Energy-saving type double-stirring mixing tank and control method thereof

A double-stirring and stirring tank technology, which is applied in the direction of mixer accessories, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problem of low rolling force, inability to effectively realize high-viscosity materials, and blind spots in tanks, etc. problem, to achieve the effect of a large mixing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

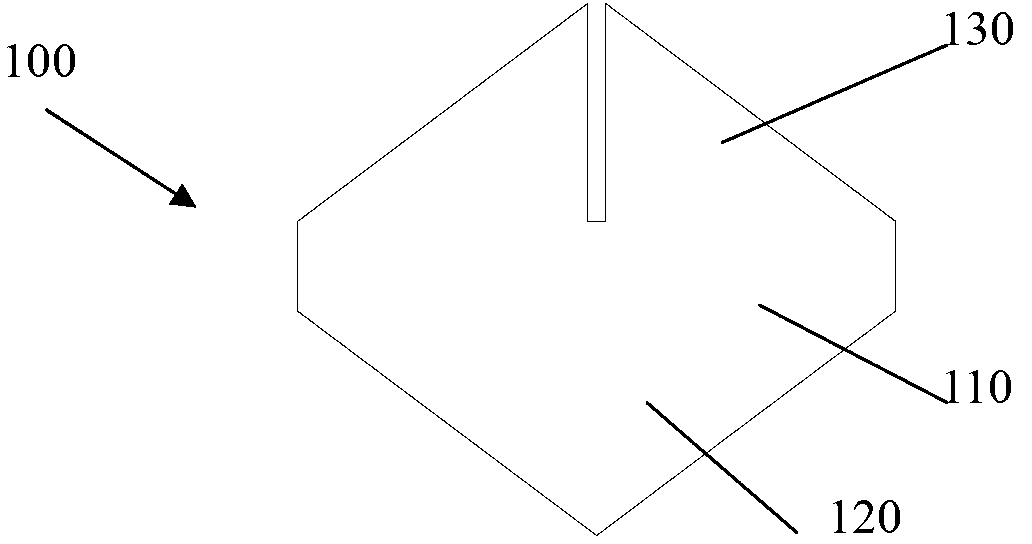

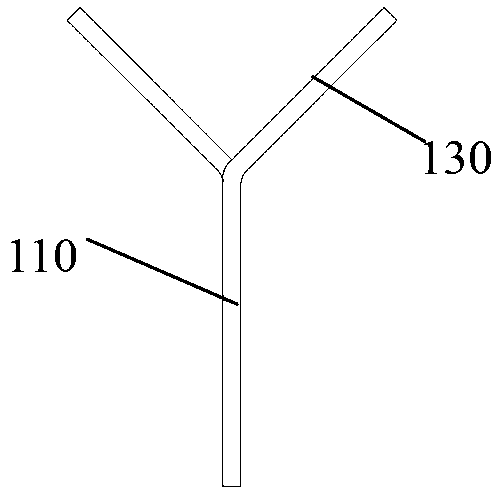

[0031] like figure 1 As shown, the double stirring tank of the present invention includes a controller, a tank body 1 with a discharge port 11 formed in the center of the bottom, a tank cover 2 arranged on the top of the tank body, and a tank cover rotatably and fixedly connected to the tank cover. Stirring rod 3, at least one pair of stirring blades 4 arranged in the tank body and fixedly connected with the stirring rod, the transmission cylinder 5 rotatably sleeved on the outside of the stirring rod, arranged inside the tank body And the peripheral stirring mechanism 6 fixedly connected with the transmission cylinder, and the internal drive motor 7 and the internal drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com