Bidirectional processing cutter set and wall breaking device

A two-way processing and knife set technology, which is applied in the field of food processing, can solve the problems that affect the comfort experience of consumers and the motor load is not constant, and achieve the effects of suppressing the generation of fixed vortex, uniform heat exchange, and high pulp yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

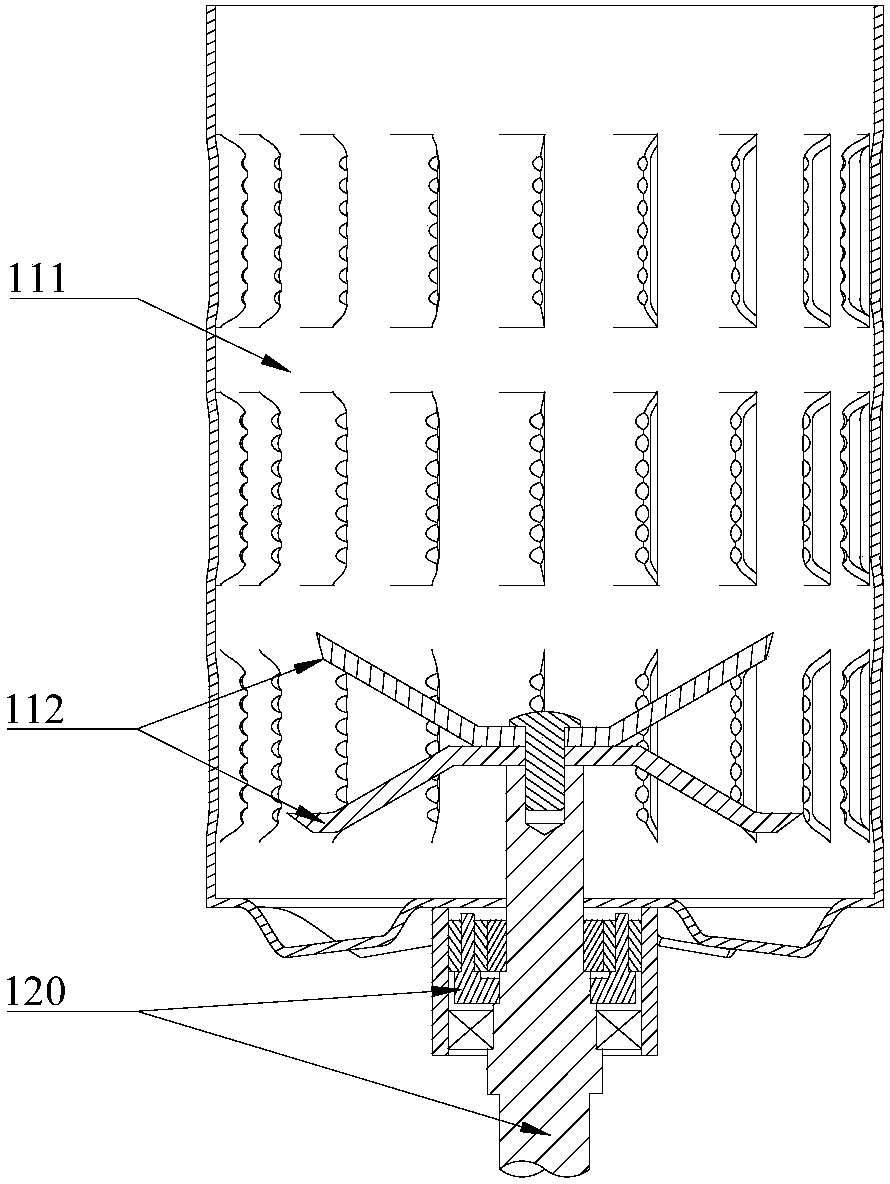

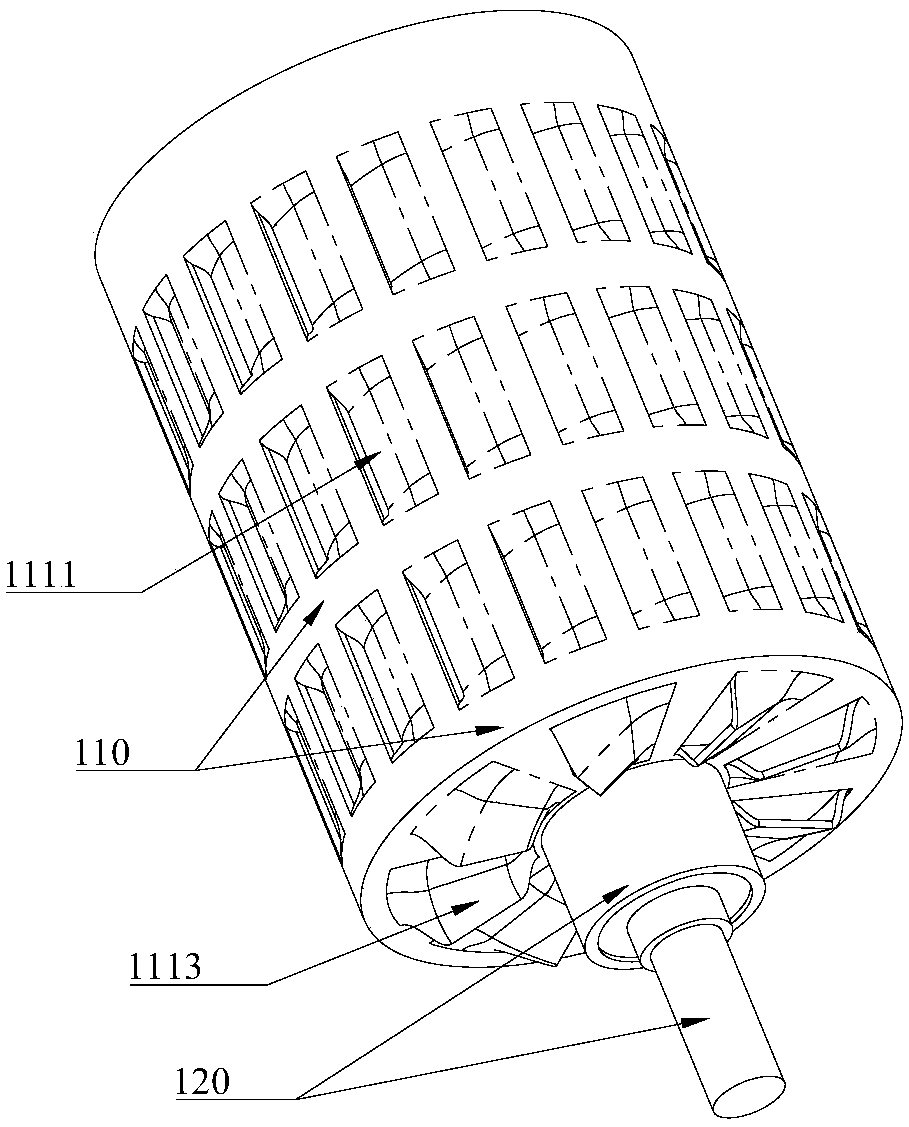

[0052] refer to figure 1 and figure 2 , the present embodiment provides a two-way processing cutter set, including a cutter head 112, a cutter cylinder 111, a transmission device 120 and a driving device, the output end of the driving device is connected to the input end of the transmission device 120, and the transmission device 120 includes a first output end and the second output end, the relative position of the first output end and the second output end is set coaxially, the rotation direction of the first output end is opposite to the rotation direction of the second output end, the cutter head 112 is installed on the first output end, and the knife barrel 111 is installed on the second output end, and the cutter head 112 is arranged in the cutter barrel 111 .

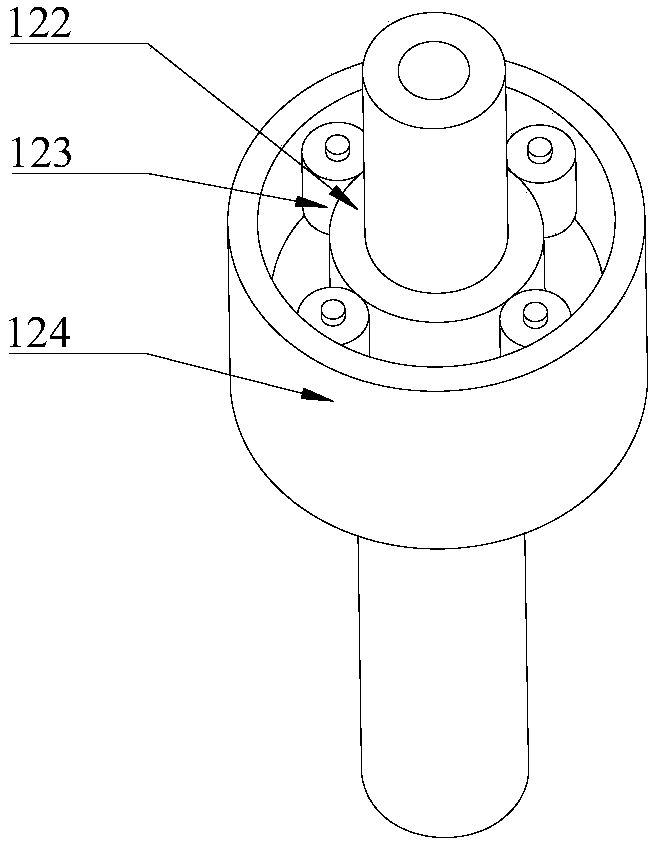

[0053] refer to image 3 and Figure 4 , the transmission device 120 includes a transmission shaft 121, a first gear 122, a second gear 123 and an internal gear 124, the transmission shaft 121 is fixedly conn...

Embodiment 2

[0072] refer to Figure 13 , the present embodiment provides a wall breaking device, including the above bidirectional processing knife set.

[0073] The wall-breaking device also includes a host, a cup body 100 and a knife seat 130, the cup body 100 is arranged on the host machine, the cup body 100 includes a housing chamber 1114, the knife cylinder 111 is located in the housing chamber 1114, and the knife seat 130 is installed on the cup body 100 At the bottom, the second gear 123 is fixedly connected to the tool seat 130 through the tool seat mating surface 101 , and the transmission shaft 121 is connected to the tool seat 130 through the second bearing 126 .

[0074] Several protruding shafts can be set on the tool holder 130, and these protruding shafts are arranged at intervals around the circumference of the transmission shaft 121, and the spacing between these protruding shafts is the same as the spacing between the plurality of second gears 123, and the plurality of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com