Lifting device for storing cement and lifting method

A cement and box technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as incomplete throwing of materials, impact of bucket body holding capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

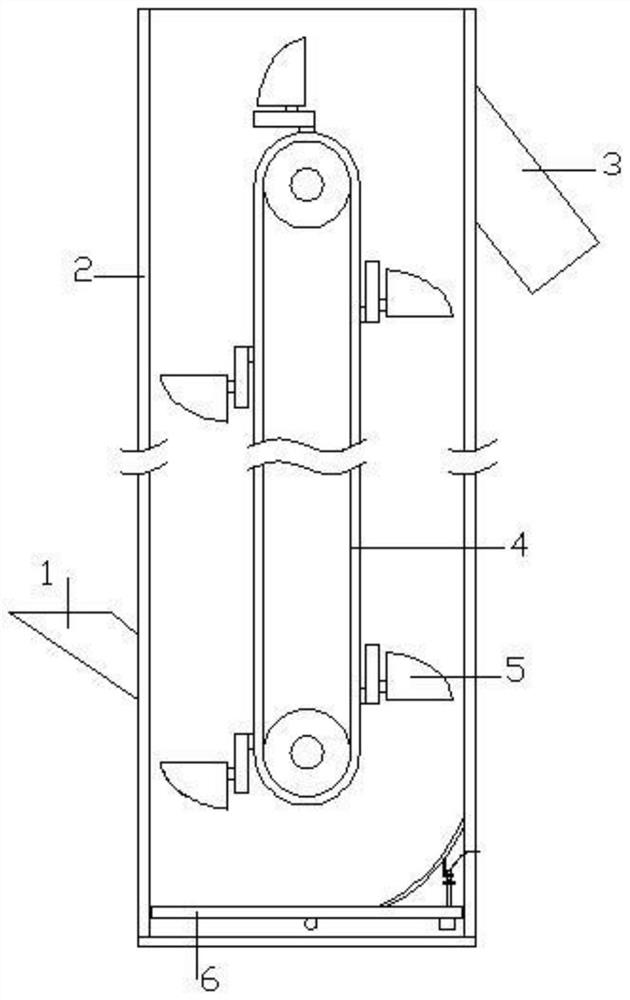

[0026] like figure 1 The shown lifting device for storing cement includes a box body 2 provided with a feeding port 1 and a discharging port 3, and a lifting chain 4 that is rotatably arranged in the box body, and a number of lifting hoppers 5 are installed on the lifting chain 4. An upper sprocket and a lower sprocket which are adapted to the lifting chain are installed on the body, and the axle of the upper sprocket is connected to the drive motor.

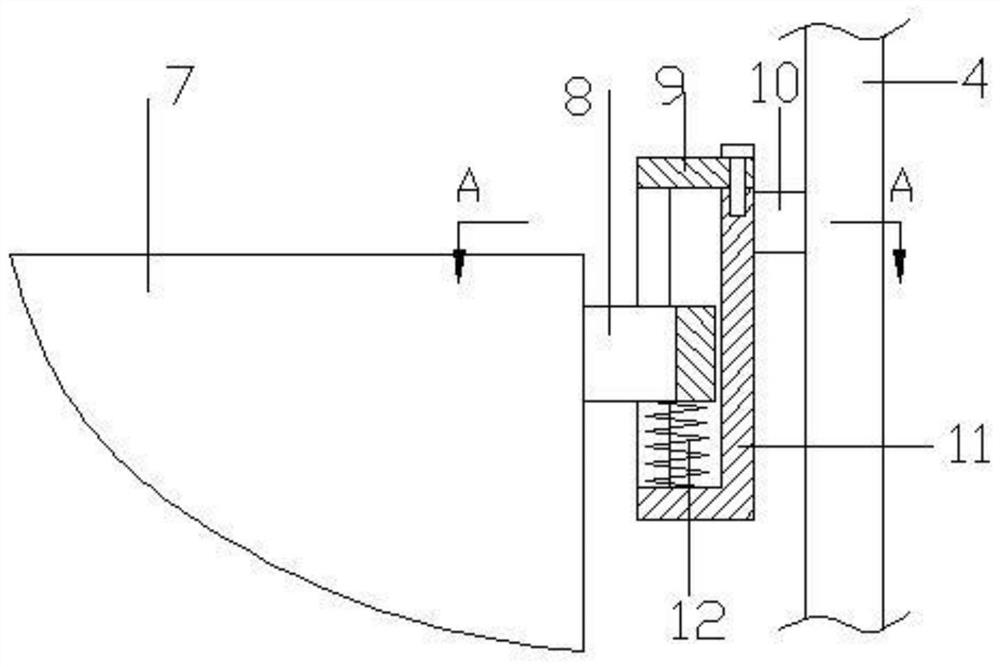

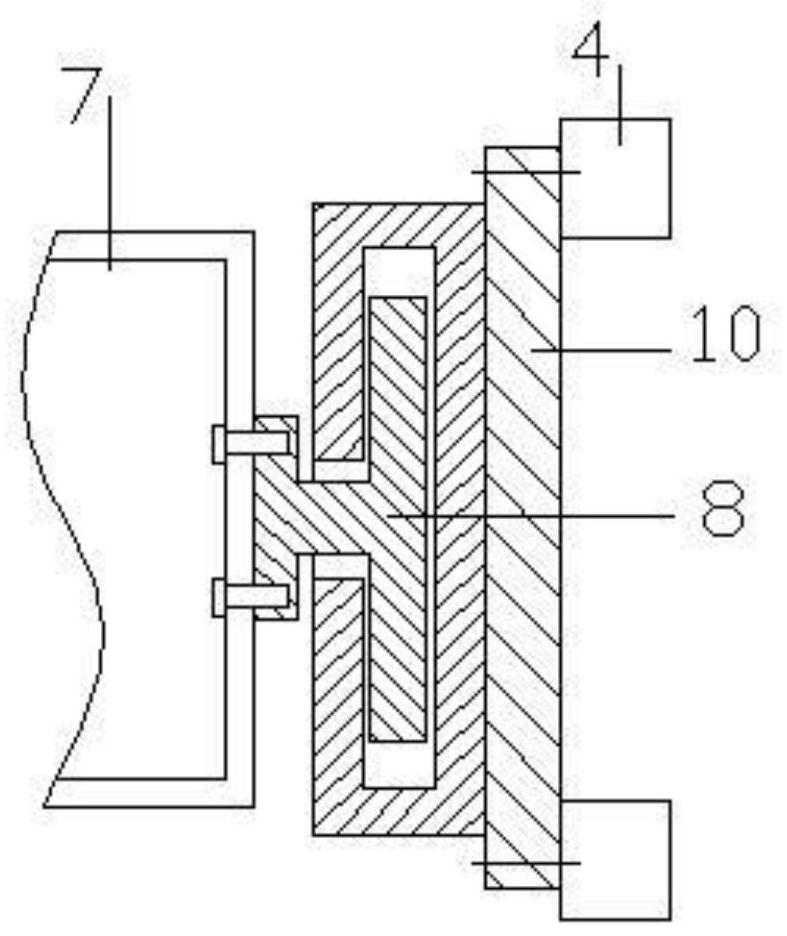

[0027] The lifting hopper 5 includes a bucket body 7 and a fixed block 11 fixed to the lifting chain. The fixed block is provided with a vertically extending chute, and a slider 8 fixed to the bucket body is slidably arranged in the chute. The lower end of 8 is connected with the bottom plate of the chute through the impact spring 12, a limit plate 9 located above the slider is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com