Bi-directional cement soil mixing pile machine

A technology of cement-soil mixer and fuselage, which is applied in the direction of sheet pile wall, earthwork drilling, drilling equipment, etc. It can solve the problems of low work efficiency, slurry leakage, and cement slurry leakage from the ground, so as to ensure the quality of the pile body and ensure the success The quality of the pile and the effect of mixing fully and evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

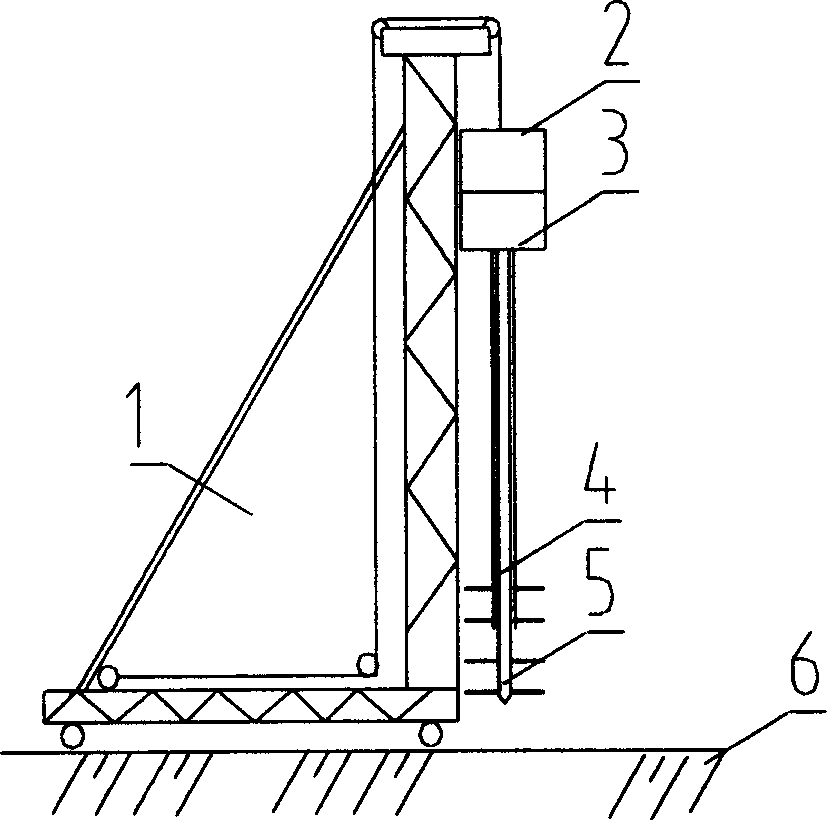

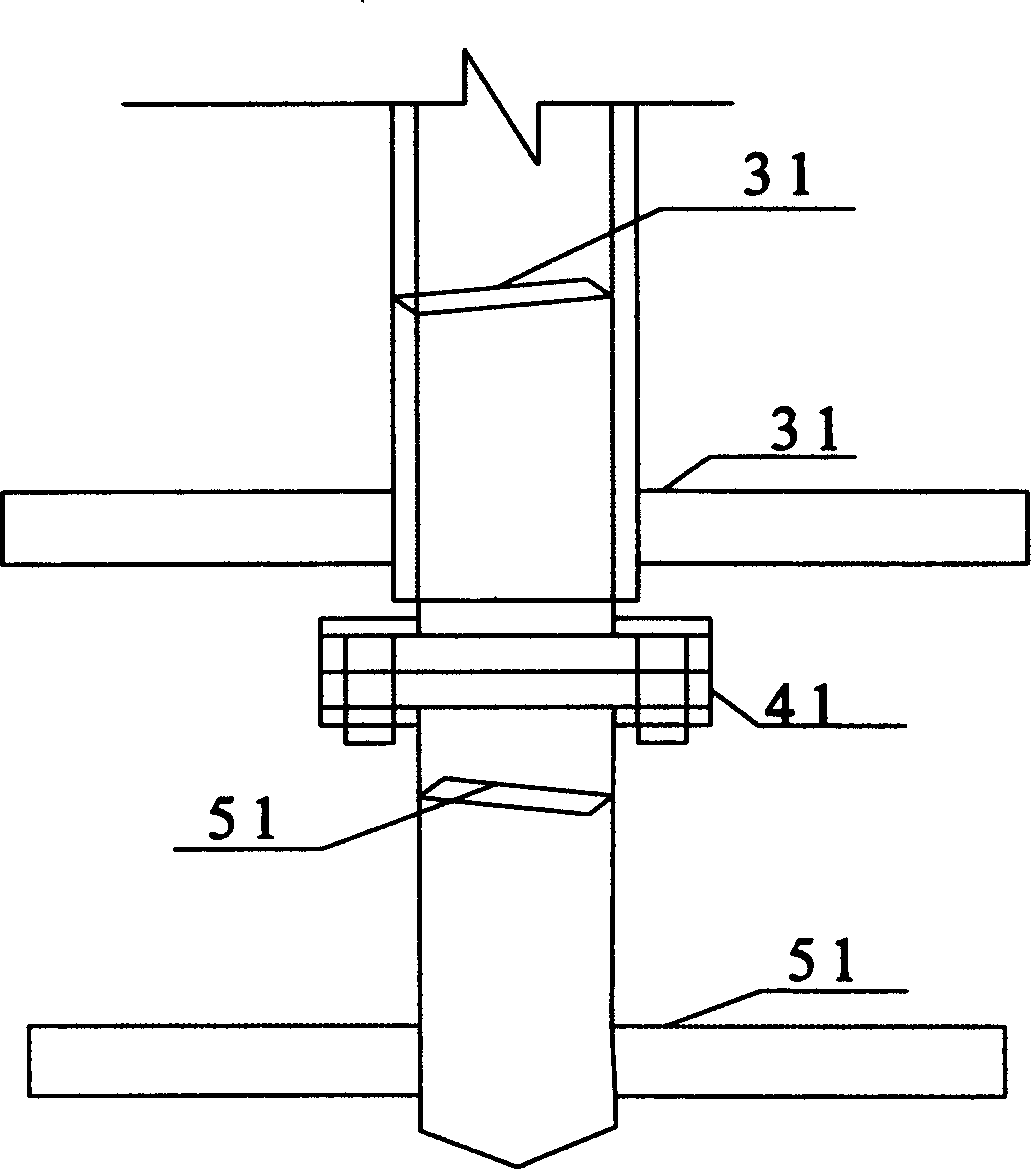

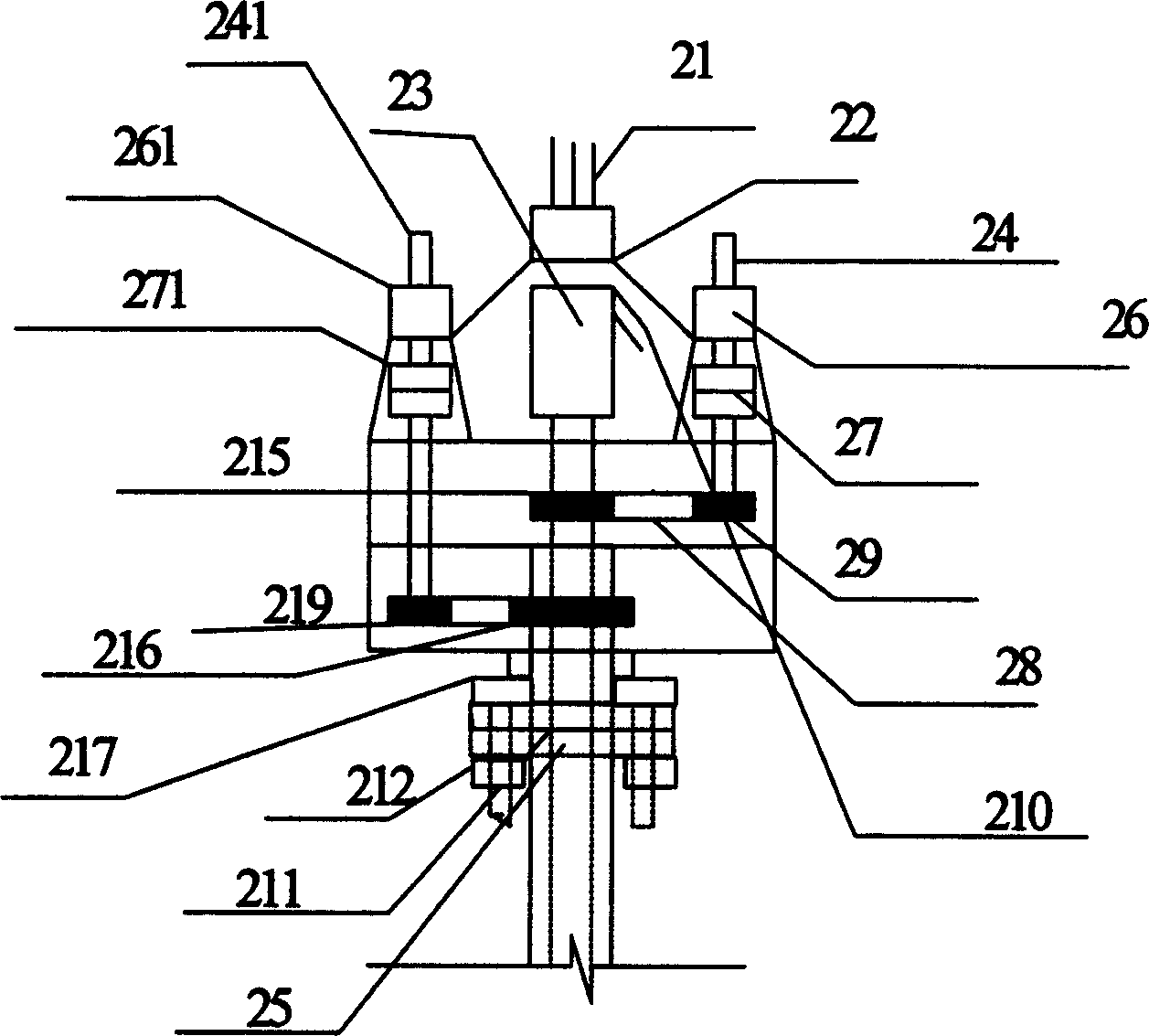

[0021] The two-way cement-soil mixer of the present invention is made up of machine body 1, power transmission system 2, outer drill rod 3, inner drill rod 4, drill bit 5 by mixer, wherein, power transmission system 2 is positioned at the upper part of fuselage 1, inner drill rod 4 Located in the outer drill pipe 3, the inner drill pipe 4 is connected with the inner drill pipe power transmission system connection flange 211 in the power transmission system 2, the outer drill pipe 3 is connected with the outer drill pipe power transmission system connection flange 25, and the drill bit 5 is located at the bottom of inner drill rod 4. The power transmission system 2 has two sets of symmetrical driving devices, respectively driving the outer drill rod 3 and the inner drill rod 4; the inner drill rod motor 24 is connected to the inner drill rod reducer 26, and the output end of the inner drill rod reducer 26 is connected to the inner drill rod The rod connector 27, the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com