A magnetic levitation switch

A turnout and maglev technology, applied in roads, tracks, buildings, etc., can solve the problems of difficult manufacturing of turnout beams, large side bends, length increase of turnouts and turnout beams, etc., to ensure stability and safety, and large switch angles , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

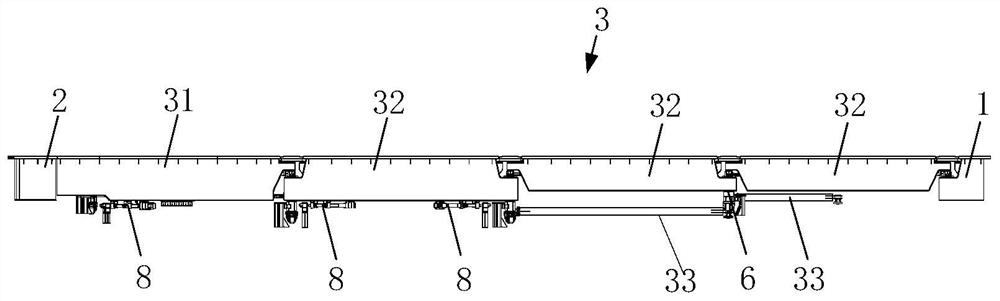

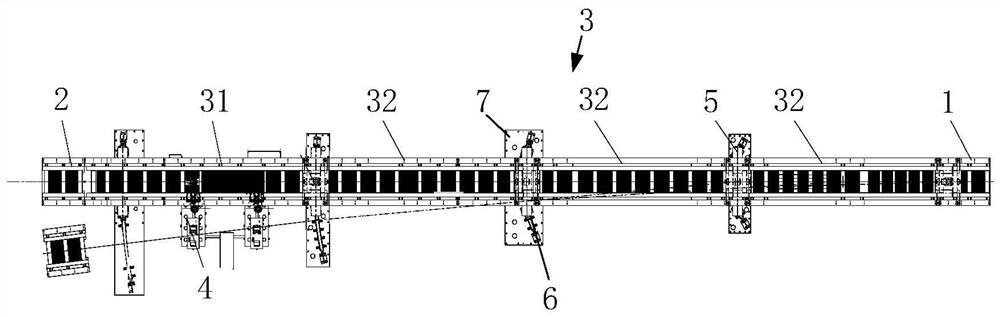

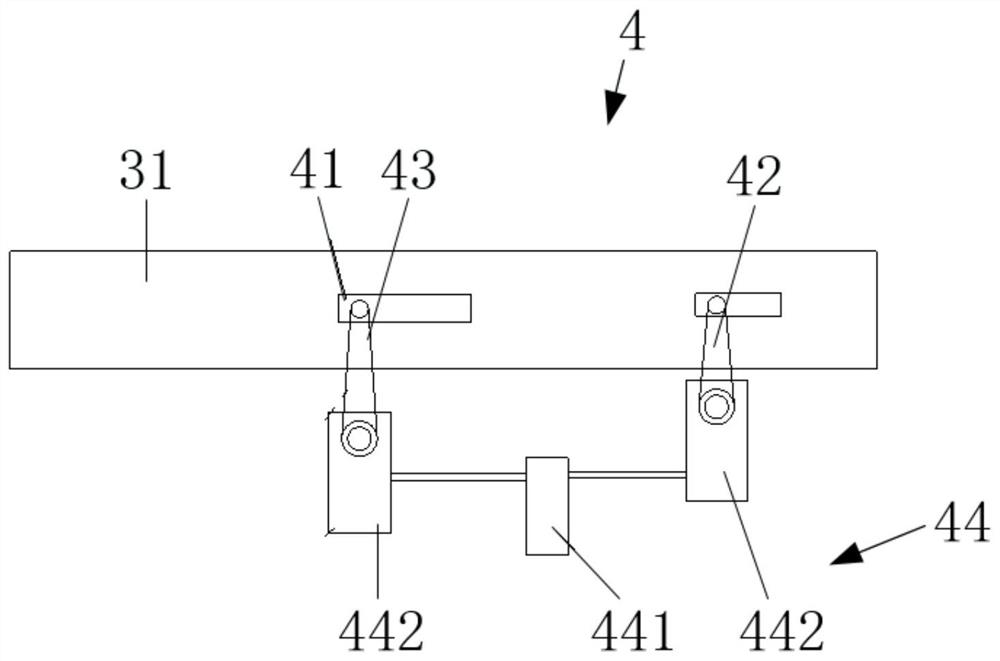

[0027] Such as figure 1 and figure 2 As shown, the maglev turnout of this embodiment includes a fixed end stack beam 1 , a movable end stack beam 2 and a movable turnout beam 3 . Among them, the movable turnout beam 3 is arranged between the fixed end stacking beam 1 and the movable end stacking beam 2, one end of the movable turnout beam 3 is hinged with the fixed end stacking beam 1, and the other end of the movable turnout beam 3 is switched on the movable turnout beam 3 It is docked with one of the movable end stack beams 2 . In this embodiment, the movable turnout beam 3 includes an active beam 31 and at least two groups of driven beams 32, and adjacent beam bodies are hinged to each other. Wherein, the active beam 31 is arranged near the stacking beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com