Catalytic cracking lifting pipe material feeding mixing section structure for promoting efficient mixing of raw oil and catalyst

A catalytic cracking and riser technology, which is applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of increased oil, repeated contact with agents, more severe catalyst back-mixing, and catalyst back-mixing, so as to promote efficient mixing, The effect of shortened time and reduced space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

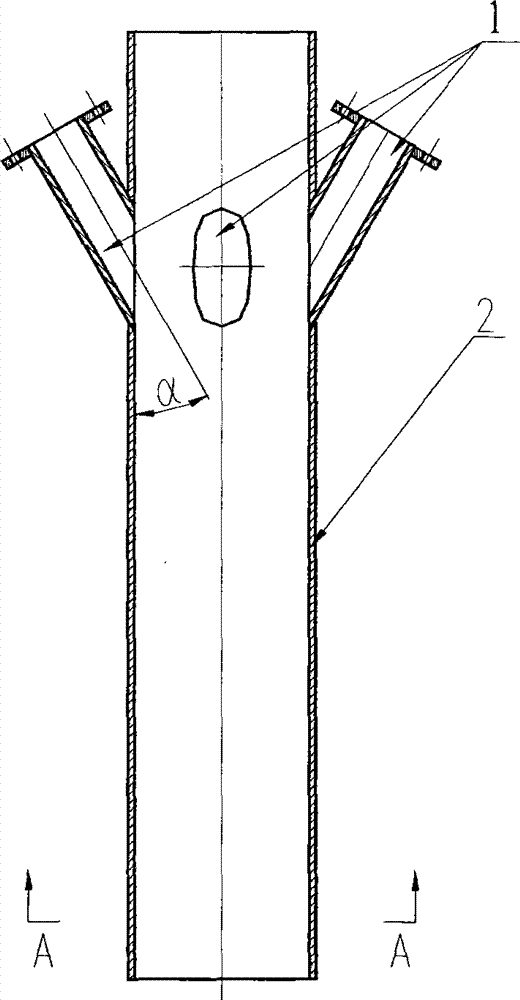

[0032] Such as figure 1 , figure 2 As shown, a catalytic cracking riser feed mixing section structure that promotes the mixing of raw oil and catalyst. In the feed mixing section of the riser, the catalyst flows from the bottom to the top, and the raw oil is sprayed obliquely downward into the feed mixing section of the riser through the nozzle installed in the installation sleeve 1 of the feed oil atomization nozzle. The countercurrent contact of oil and agent forms a "cross-countercurrent" mixed flow, which can strengthen the mixing effect.

[0033] On the pipe wall 2 of the feed mixing section of the riser, the installation sleeve 1 of the raw material oil atomization nozzle is arranged, and the raw material oil atomization nozzle is arranged in the nozzle installation sleeve 1, and the installation sleeve 1 is connected with the riser. The included angle α between the axis of the installation sleeve 1 and the pipe wall 2 of the riser below is 10°-70° obliquely downward,...

Embodiment 2

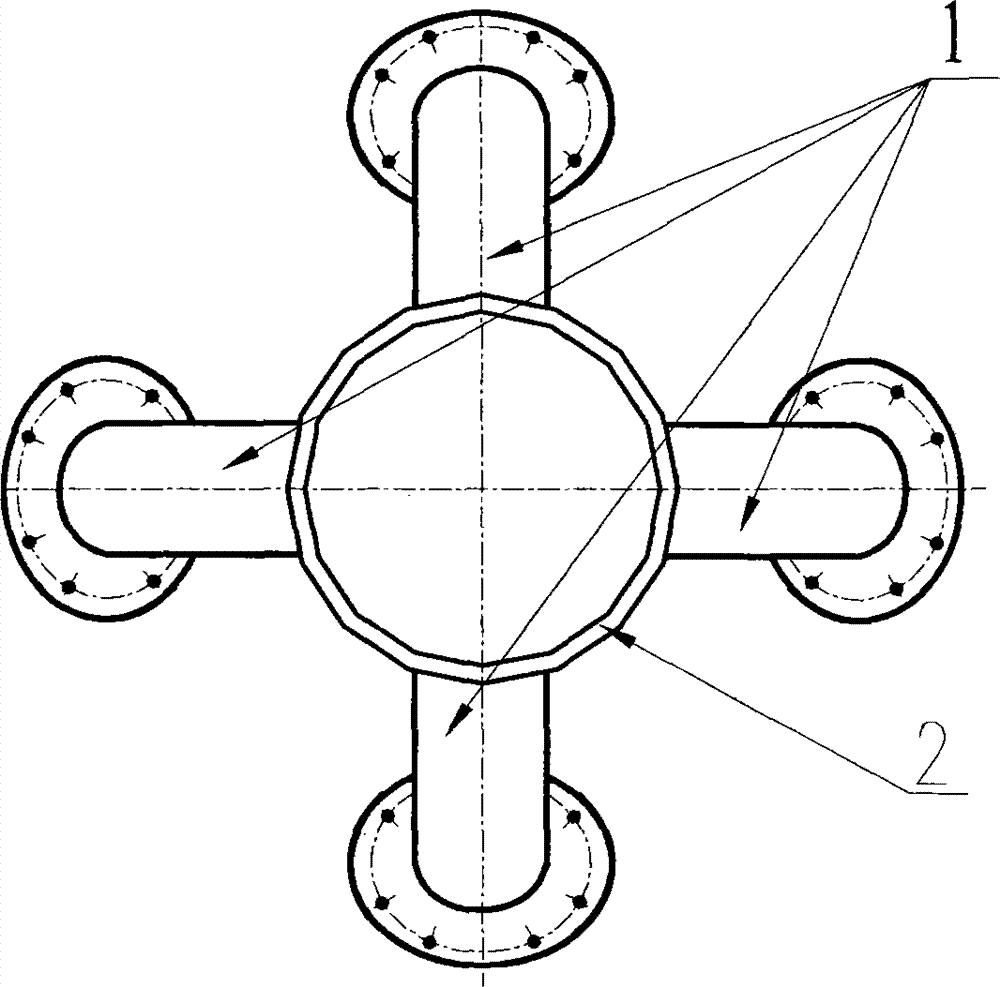

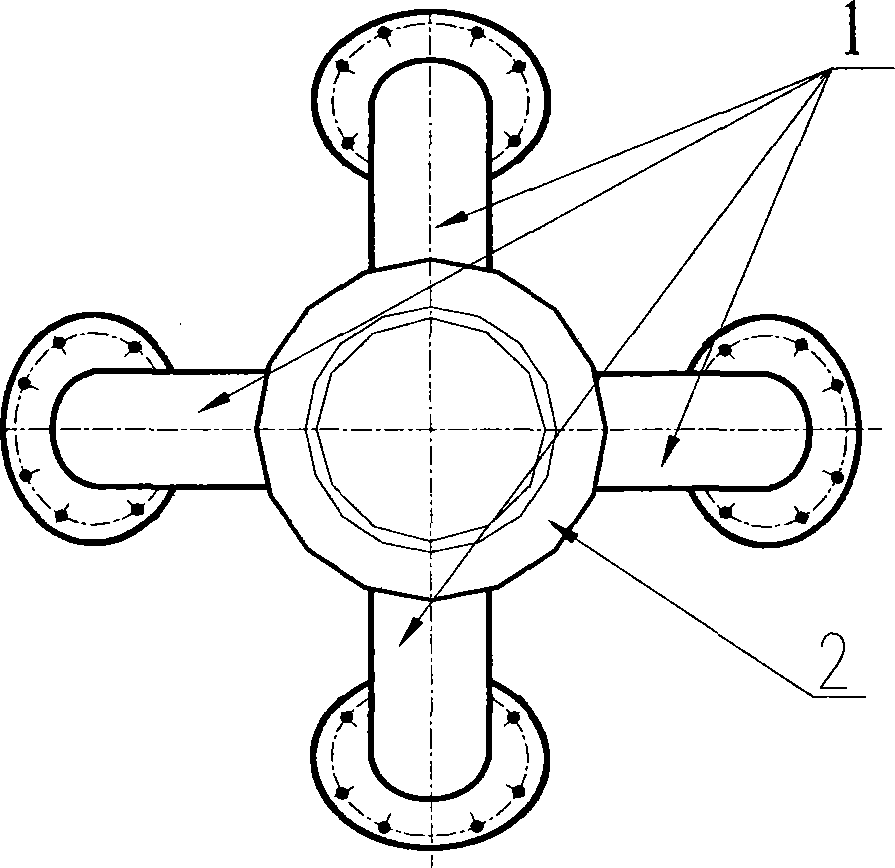

[0036] Such as image 3 , Figure 4 As shown, a catalytic cracking riser feed mixing section structure that promotes the mixing of raw oil and catalyst. In the feed mixing section of the riser, the catalyst flows from the bottom to the top. The raw oil is sprayed obliquely downward into the feed mixing section of the riser through the nozzle installed on the installation sleeve 1 of the raw oil atomization nozzle. The lower riser of the nozzle installation sleeve 1 has a variable diameter, and the cross section of the riser increases from bottom to top, and the expansion angle γ is 2° to 30°, which is 10° in this embodiment. In the feed section of the riser, the oil and the agent are in countercurrent contact, thereby forming a "cross-countercurrent" mixed flow, which can enhance the mixing effect.

[0037] On the pipe wall 2 of the feed mixing section of the riser, an installation sleeve 1 of a raw material oil atomization nozzle is arranged, and a raw material oil atomiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com