Pesticide spraying vehicle with large spraying range

A spraying range and spraying vehicle technology, applied in the field of pesticide spraying vehicles, can solve the problems of large spraying dead angle, small spraying range, small nozzle moving range, etc., and achieve the effect of reducing spraying dead angle, solving sedimentation and preventing sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

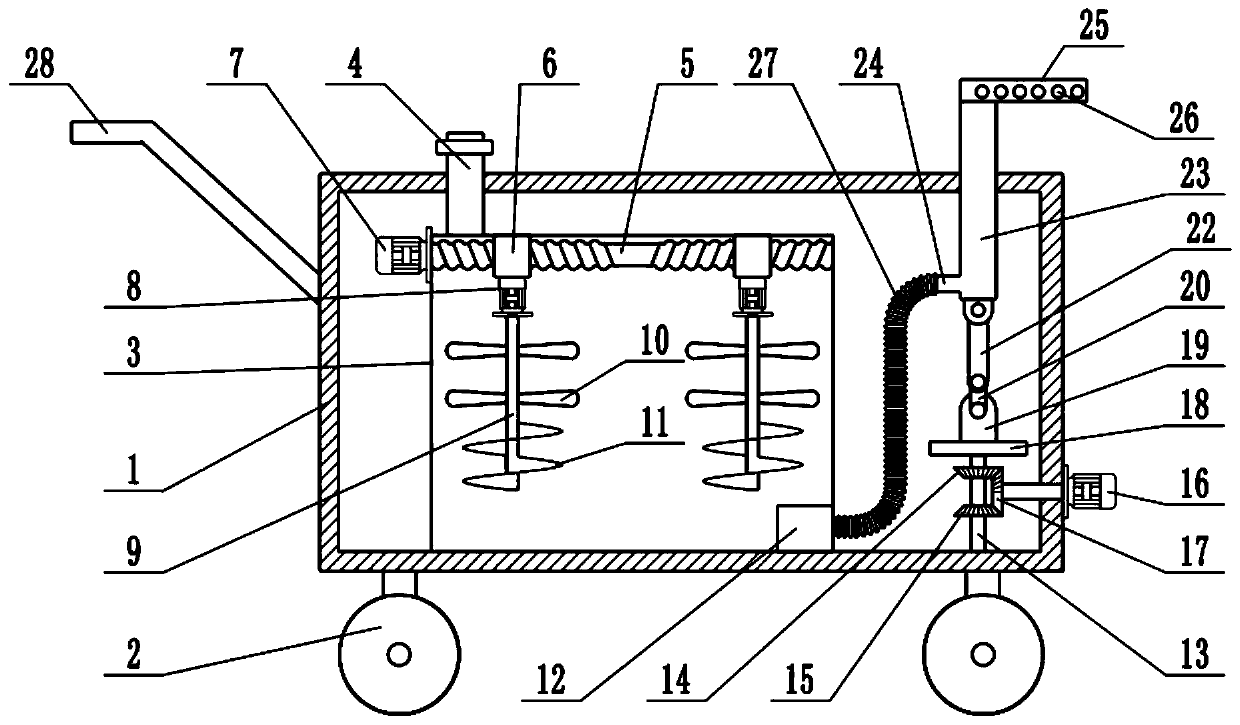

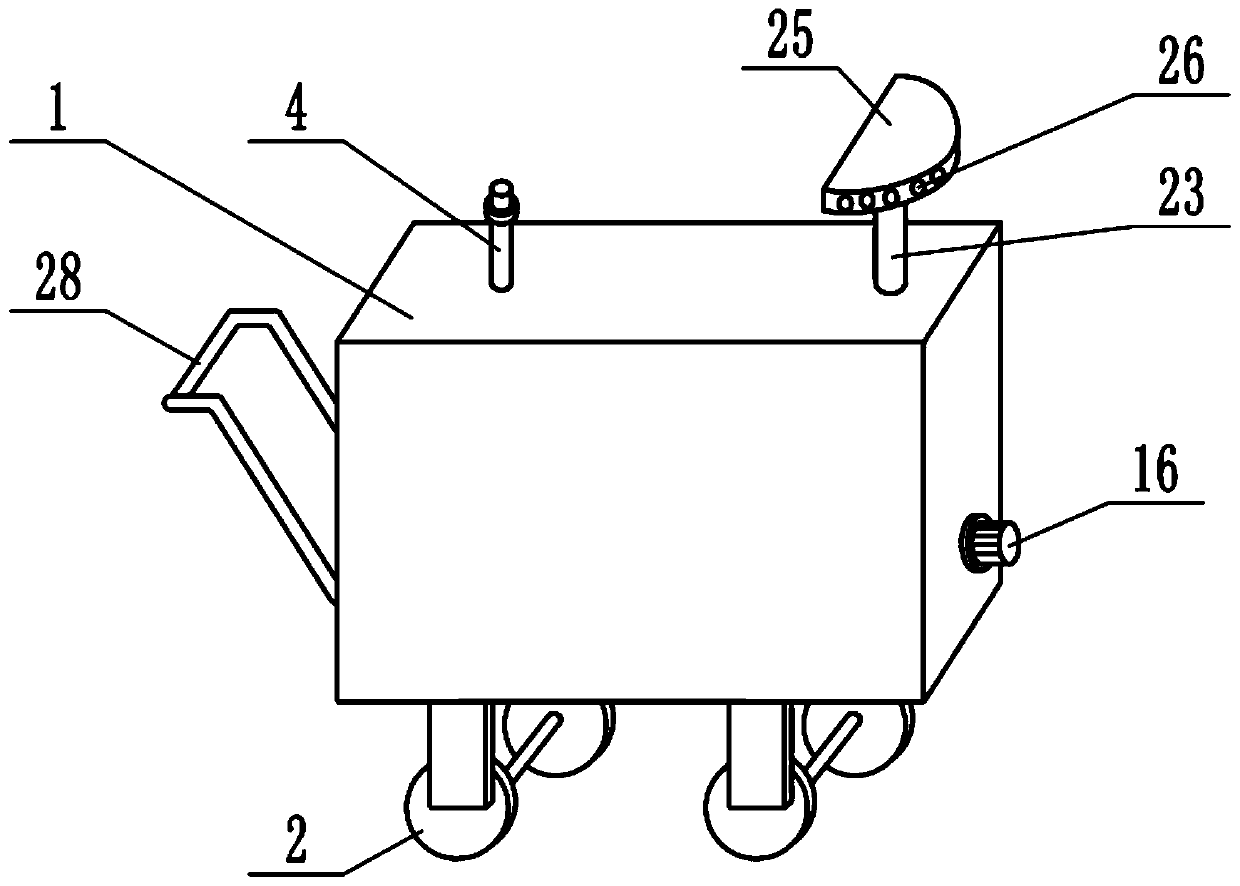

[0021] see Figure 1-3 , in an embodiment of the present invention, a pesticide spraying vehicle with a large spraying range includes a casing 1, a roller 2, a liquid storage tank 3, a water pump 12, a drug delivery pipe 23 and a spraying plate 25, and the bottom of the casing 1 is equipped with a roller 2. A liquid storage tank 3 is installed inside the housing 1, and a water injection pipe 4 is installed on the top of the liquid storage tank 3. The water injection pipe 4 extends through the housing 1 to the top of the housing 1, and the pesticide is injected into the liquid storage tank 3 through the water injection pipe 4. , the bottom of the liquid storage tank 3 is equipped with a water pump 12.

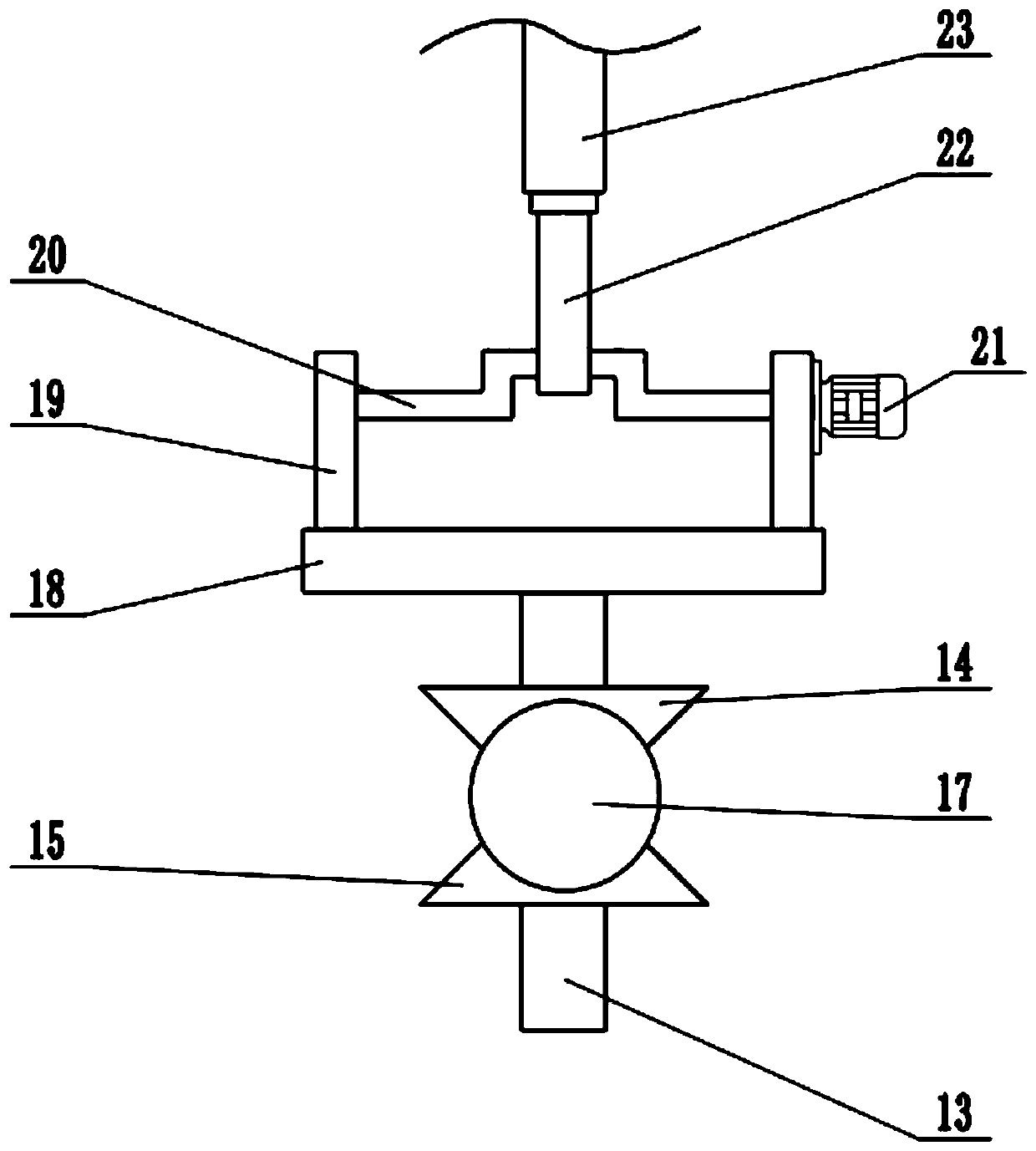

[0022] The bottom of the housing 1 is rotatably connected with a rotating shaft 13, the upper bevel gear 14 and the lower bevel gear 15 are set on the rotating shaft 13, the outer wall of the housing 1 is fixedly connected with a rotating motor 16, and the shaft extension end of...

Embodiment 2

[0025] On the basis of Embodiment 1, a stirring mechanism is installed inside the liquid storage tank 3, and the stirring mechanism includes a two-way screw rod 5, a slider 6, a forward and reverse motor 7, a stirring motor 8, a stirring shaft 9, a stirring blade 10 and a screw Plate 11, the interior of liquid storage tank 3 is equipped with two-way screw rod 5, the left and right ends of two-way screw rod 5 are respectively connected with the side wall of liquid storage tank 3 in rotation, two-way screw rod 5 is provided with slide block 6, slide block There are two of 6, which are symmetrically arranged left and right. The upper surface of the slider 6 is slidingly connected with the top of the liquid storage tank 3. The outer wall of the liquid storage tank 3 is fixedly connected with the forward and reverse motor 7, and the shaft extension end of the forward and reverse motor 7 It is connected with the end of the two-way screw rod 5 to control the positive and negative rota...

Embodiment 1、 Embodiment 2

[0026] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: the configured pesticide solution is injected into the liquid storage tank 3 through the water injection pipe 4, the stirring motor 8 is started, and the stirring blade 10 and the spiral plate 11 are driven to rotate. 10 Stir the pesticide in the liquid storage tank 3, use the spiral plate 11 to stir the pesticide at the bottom layer, so that the pesticide is tumbling upwards to prevent the pesticide from depositing, and at the same time, control the positive and negative rotation of the forward and reverse motor 7, which can drive the two-way screw rod 5 to rotate forward and reverse, Thereby driving the two sliders 6 to move toward each other or back, thereby expanding the stirring range of the stirring blade 10 and the spiral plate 11, making the pesticide mixing more uniform, starting the water pump 12, and transporting the pesticide in the liquid storage tank 3 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com