Fluid dynamic machine with turning wheel transmission piston speed-changing mechanism

A technology of speed change mechanism and transmission piston, applied in rotary piston machinery, rotary or oscillating piston engine, rotary piston engine, etc., can solve the problem of poor stability, affecting the structural performance of piston compressor and piston engine, complex structure, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

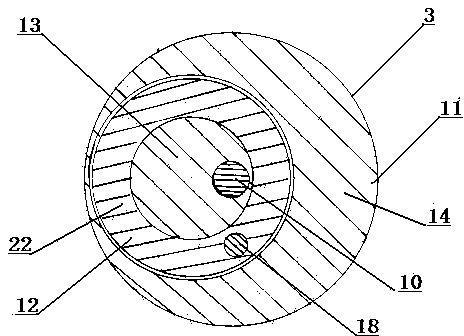

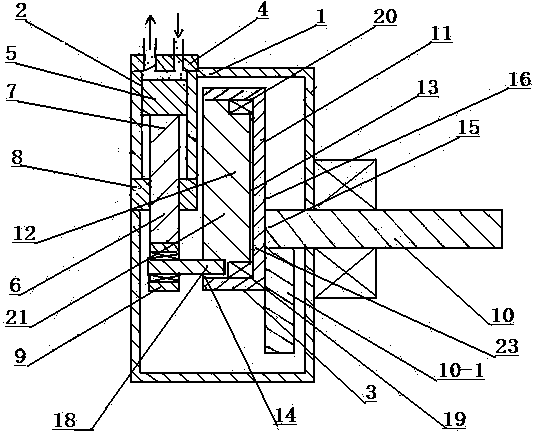

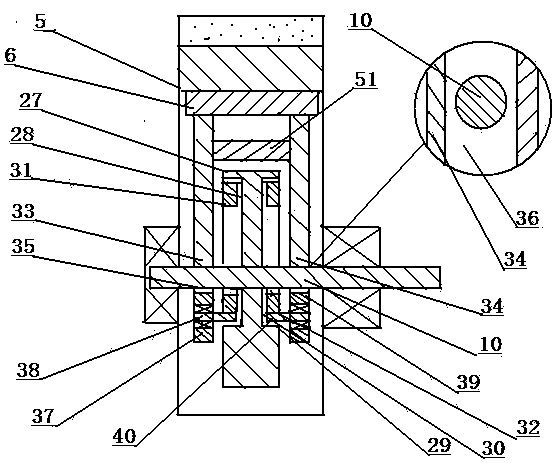

[0029] Such as figure 1 , figure 2 , image 3 As shown, the rotary transmission piston speed change mechanism is made up of body 1, cylinder-piston linkage 2 and rotary transmission mechanism 3. Such as figure 2As shown, the cylinder-piston linkage mechanism 2 is composed of a cylinder 4, a piston 5 and a connecting rod 6, the cylinder 4 is fixed on the body 1, the bottom of the piston 5 and the rod body 7 of the connecting rod 6 are fixed to each other, and the rod body 7 of the connecting rod 6 is outside Covered with a sliding sleeve 8, the sliding sleeve 8 is fixed on the inner wall of the body 1 or fixed on the bottom of the cylinder 4, the rod body 7 linearly slides in the sliding sleeve 8, and the tail of the connecting rod 6 is fixed with a connecting rod sleeve 9. The runner transmission mechanism 3 is made up of transmission shaft 10 , runner disc 11 and runner body 12 . Such as figure 2 As shown, the bearing support at one end of the transmission shaft 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com