Inhomogeneous plate line electric precipitation method and assembly and electric precipitation device

A technology for dust removal components and electrostatic precipitators, applied in the field of electrostatic precipitators, can solve the problems of high energy consumption, increased investment, substandard discharge of electrostatic precipitators, etc., and achieves the effects of simple operation, increased collision probability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

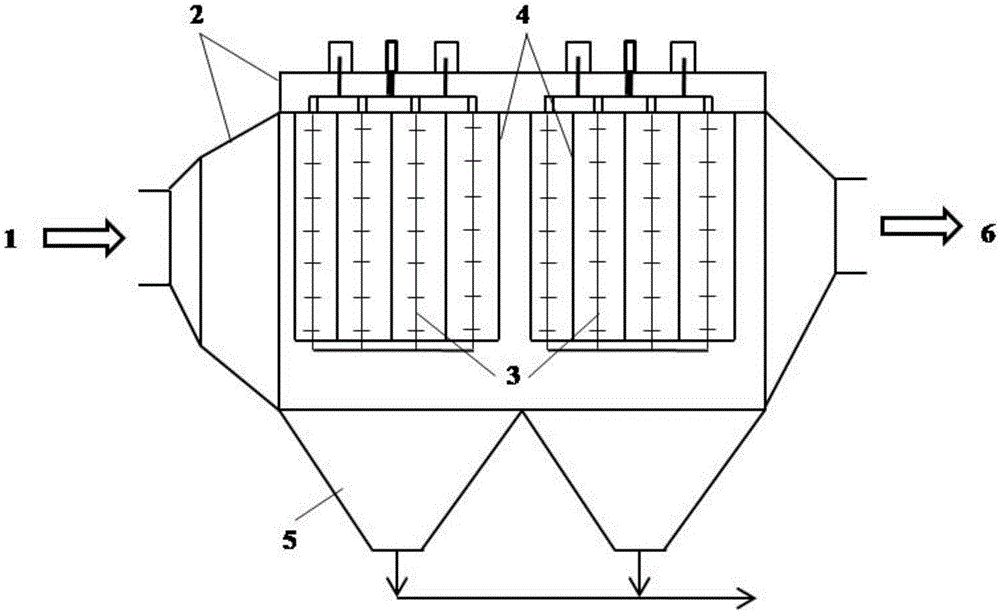

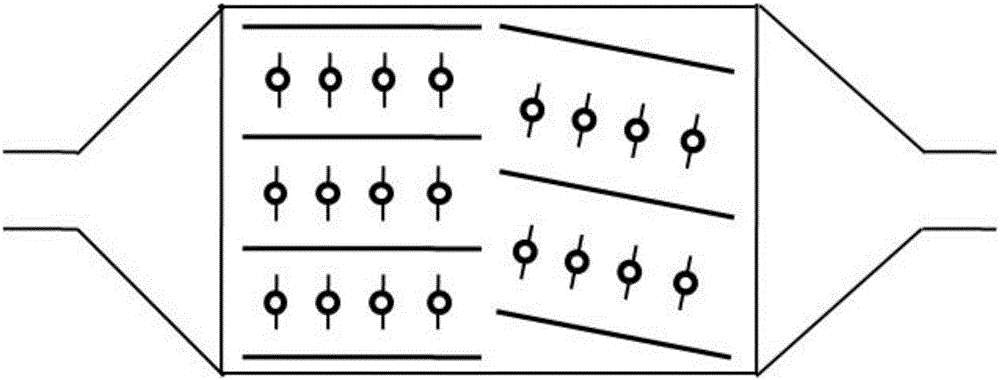

[0051] Such as figure 2 As shown, the electric precipitator has two dust removal units, and the dust removal units in the direction from the inlet 1 to the outlet 6 are the first dust removal unit, the second dust removal unit, etc., and the following embodiments are the same. The anode plate 4 of the first dust removal unit is parallel to the casing 2 (that is, the horizontal direction), the angle between the two is 0°, the angle between the anode plate 4 of the second dust removal unit and the casing 2 is 10°, and the first dust removal unit The same pole distance of the anode plate 4 is smaller than the same pole distance of the anode plate of the second dust removal unit. When the flue gas inlet flow rate is 0.8-1.2m / s, the width and length of each dust removal unit are determined according to the flue gas flow rate and residence time, and the total particulate matter is removed The efficiency exceeds 93.6%, and the removal efficiency of PM2.5 exceeds 83.1%.

Embodiment 2

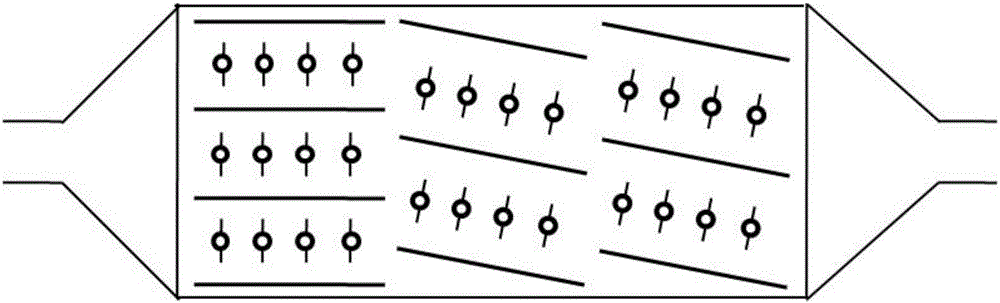

[0053] Such as image 3 As shown, the electrostatic precipitator has three dust removal units. The anode plate 4 of the first dust removal unit is parallel to the casing 2, and the angle between the two is 0°. The angle between the anode plate 4 of the second dust removal unit and the casing 2 is 20°, the angle between the anode plate 4 of the third dust removal unit and the housing 2 is still 20°, the anode plate 4 of the second dust removal unit is parallel to the anode plate 4 of the third dust removal unit, and the anode plates 4 of the three dust removal units At the same pole distance, when the flue gas inlet flow rate is 0.8-1.2m / s, the width and length of each dust removal unit are determined according to the flue gas flow rate and residence time. The total particulate matter removal efficiency is about 97.5%, and the PM2.5 removal efficiency exceeds 86.4 %.

Embodiment 3

[0055] Such as Figure 4 As shown, the electrostatic precipitator has three dust removal units, the angle between the anode plate 4 and the housing 2 of the three dust removal units is 10°, and the anode plate 4 of the first dust removal unit is parallel to the anode plate 4 of the third dust removal unit , And the direction of the included angle of the anode plate 4 of the second dust removal unit is opposite. The anode plates 4 of the three dust removal units have the same pole pitch. When the flue gas inlet flow rate is 0.8-1.2m / s, the width and length of each dust removal unit are based on the flue gas The flow rate and residence time are determined, the total particle removal efficiency is about 98.4%, and the PM2.5 removal efficiency exceeds 89.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com