Self-rolling type low-temperature protective sleeve for aviation

A technology of low temperature protection and protective sleeve, which is applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problems that the cable protective sleeve cannot resist the low temperature environment, the overall quality of the cable protective sleeve is not good, and the use of the cable is affected, so as to improve the Mixing efficiency, clean up, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A self-rolling low-temperature protective cover for aviation, which is made by the following steps:

[0044] S1. Put the mixture obtained after mixing the protective sheath materials into a kneader, control the air pressure to 0.2MPa, and carry out kneading and banburying for 10 minutes;

[0045] S2, heating the mixture after banburying to 110°C, and masticating for 1 hour;

[0046] S3, adding the masticated mixture into the open mill, kneading at 110°C for 10 minutes, and then wrapping the mixture, the wrapping temperature is 40°C;

[0047] S4. Add the kneaded mixture to a mixing and stirring device to mix and stir evenly, then perform pelletizing and extruding to obtain a self-rolling low-temperature protective cover for aviation.

[0048] The protective sheath material is one or more of polyethylene, polyvinyl chloride, polypropylene and nylon mixed in any proportion.

Embodiment 2

[0050] A self-rolling low-temperature protective cover for aviation, which is made by the following steps:

[0051] S1. Put the mixture obtained after mixing the protective sheath materials into a kneader, control the air pressure to 0.25MPa, and carry out kneading and banburying for 12 minutes;

[0052] S2, heating the mixture after banburying to 115°C, and masticating for 1.5h;

[0053] S3, adding the masticated mixture into the open mill, kneading for 12 minutes under the condition of 115°C, and then wrapping the mixture, the wrapping temperature is 45°C;

[0054] S4. Add the kneaded mixture to a mixing and stirring device to mix and stir evenly, then perform pelletizing and extruding to obtain a self-rolling low-temperature protective cover for aviation.

[0055] The protective sheath material is one or more of polyethylene, polyvinyl chloride, polypropylene and nylon mixed in any proportion.

Embodiment 3

[0057] A self-rolling low-temperature protective cover for aviation, which is made by the following steps:

[0058] S1. Put the mixture obtained after mixing the protective sheath materials into a kneader, control the air pressure to 0.3MPa, and carry out kneading and banburying for 15 minutes;

[0059] S2, heating the mixture after banburying to 120° C., and masticating for 2 hours;

[0060] S3, adding the masticated mixture into the open mill, kneading at 120°C for 15 minutes, and then wrapping the mixture, the wrapping temperature is 50°C;

[0061] S4. Add the kneaded mixture to a mixing and stirring device to mix and stir evenly, then perform pelletizing and extruding to obtain a self-rolling low-temperature protective cover for aviation.

[0062] The protective sheath material is one or more of polyethylene, polyvinyl chloride, polypropylene and nylon mixed in any proportion.

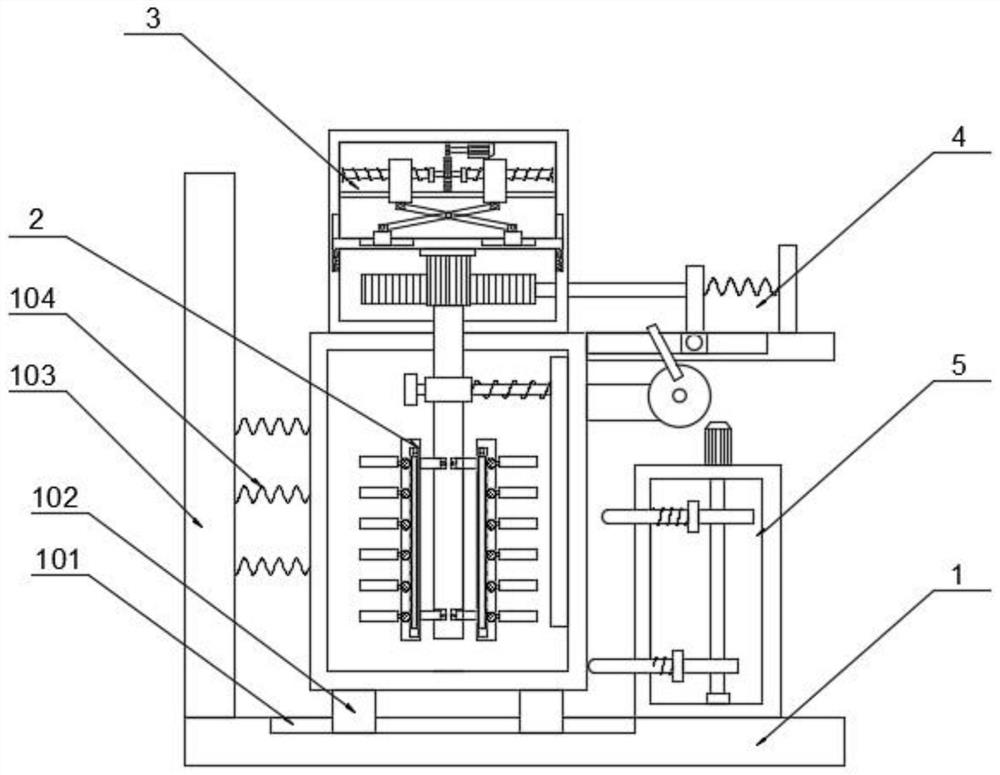

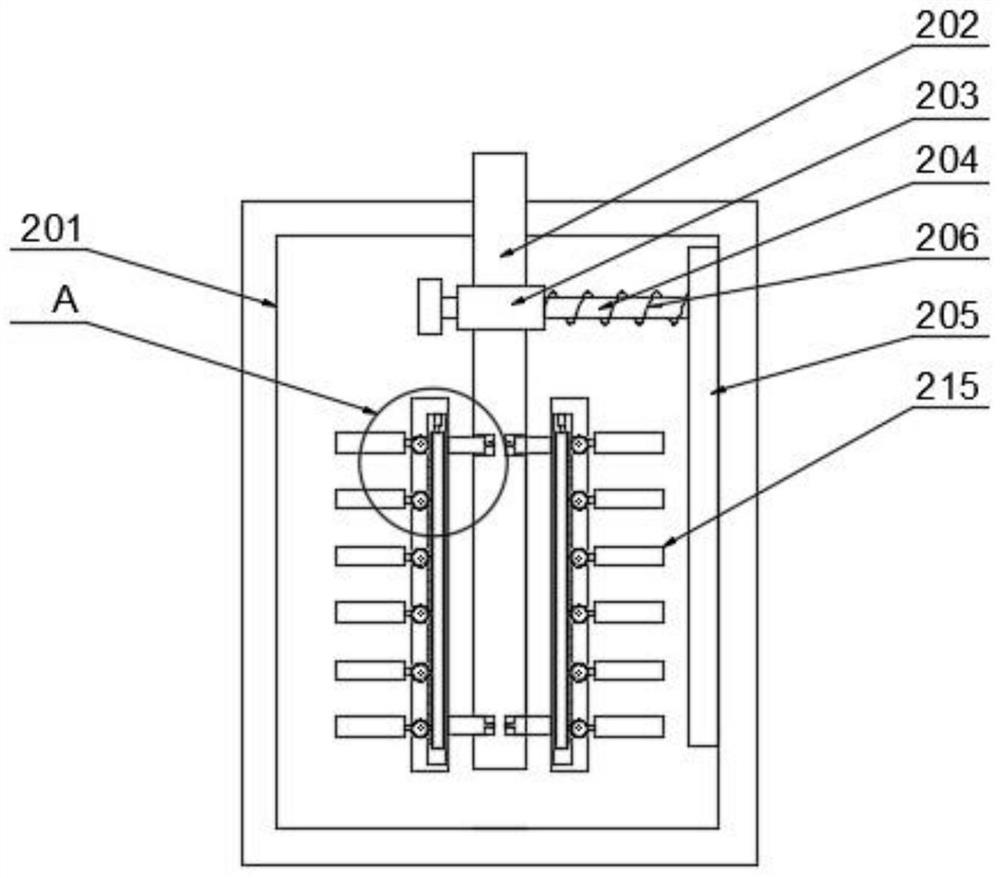

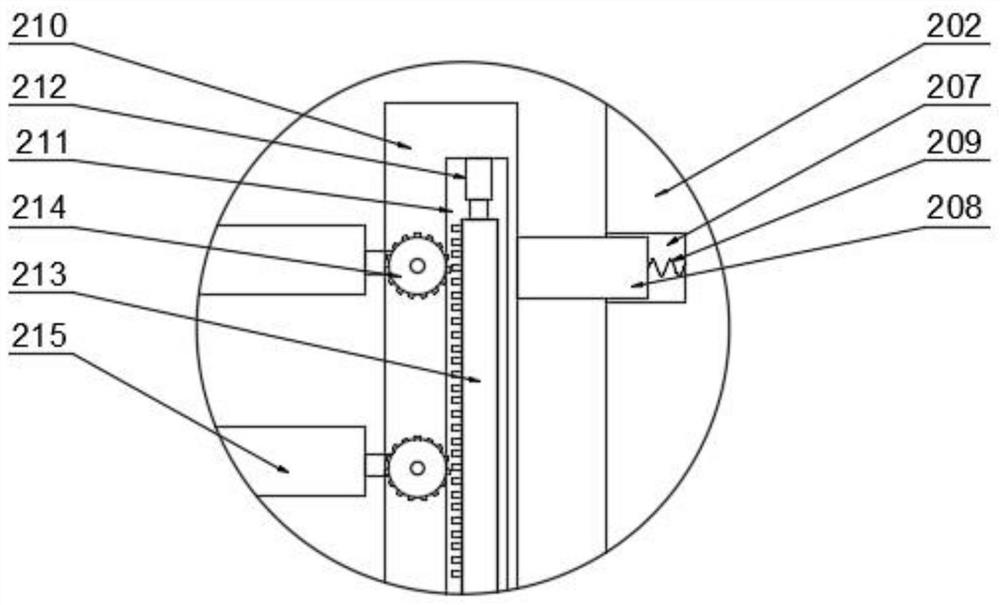

[0063] see Figure 1-7 , the mixing and stirring equipment described in the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com