Heavy oil catalytic cracking feeding atomizing nozzle

A heavy oil catalytic and atomizing nozzle technology, which is applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of high feed oil injection speed, mutual influence of inlet area, and wear of steam injection holes, so as to suppress ejection backflow and eliminate Large-diameter droplets and anti-coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in conjunction with accompanying drawing and specific embodiment;

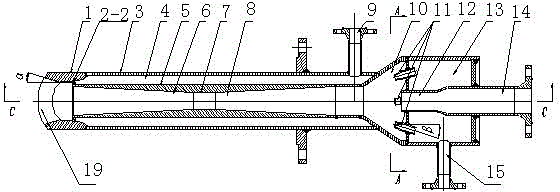

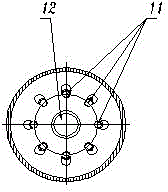

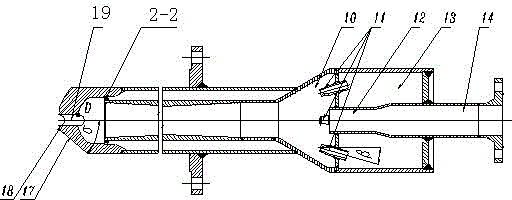

[0037] Such as figure 1 shown, and refer to figure 2 , image 3 , Figure 4 , a feed atomizing nozzle for catalytic cracking of heavy oil, the nozzle includes an inner pipe 5, an outer pipe 3, a nozzle 1, a raw oil inlet 14 and a primary steam inlet 15; the ring between the inner pipe 5 and the outer pipe 3 The cavity forms an annular secondary steam chamber 4 and is provided with a secondary steam inlet 9; the inner pipe 5 has a constriction section 6, a throat section 7 and a diffusion section 8, and the front end of the nozzle 1 has a nozzle outlet 19; the raw material The oil inlet 14 communicates with the manifold chamber 13, and communicates with the frustum-shaped mixing chamber 10 through the raw oil nozzle 12; the primary steam nozzle 11 communicates with the primary steam inlet 15, and the primary steam nozzle 11 is a ring A plurality of surrounding stoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com