Rotating and revolving magnetic stirrer for production of conductive gold balls

A magnetic stirrer, self-revolution technology, applied in the field of stirrer, can solve problems such as poor mixing effect, and achieve the effect of uniform and sufficient stirring and excellent surface treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

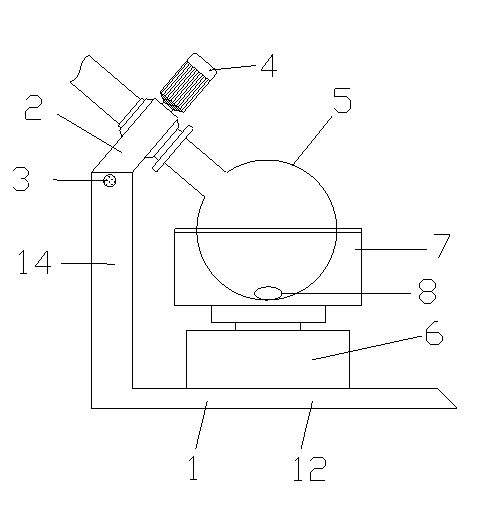

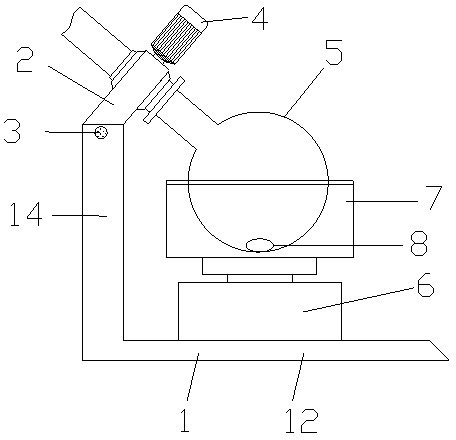

[0011] Such as figure 1 As shown, the present invention proposes a kind of rotation and revolution magnetic force stirrer that is used for the production of conductive golden ball, and it comprises a machine base 1, a mounting bar 2, an angle adjusting button 3, a rotating motor 4, a flask 5, a magnetic force stirring Device 6, a water bath 7, a magnetic rotor 8.

[0012] The base 1 includes a base 12 and a support bar 14 perpendicular to the base 12 .

[0013] The mounting rod 2 is rotatably pivotally connected to the top of the supporting rod 14 . It is only necessary to rotate when adjusting the angle of the mounting rod 2, and the rotation angle is within 90 degrees.

[0014] The angle adjustment knob 3 is installed on the support rod 14 .

[0015] The angle between the installation rod 2 and the support rod 14 can be adjusted by twisting the angle adjustment knob 3 .

[0016] The rotary motor 4 is installed on the installation rod 2 .

[0017] The neck of the flask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com