Enrichment device for aerosol particles

An aerosol particle enrichment technology, which is applied to the improvement of process efficiency, preparation of test samples, printing, etc., can solve the problems of high-precision enrichment of aerosol particles, weak lateral force, etc., and achieve high precision The effect of enriching and increasing the stress time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

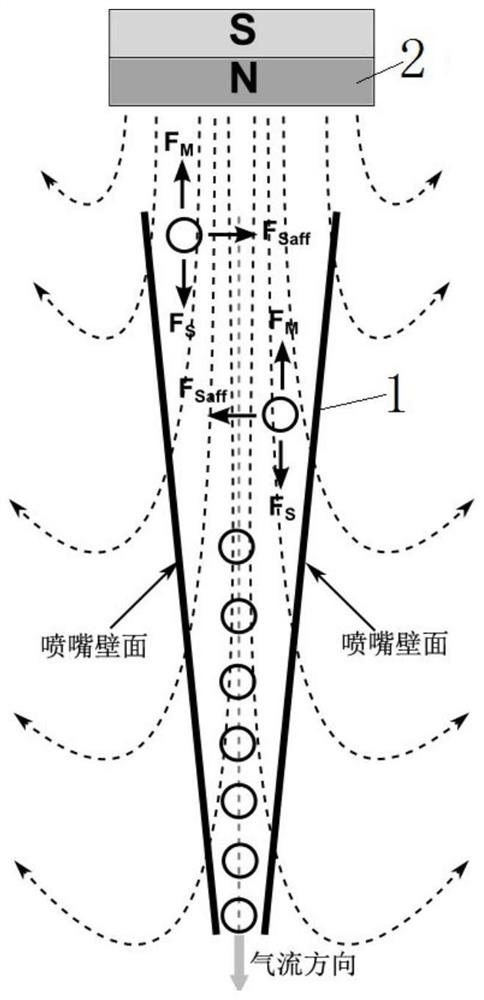

[0043] as attached figure 1 As shown, this embodiment provides an aerosol particle enrichment device for enriching magnetic aerosol particles, including an enrichment nozzle 1 and a magnetic field generator; the magnetic field generator is arranged outside the enrichment nozzle 1 , used to form a magnetic field distribution in the enrichment nozzle 1, and the direction of the magnetic field distribution is parallel to the axis direction of the enrichment nozzle 1; the magnetic aerosol particles are subjected to the magnetic field force from the outlet end of the enrichment nozzle 1 to the direction of the enrichment nozzle 1 entry port.

[0044] The enrichment nozzle 1 adopts a linear tapering nozzle, and the cross-sectional area of the linear tapering nozzle gradually decreases from the inlet end to the outlet end; the magnetic field generator adopts a permanent magnet 2; the permanent magnet 2 is arranged at the inlet end of the enrichment nozzle 1 , and set in the center...

Embodiment 2

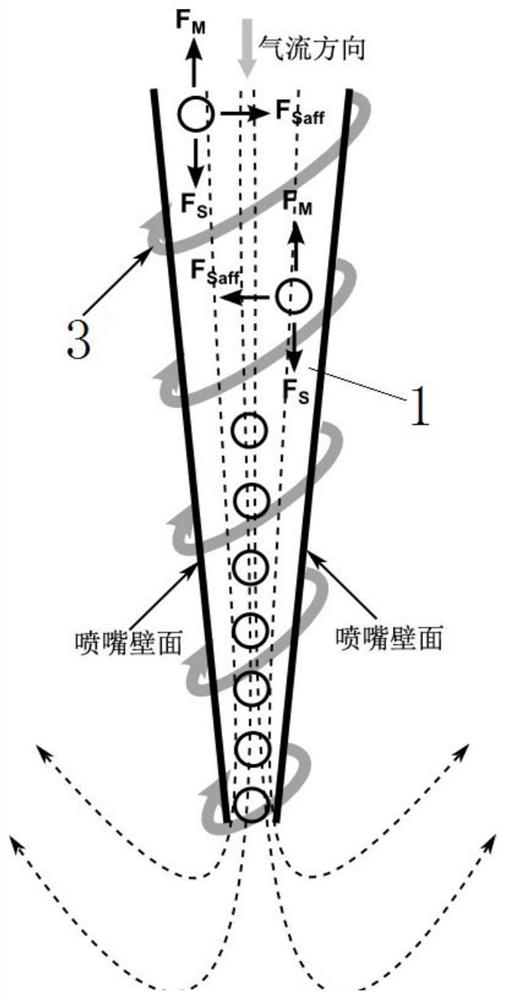

[0051] as attached figure 2 As shown, the structure principle of this embodiment 2 is basically the same as that of embodiment 1, the difference is that the permanent magnet 2 is replaced by the energized helical coil 3; wherein, the energized helical coil 3 is evenly wound on the outer wall surface of the enrichment nozzle 1 ; The energized helical coil 3 is used to form a magnetic field distribution around the enrichment nozzle 1 , and the direction of the magnetic field distribution is parallel to the axis direction of the enrichment nozzle 1 .

[0052] Another implementation is provided in Example 2, that is, the enrichment nozzle 1 is formed by direct winding with an energized helical coil.

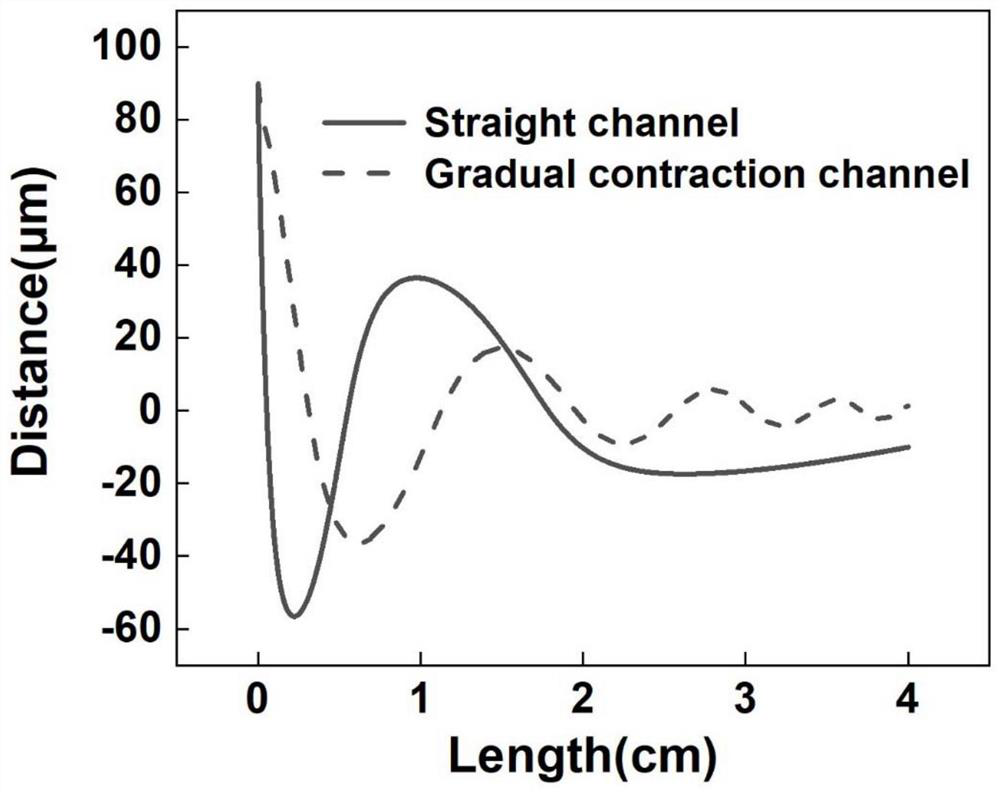

[0053] The enrichment device for aerosol particles described in Examples 1 and 2 of the present invention can significantly increase the stress time of magnetic aerosol particles in the enrichment nozzle, enhance the Safman lift effect on magnetic aerosol particles, and make the mag...

Embodiment 3

[0057] as attached Figure 5-8 As shown, an aerosol particle enrichment device is provided in Example 3, which is used to enrich charged aerosol particles, including an enrichment nozzle 1 and an electric field generator; the electric field generator is arranged on the enrichment nozzle 1 outside, used to form the electric field distribution in the enrichment nozzle 1, and the direction of the electric field distribution is parallel to the axial direction of the enrichment nozzle 1; the charged aerosol particles are subjected to the electric field force in the electric field distribution, and the direction of the electric field force is determined by the enrichment nozzle 1 The outlet end of the nozzle 1 points to the inlet end of the enrichment nozzle 1; wherein, the electric field distribution direction is opposite to the airflow direction carrying positive aerosol particles, and the electric field distribution direction is the same as the airflow movement direction carrying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com