Clay mud making crushing and stirring device

A technology for mixing device and clay, which is applied to clay mixing device, clay preparation device, clay processing equipment, etc., can solve problems such as unfavorable mud-forming work, influence on crushing efficiency of clay, influence on ceramic production efficiency, etc., so as to improve the range of mixing. , Improve the shock absorption effect, improve the effect of stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

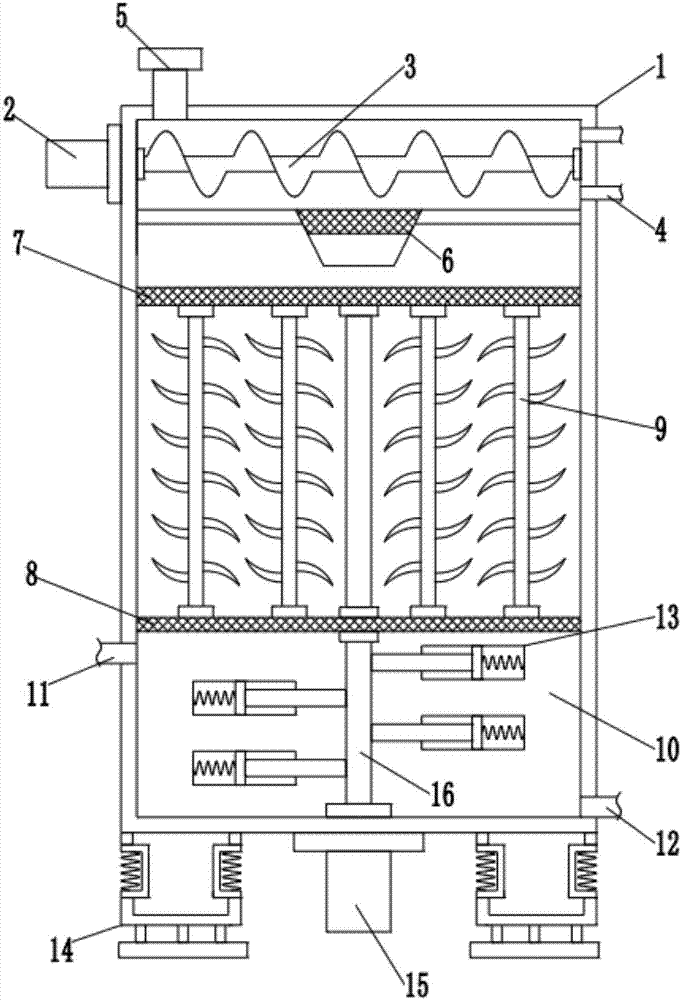

[0026] like figure 1 As shown, a crushing and agitating device for clay mud making includes a device body 1, and the device body 1 mainly includes a feed port 5, a crushing knife roller 9 and a mud making chamber 10; the top of the device body 1 is provided with a feeding Port 6, feed port 6 are connected with the device body 1, and the crushing motor 2 is fixedly connected to the left side wall of the device body 1, a partition is arranged in the device body 1, and a screw is arranged in the device body 1 above the partition. Crushing rod 3, one end of the spiral crushing rod 3 is connected with the crushing motor 2, and the other end of the spiral crushing rod 3 is rotationally connected with the inner wall of the device body 1, a gauze funnel 6 is arranged on the partition, and the right side wall of the device body 1 is arranged above There is a hot air inlet pipe 4, which is used to feed hot air to dry the pottery clay, so as to facilitate the crushing work of the pottery...

Embodiment 2

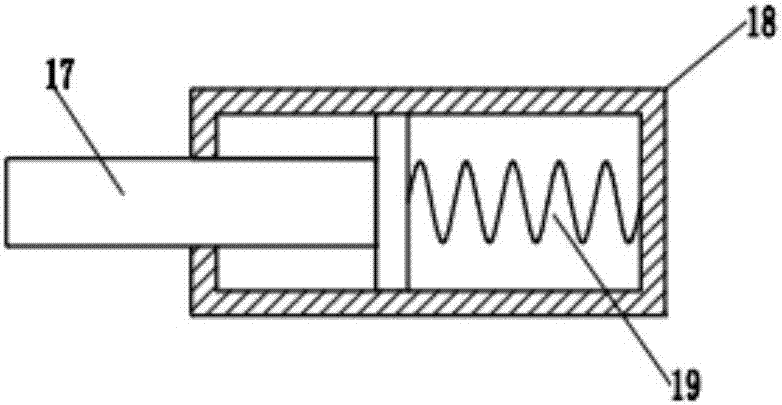

[0031] like figure 1 and figure 2 As shown, a crushing and stirring device for clay mud making, on the basis of Example 1, the stirring rod 13 also includes a fixed rod 17 and a sliding sleeve 18, and the end of the fixed rod 17 is integrally formed and fixedly connected with The fixed block and the sliding sleeve 18 are sleeved on the surface of the fixed rod 17, and the fixed block is fixedly connected with a telescopic spring 19, and the end of the telescopic spring 19 is fixedly connected with the inner wall of the sliding sleeve 18.

[0032] In this embodiment, the rotating shaft 16 drives the stirring rod 13 to rotate. During the rotating process of the stirring rod 13, the sliding sleeve 18 moves outside the fixed rod 17 due to the centrifugal force, which increases the mixing range of mud making and improves the mud making efficiency.

Embodiment 3

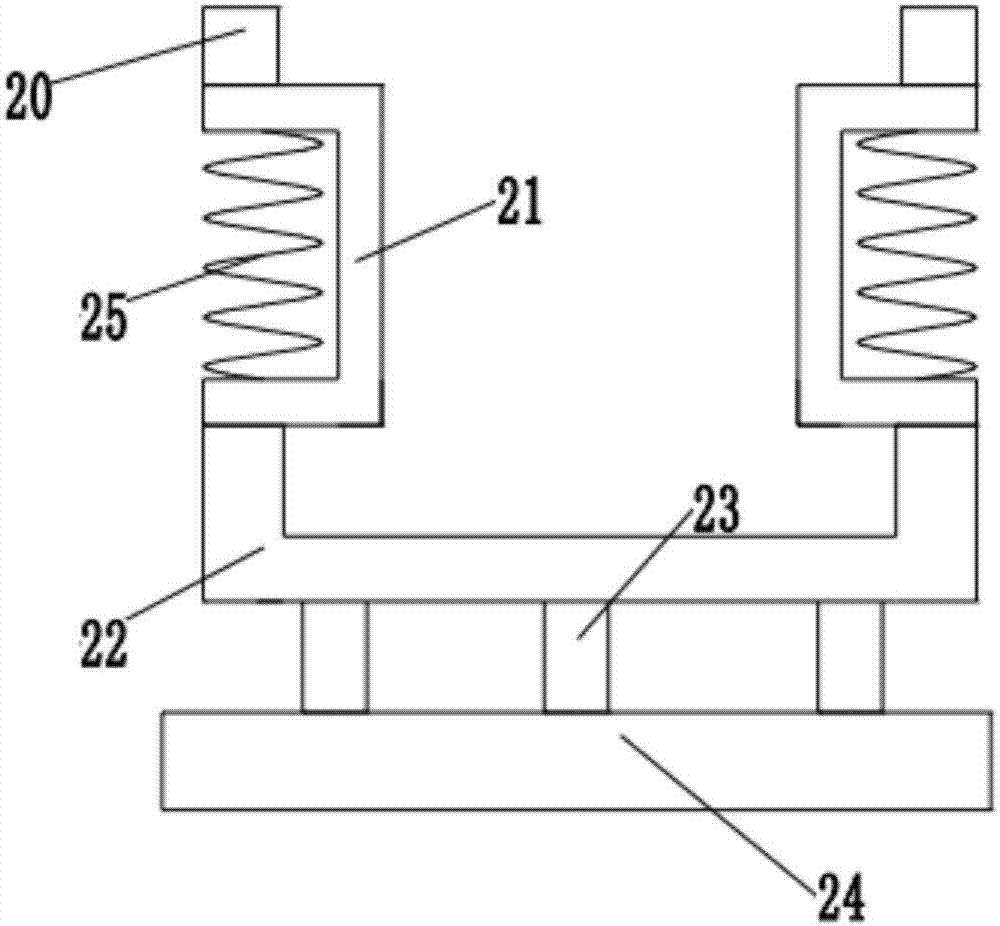

[0034] like figure 1 and image 3 As shown, a crushing and stirring device for making mud from pottery clay, on the basis of Embodiment 1, also includes a shock absorbing support device 14, the bottom of the device body 1 is fixedly connected with a shock absorbing support device 14, and the shock absorbing The supporting device 14 mainly includes a fixing part 20, a U-shaped steel plate 21, a connecting seat 22, a connecting part 23, a base 24 and a damping spring 25; the bottom of the device body 1 is fixedly connected with the fixing part 20, and the bottom of the fixing part 20 is fixedly connected There is a U-shaped steel plate 21, the U-shaped steel plate 21 is fixedly connected with a shock absorbing spring 25, and the bottom of the U-shaped steel plate 21 is fixedly connected with a connecting seat 22, and the bottom of the connecting seat 22 is connected to the base 24 through a connecting piece 23.

[0035] In this embodiment, the device body 1 vibrates during use....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com