A control device and control method for the knitting process of a double-needle bed warp knitting machine

A double-needle-bed warp knitting machine and control device technology, applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of slow machine running speed, complex form and structure, cumbersome and other problems, and achieve convenient pattern replacement and operation. The effect of stable and reliable, simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

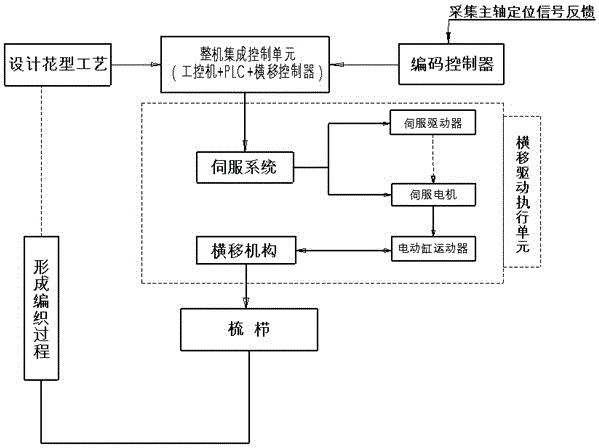

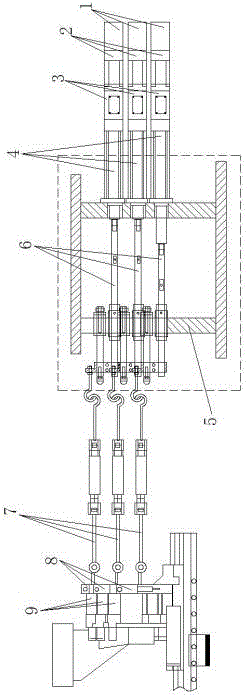

[0025] Embodiment 1: see attached figure 1 , attached figure 2 A control device for the knitting process of a double-needle bed warp knitting machine, comprising a whole machine integrated control unit, two encoding controllers, and a traverse drive execution unit.

[0026] Two encoding controllers are installed on the main shaft of the double-needle bed warp knitting machine. The integrated control unit of the whole machine includes industrial computer, PLC controller, intelligent traverse controller, the first communication output terminal of the industrial computer and the signal of the PLC controller. The collection port is electrically connected, and the second communication output end of the industrial computer is electrically connected with the signal input end of the intelligent traverse controller.

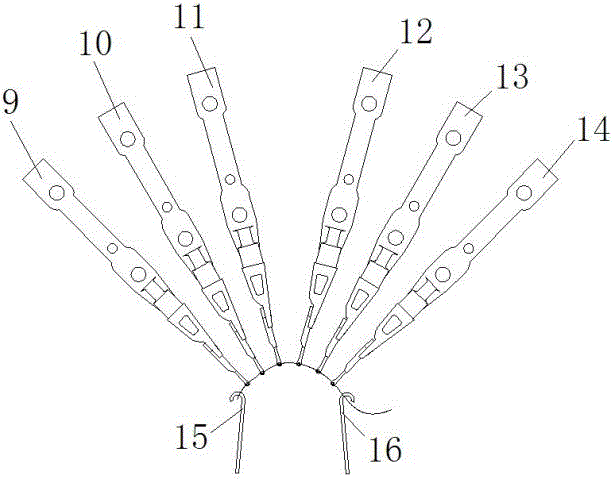

[0027] The traversing drive execution unit includes six servo systems, six reduction boxes 3, six electric cylinder movers 4, and a traversing mechanism. The servo syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com