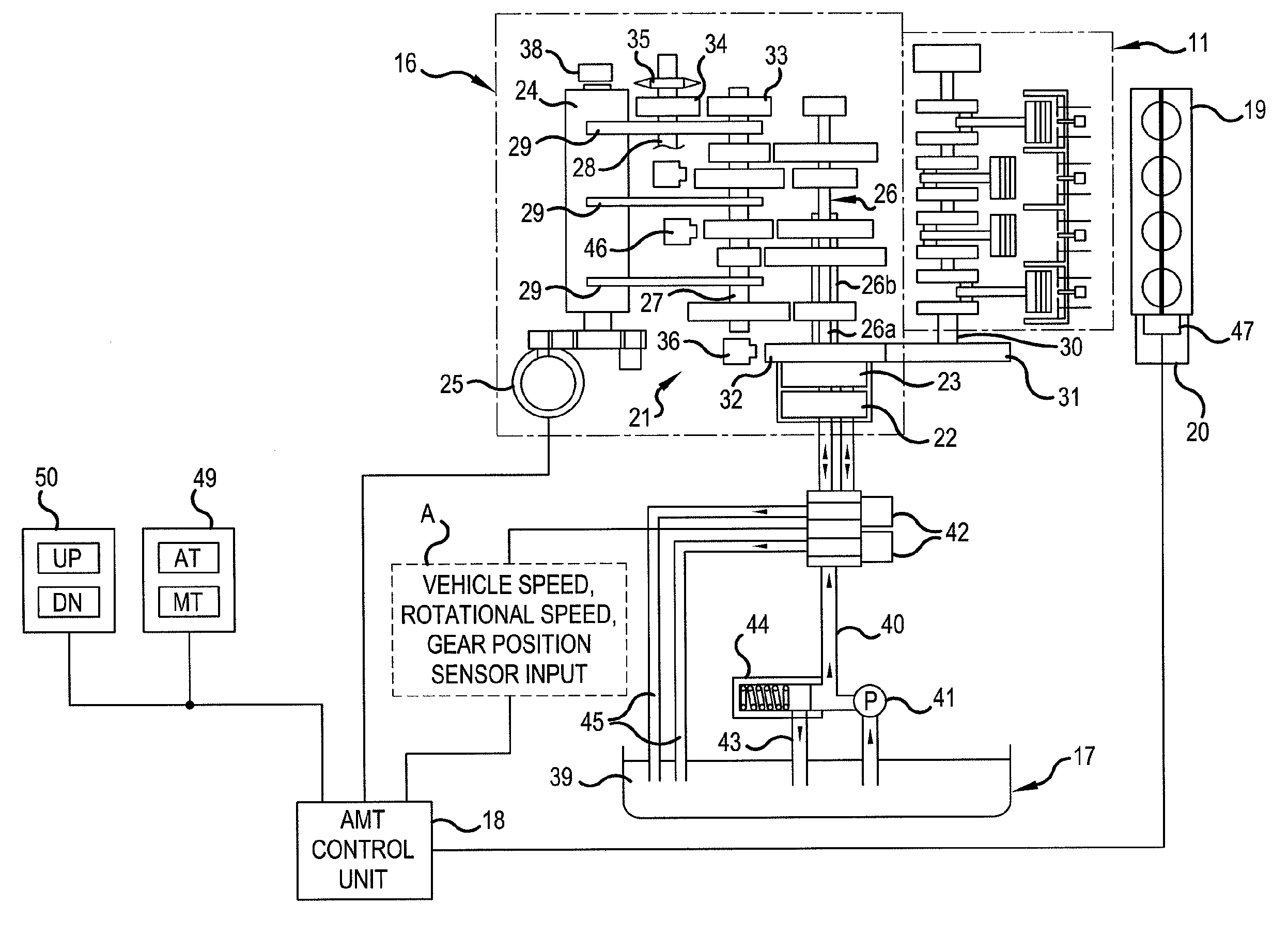

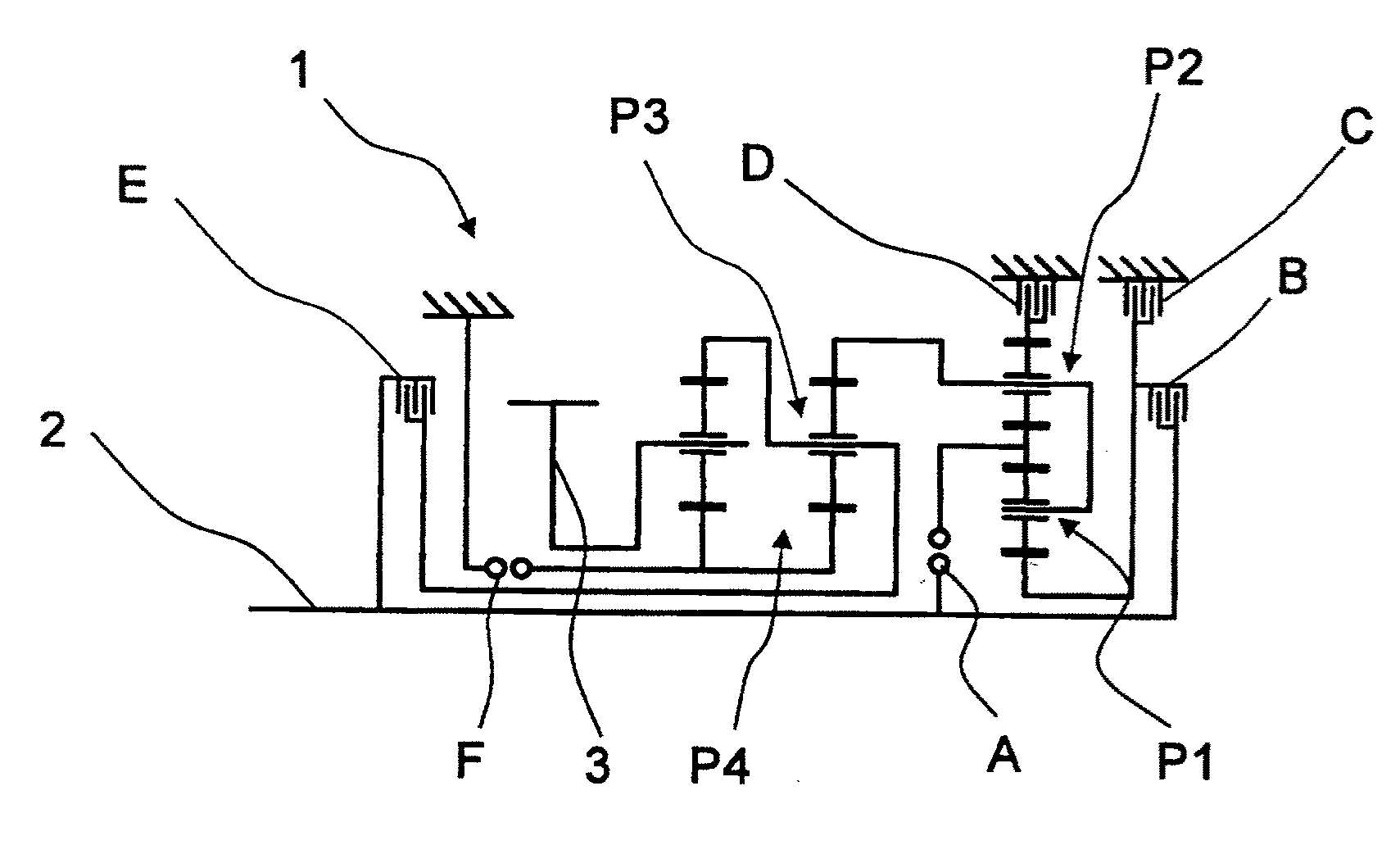

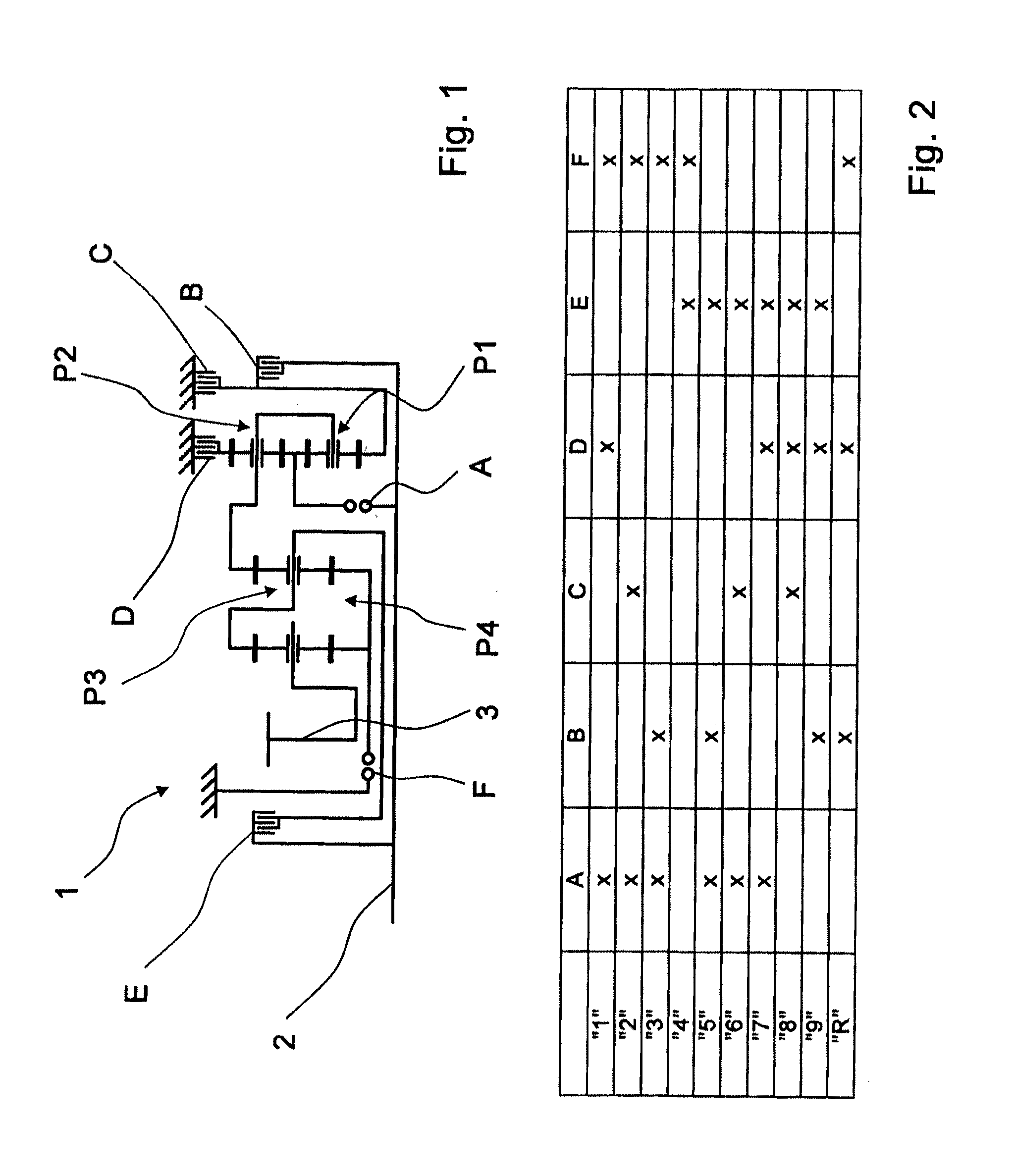

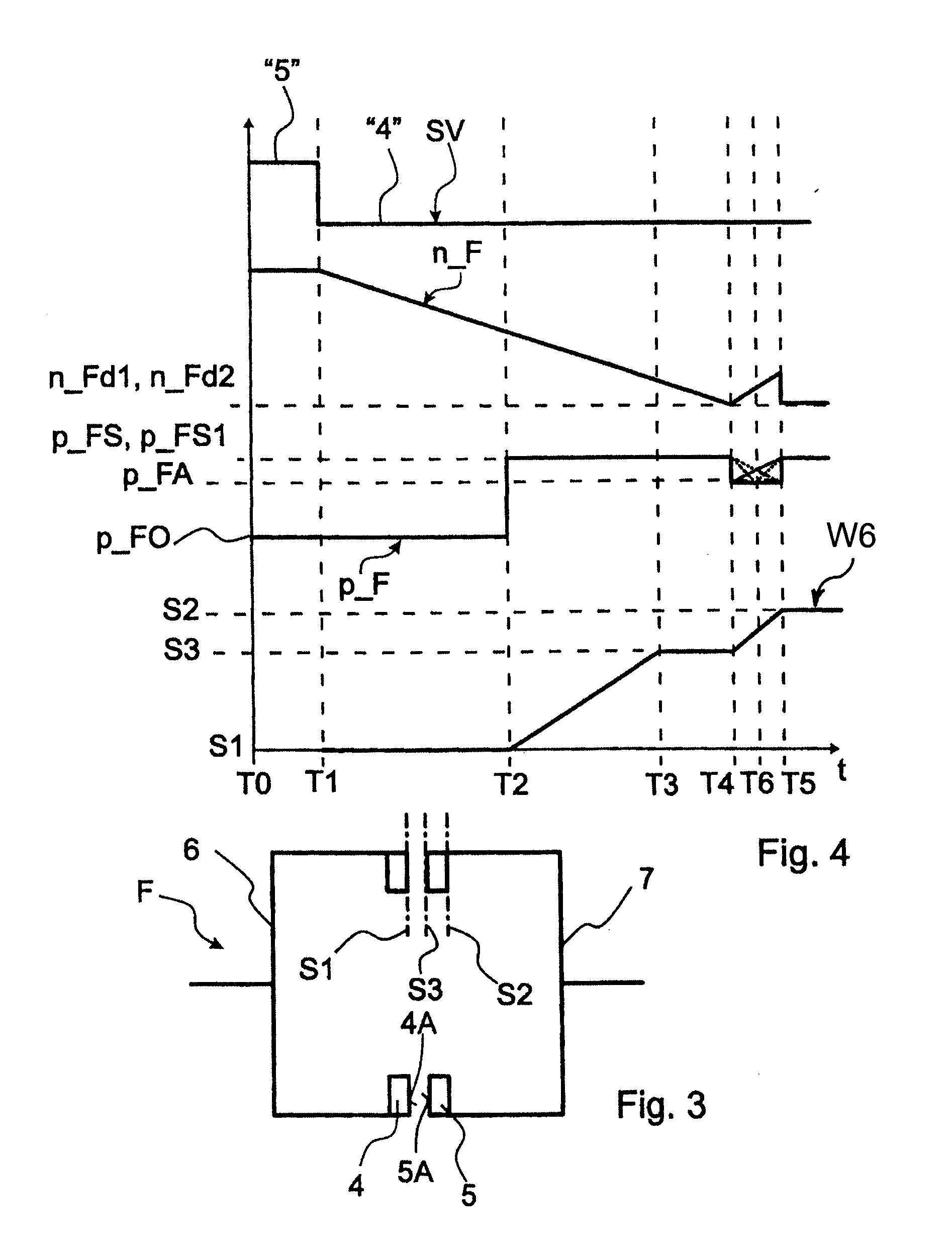

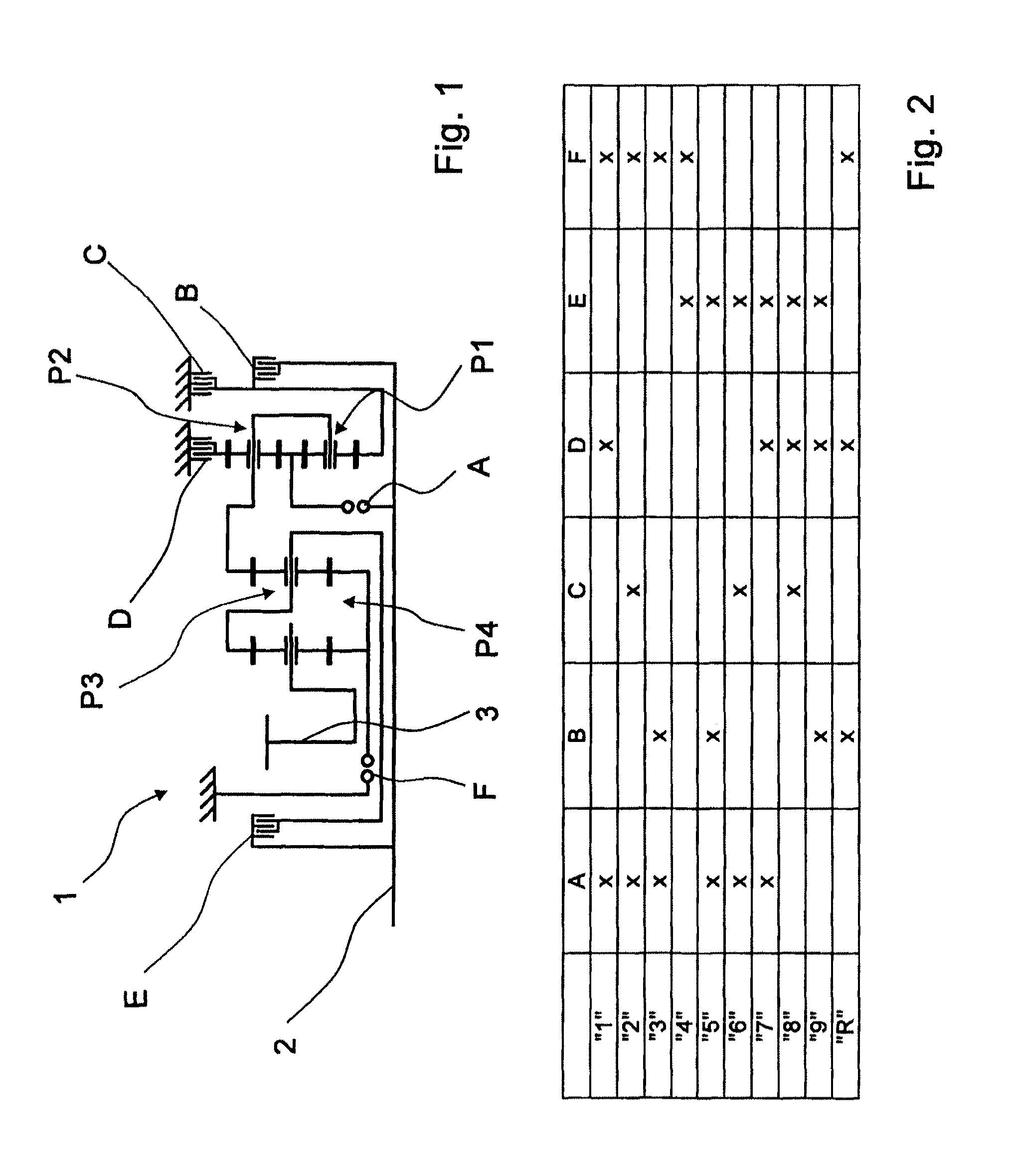

Method for operating a transmission with at least one positive-locking shifting element

ActiveUS20110301819A1Improve shift qualitySpoil shifting qualityDigital data processing detailsGearingTooth positionElectrical and Electronics engineering

A method of operating a transmission (1) with at least one interlocking shift element (F) having at least two shift element halves that can be brought into interlocked engagement with one another. When a command is received to close the interlocking shift element (F), a current rotational speed difference between the shift element halves of the interlocking shift element (F) and the current positions of the shift element halves are determined. If the rotational speed difference is smaller than a first speed difference threshold value and if a tooth-on-tooth position has occurred at the interlocking shift element (F), then to release the tooth-on-tooth position, the actuation force is changed to a release level at which a rotational speed difference above a second speed difference threshold value is produced between the shift element halves.

Owner:ZF FRIEDRICHSHAFEN AG

Limited slip differential

InactiveUS20100056313A1Easy to installMeet convenient maintenanceGear lubrication/coolingTransmission elementsLimited-slip differentialRotation velocity

A limited slip differential includes a driving plate, backing plates, differential gear assemblies, and a transmission assembly engaged together inside a sealed casing where fluid is pumped. The driving plate has pairs of communicated openings for interlocking two gears of each gear assembly, which extend by opposite directions from the driving plate for separately engaging with the transmission assembly. While synchronously rotating the plates, the gear assemblies are alternatively soaked into the fluid and each permits the fluid passing among the gears for adjusting the rotational speed. In the event that the rotational speed difference of axle shafts of the vehicle exceeds a threshold value, the LSD applies at least one gear assembly to generate a back pressure and efficiently block the fluid passing through the gears for limiting mutual rotational speed difference, hence achieving a limited-slip effect.

Owner:LEE KUO MING +1

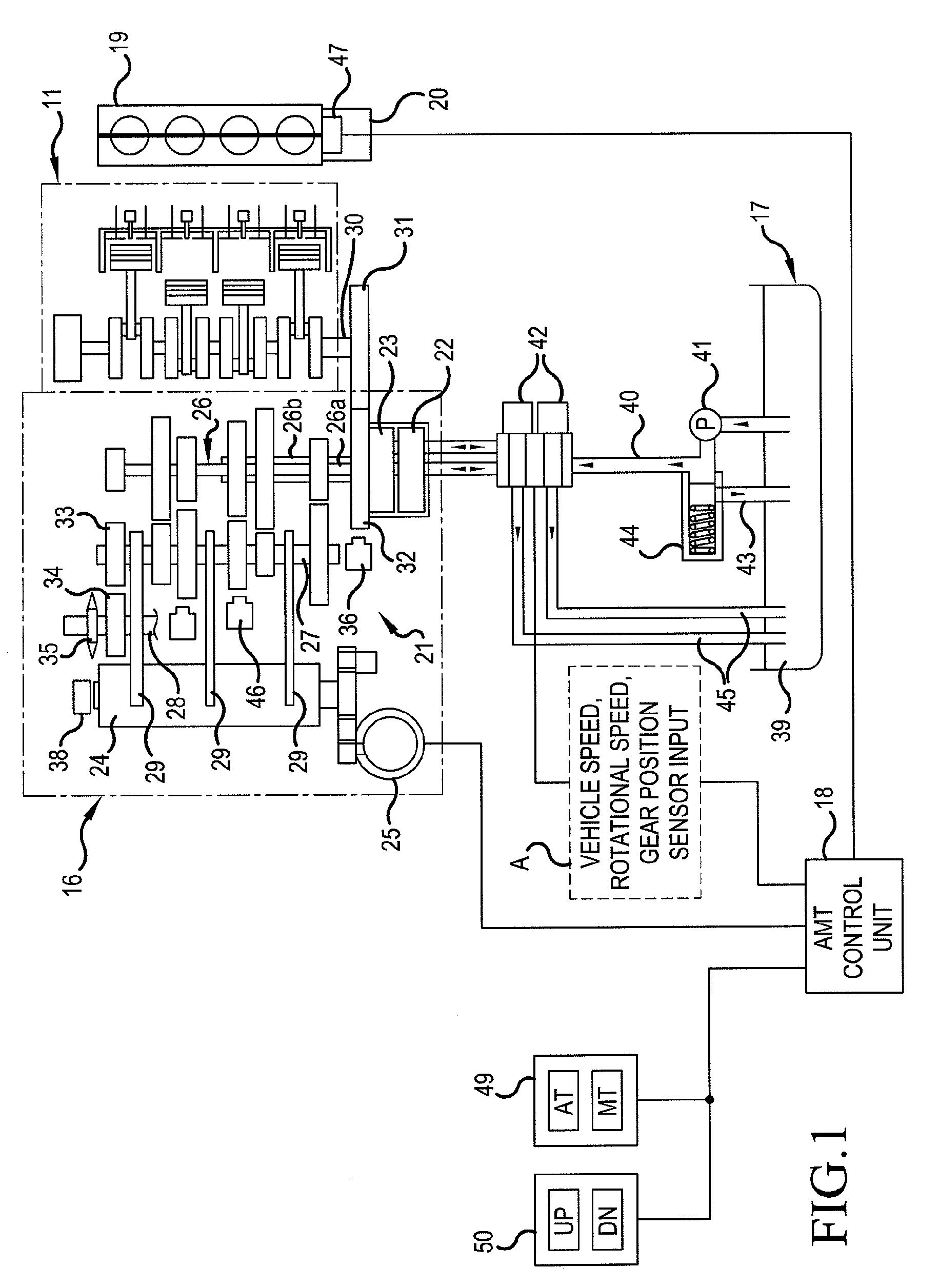

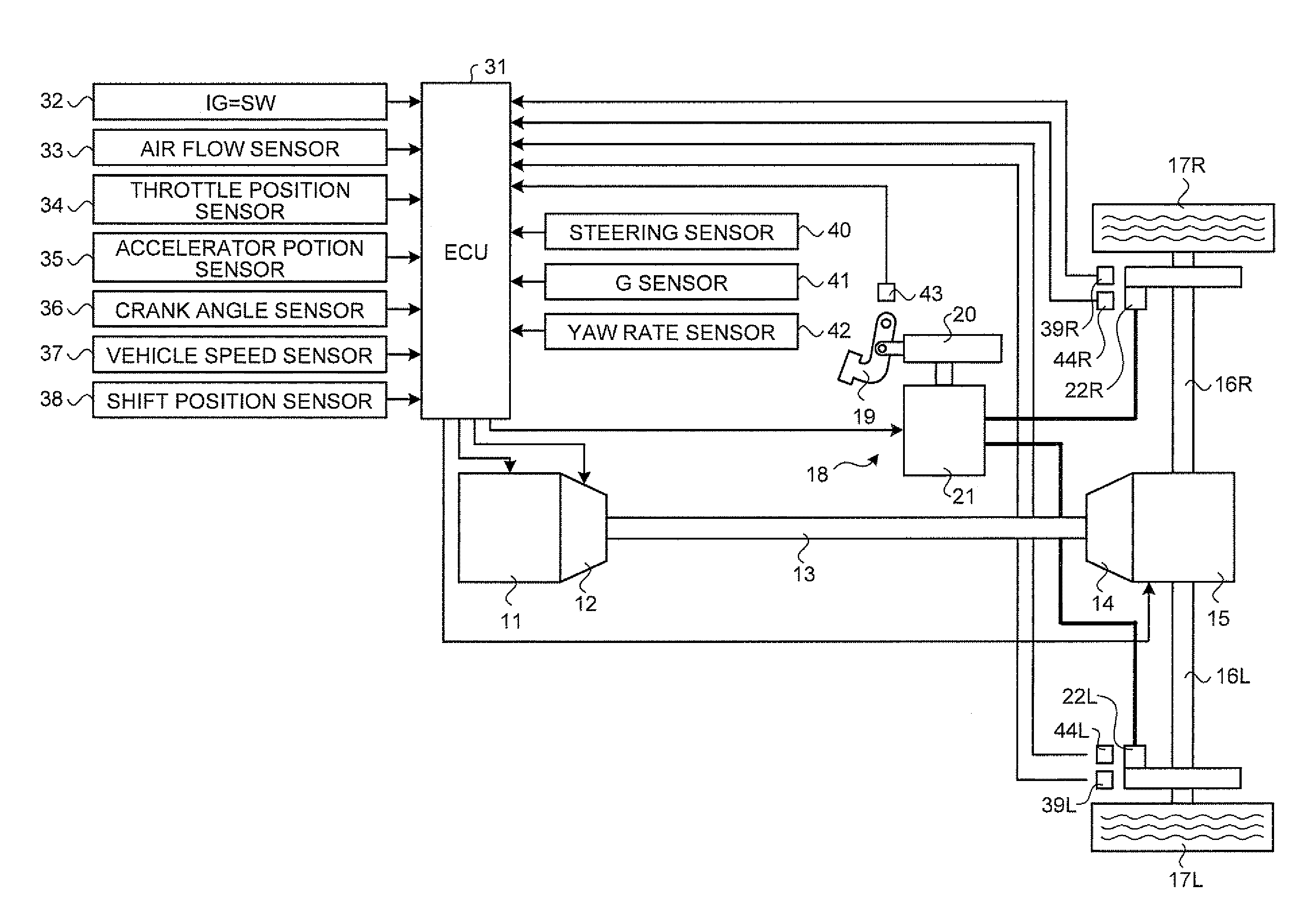

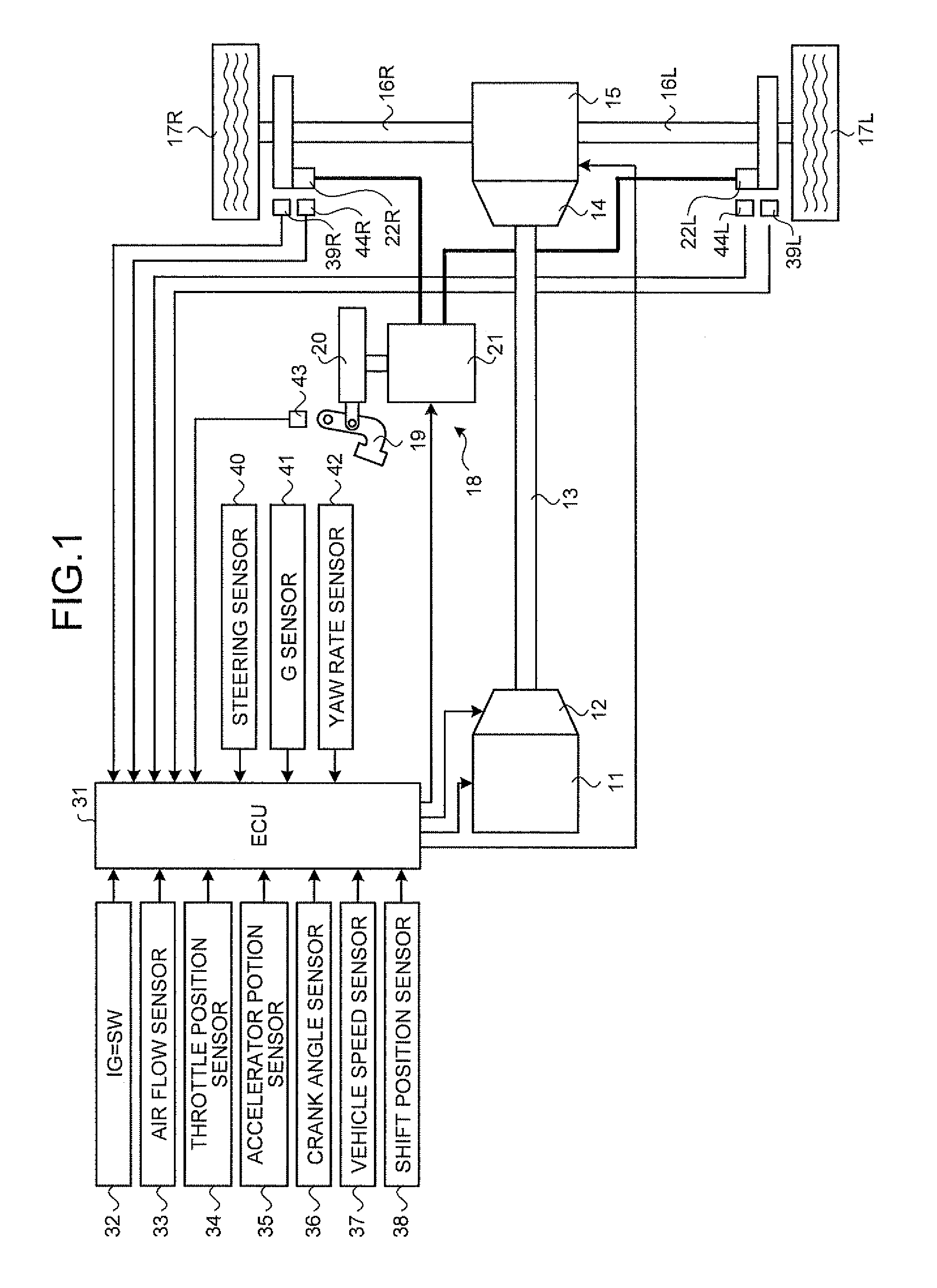

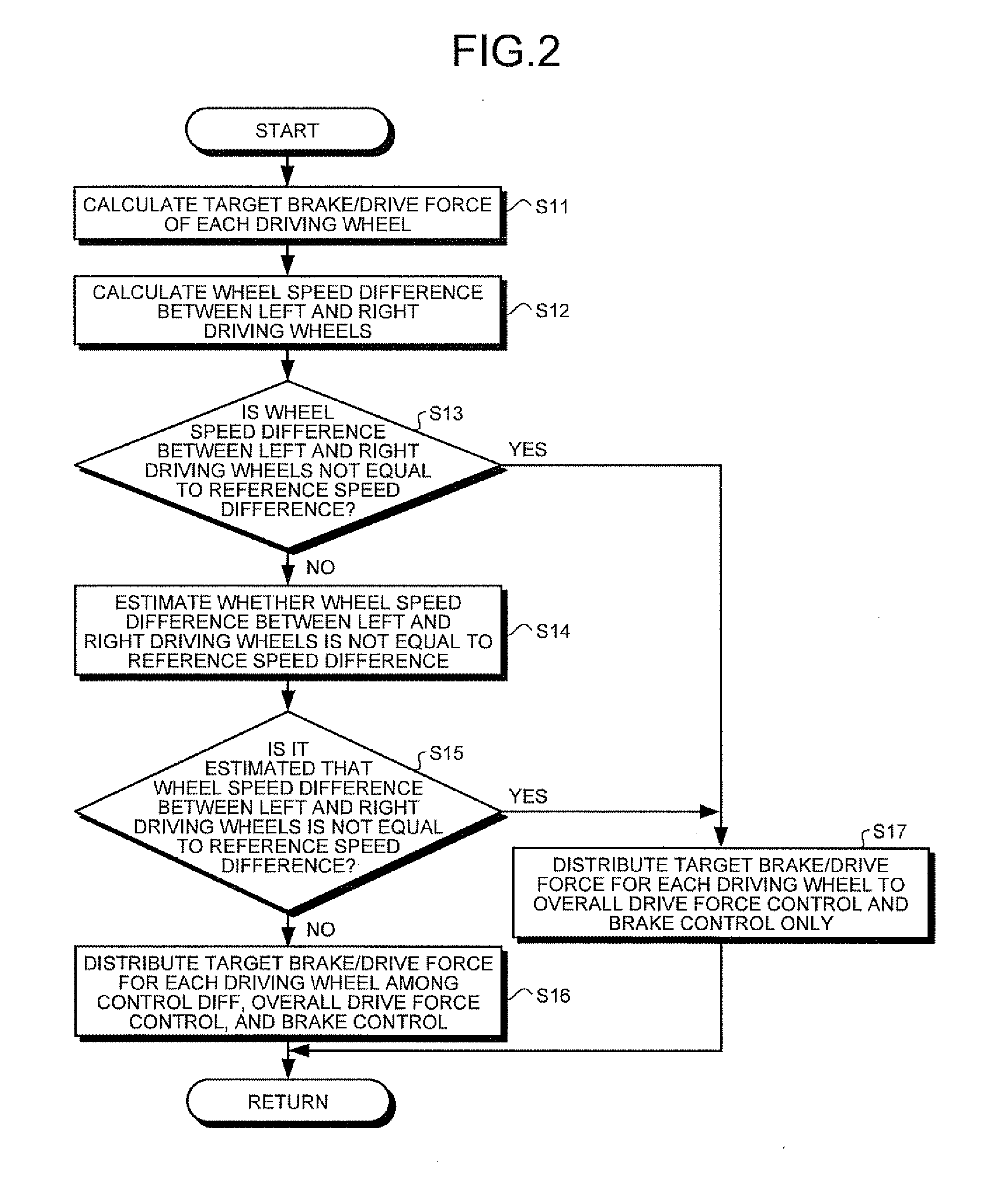

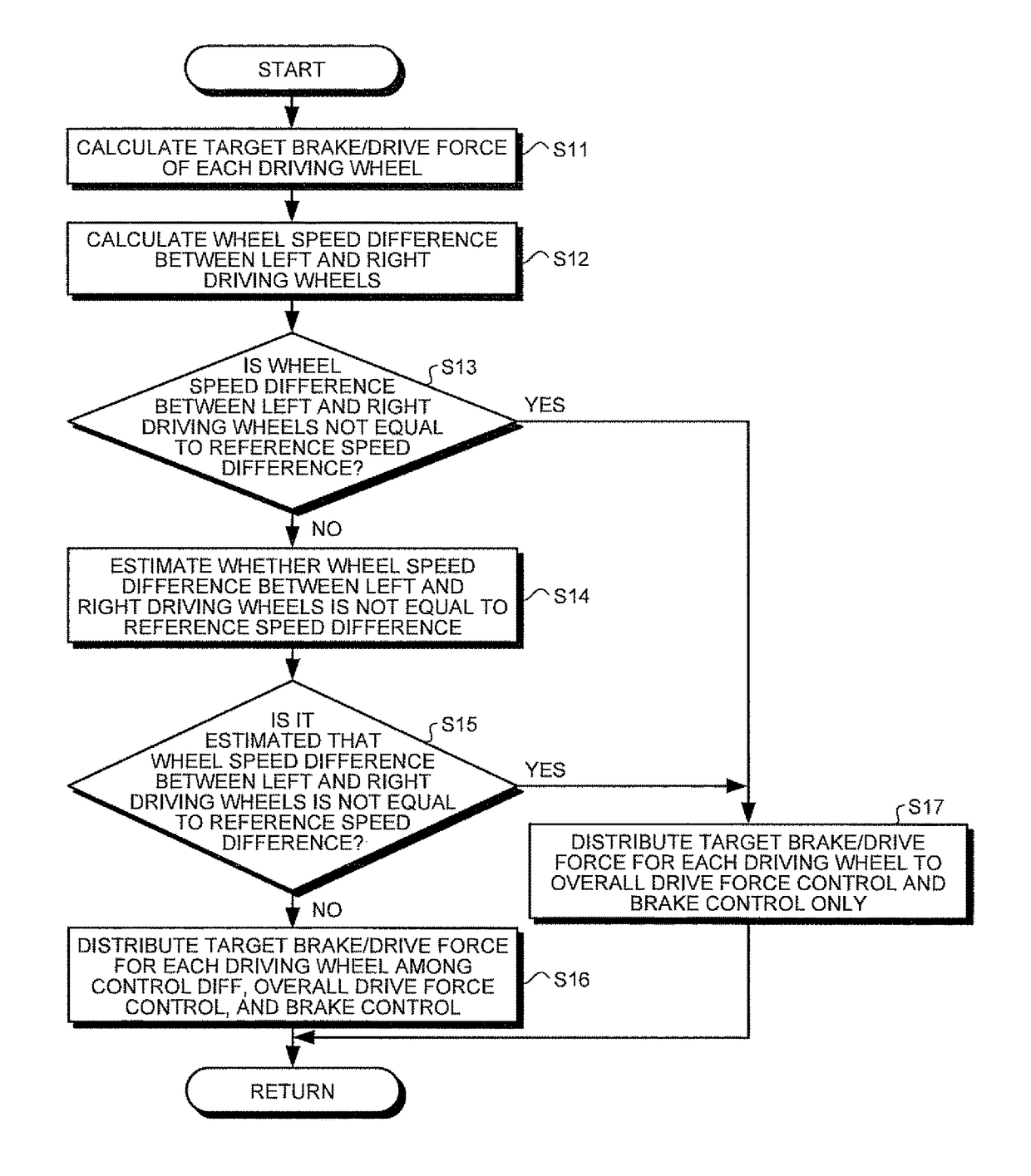

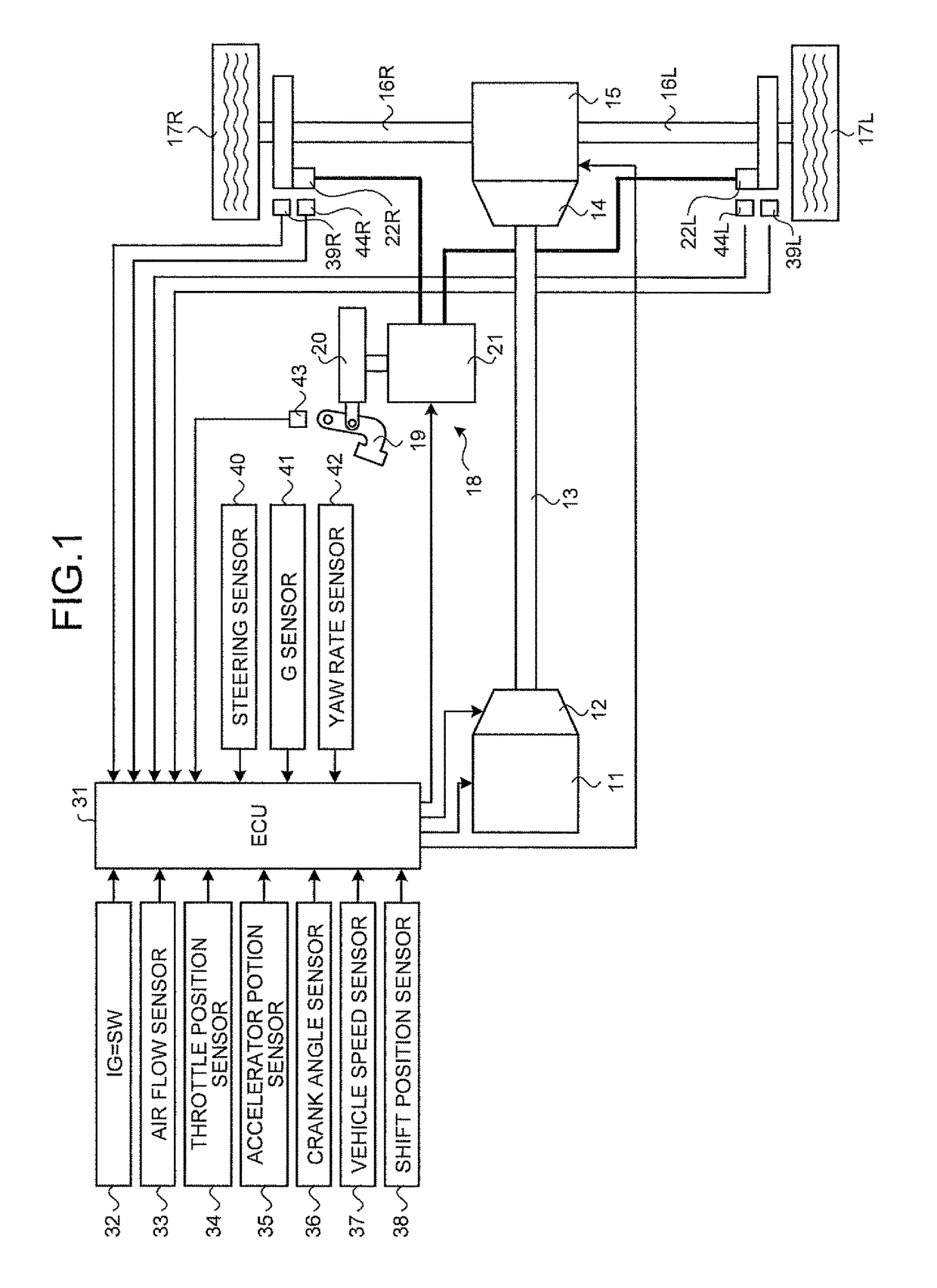

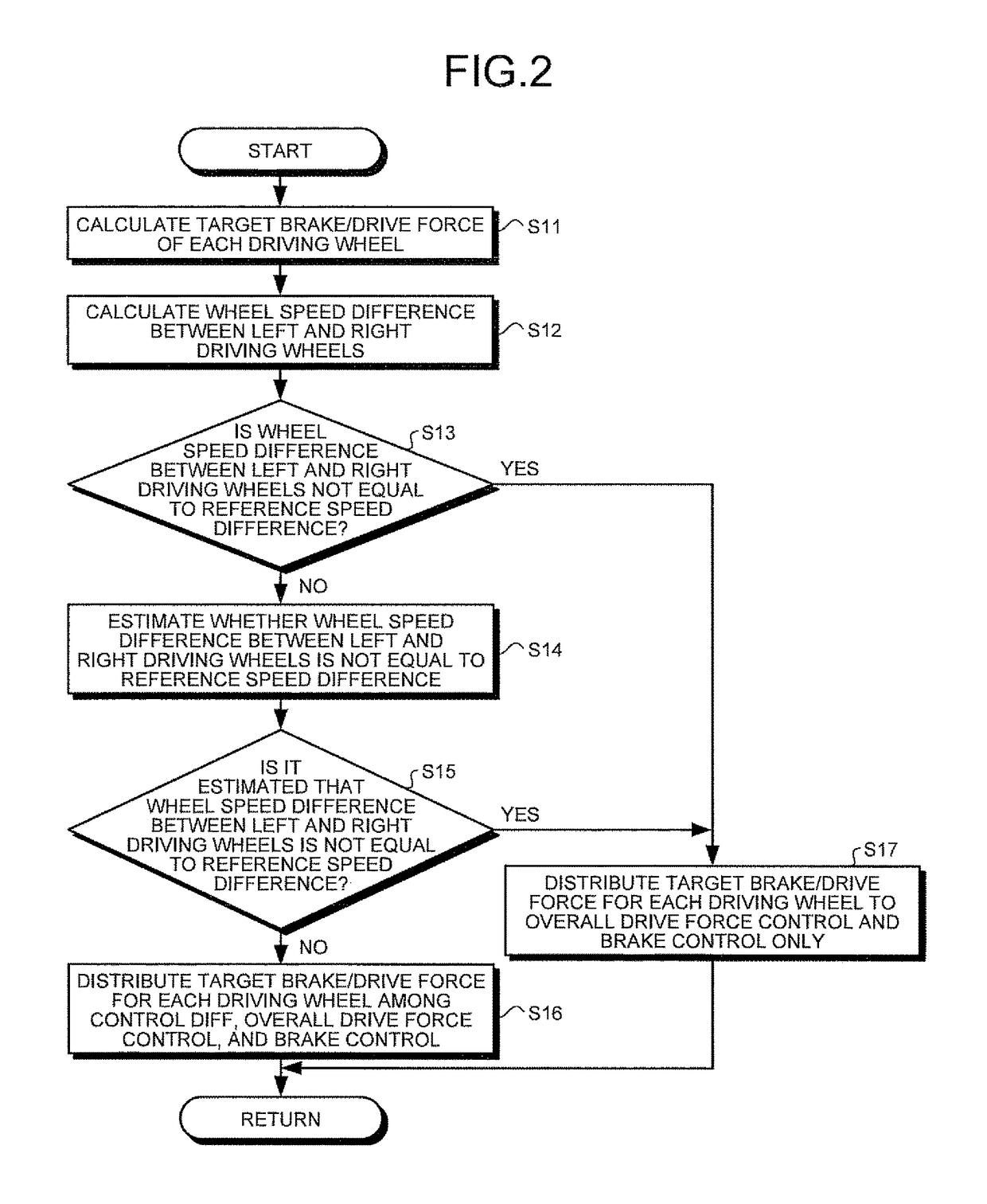

Brake/drive force controlling apparatus for vehicle

ActiveUS20100168953A1Increase in sizeIncrease speed differenceVehicle testingBrake system interactionsBrake forceControl system

A brake / drive force controlling apparatus for a vehicle includes an engine for applying drive forces to driving wheels of the vehicles, a control diff for distributing the drive forces to the left and right driving wheels independently, and an electronic control system brake device for applying brake forces to the left and right driving wheels independently. An ECU is configured so as to be able to control the engine, the control diff, and the electronic control system brake device according to an operating state of the vehicle. When the electronic control system brake device is operated, this ECU stops the operation of the control diff, thereby avoiding a sudden input of load on the drive force distribution mechanism, regardless of the running state of the vehicle. This makes the apparatus simpler and more lightweight.

Owner:TOYOTA JIDOSHA KK

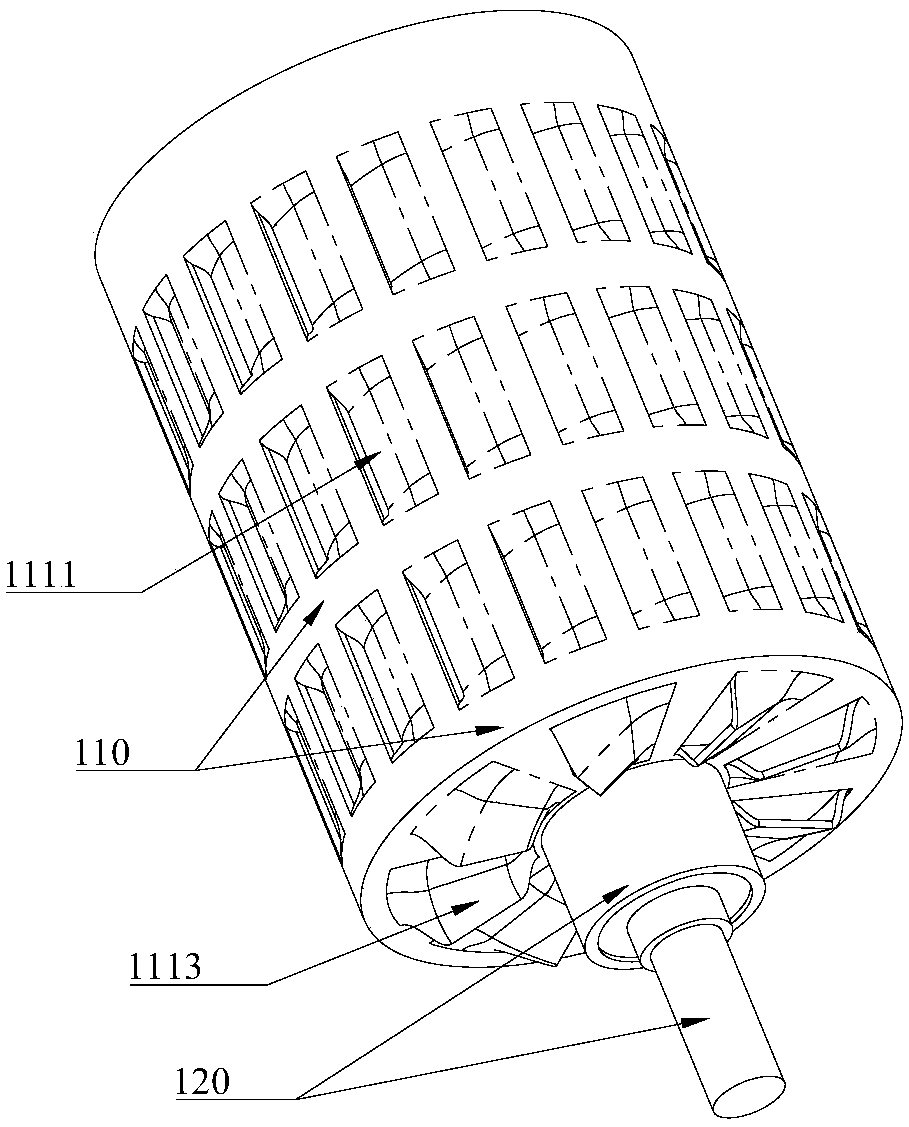

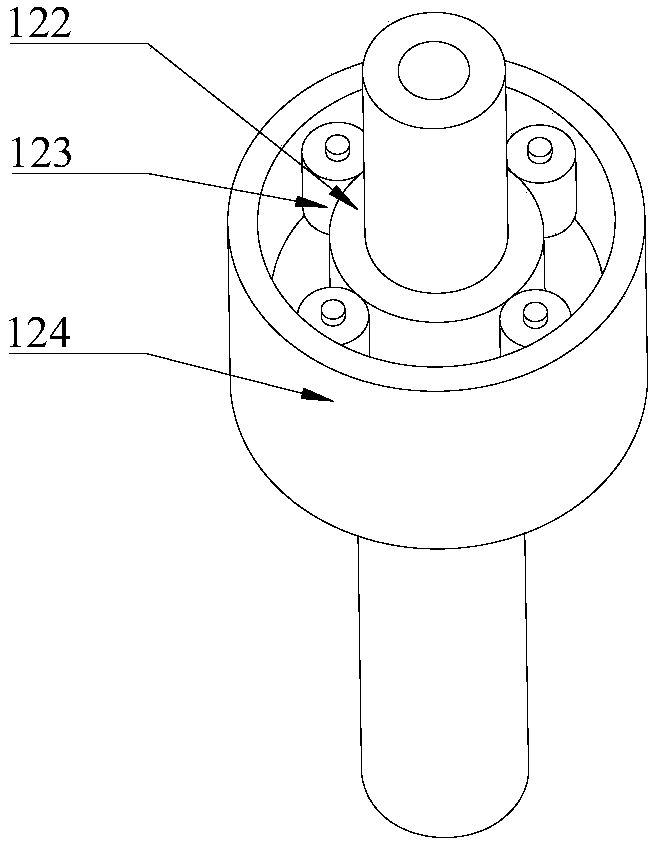

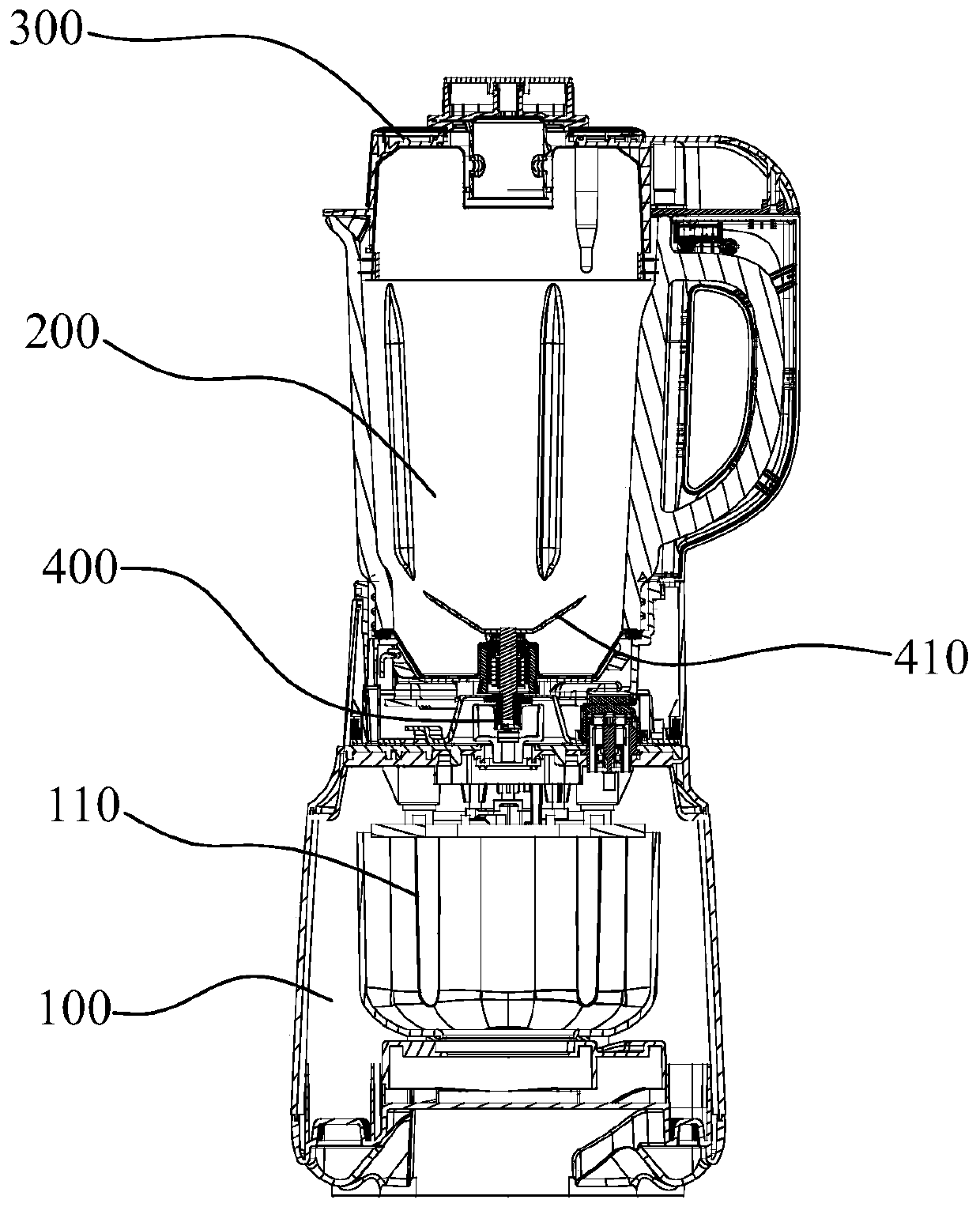

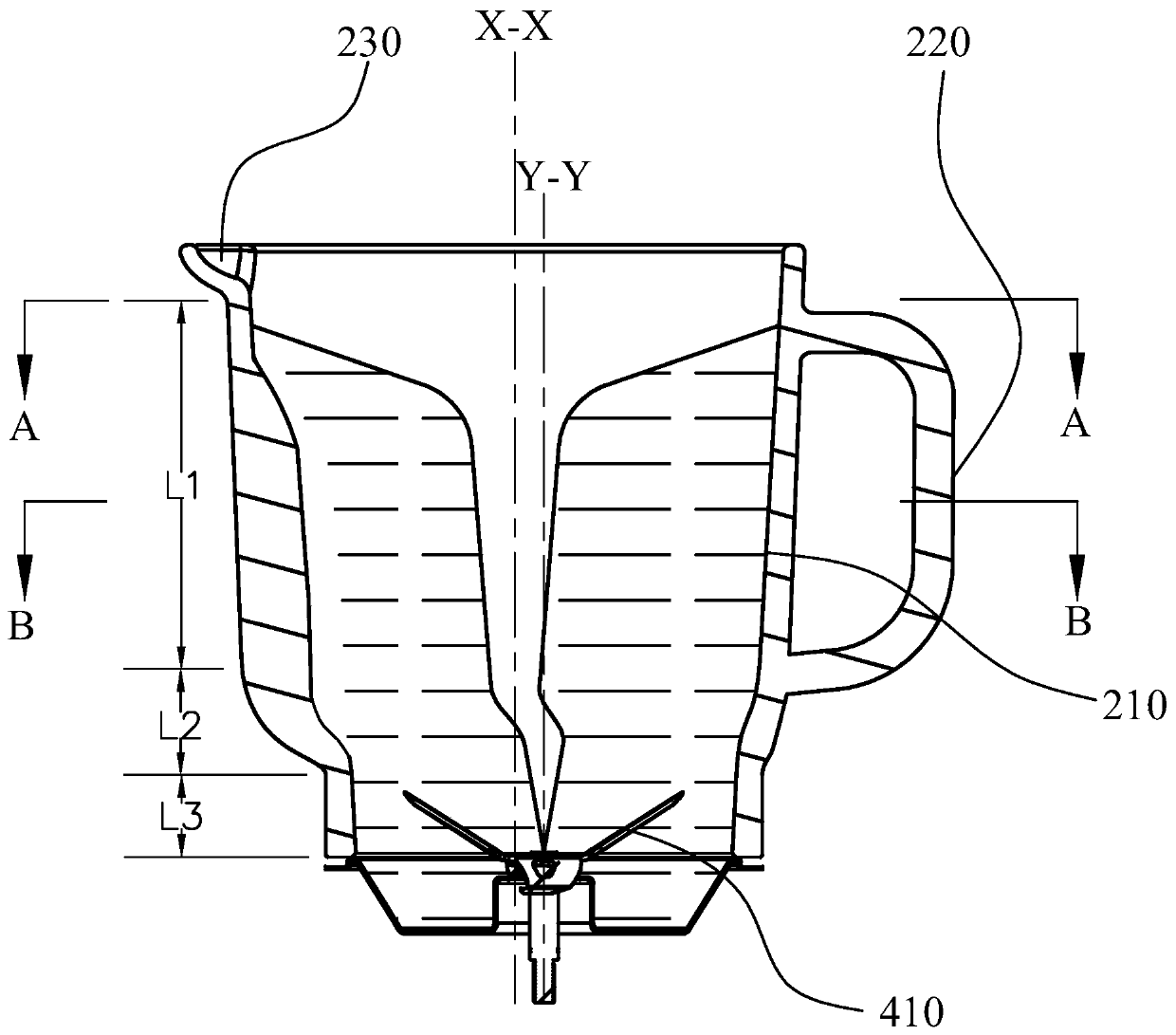

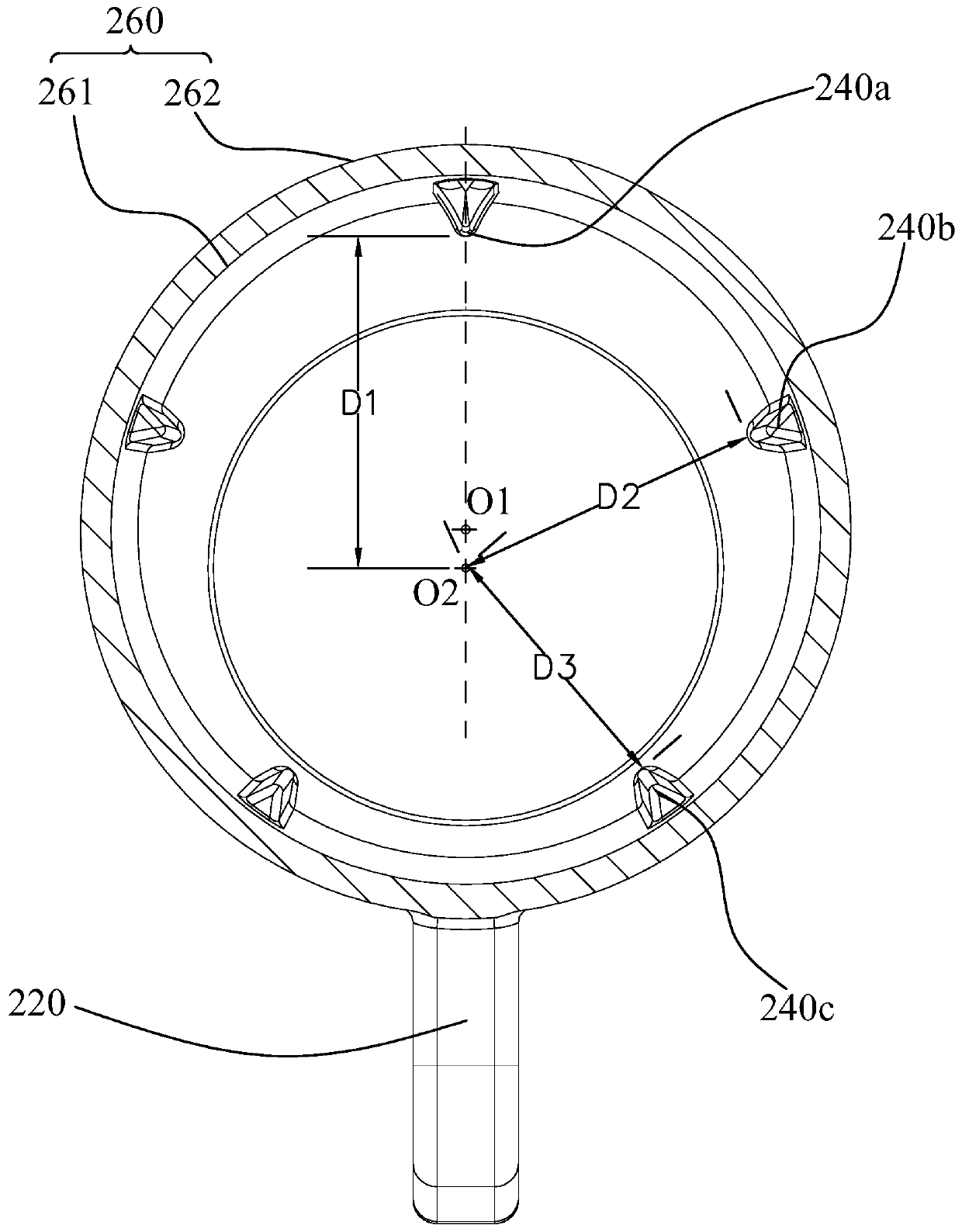

Bidirectional processing cutter set and wall breaking device

The invention provides a bidirectional processing cutter set and a wall breaking device and belongs to the field of food processing. The bidirectional processing cutter set comprises a cutter head, acutter cylinder, a transmission device and a driving device, wherein the output end of the driving device is connected with the input end of the transmission device, the transmission device comprisesa first output end and a second output end, the first output end and the second output end are coaxially arranged, the rotation direction of the first output end is opposite to the rotation directionof the second output end, the cutter head is arranged at the first output end, the cutter cylinder is arranged at the second output end, and the cutter head is arranged in the cutter cylinder. The directional processing cutter set disclosed by the invention can increase speed difference and contact chance between food materials and the cutter, so that a processing efficiency is effectively improved; the bidirectional processing cutter set has good stirring and foam breaking effects, makes the food materials evener and avoids bottom sticking; the bidirectional processing cutter set further canmaintain stable motor load and has a motor protection effect.

Owner:SICHUAN UNIV

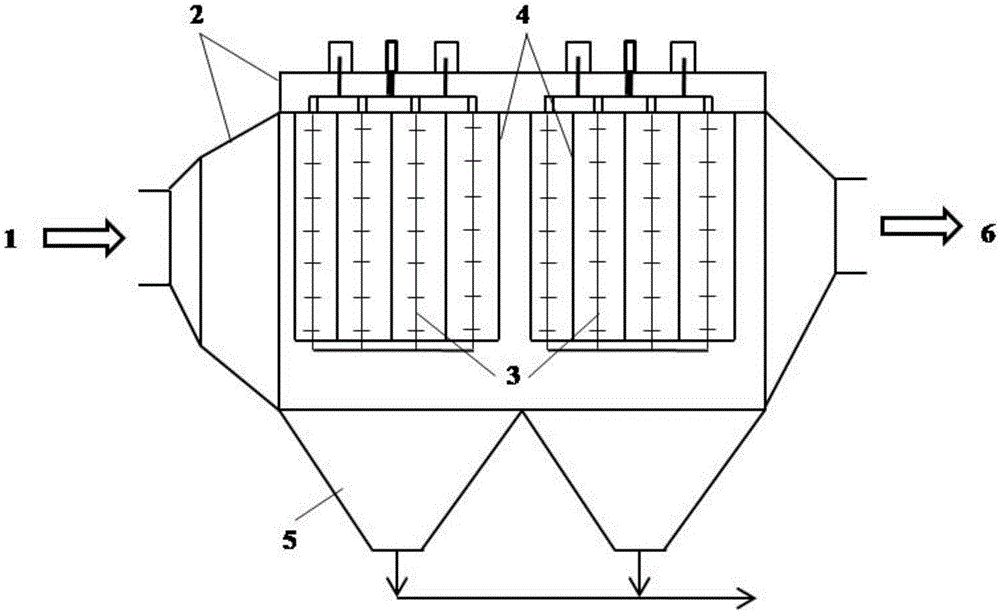

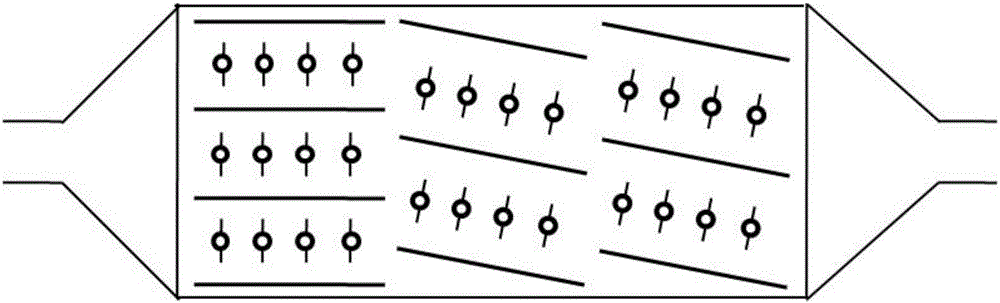

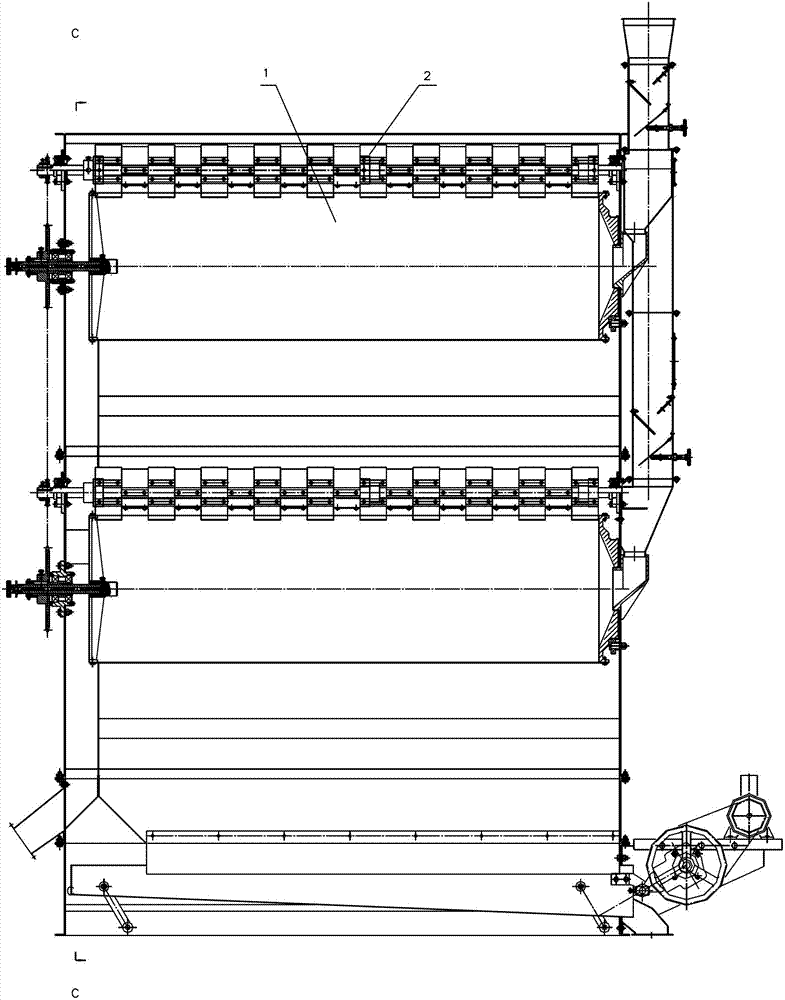

Inhomogeneous plate line electric precipitation method and assembly and electric precipitation device

ActiveCN106733195AImprove purification efficiencyIncrease speed differenceElectrode constructionsElectricityEngineering

The invention relates to the technical field of electric precipitation, in particular to an inhomogeneous plate line electric precipitation method and assembly and an electric precipitation device. The inhomogeneous plate line electric precipitation assembly comprises a plurality of sets of precipitation units arranged in sequence, each precipitation unit comprises a plurality of anode plates in parallel, and a plurality of cathode lines are arranged between adjacent anode plates; the anode plates are horizontally arranged or are arranged in an inclined manner, and the anode plates of every two adjacent precipitation units are not located on one straight line. According to the inhomogeneous plate line electric precipitation assembly, the inhomogeneous plate line electric precipitation method is adopted for arranging the anode plates and the cathode lines in all precipitation units, the anode plates are horizontally arranged or are arranged in the inclined manner, smoke turning and deflection are finally achieved, and the high purification effect is achieved. The device is simple in structure, and the purification standard can be achieved without combining other precipitation equipment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

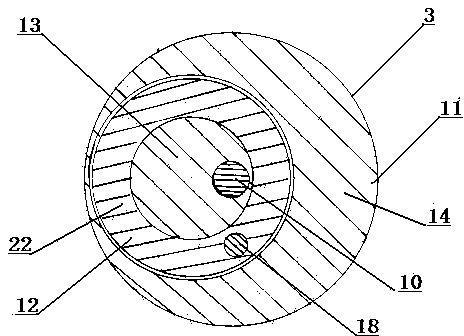

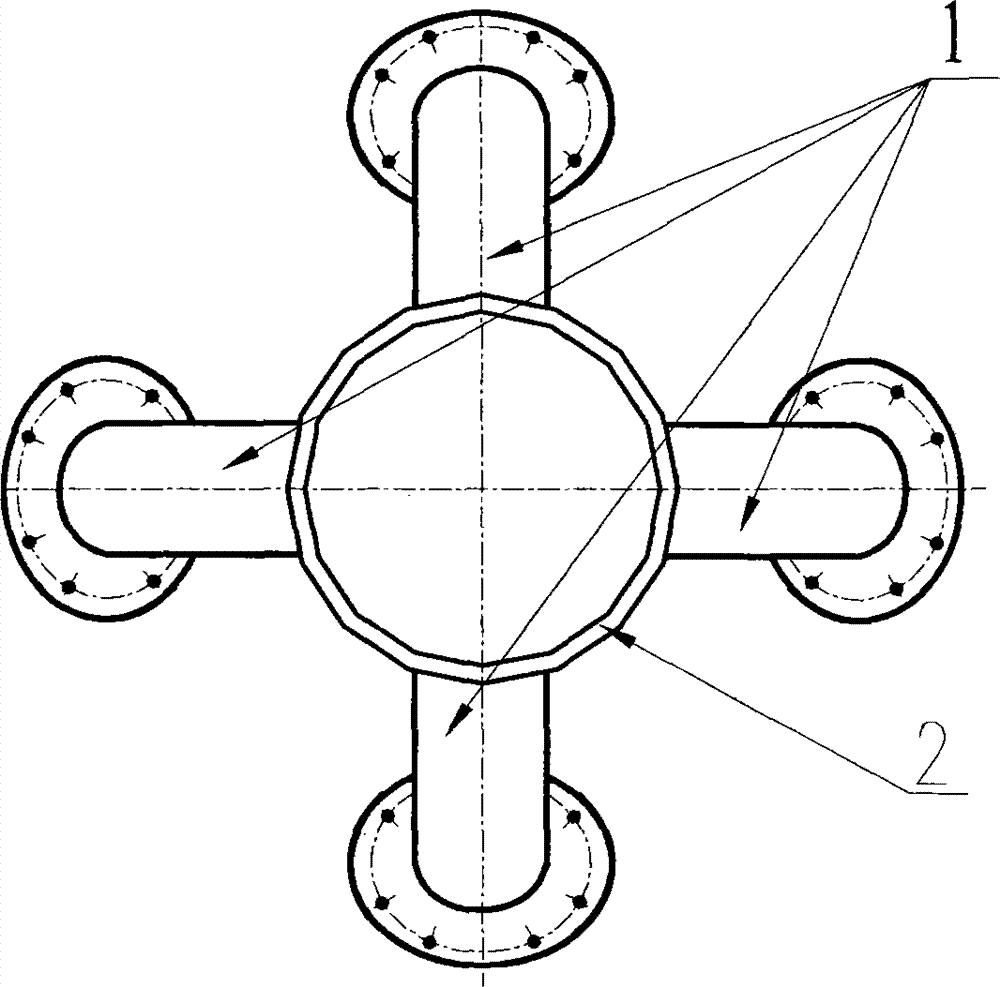

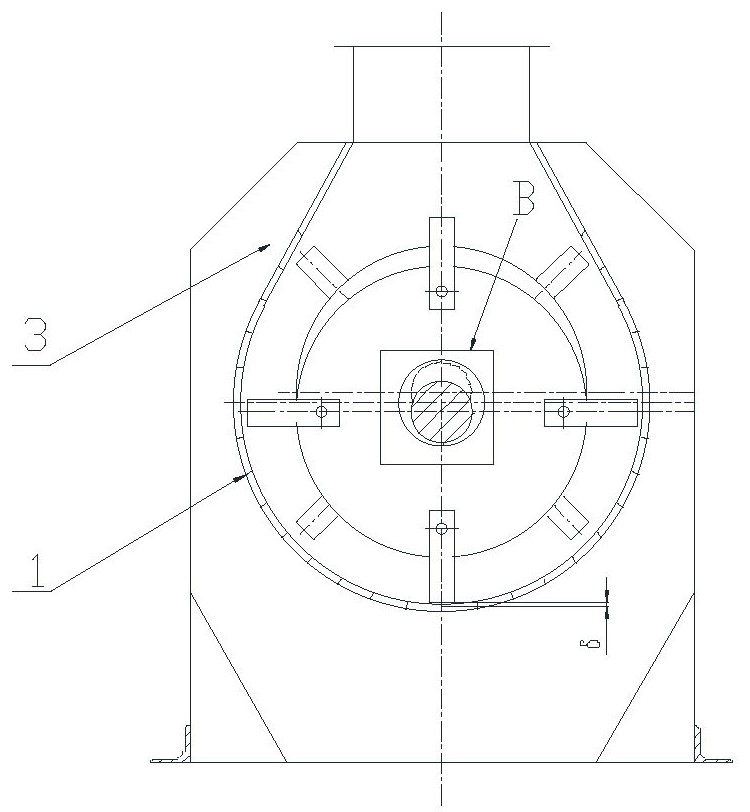

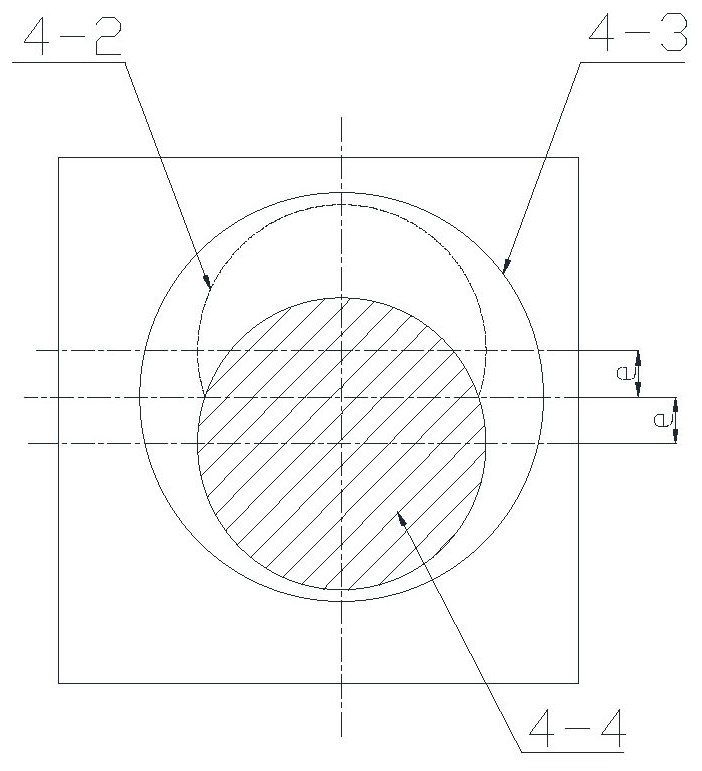

Fluid dynamic machine with turning wheel transmission piston speed-changing mechanism

InactiveCN104265374AHigh speedIncrease speed differenceInternal combustion piston enginesRotary piston pumpsDrive shaftReciprocating motion

The invention relates to a fluid dynamic machine with a turning wheel transmission piston speed-changing mechanism. The fluid dynamic machine comprises a machine body (1), an air cylinder piston linkage mechanism (2) and a turning wheel transmission mechanism (3), wherein a turning wheel disc (11) and a transmission shaft (10) of the turning wheel transmission mechanism (3) are concentrically or eccentrically mounted, a turning wheel groove (13) is formed in a disc surface (14) of the turning wheel disc (11), a turning wheel body (12) is supported and mounted in the turning wheel groove (13) through a bearing, a rotating shaft (18) is mounted on the turning wheel body (12), and a connecting rod sleeve (9) at the tail of a connecting rod (6) sleeves the outer part of the rotating shaft (18); the turning wheel disc (11) rotates, and the turning wheel body (12) drives the connecting rod (6) and a piston (6) to do the variable-speed reciprocating motion.

Owner:南通金鼎天轮动力科技有限公司

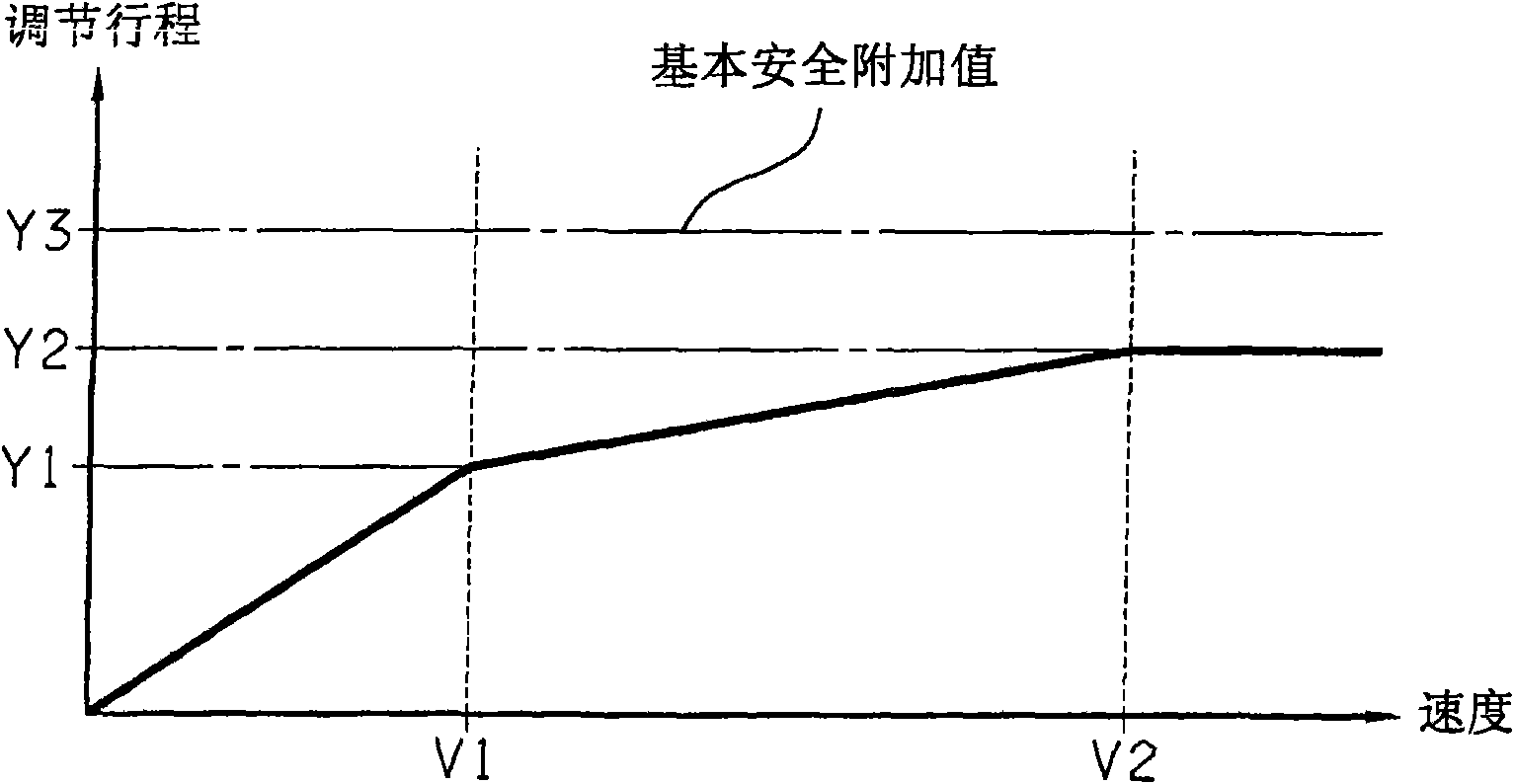

Method for dynamically determining a clutch rest point

InactiveCN101631965ARapid responseTaking into account the speed differenceClutchesEngineeringActuator

Owner:ZF FRIEDRICHSHAFEN AG

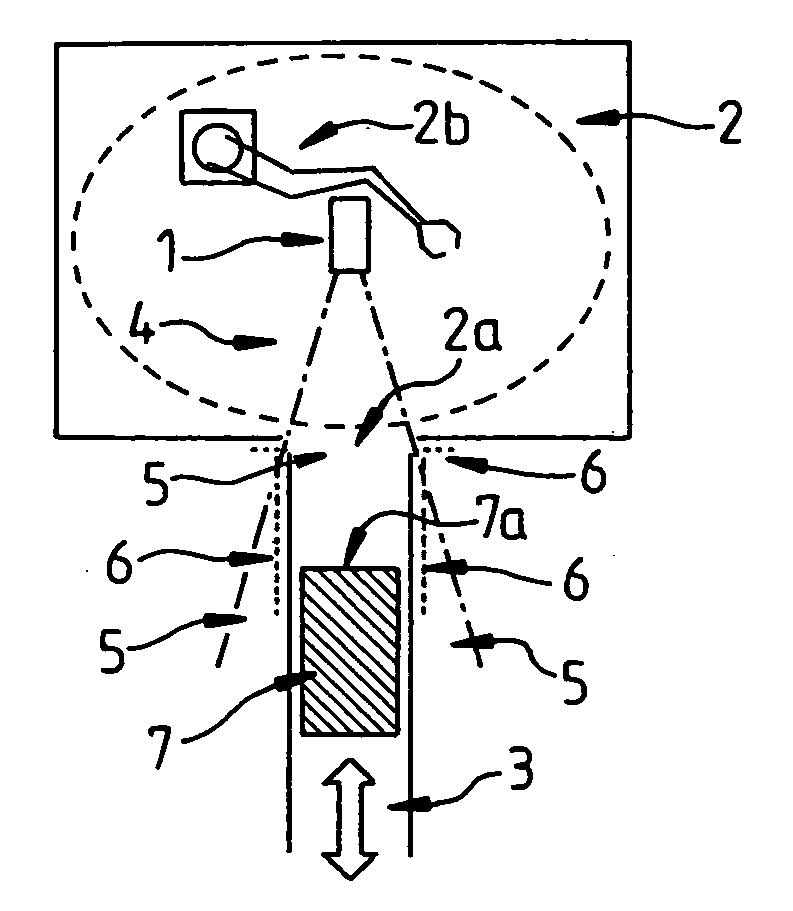

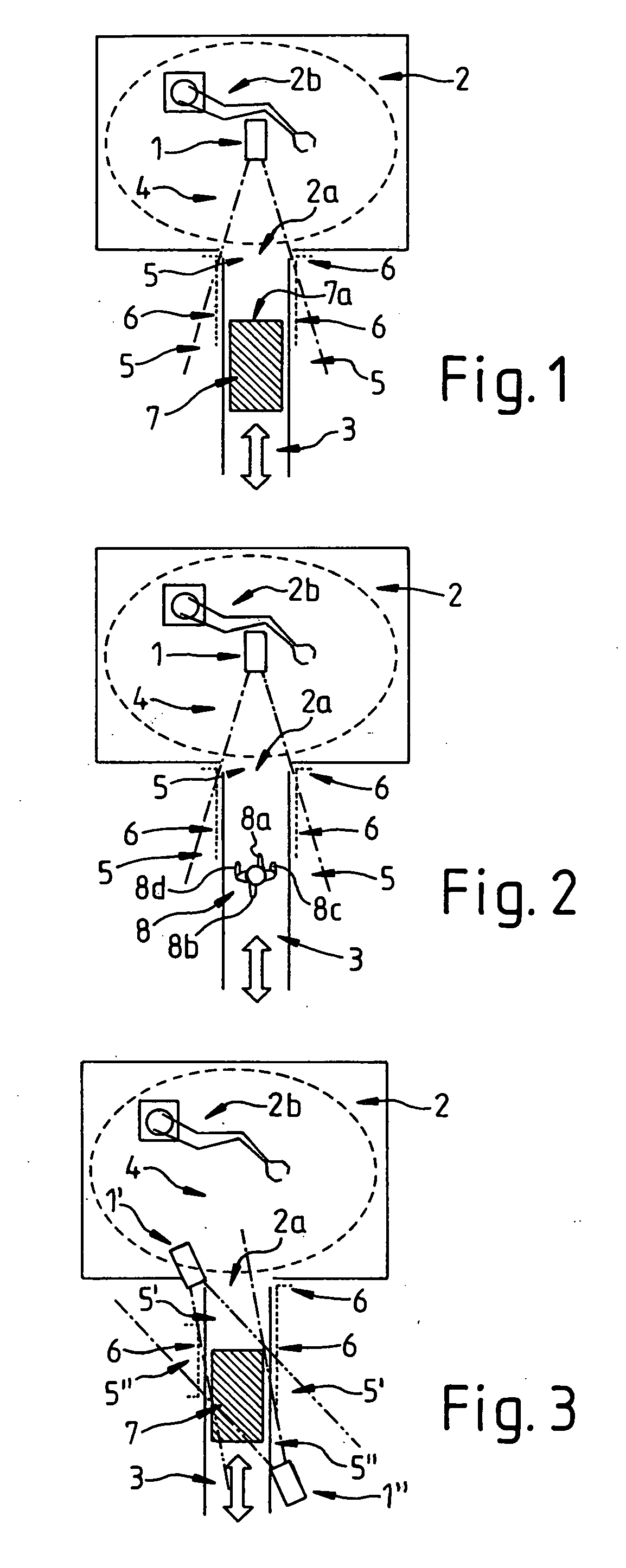

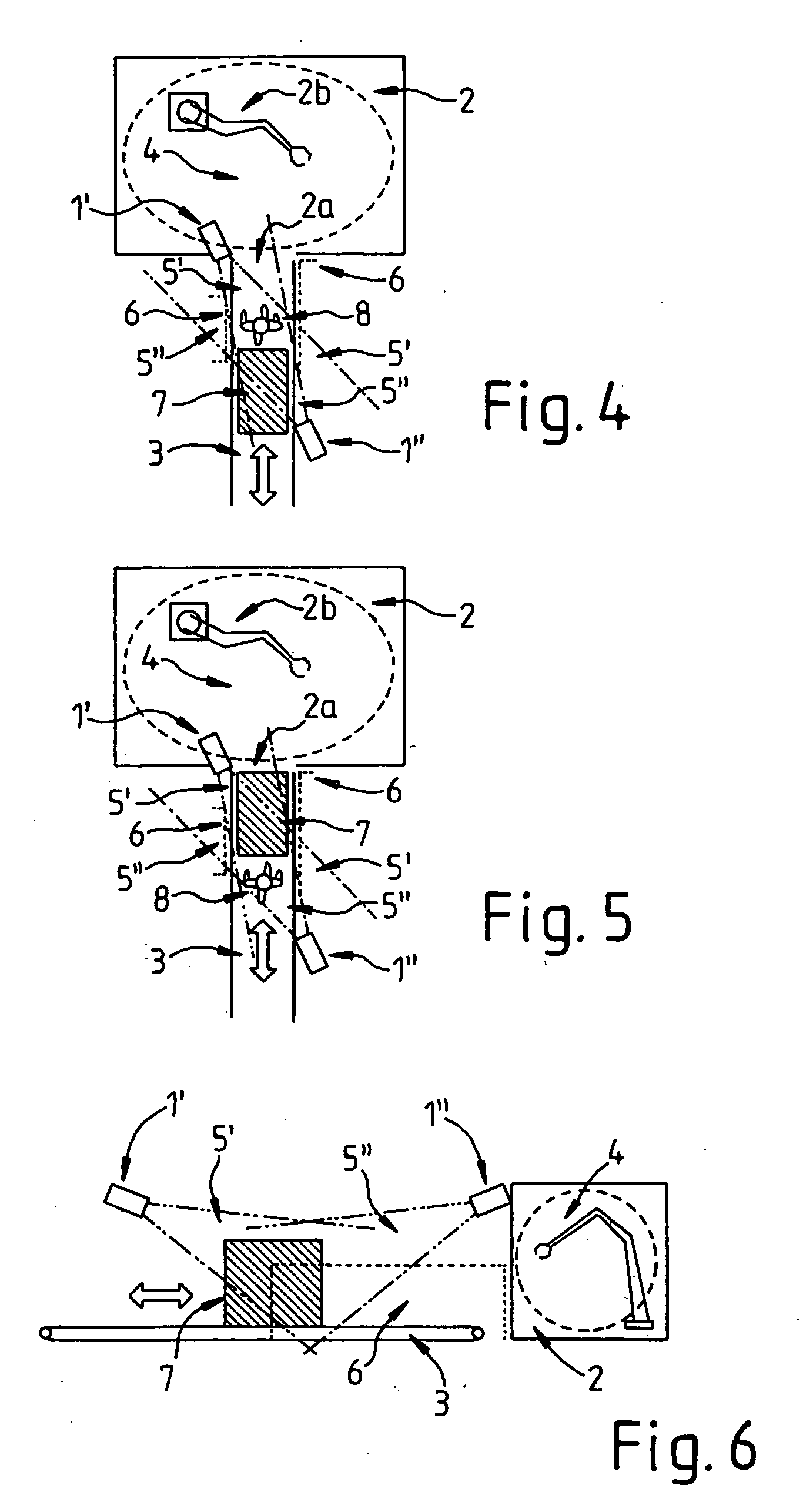

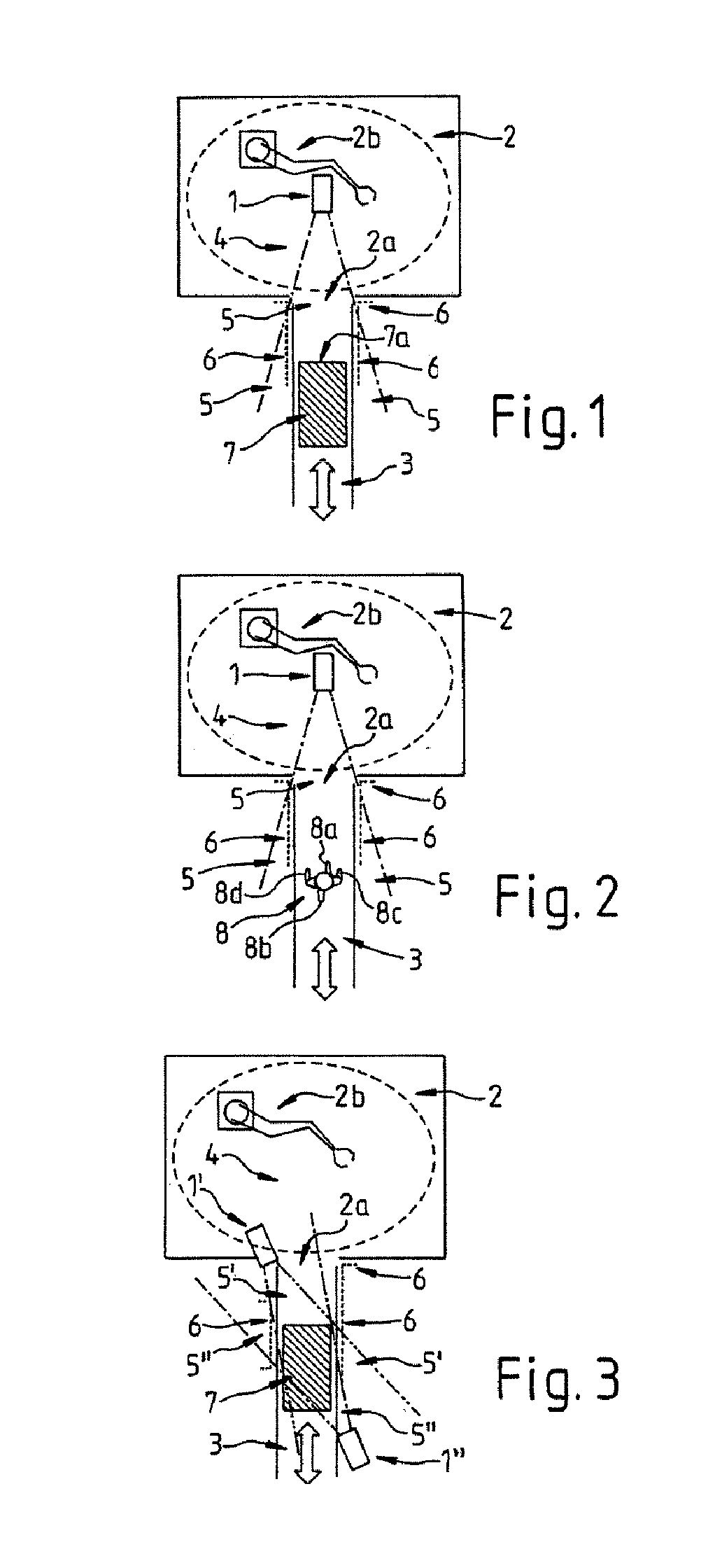

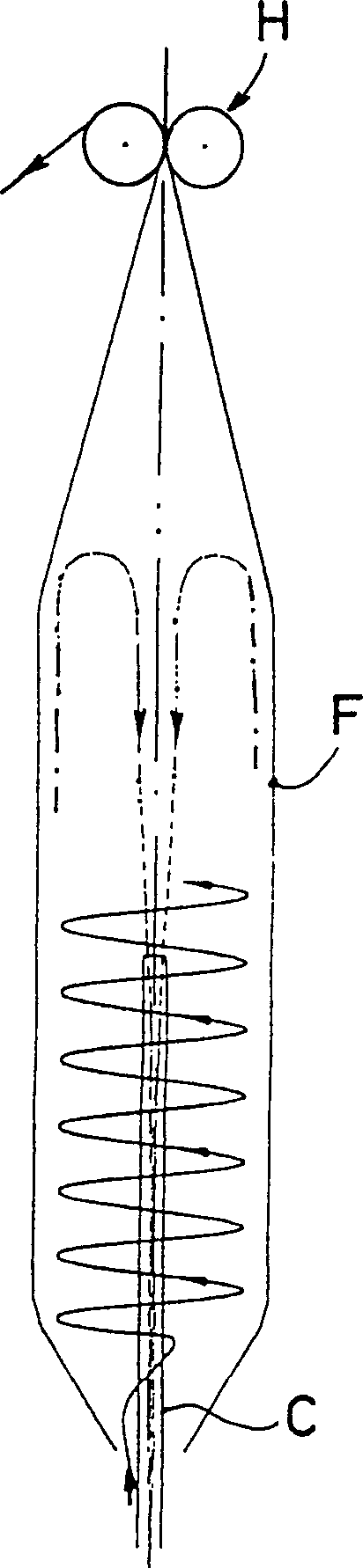

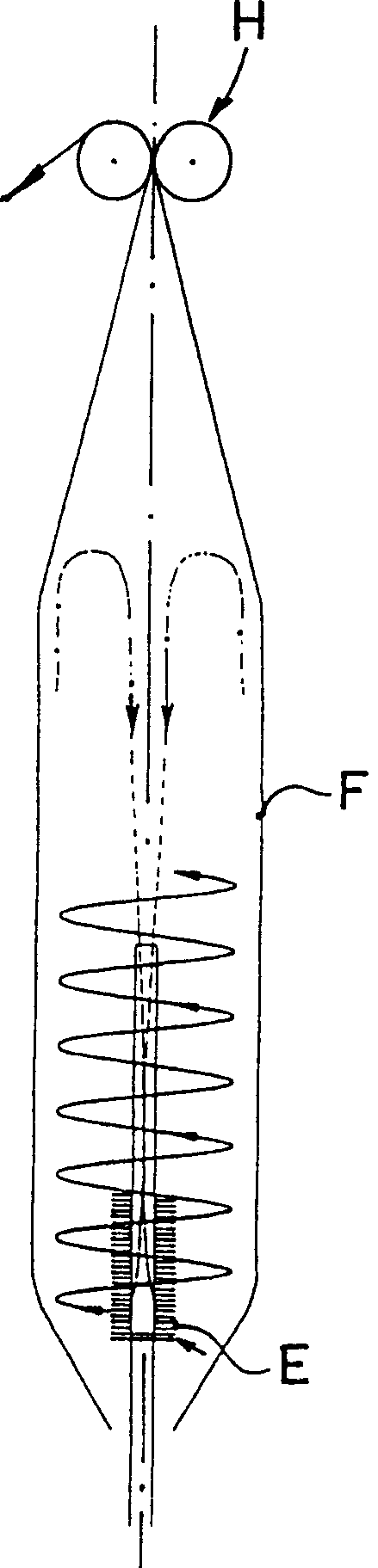

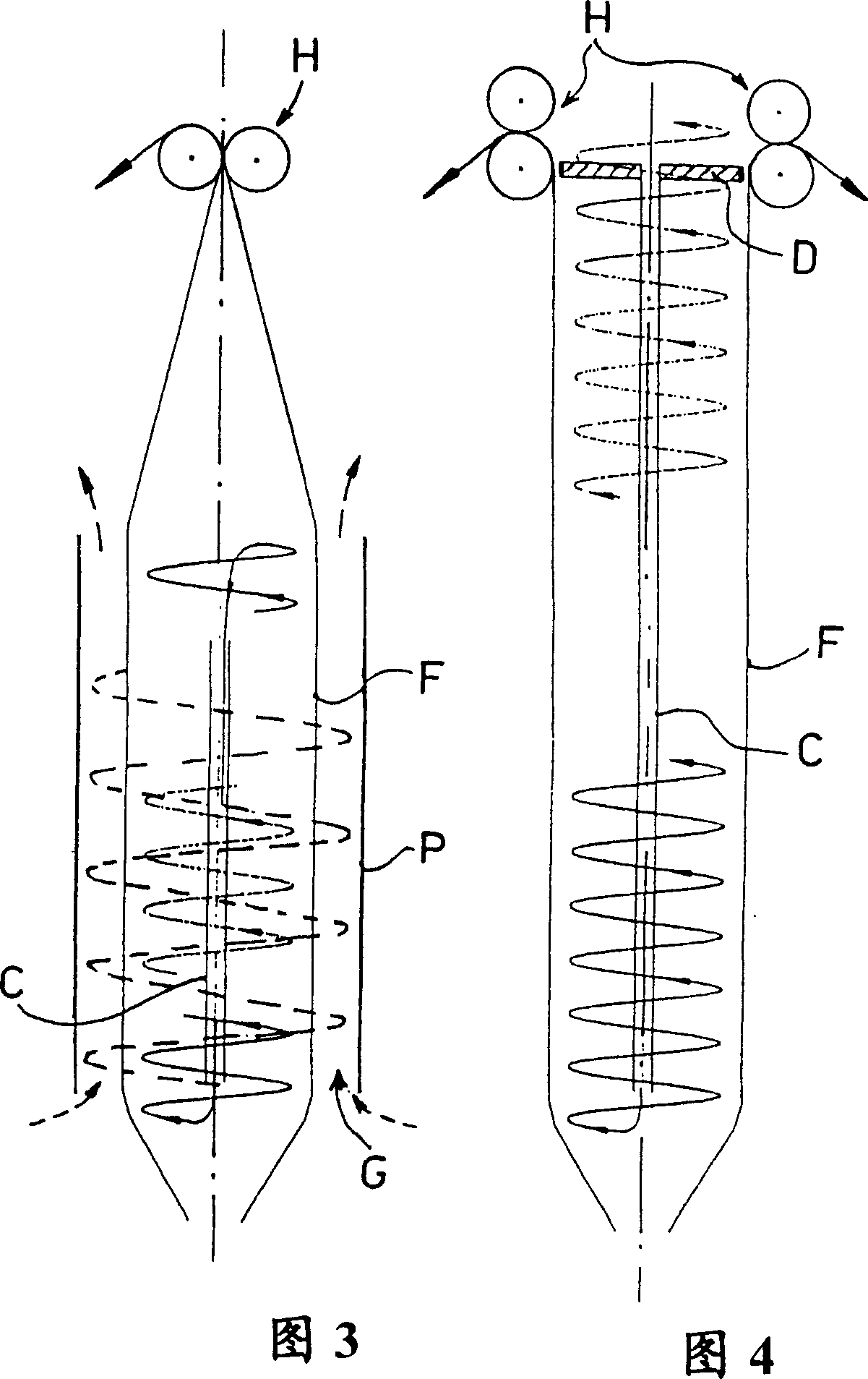

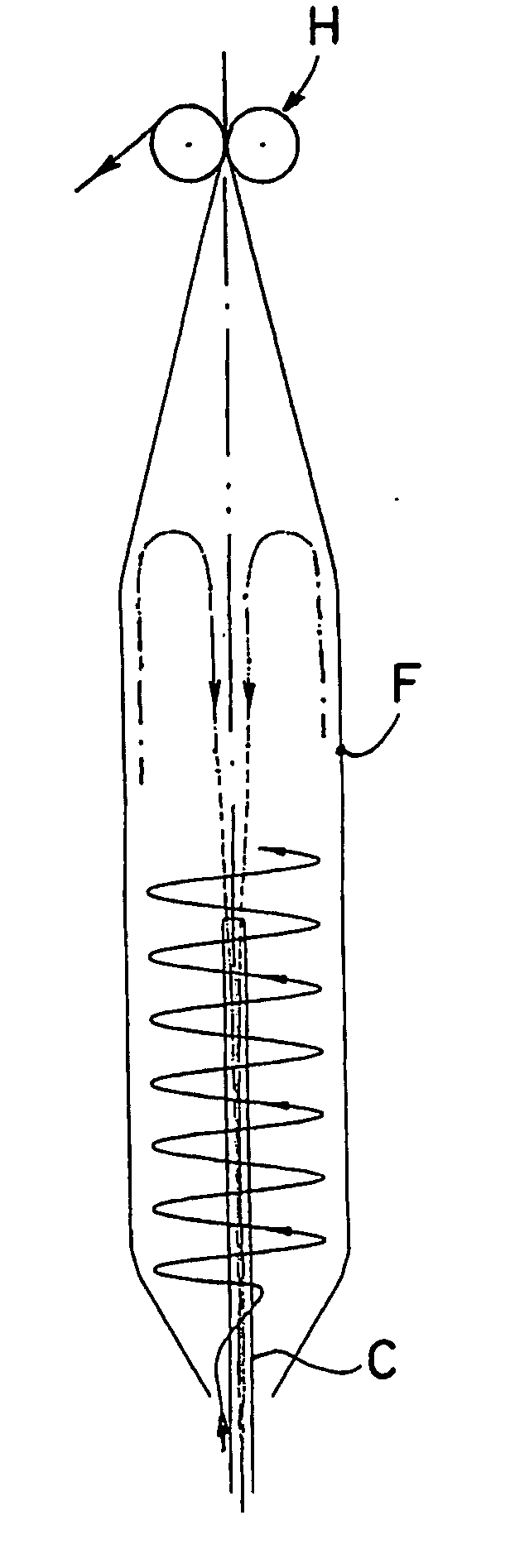

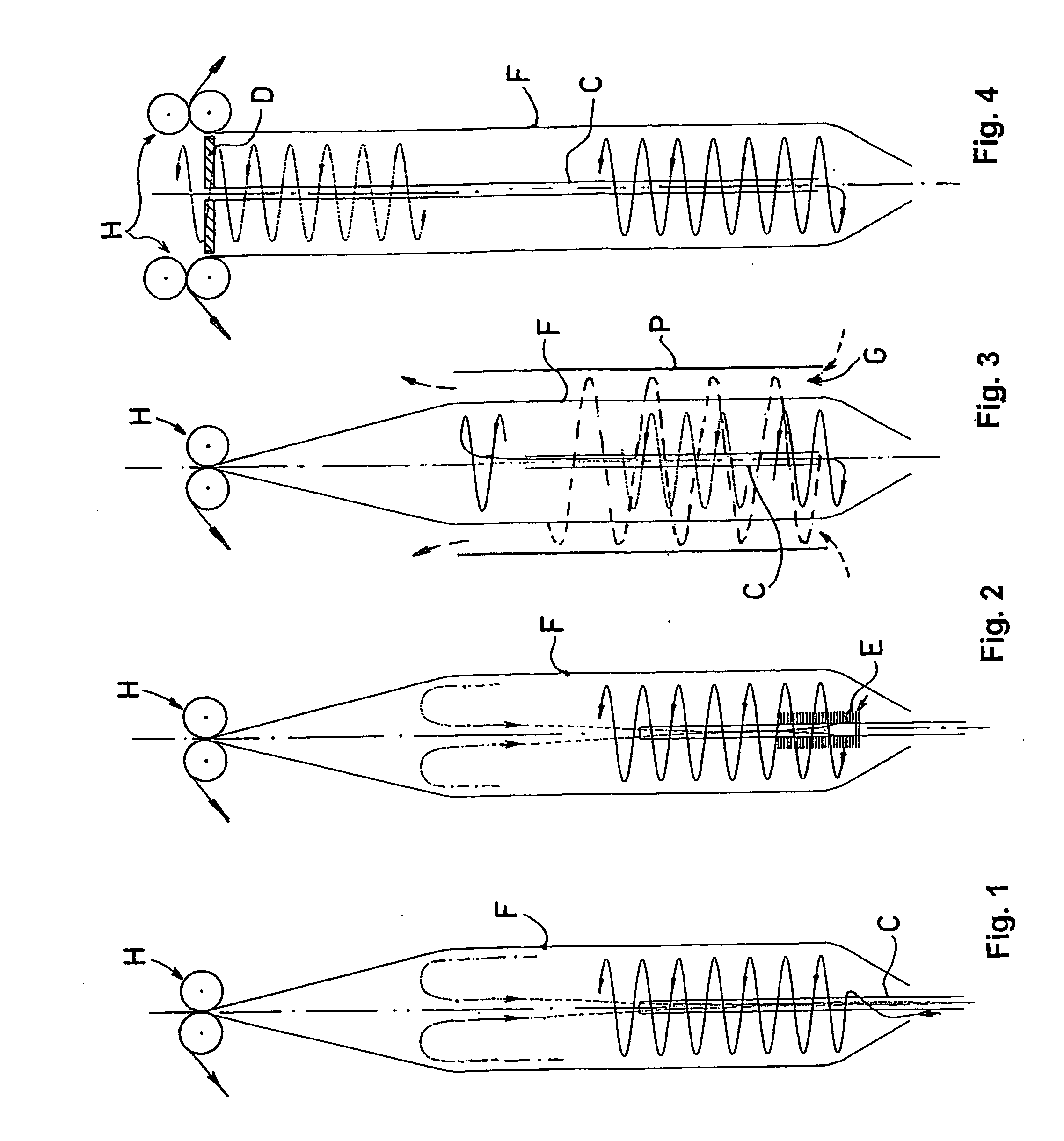

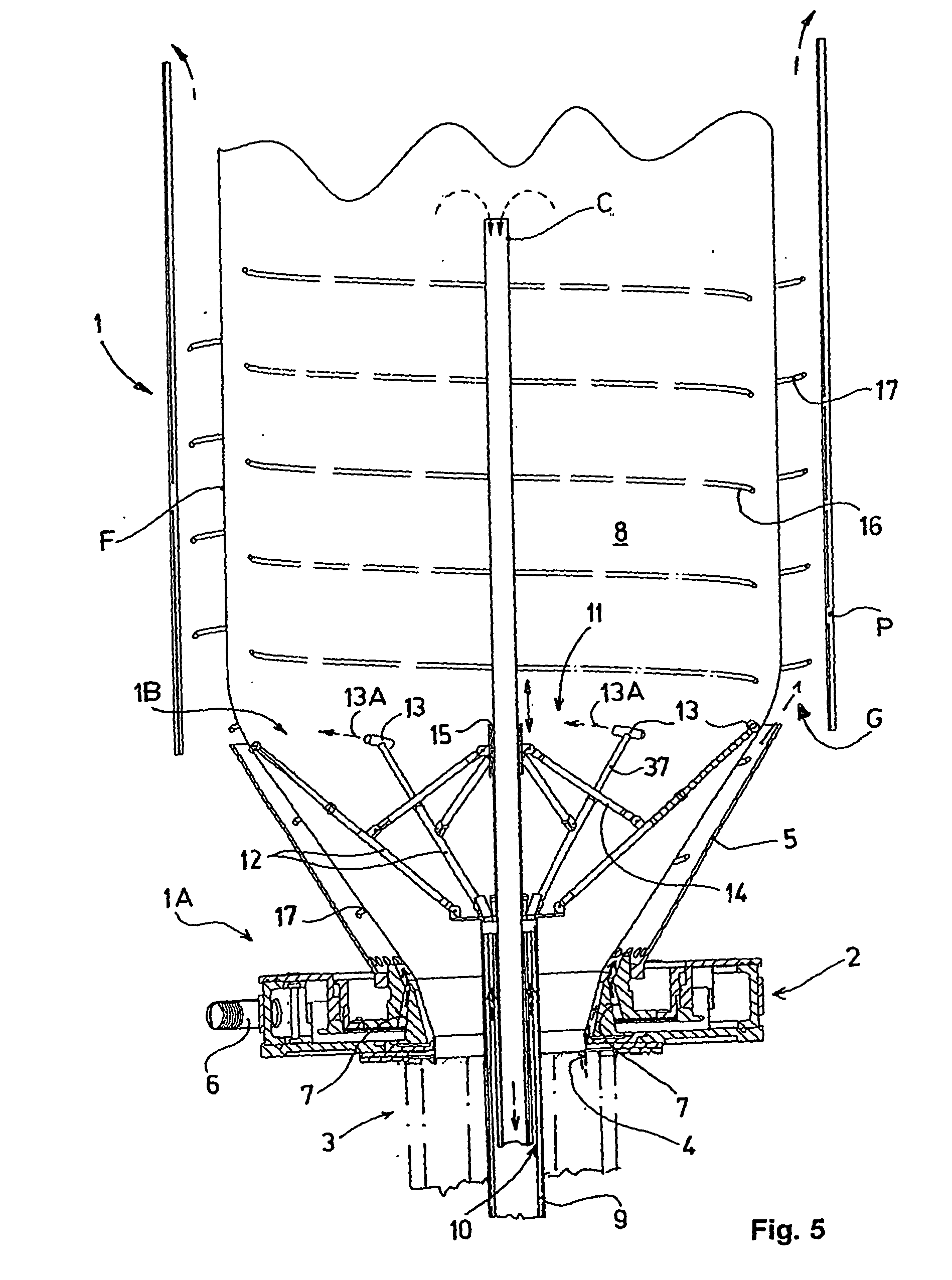

Method and apparatus for cooling extruded soft tube made of plastic film

This invention relates to a method for cooling extruded plastic foil hose (F), which is cooled down by driving a pressurized coolant along the internal and / or external skirt of the foil hose (F). The coolant is fed in the area of a drawing aperture (4) tangentially to the foil hose (F), and the coolant thus generated is driven as a spiral stream (16, 17) from the tangential inlet (6) to the outlet by a centrifugal force affecting the coolant along the internal and / or external surface of the foil hose (F), and by the density and pressure differences between various parts of the coolant. Said apparatus (1) comprises an internal cooling unit (1B) equipped with a distribution drum (2) provided with nozzles (13) with tangential inlets (13A). Its external cooling unit (1A) has a tangential inlet (6), which is in connection with a ring channel (G) around the foil hose (F), delimited by a tubular element (5, P).

Owner:DR-派克Ⅱ有限公司

Clutch control system for transmission

InactiveUS9062764B2Discontinue switching operationQuick identificationDigital data processing detailsGearing controlClutch controlControl system

A clutch control system for a transmission for detecting if hydraulic control during shifting is not executed. A first clutch and a second clutch are switched from a disengagement state to an engagement state by receiving a predetermined pressure generated by a hydraulic pump. A transmission executes shifting to an adjacent gear step by operation of switching the engagement state of the first clutch and of the second clutch from one side to the other side. If an elapse time t from the start of clutch switching operation reaches a predetermined time and an input-output speed ratio which is a ratio between engine speed and counter shaft rotational number falls within a predetermined range corresponding to a gear step before shifting, the transmission control unit discontinues the clutch switching operation by stopping the supply of hydraulic pressure to the other side clutch to bring it into the disengagement state.

Owner:HONDA MOTOR CO LTD

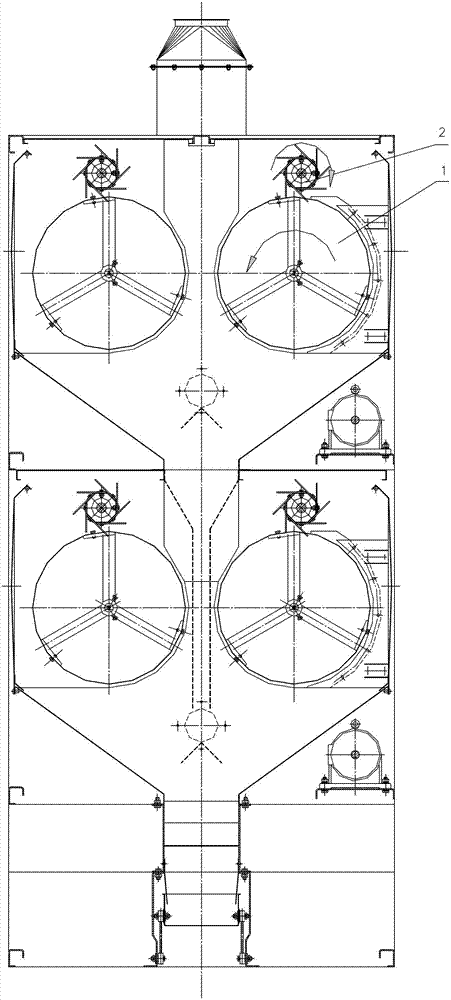

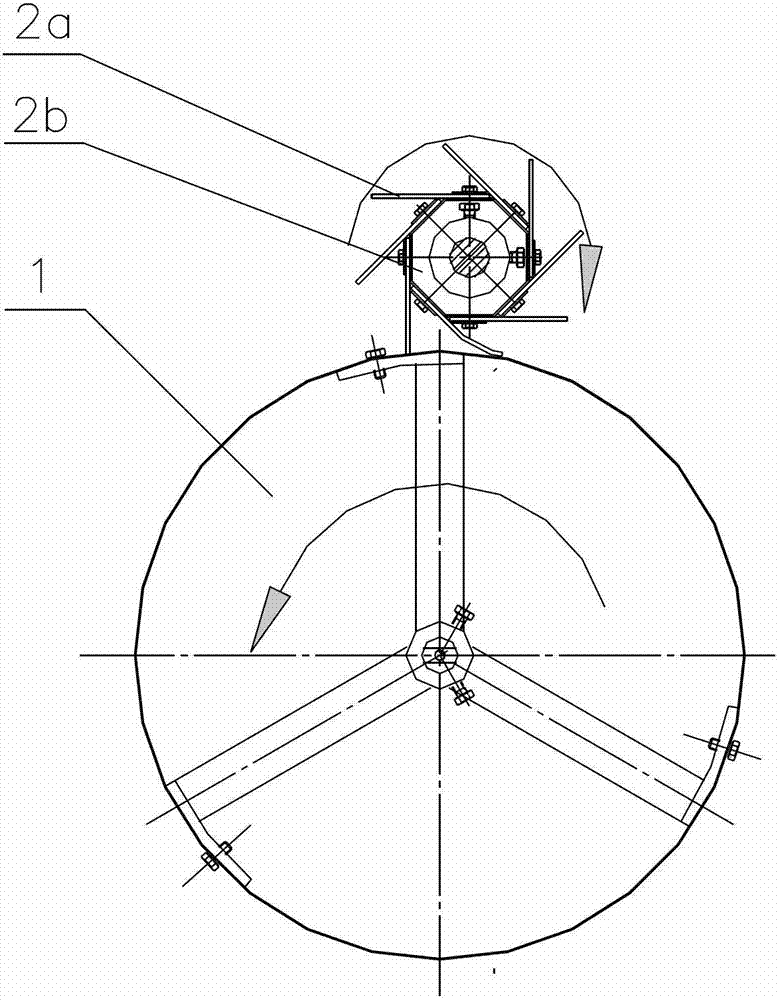

Beating sieve cleaning mechanism of peanut rotary drum grader

The invention relates to a modified structure of a peanut grader in an agriculture machine, and discloses a beating sieve cleaning mechanism of a peanut rotary drum grader. The beating sieve cleaning mechanism of the peanut rotary drum grader comprises grading rotary drums (1) of the peanut rotary drum grader; beating shafts (2b) parallel to axes of the grading rotary drums (1) are arranged on outer sides of the grading rotary drums (1), and a plurality of beating rollers (2) are configured on each beating shaft (2b) along the length direction of the axis of the corresponding grading rotary drum (1); a plurality of rectangular beating plates (2a) are fixed to the outer peripheral wall of each beating shaft (2b) in a cantilever manner, and are flexible elastic plates, one end of each beating plate (2a) is fixed to the outer wall of the corresponding beating shaft (2b), and an included angle is formed by each beating plate (2a) and a radial line fixed onto the outer wall of the corresponding beating shaft (2b), and ranges from positive or minus 90 degrees to positive or minus 150 degrees; 1 / 2-1 / 3 parts of the beating plates (2a) of the beating rollers (2) in length directions of the beating plates (2a) are in contact with surfaces of the grading rotary drums (1) during rotation; and rotational directions of the beating rollers are opposite to those of the grading rotary drums, and linear velocities of contact positions among the beating plates on the beating rollers and the surfaces of the grading rotary drums are different. The beating sieve cleaning mechanism solves the problem of blockage of sieves of existing grading rotary drums in a peanut pod grading procedure.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

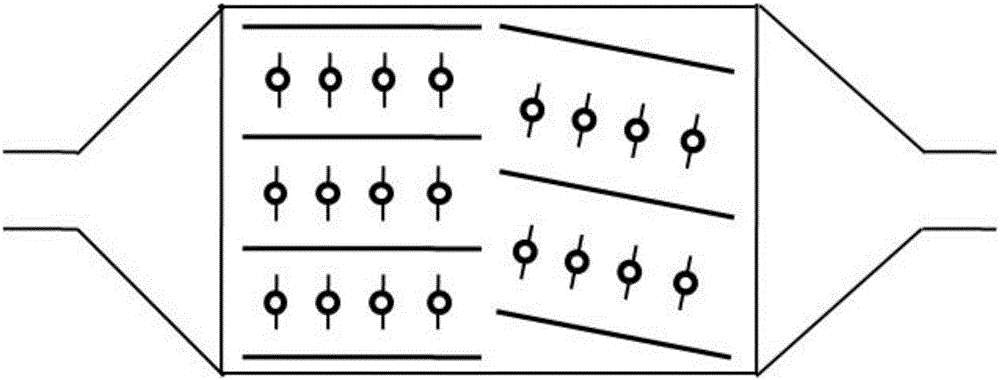

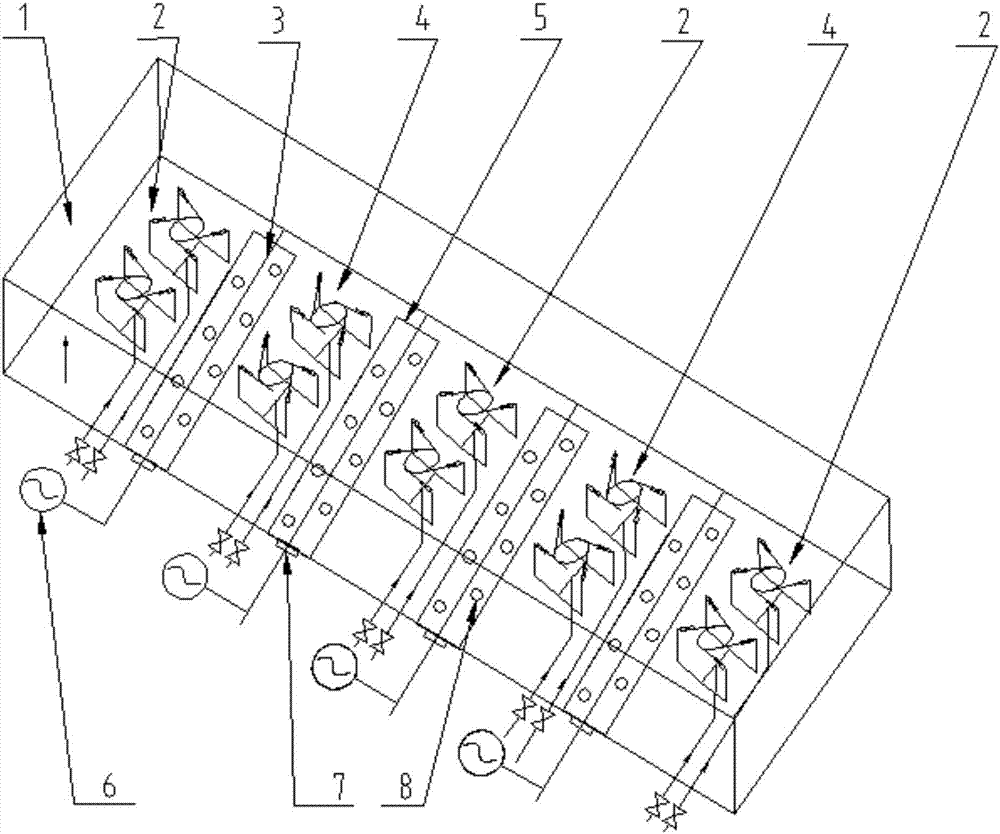

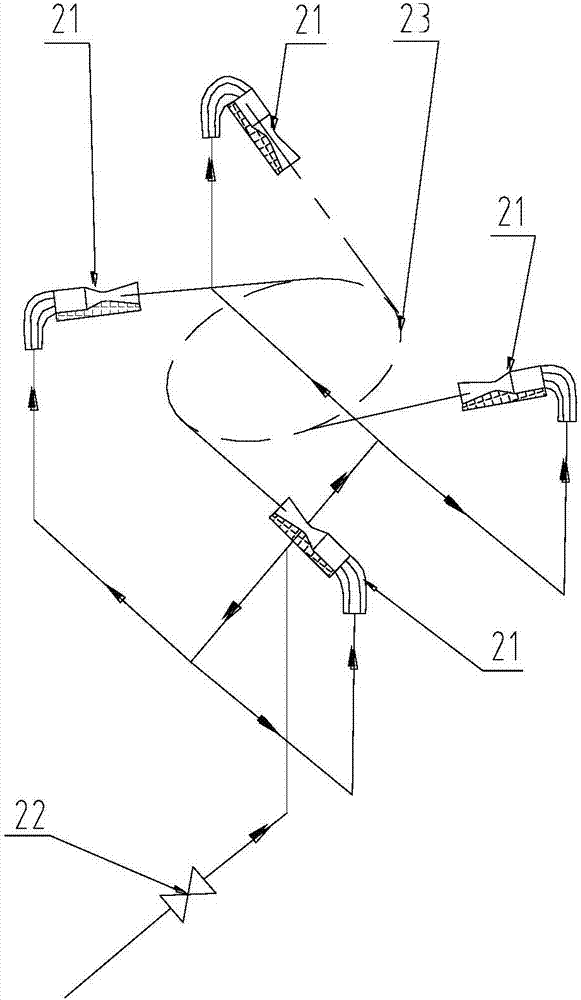

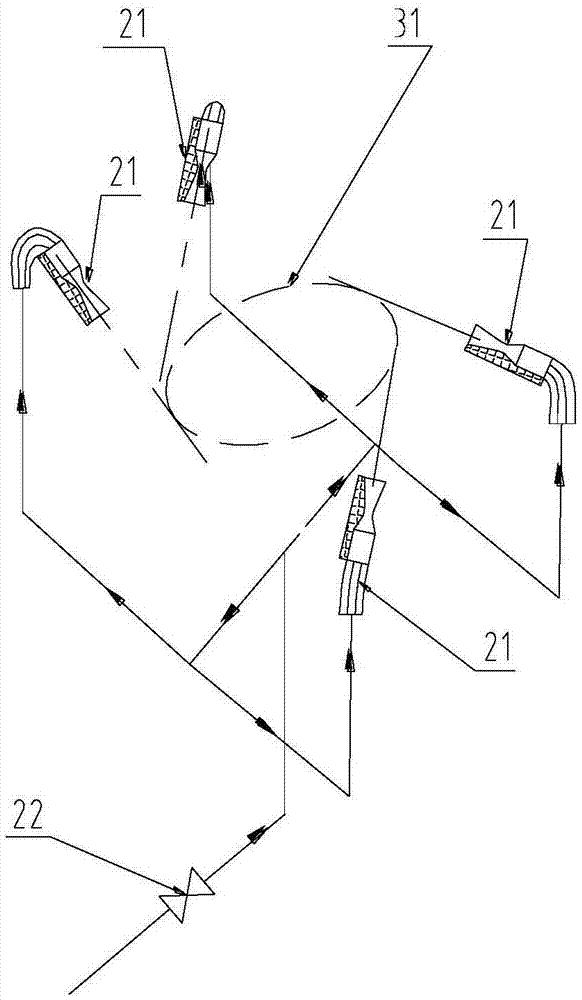

Ammonia-nitrogen mixing device for ammonia injection system of thermopower boiler

PendingCN107875847AImprove the mixing effectIncrease speed differenceGas treatmentTransportation and packagingLow loadFlue gas

The invention particularly relates to an ammonia-nitrogen mixing device for an ammonia injection system of a thermopower boiler. According to the ammonia-nitrogen mixing device, the problem of non-uniform ammonia-nitrogen mole ratio in flue gas at a catalyst inlet of an SCR (Selective Catalytic Reduction) denitrification system of a large-sized thermopower boiler is solved. The ammonia-nitrogen mixing device comprises clockwise mixer unit groups, anticlockwise mixer unit groups, air distribution plates, motors, sealing devices and the like; laval nozzles are used for generating supersonic ammonia current for strongly entraining surrounding flue gas; ammonia gas nozzles are distributed in a corner tangential mode to form a strongly-rotating vortex region for intensifying the mixing of the ammonia gas and the flue gas. According to the ammonia-nitrogen mixing device disclosed by the invention, by adopting the porous air distribution plates, relative speed difference of the ammonia gas and the flue gas is improved, and the problem that the ammonia gas and the flue gas are difficult to be mixed when the boiler operates at a low load is solved; relative deviation of the ammonia-nitrogenmole ratio in the flue gas at a catalyst layer inlet along the width direction can be smaller than 5 percent, and relative deviation of the ammonia-nitrogen mole ratio along the depth direction is smaller than 3 percent.

Owner:SHANXI UNIV

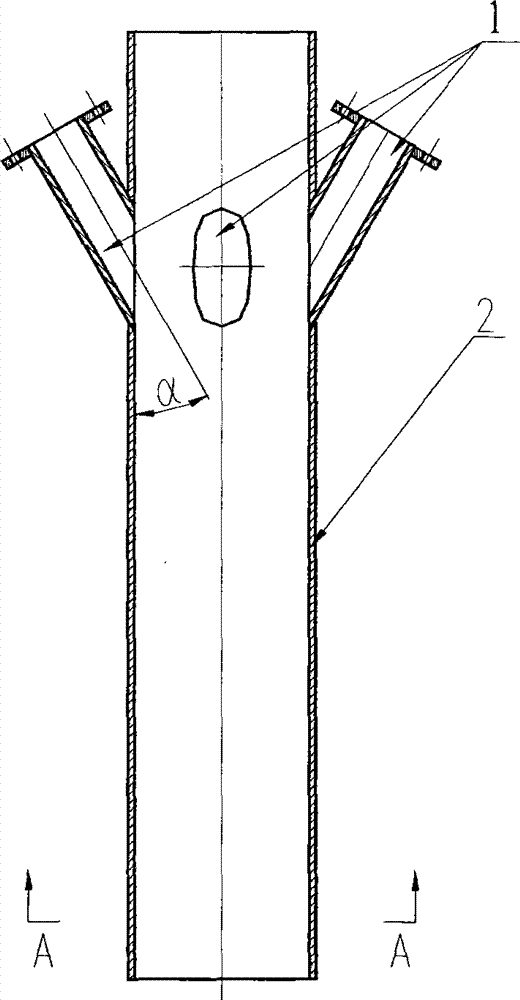

Catalytic cracking lifting pipe material feeding mixing section structure for promoting efficient mixing of raw oil and catalyst

ActiveCN104774641AIncrease the "mix" intensityHigh strengthCatalytic crackingChemical/physical processesSpray nozzlePetrochemical

The present invention belongs to the technical field of petrochemical industry, and relates to a lifting pipe reactor material feeding mixing section structure for promoting efficient mixing of raw oil and a catalyst in a catalytic cracking process. According to the present invention, a raw oil atomization spraying nozzle adopts an obliquely downward material feeding installation manner along to the axial direction of the lifting pipe so as to achieve oil-catalyst countercurrent contact in the catalytic cracking lifting pipe material feeding mixing section; the raw oil atomization spraying nozzle installation bushing (1) is obliquely and downward arranged on the lifting pipe reactor pipe wall (2) along the axial direction, and the raw oil atomization spraying nozzle is arranged in the raw oil atomization spraying nozzle installation bushing (1); in the used material feeding mixing section structure of the present invention, the raw oil droplets sprayed by the raw oil atomization spraying nozzle and the catalyst particles are subjected to countercurrent contact, such that the state between the raw material jet and the catalyst presents the cross-countercurrent mixing flow so as to improve the oil-catalyst contact and mixing situation in the catalytic cracking lifting pipe material feeding mixing section; and the complete mixing flow is subjected to transition to achieve the plug flow after the raw oil and the catalyst are rapidly mixed so as to reduce the space required by the mixing process, shorten the time required by the mixing process, and improve the reaction efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

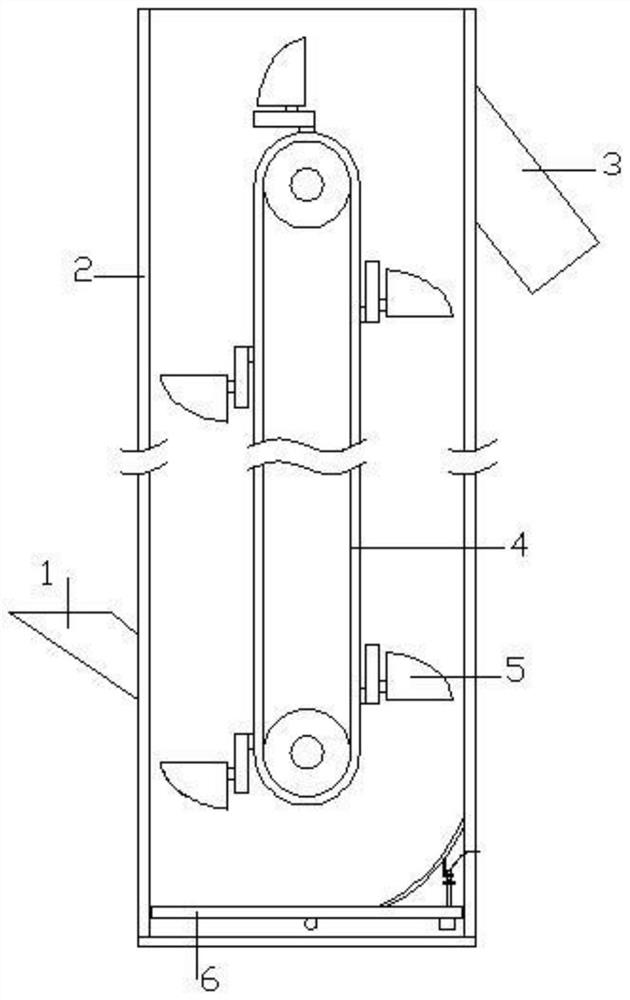

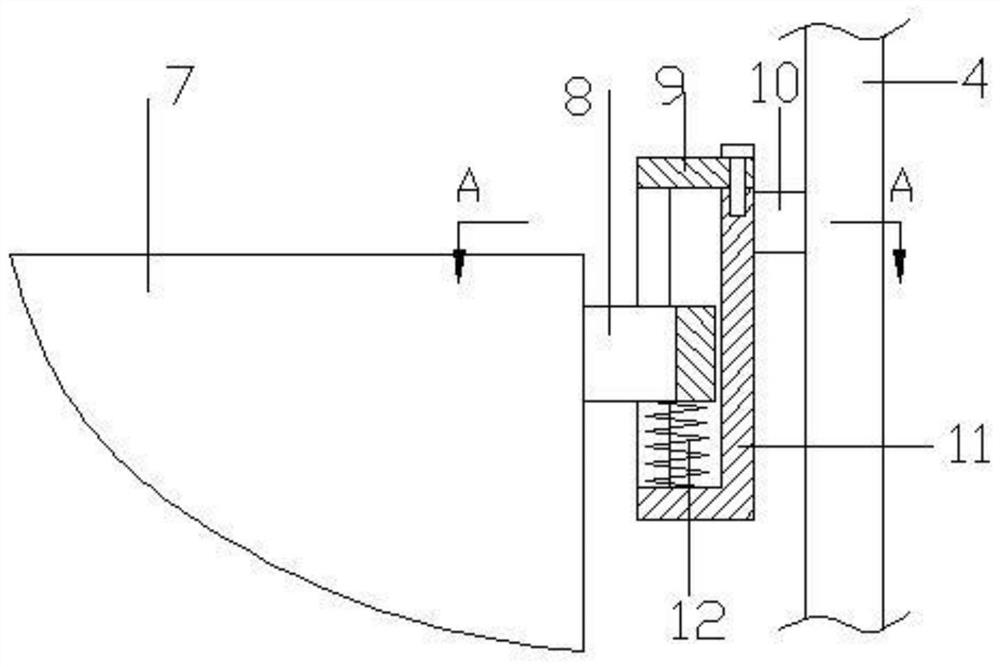

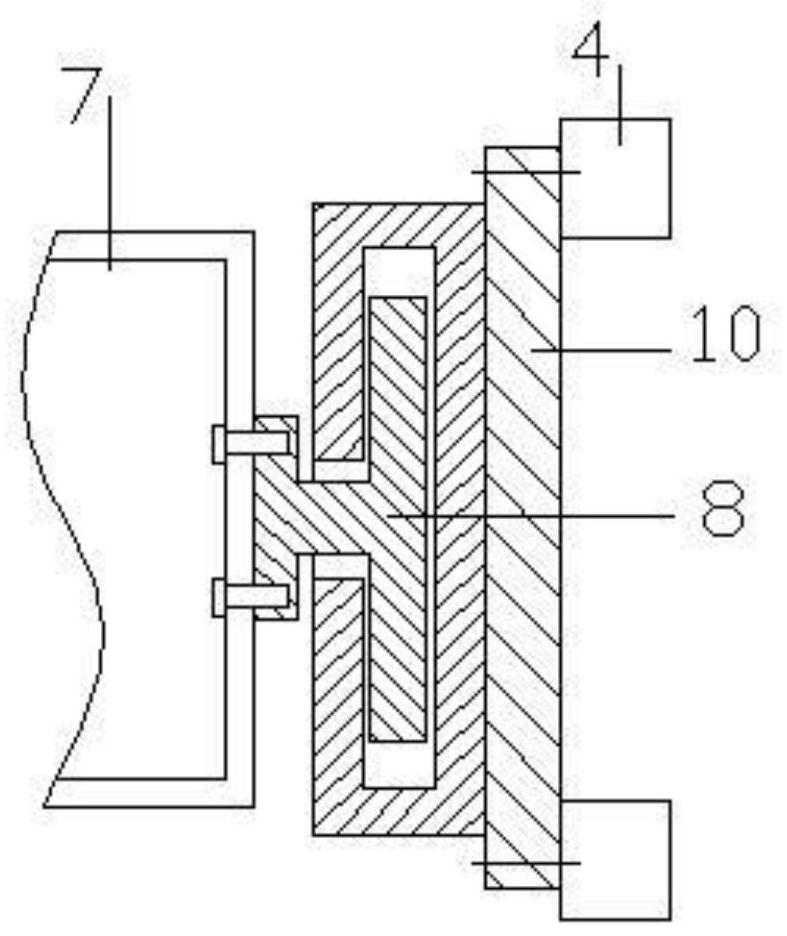

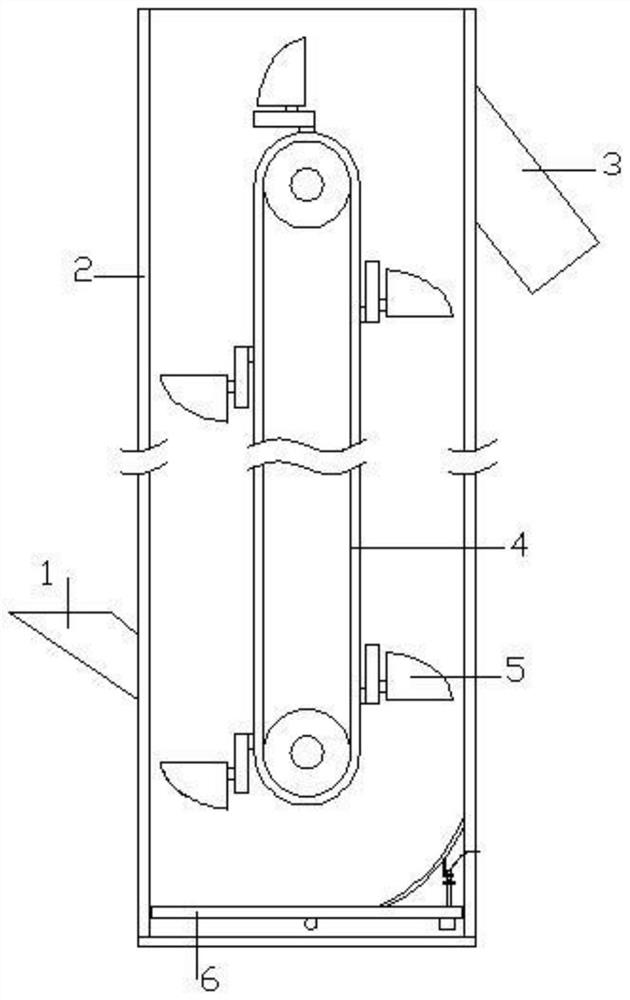

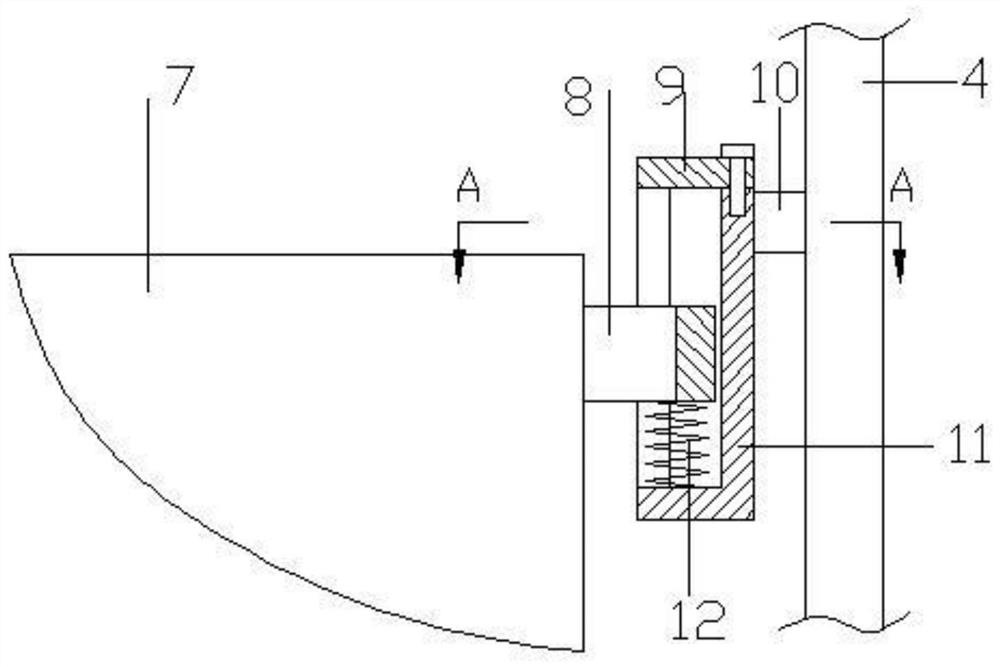

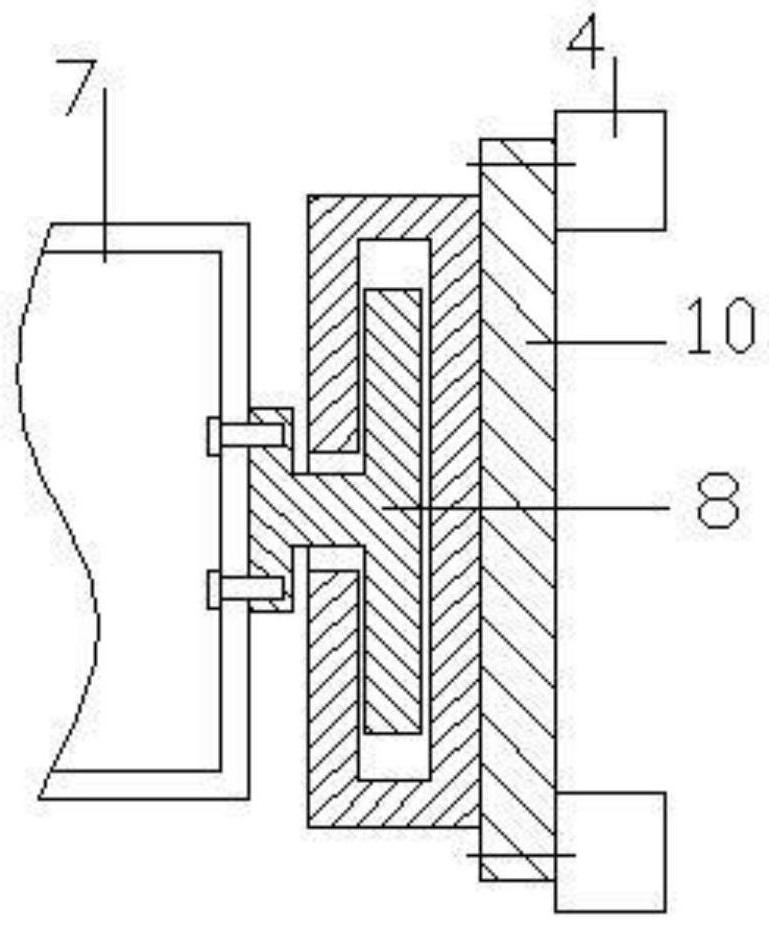

Lifting device for storing cement and lifting method

ActiveCN112919009ARealize lack of material alarmLarge turning angleConveyorsControl devices for conveyorsCement MaterialProximity sensor

The invention relates to a lifting device for storing cement and a lifting method. The lifting device for storing cement comprises a box body provided with a feeding port and a discharging port and a lifting chain rotationally arranged in the box body, and a lifting hopper is installed on the lifting chain and comprises a hopper body and a fixing block fixedly connected with the lifting chain; and a sliding groove extending in the vertical direction is formed in the fixing block, a sliding block fixedly connected with the hopper body is arranged in the sliding groove in a sliding mode, the lower end of the sliding block is connected with a bottom plate of the sliding groove through an impact spring, a limiting plate located above the sliding block is fixedly arranged on the fixing block, and the distance between the sliding block and the limiting plate is smaller than the length of the impact spring in the natural state. According to the lifting device for storing cement, by arranging the impact spring and the limiting plate, the hopper body is accelerated and blocked during material throwing, the speed difference between the hopper body and cement is increased, and the material throwing effect is improved; and by arranging a bearing plate and a proximity sensor, a material shortage alarm in the box body is realized by utilizing the lever principle so that a worker can conveniently know the material feeding condition in the box body.

Owner:临沂中联水泥有限公司

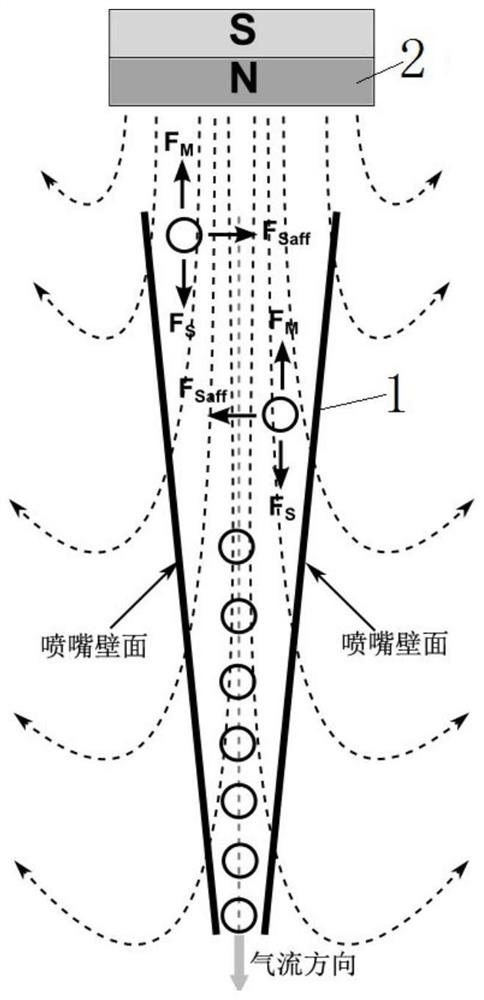

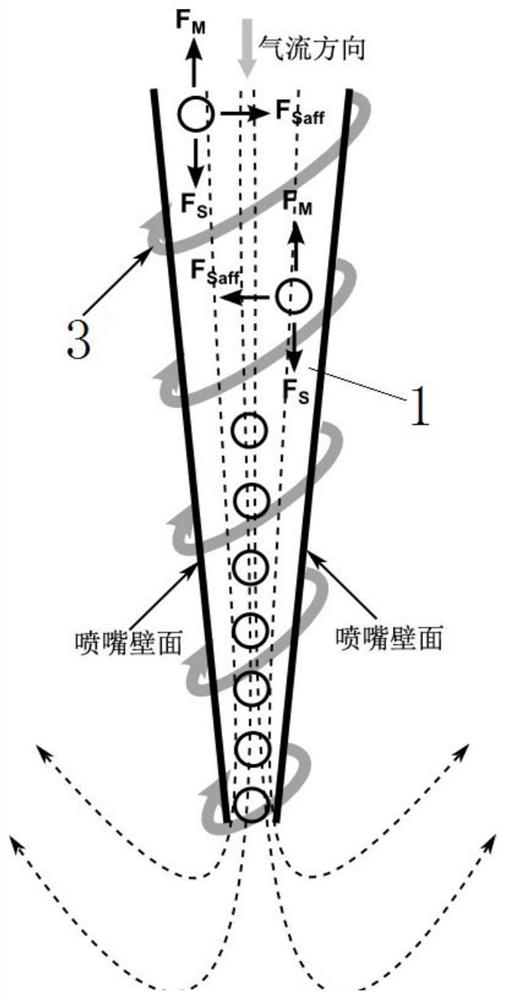

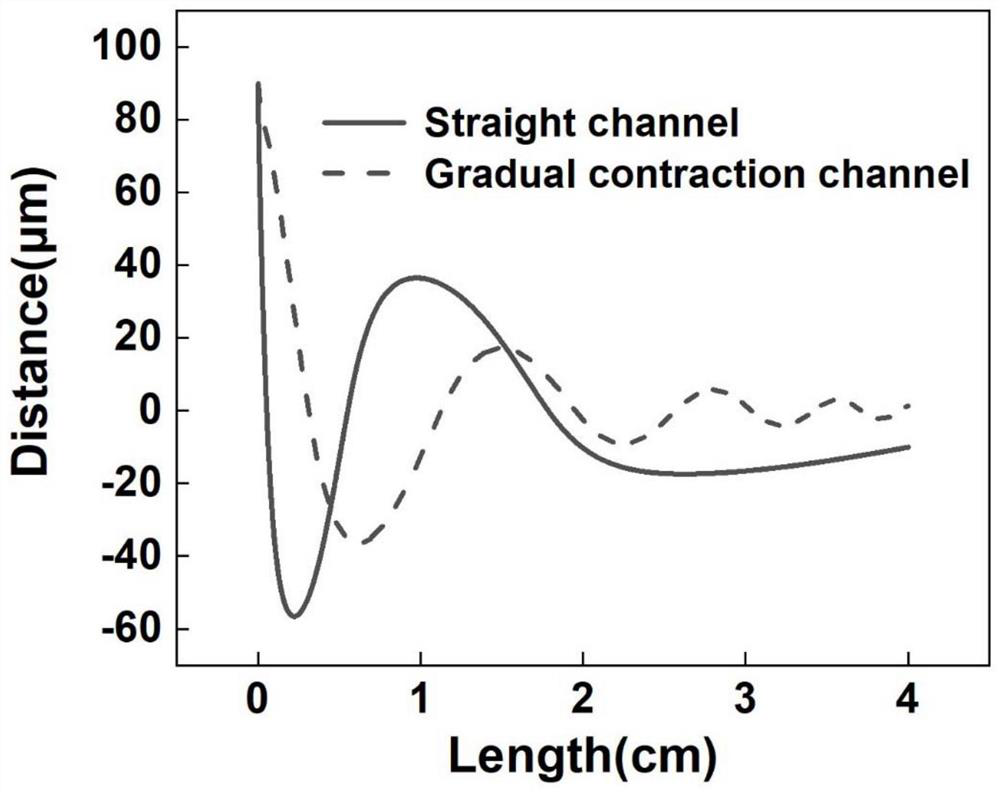

Enrichment device for aerosol particles

ActiveCN113109107AProlong the stress timeEnhanced Safman lift effectAdditive manufacturing apparatusPreparing sample for investigationEngineeringAdditive layer manufacturing

The invention discloses an enrichment device for aerosol particles. The enrichment device comprises an enrichment nozzle and an external force field generating device, the external force field generating device is used for forming external force field distribution in the enrichment nozzle, and the external force field distribution direction is parallel to the axis direction of the enrichment nozzle; the aerosol particles are acted by an external force field in the distribution of the external force field, and the acting direction of the external force field on the aerosol particles points to the inlet end of the enrichment nozzle from the outlet end of the enrichment nozzle; external force field distribution is formed in the enrichment nozzle through the external force field generating device, the stress time of aerosol particles in the enrichment nozzle can be remarkably prolonged, the Savman lift force effect borne by the aerosol particles is enhanced, the aerosol particles efficiently move to the central axis of the enrichment nozzle, and the efficient and high-precision enrichment of aerosol particles in a shorter channel length is realized; and the enrichment device has huge application potential in the fields of additive manufacturing 3D printing, ink-jet printing, biomedicine, environment detection and the like.

Owner:XI AN JIAOTONG UNIV

Food processor with good denoising effect

InactiveCN110710898AReduce intensityIncrease contact rateKitchen equipmentElectric machineryStructural engineering

The invention relates to a food processor with a good denoising effect. The food processor comprises a machine base, a cup body and a cup cover, wherein a motor is arranged in the machine base; the cup body is arranged on the machine base; a crushing cutter driven by the motor is arranged at the bottom in the cup body; at least two diversion bars integrally molded with the cup body are arranged onthe inner side wall of the cup body; the cup cover covers the opening part of the cup body; the cup body comprises an upper part composed of first concentric circles, a lower part composed of secondconcentric circles, and an eccentric transition part connected between the upper part and the lower part; the minimal diameter of the first concentric circles is more than the maximum diameter of thesecond concentric circles; and the first concentric circles and the second concentric circles are not in a same axis. By using the technical scheme, when the equipment is in work, gyration centers ofliquid streams of the upper part and the lower part are not in the same axis, a vortex is certainly distorted under the effect of the two liquid streams; noise generated by the liquid stream of the lower part in the action area of the crushing cutter is reflected and refracted in the distorted vortex, so that a part of energy of the noise is lost, and thus the intensity of the noise is reduced.

Owner:HONGYANG HOME APPLIANCES

Method and apparatus for cooling extruded plastic foil hoses

InactiveUS20060202374A1Improve productivityEliminate deficienciesCeramic shaping apparatusFlat articlesCentrifugal forcePressure difference

A method and apparatus for cooling extruded plastic foil hose, which is cooled down by driving a pressurized coolant along the internal and / or external skirt of the foil hose. The coolant is fed in the area of a drawing aperture tangentially to the foil hose, and the coolant thus generated is driven as a spiral stream from the tangential inlet to the outlet by a centrifugal force affecting the coolant along the internal and / or external surface of the foil hose, and by the density and pressure differences between various parts of the coolant. The apparatus includes an internal cooling unit equipped with a distribution drum provided with nozzles with tangential inlets. Its external cooling unit has a tangential inlet, which is in connection with a ring channel around the foil hose, delimited by a tubular element.

Owner:PELCZ ANTAL +1

Method for operating a transmission with at least one positive-locking shifting element

ActiveUS8483918B2Improve shift qualitySpoil shifting qualityDigital data processing detailsGearingMechanical engineeringTooth position

A method of operating a transmission (1) with at least one interlocking shift element (F) having at least two shift element halves that can be brought into interlocked engagement with one another. When a command is received to close the interlocking shift element (F), a current rotational speed difference between the shift element halves of the interlocking shift element (F) and the current positions of the shift element halves are determined. If the rotational speed difference is smaller than a first speed difference threshold value and if a tooth-on-tooth position has occurred at the interlocking shift element (F), then to release the tooth-on-tooth position, the actuation force is changed to a release level at which a rotational speed difference above a second speed difference threshold value is produced between the shift element halves.

Owner:ZF FRIEDRICHSHAFEN AG

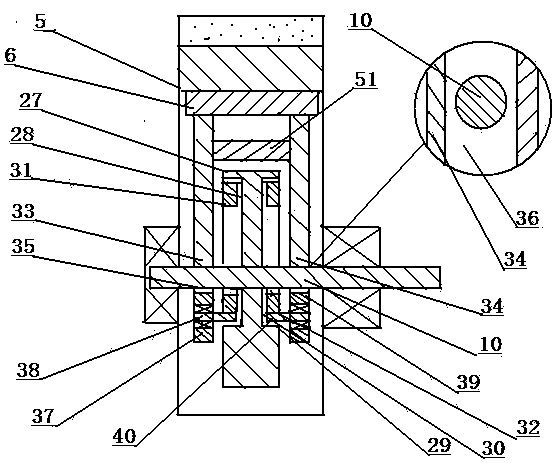

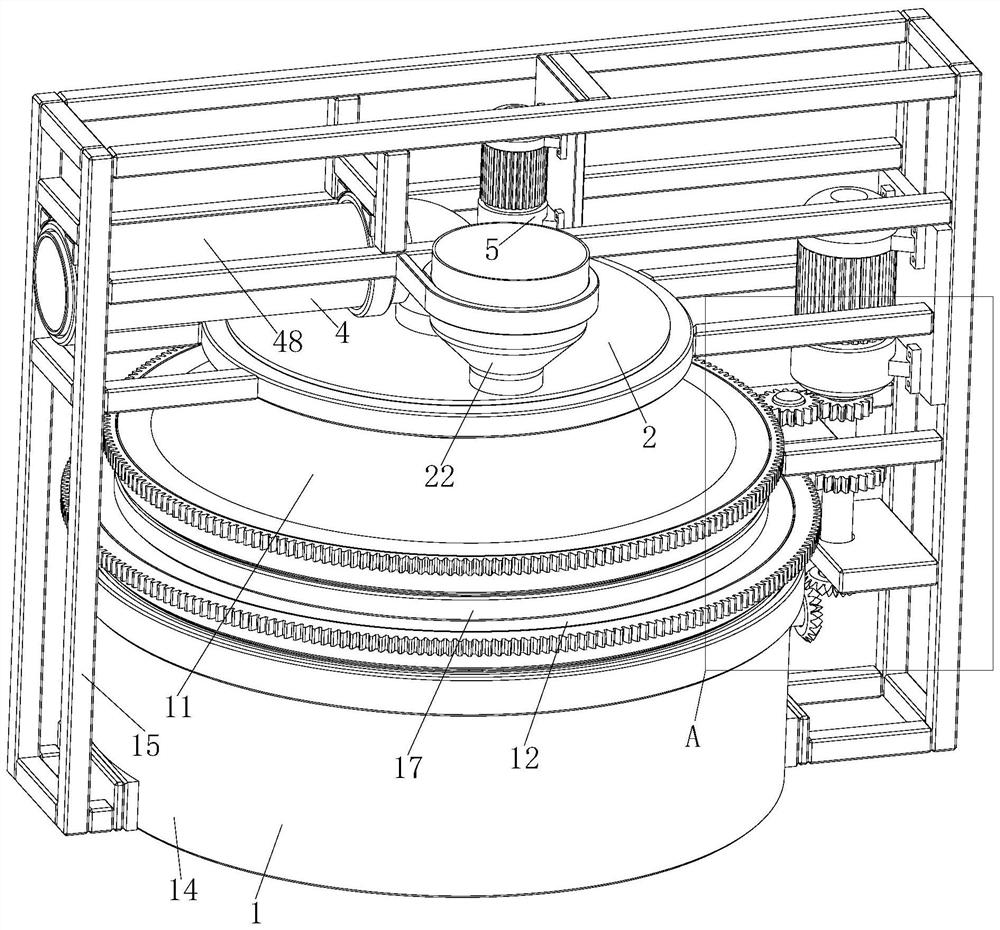

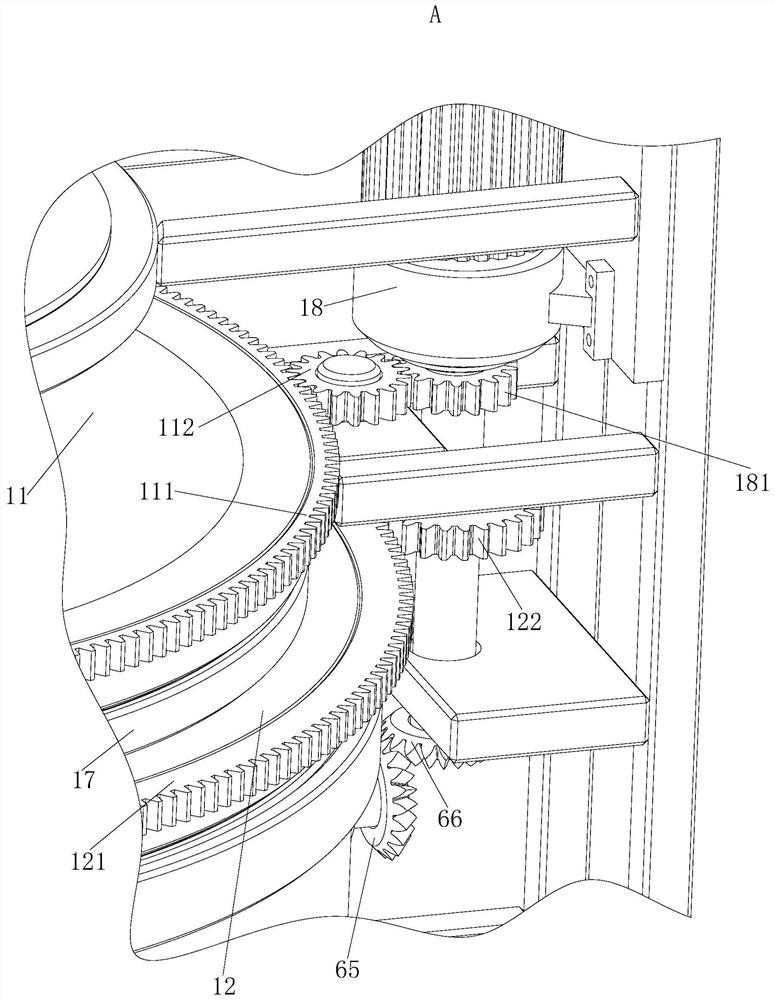

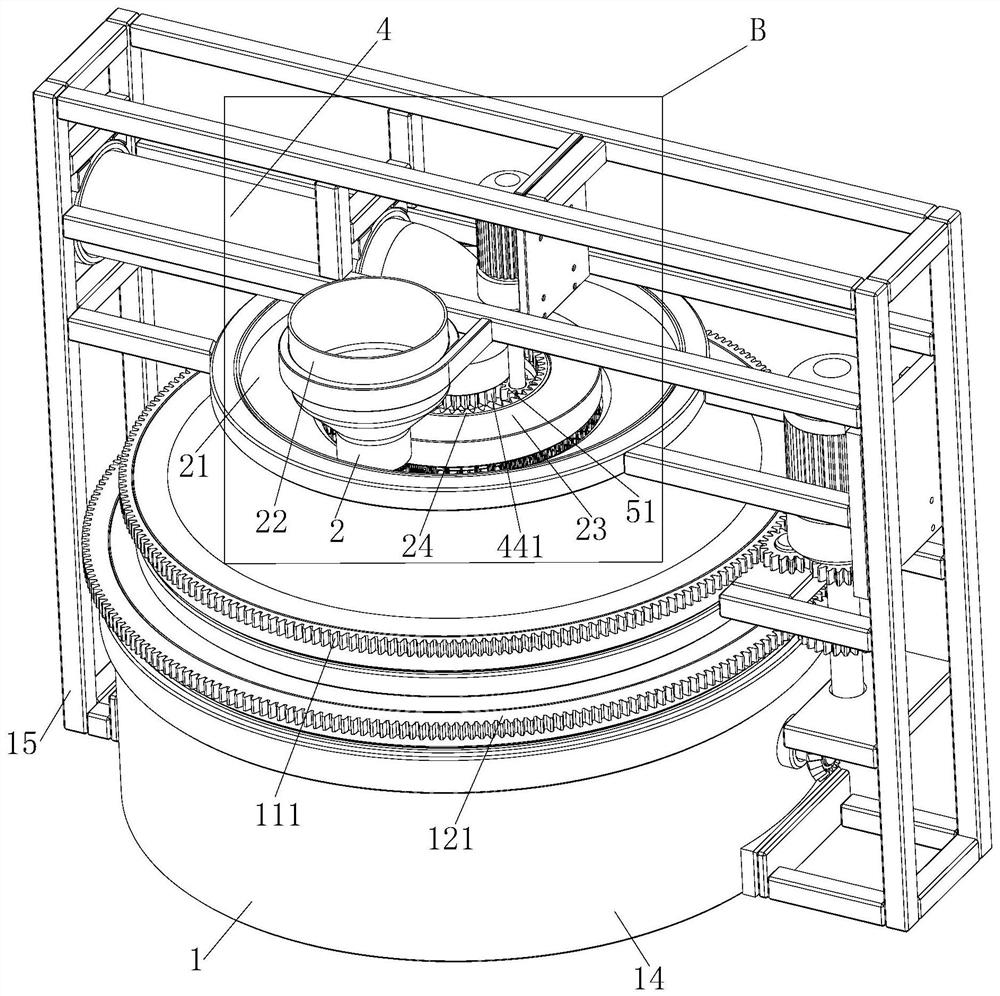

Double-millstone type circulating grinding machine for new material production

InactiveCN112934329AImprove qualityIncrease the speed differenceGrain treatmentsGear wheelElectric machinery

The invention belongs to the technical field of new materials, and particularly relates to a double-millstone type circulating grinding machine for new material production. The double-millstone type circulating grinding machine comprises a grinding component, a feeding component, a conveying component and a separating component. A first motor drives a first gear and a third gear to rotate, a first gear ring and a second gear ring are driven to rotate in the opposite directions, an upper millstone and a lower millstone are driven to rotate in the opposite directions, and then raw materials are ground. The conveying component conveys the ground powder into the separating component, conveys qualified powder out of a grinding machine, and conveys unqualified powder into the grinding component to be ground again. The upper millstone and the lower millstone rotate in the opposite directions to increase the speed difference between the upper surface and the lower surface of the materials, so that the raw materials are fully ground, and the quality of new materials is improved. As the unqualified powder is conveyed into the grinding component to be ground again, the unqualified powder is prevented from being conveyed out of the grinding machine, therefore the qualified rate of the new materials is increased, and the quality of the new materials is further improved.

Owner:邢金丽

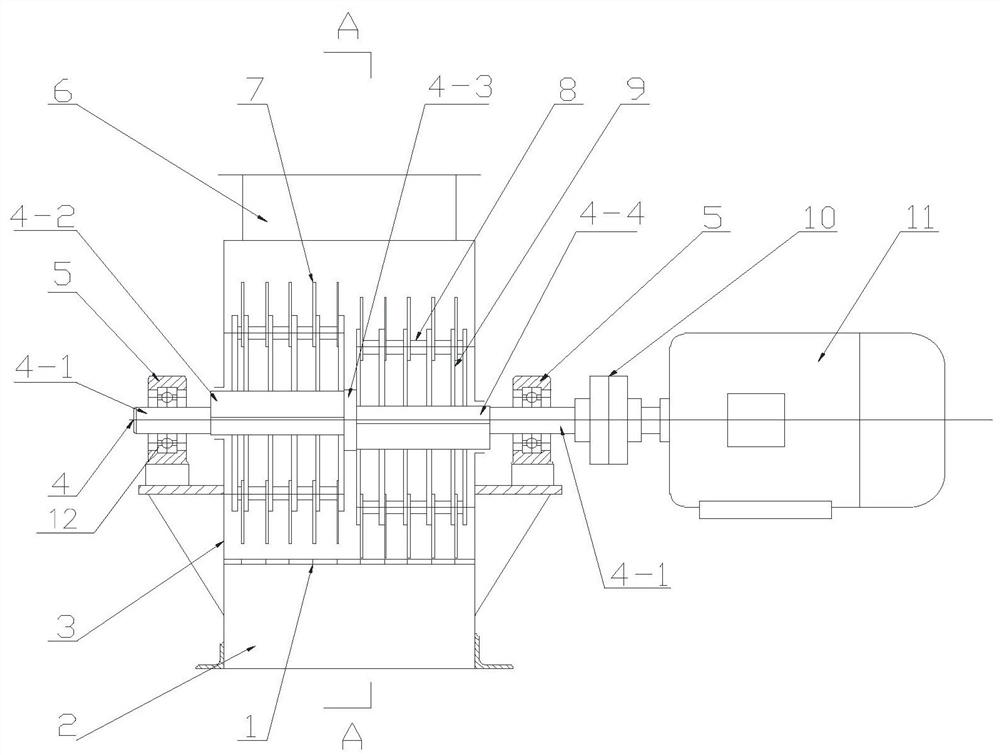

A symmetrical eccentric spindle assembly hammer mill

ActiveCN111774149BIncrease speed differenceIncrease the striking powerGrain treatmentsStructural engineeringMechanical engineering

Owner:LIYANG HONGYUE MASCH MFG CO LTD

A catalytic cracking feed atomizing nozzle

ActiveCN106010630BAtomized particle sizeFully contactedCatalytic crackingLiquid spraying apparatusPetroleum engineeringRaw material

The invention discloses a novel atomizing feed nozzle for catalytic cracking. The nozzle comprises a spray head, a venturi, an outer tube, an inner tube, a raw material oil inlet, a steam inlet and a steam hole plate. Steam atomizes raw material oil in a mixed atomization chamber for the first time, steam carrying raw material oil enters the venturi and passes through a contraction section, the circulation area is contracted, then steam carrying raw material oil passes through a throat section and is sprayed out of an expansion section, and therefore steam atomizes raw material oil for the second time; steam carrying out raw material oil enters a nozzle outlet of the spray head for atomization for the third time. The nozzle outlet of the spray head has multiple arrangement forms, a wide screen is formed when steam carrying raw material oil is sprayed out, sufficient contact and reaction of raw material oil and a catalyst are promoted, and meanwhile catalyst cracking is effectively lowered.

Owner:石宝珍 +1

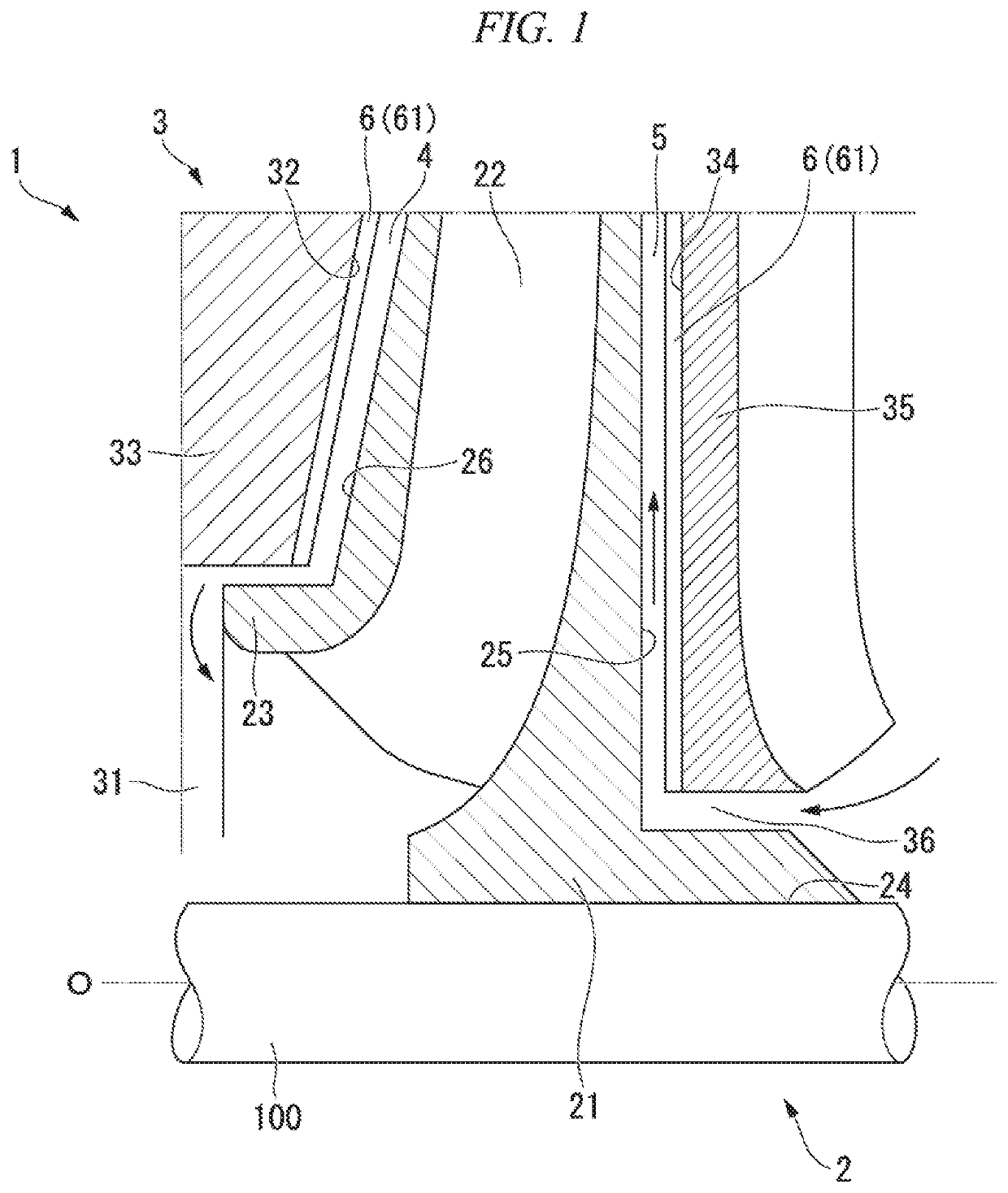

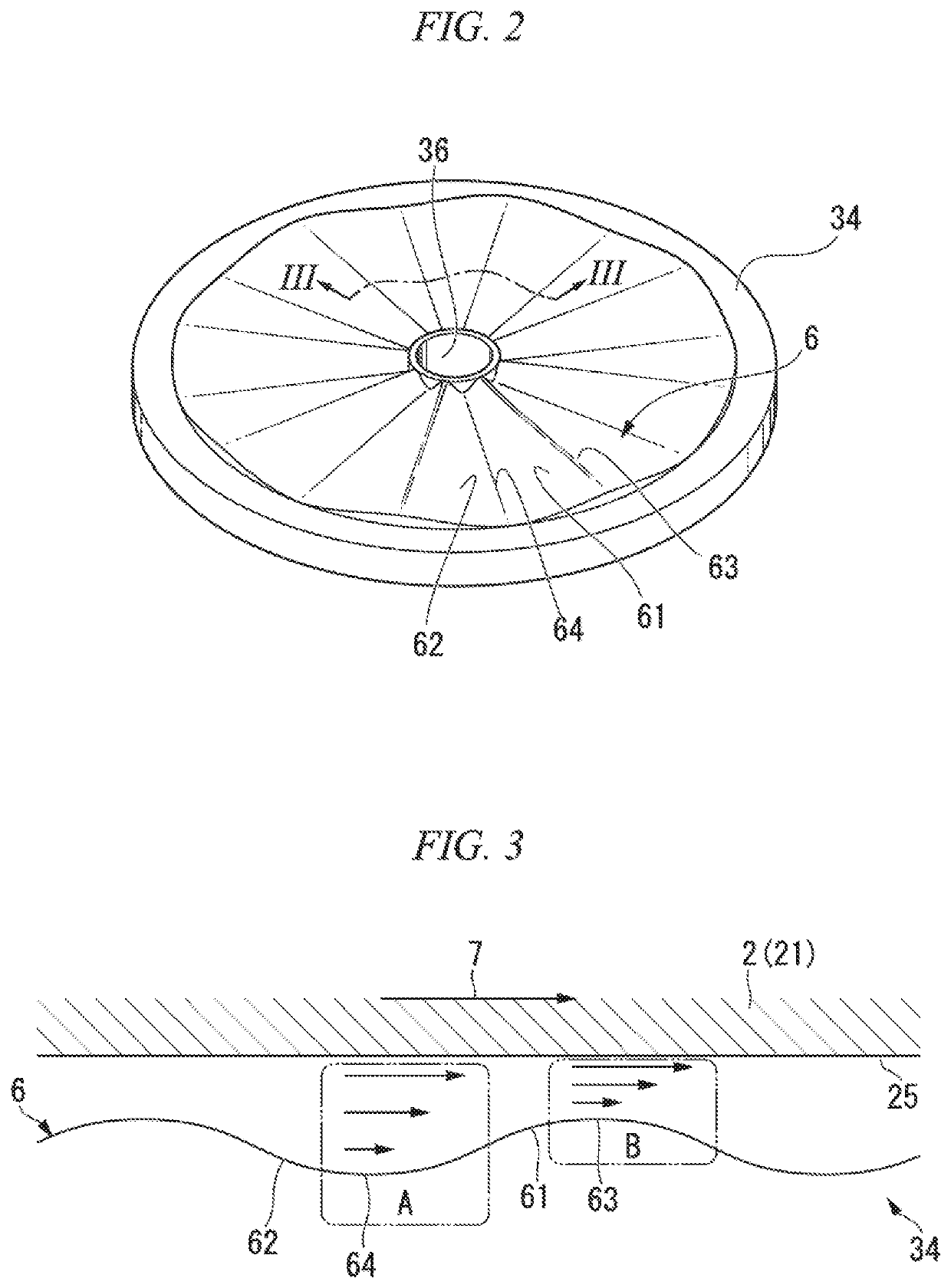

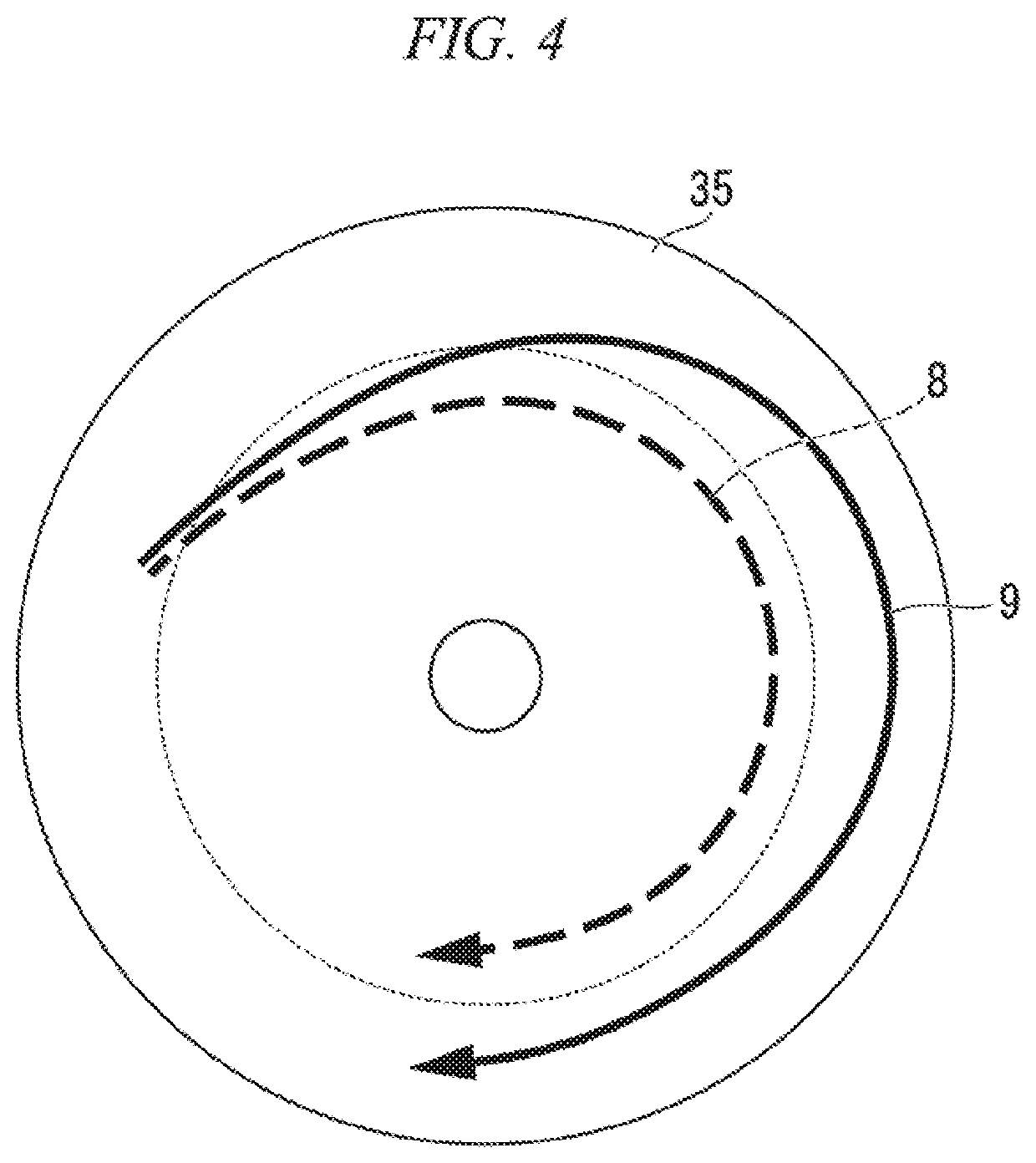

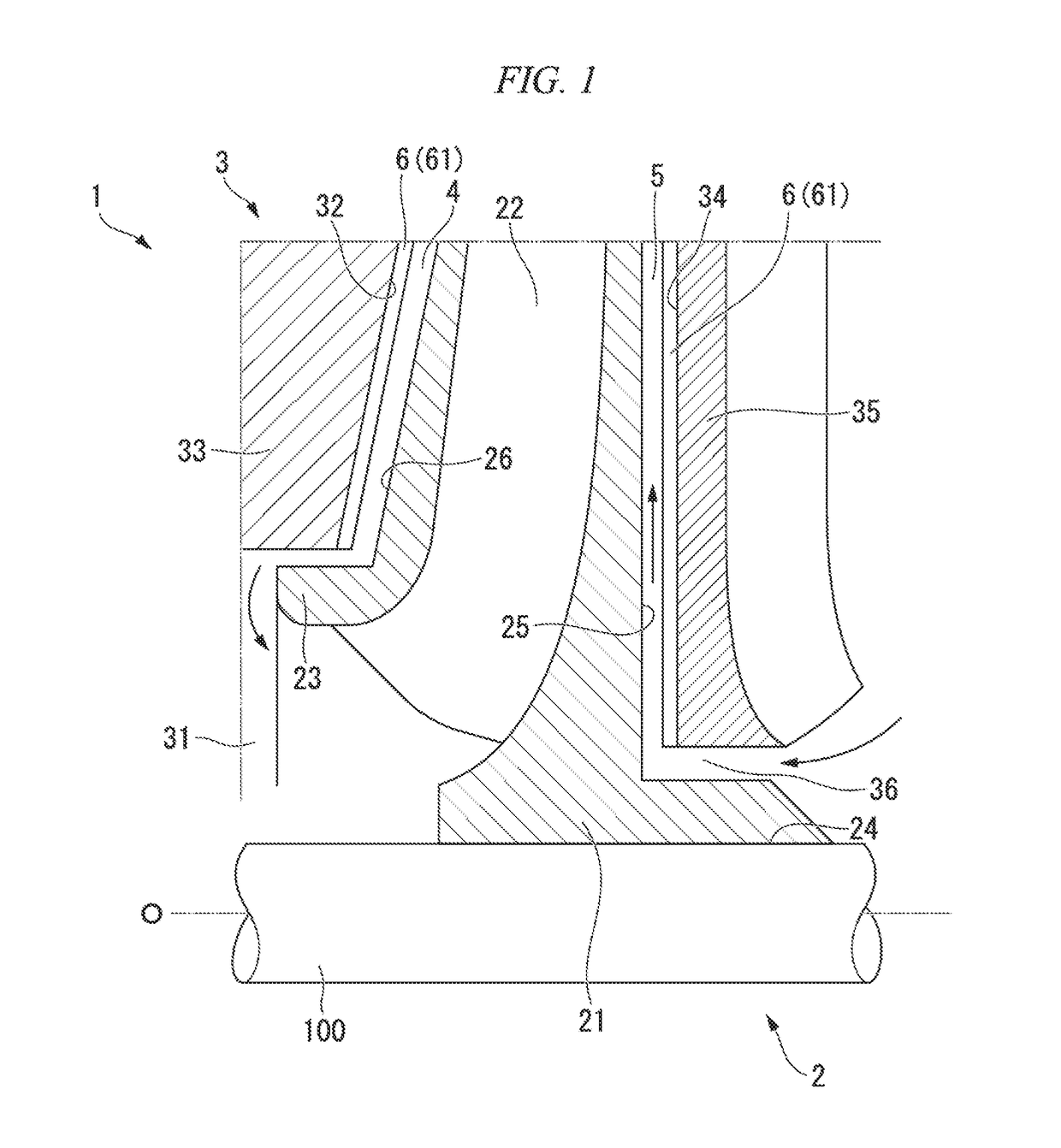

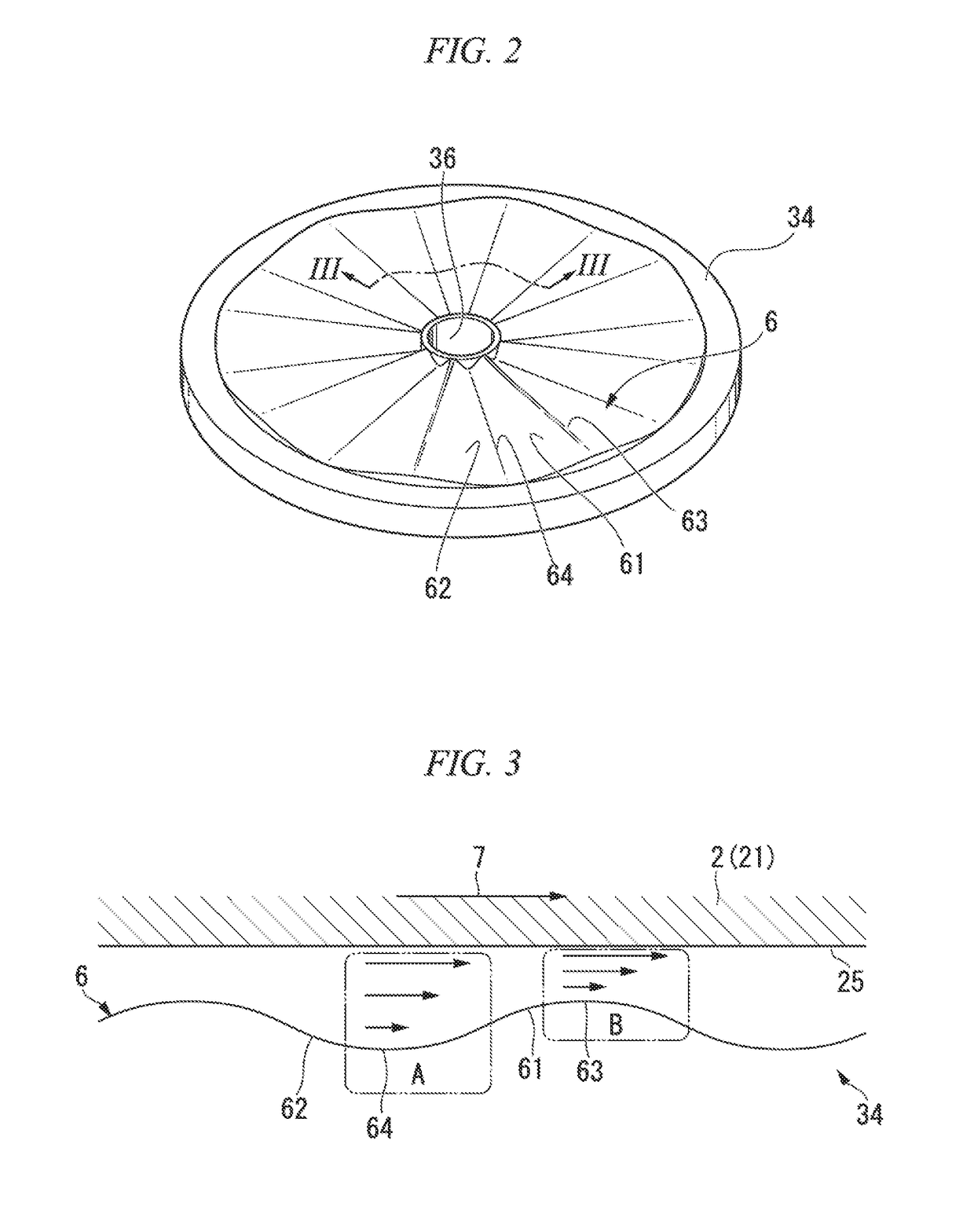

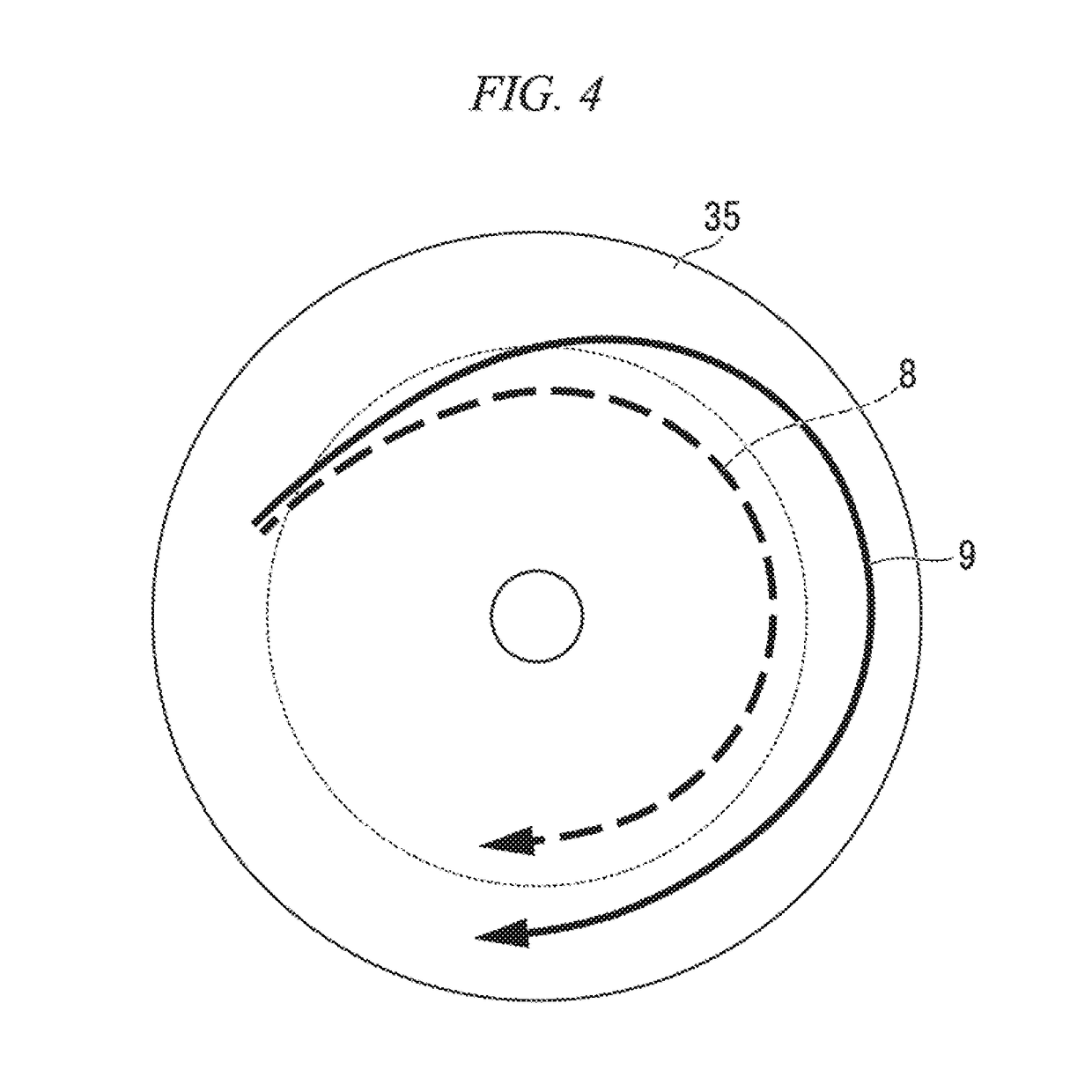

Centrifugal turbo machinery

ActiveUS10801520B2Reduce speed differenceIncrease speed differenceEngine manufacturePump componentsImpellerEngineering

A centrifuge turbo machinery includes an impeller which rotates about an axis to pressure-feed fluid flowing along the axis to an outer side in a radial direction, and a casing which accommodates the impeller and has a facing surface facing the impeller in an axial direction. A convex portion relatively close to the impeller and extending in the radial direction and a concave portion relatively spaced apart from the impeller and extending in the radial direction are alternately and continuously formed on the facing surface in a circumferential direction.

Owner:MITSUBISHI HEAVY IND LTD

A kind of lifting device and lifting method for storing cement

ActiveCN112919009BRealize lack of material alarmLarge turning angleConveyorsControl devices for conveyorsClassical mechanicsNatural state

The invention relates to a lifting device for storing cement and a lifting method, wherein a lifting device for storing cement comprises a box body provided with a feeding port and a discharging port, and a lifting chain rotatably arranged in the box body, and the lifting chain is installed on the lifting chain. There is a lifting hopper. The lifting hopper includes a bucket body and a fixed block fixed with the lifting chain. The fixed block is provided with a vertically extending chute, and a slider fixed to the bucket body is slid in the chute. The lower end of the slide is connected with the bottom plate of the chute through an impact spring, a limit plate above the slider is fixed on the fixed block, and the distance between the slider and the limit plate is less than the length of the impact spring in its natural state. In the present invention, an impact spring and a limit plate are arranged when passing through, and the bucket body is accelerated and blocked when the material is thrown, thereby increasing the speed difference between the bucket body and the cement, and improving the throwing effect; The lever principle realizes the alarm of material shortage in the box, which is convenient for the staff to understand the feeding situation into the box.

Owner:临沂中联水泥有限公司

Brake/drive force controlling apparatus for vehicle

ActiveUS9789875B2Increase in sizeIncrease speed differenceVehicle testingBrake system interactionsDrive wheelElectronic control system

A brake / drive force controlling apparatus for a vehicle includes an engine for applying drive forces to driving wheels of the vehicles, a control diff for distributing the drive forces to the left and right driving wheels independently, and an electronic control system brake device for applying brake forces to the left and right driving wheels independently. An ECU is configured so as to be able to control the engine, the control diff, and the electronic control system brake device according to an operating state of the vehicle. When the electronic control system brake device is operated, this ECU stops the operation of the control diff, thereby avoiding a sudden input of load on the drive force distribution mechanism, regardless of the running state of the vehicle. This makes the apparatus simpler and more lightweight.

Owner:TOYOTA JIDOSHA KK

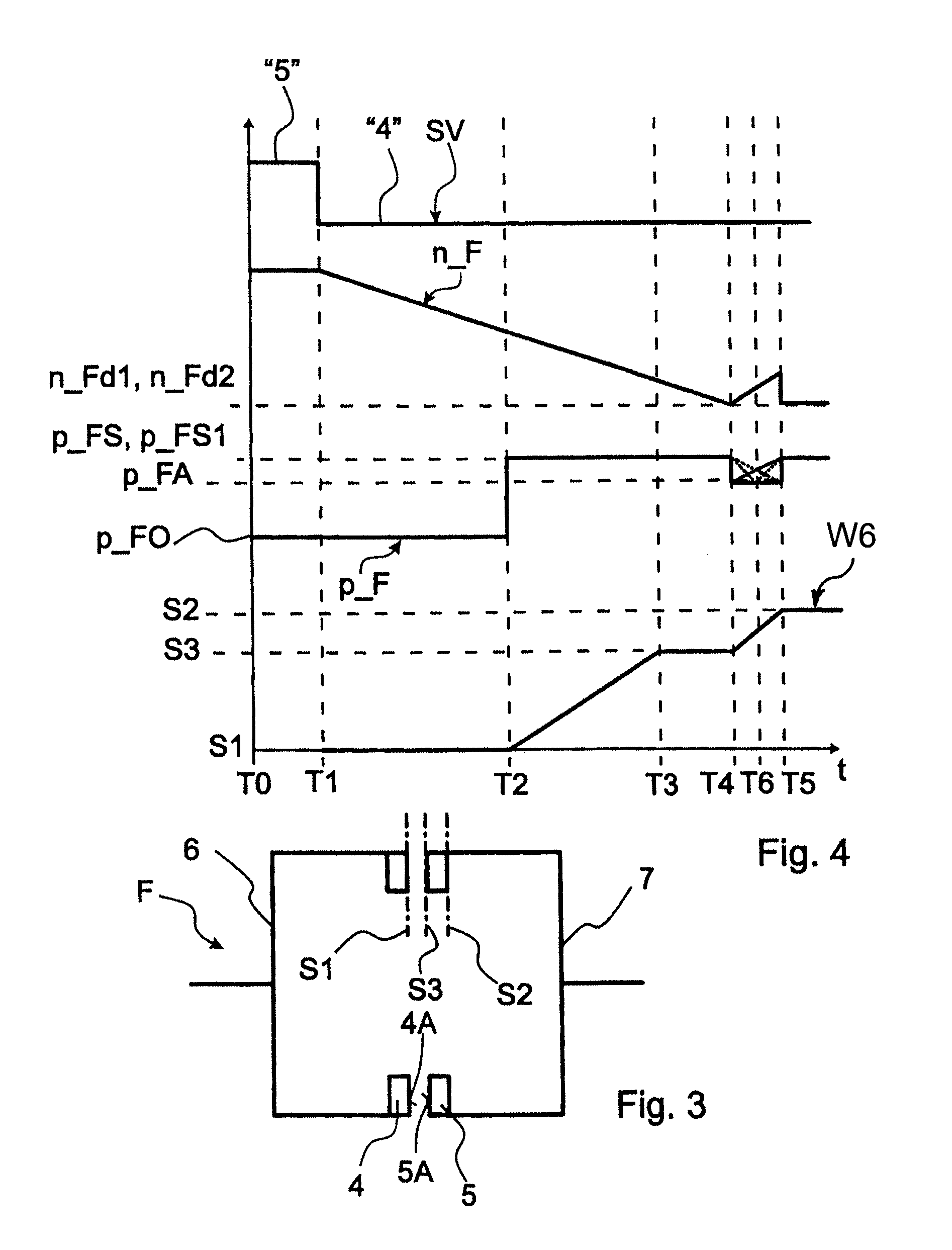

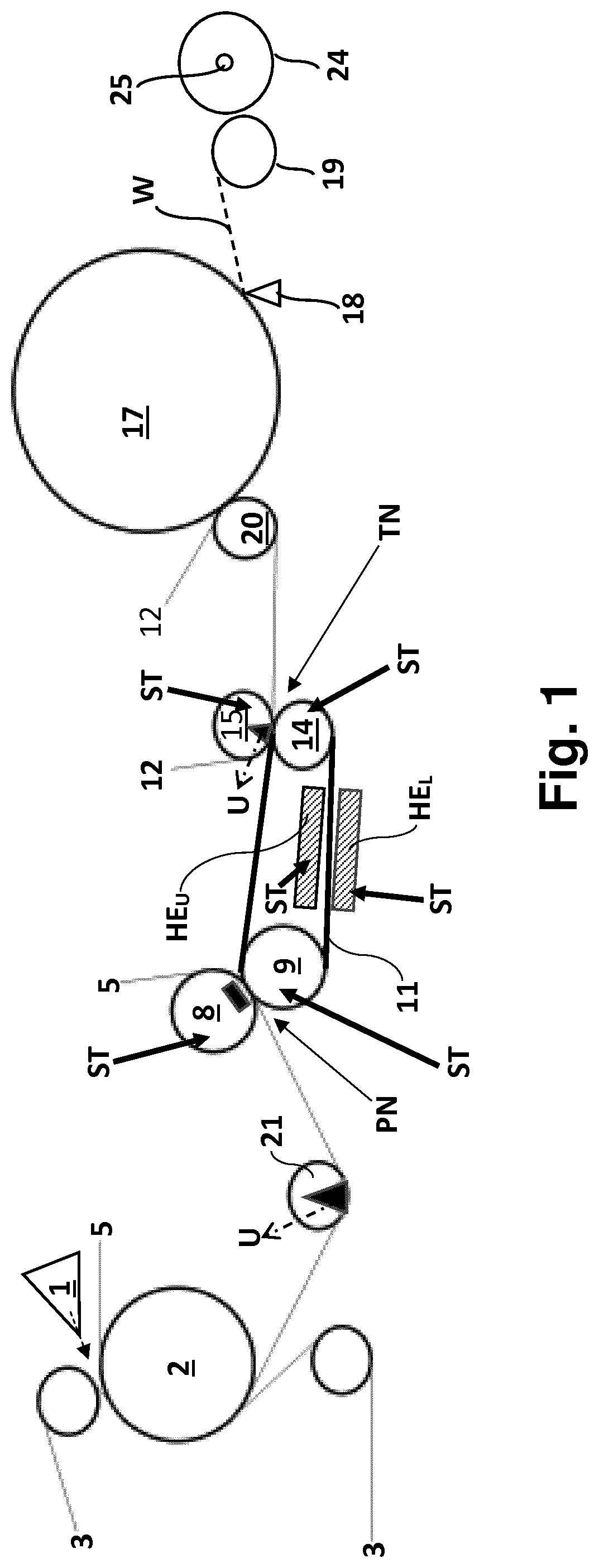

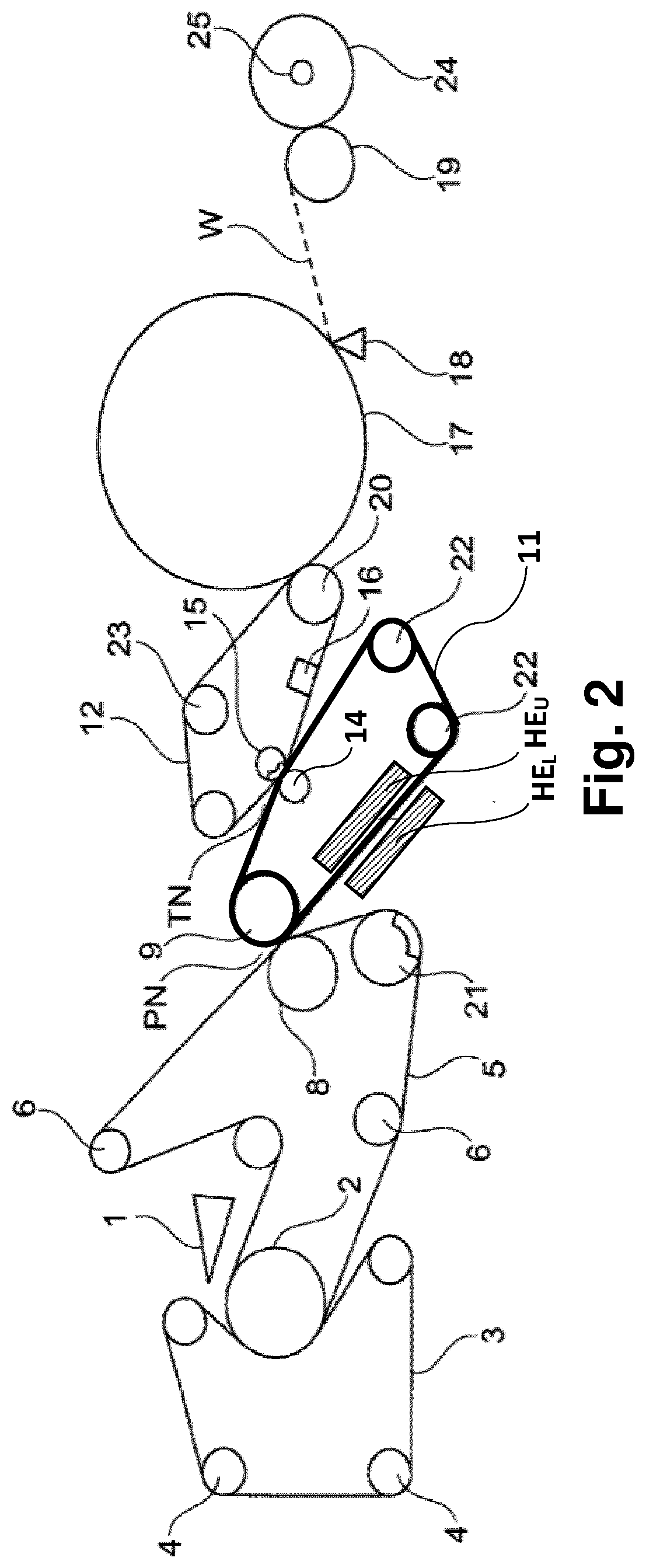

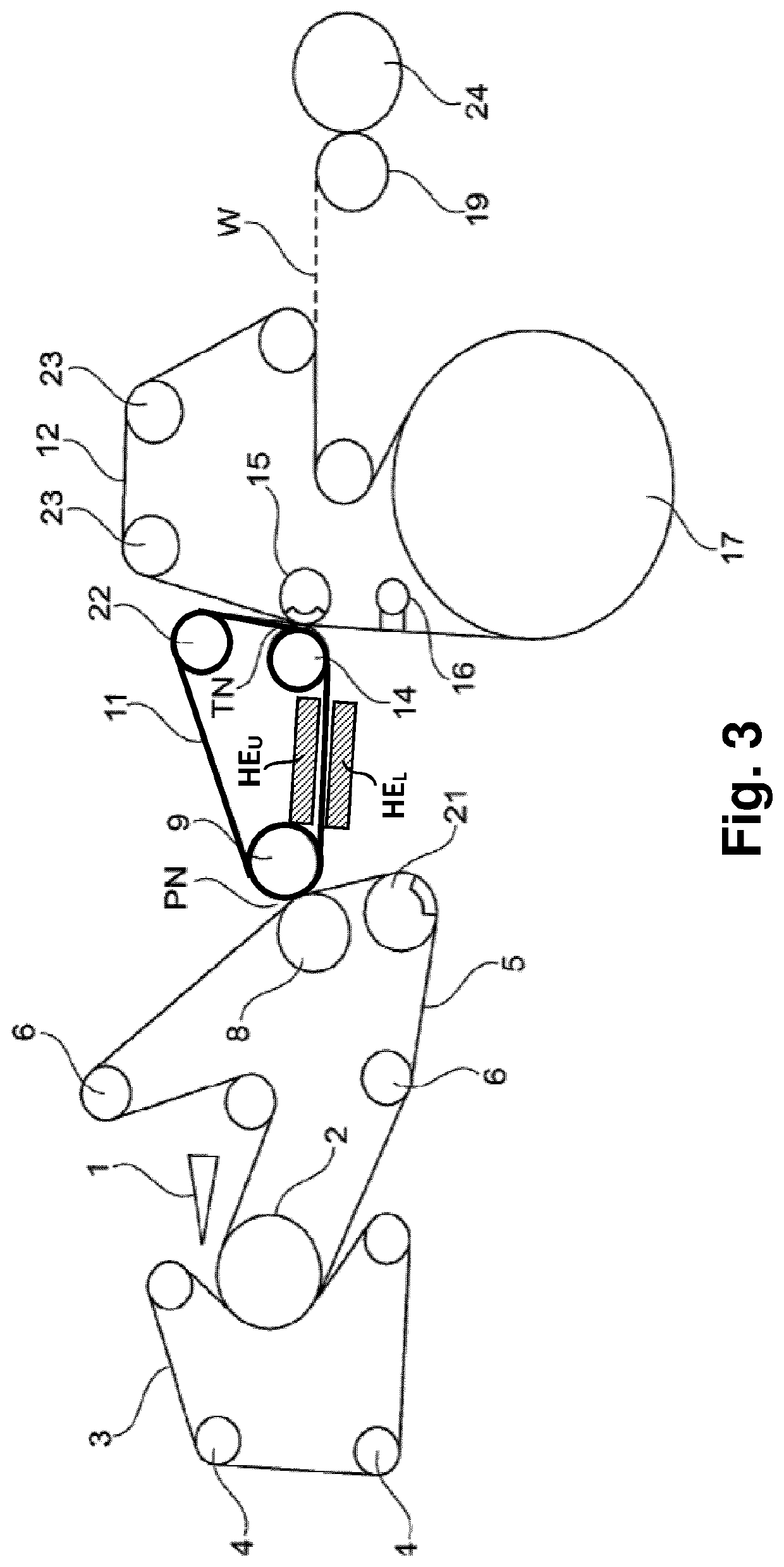

Method and a machine for producing a tissue web

ActiveUS20210010202A1Improve smoothnessGood optical performanceDryer sectionPaper/cardboardFiberSteel belt

The invention relates to a method of producing a structured fibrous web of paper suitable for tissue products. The method comprises forming a fibrous web and conveying the formed fibrous web on a water receiving felt (5) to a dewatering nip. An endless steel belt (11) with a smooth steel surface is passed through the nip together with the fibrous web and the water receiving felt (5) wherein the endless steel belt is heated by heaters (HEU, HEL). After the dewatering nip, the fibrous web is conveyed by the endless steel belt (11) to an endless textured fabric (12) which is permeable to air and to which the web is transferred from the endless steel belt (11) in a transfer nip. The textured fabric (12) runs at a lower speed than the endless belt (11). After the transfer to the textured fabric (12), the fibrous web is carried by the textured fabric (12) to a drying cylinder (17). The transfer nip is formed by two rolls of which one is a suction roll within the loop of the textured fabric. The transfer nip has a length which is 5 mm-40 mm. The endless steel belt (11) has a width that exceeds the width of the textured fabric (12). The invention also relates to a corresponding machine.

Owner:VALMET AB

Centrifugal turbo machinery

A centrifuge turbo machinery includes an impeller which rotates about an axis to pressure-feed fluid flowing along the axis to an outer side in a radial direction, and a casing which accommodates the impeller and has a facing surface facing the impeller in an axial direction. A convex portion relatively close to the impeller and extending in the radial direction and a concave portion relatively spaced apart from the impeller and extending in the radial direction are alternately and continuously formed on the facing surface in a circumferential direction.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com