A multi-stage atomizing feed nozzle

A technology of feed nozzle and atomization chamber, which is applied in cracking, injection device, catalytic cracking, etc., can solve the problems of broken catalyst, high injection speed of raw material oil, poor reaction effect, etc., and achieve the goal of increasing yield and fully contacting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Feed rate of raw oil to one nozzle is 25t / h, feed temperature is 250°C, feed pressure is 0.7MPa(G), pressure inside the reactor is 0.2MPa(G); atomizing steam is 1.0t / h, steam temperature is 250°C, steam Pressure 0.8MPa (G).

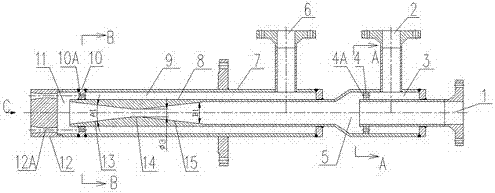

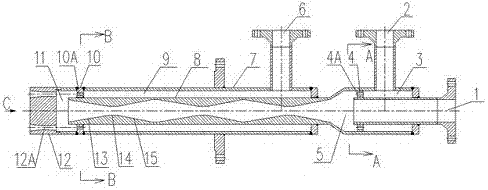

[0043] according to figure 1 Shown structure of the present invention, nozzle design example is as follows:

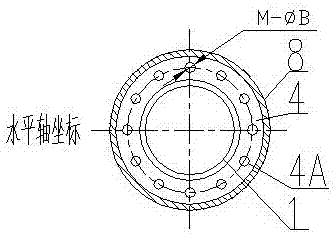

[0044] Oil inlet 1 specification DN80, steam port 2 specification DN50, steam port 6 specification DN40, outer pipe 7 inner diameter 132mm, inner pipe 8 outer diameter 89mm, φ3=35mm, B1=20°, A1=12°, 4A number M =10, φB=8mm, 10A number N=12, φD=5mm, 12A number=12, φ1=8mm, B2=15°, A2=8°α=β=15°, C1=C2=5°, L=400mm, the steam output of steam outlet 2 is 700kg / h, the steam output of steam outlet 6 is 300kg / h, 12 12A presses Figure 6 The circular arrangement shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com