Feed atomizing nozzle for catalytic cracking

A feed nozzle, catalytic cracking technology, applied in the direction of catalytic cracking, cracking, injection device, etc., can solve the problems of poor reaction effect, broken catalyst, limited contact surface between raw oil and catalyst, etc., to eliminate large-diameter droplets , the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Feed rate of raw oil to one nozzle is 25t / h, feed temperature is 250°C, feed pressure is 0.7MPa(G), pressure inside the reactor is 0.2MPa(G); atomizing steam is 1.0t / h, steam temperature is 250°C, steam Pressure 0.8MPa (G).

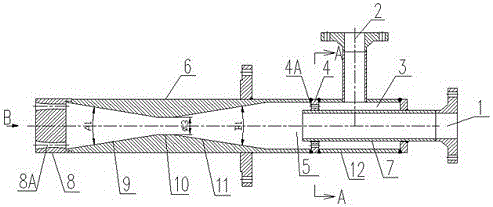

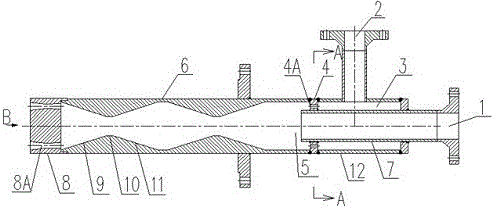

[0043] according to figure 1 Shown structure of the present invention, nozzle design example is as follows:

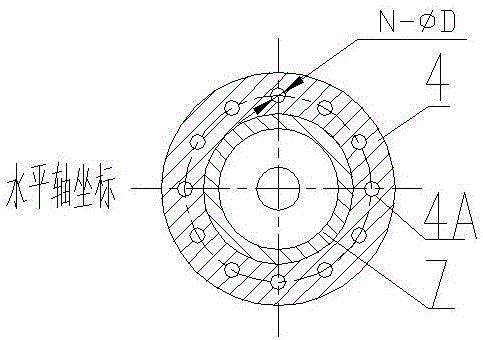

[0044] The specification of oil inlet 1 is DN80, the specification of steam port 2 is DN50, the outer diameter of throat pipe 6 is 132mm, the outer diameter of inner pipe 7 is 89mm. 4A number N=10, φD=8mm, 8A quantity=12, φ1=8mm, B2=15°, A2=6°α=β=15°, C1=C2=5°, L=400mm, steam port 2 Steam capacity 900kg / h, 12 8A buttons Figure 6 Arrangement shown where a=65, b=110.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com