Method for dynamically determining a clutch rest point

A static point and dynamic technology, applied to clutches, mechanical equipment, etc., can solve problems such as increased wear, temperature rise, and torque increase, and achieve the effect of improving reality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following exemplary embodiment is based on the fact that the motor vehicle has an internal combustion engine, the output shaft of which is connected in a rotationally fixed manner to the transmission side of the multi-disk clutch. Single-plate or double-plate clutches of a corresponding operating principle can likewise be used. The output side of the multi-plate clutch is non-rotatably connected to the input shaft of the automatic transmission. The type of operation of the multi-plate clutch is determined by the setting position of the clutch actuator, which is controlled by the electronic control unit.

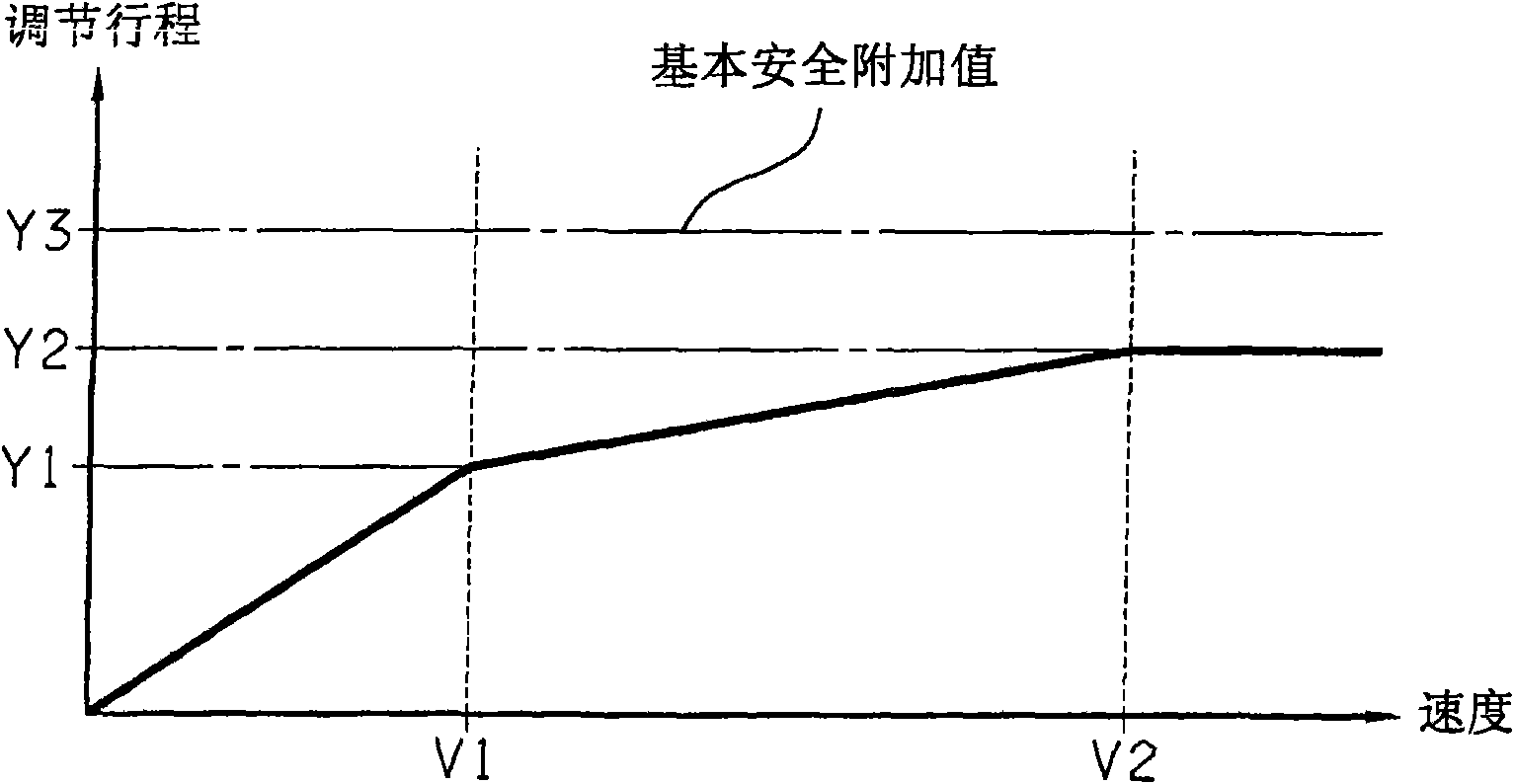

[0057] The basic resting point of the clutch is determined for the first time at the end of the vehicle production line and subsequently repeated for the clutch, for example at a workshop inspection, at an actuator adjustment value of 27 mm, for example. The control value can be determined, for example, by slowly closing the clutch when the engine output shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com