Patents

Literature

37results about How to "Reduce stirring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Olefin polymerization chelate catalyst and olefin polymerization method using the same

InactiveUS6500906B1High impact strength propertyIncrease of viscosity of solutionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSolventOlefin polymerization

This invention relates to transition metal catalyst component chelated by chelate ligand, a catalytic system comprising the transition metal catalyst component in the presence of magnesium halide, and a process for olefin polymerization using the catalytic system. The preparation of chelated transition metal catalyst component[A] are prepared by the unique synthetic method, in which Mg[AlR'(OR)3]2 reacts with chelate ligand to form Mg-Al-chelate ligand complex containing chelate ligand, and this complex reacts with metal halide compound to prepare chelated transition metal compound which is quite soluble in non-polar solvents. The olefin polymerization is performed using a catalytic system comprising the chelated transition metal catalyst component[A], MgCl2 support component[C], and an organoaluminum cocatalyst component[B]. Such polymerization produces a polymer having narrow molecular weight distribution, narrow compositional distribution, excellent morphology, and good processibility.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

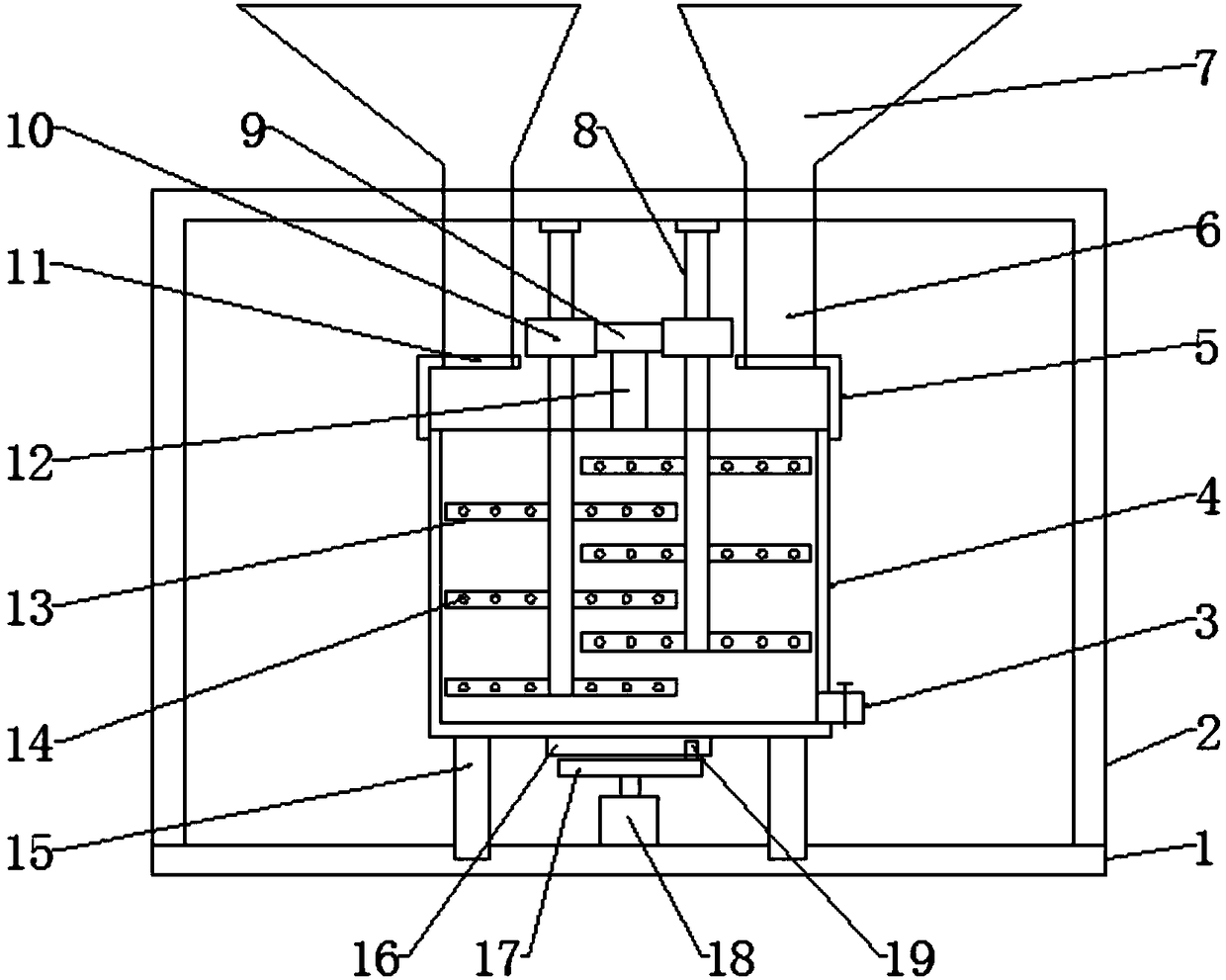

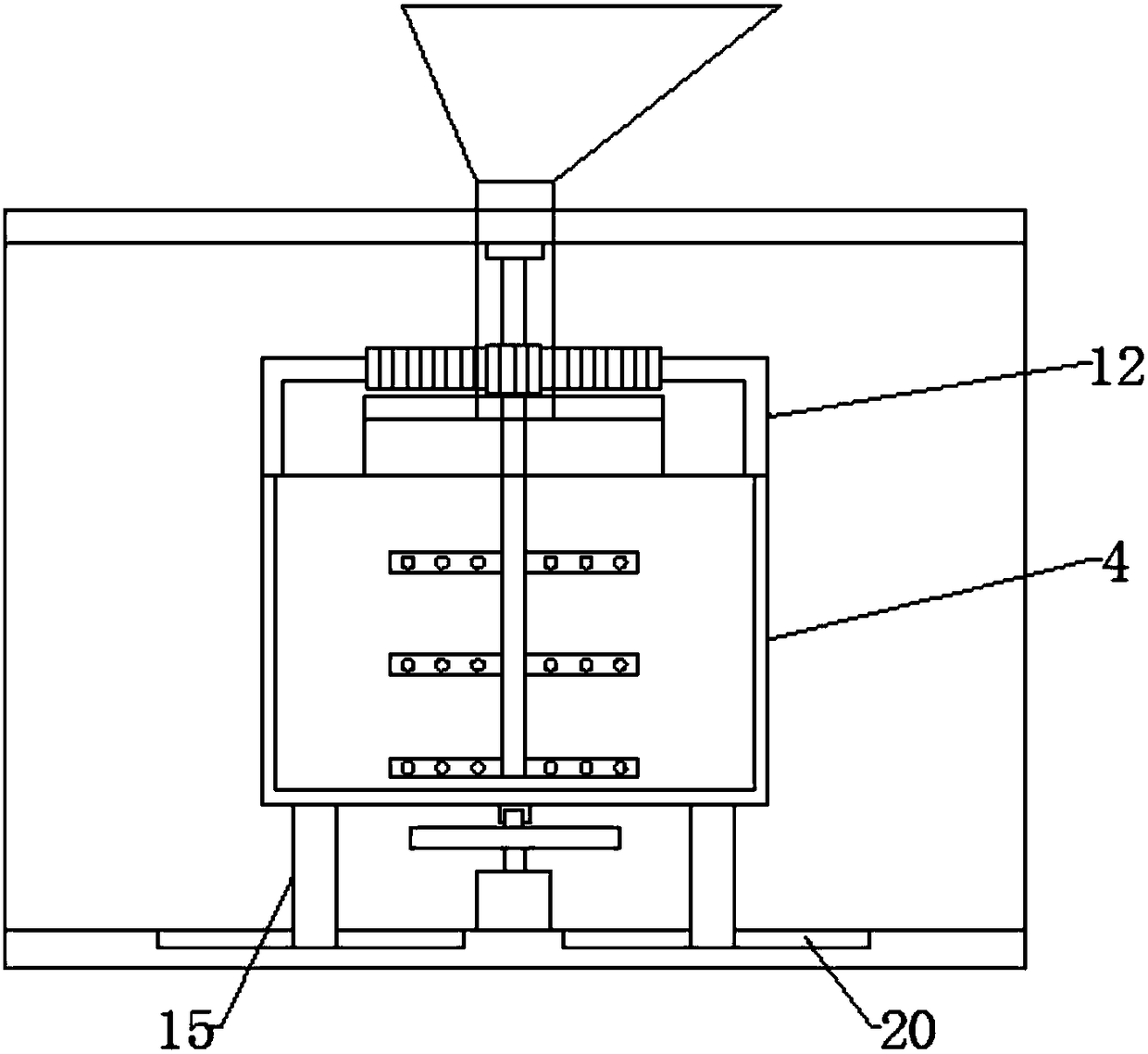

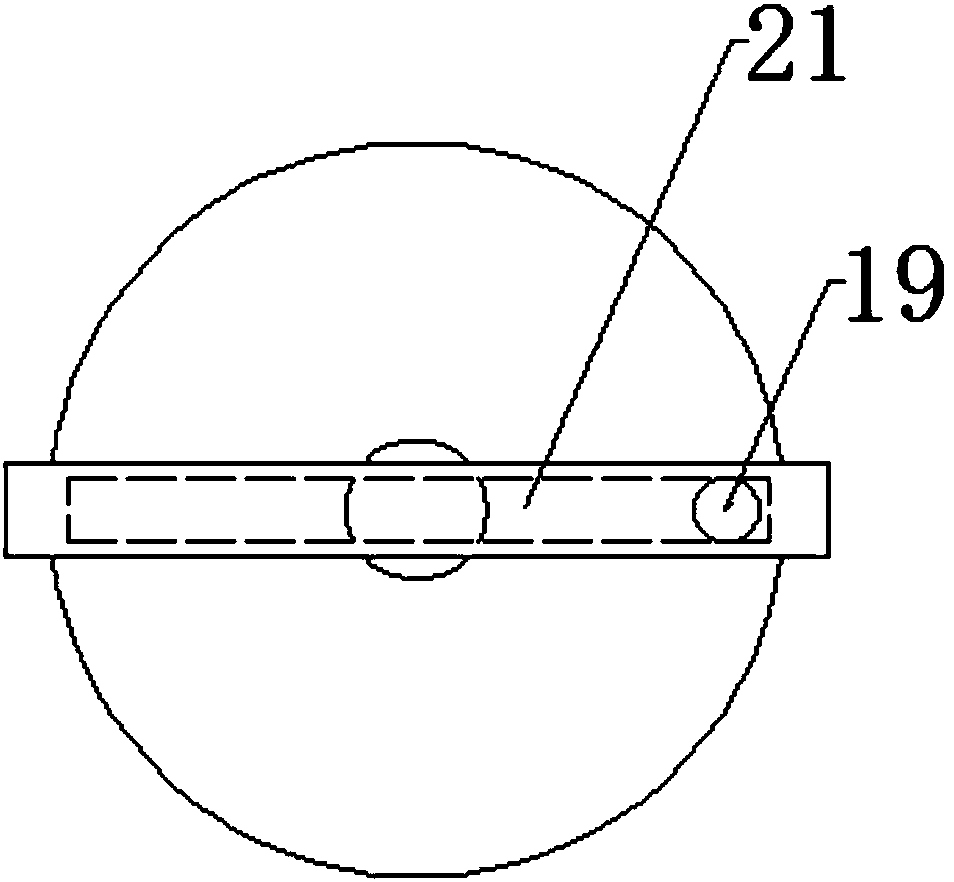

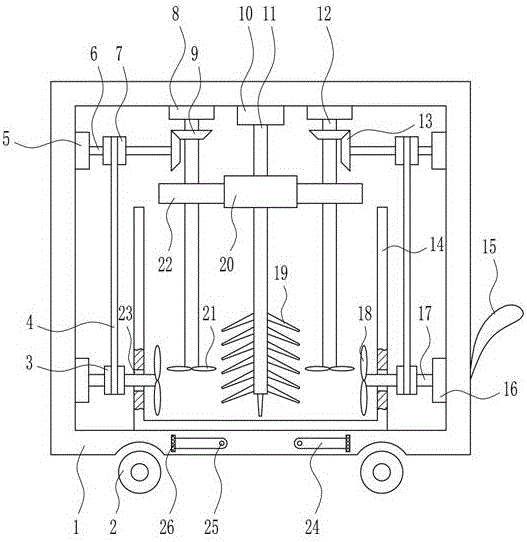

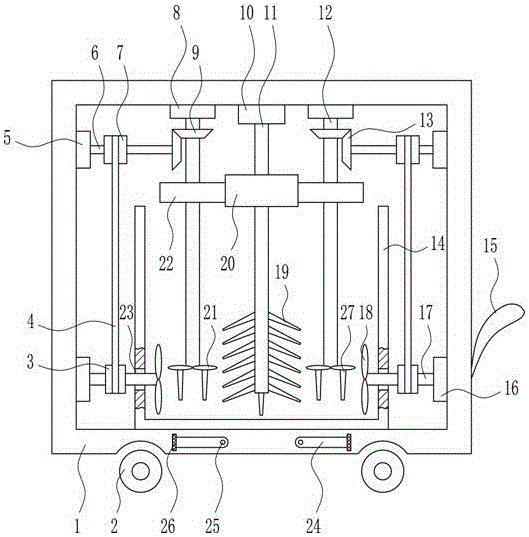

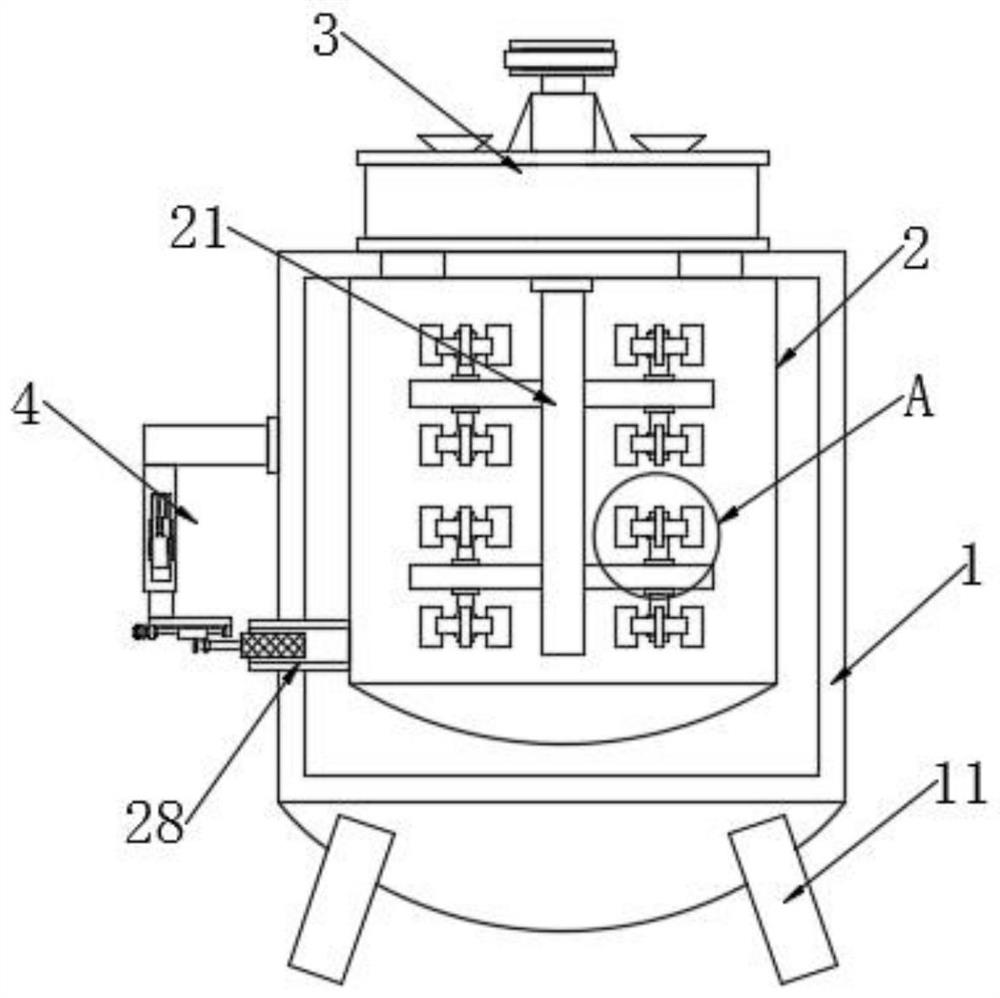

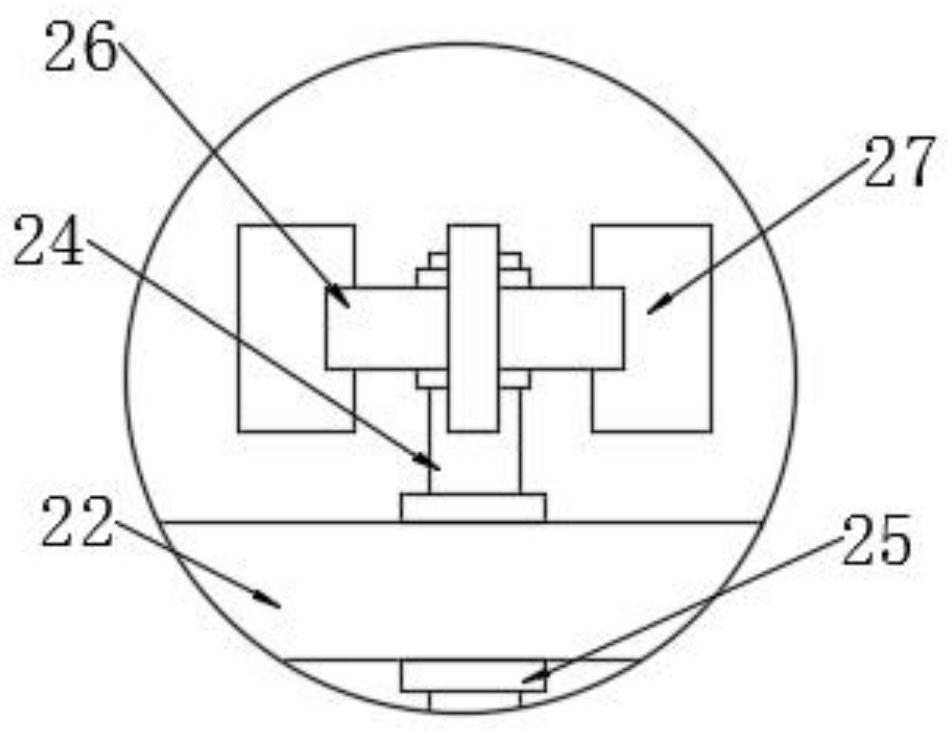

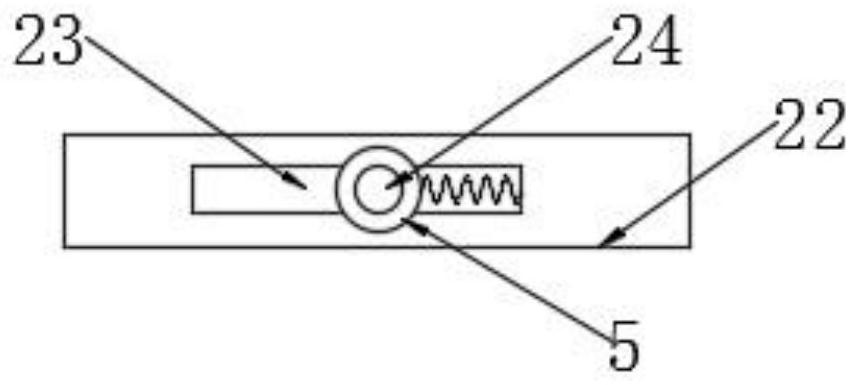

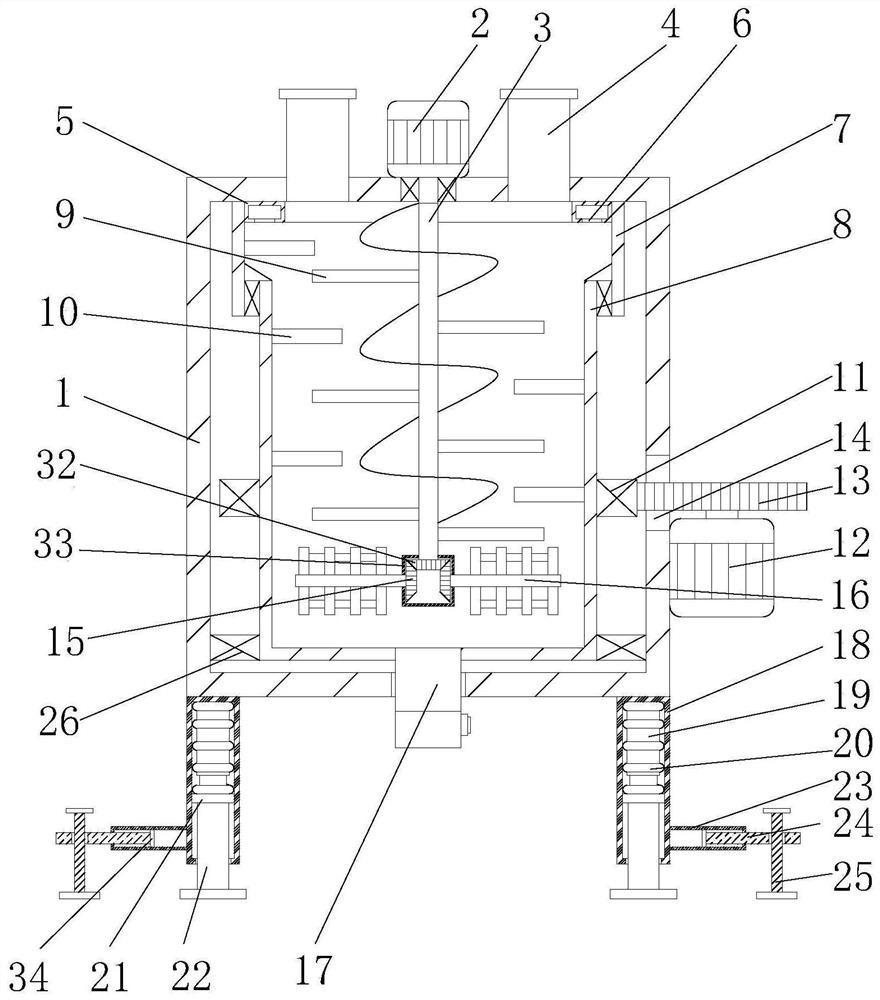

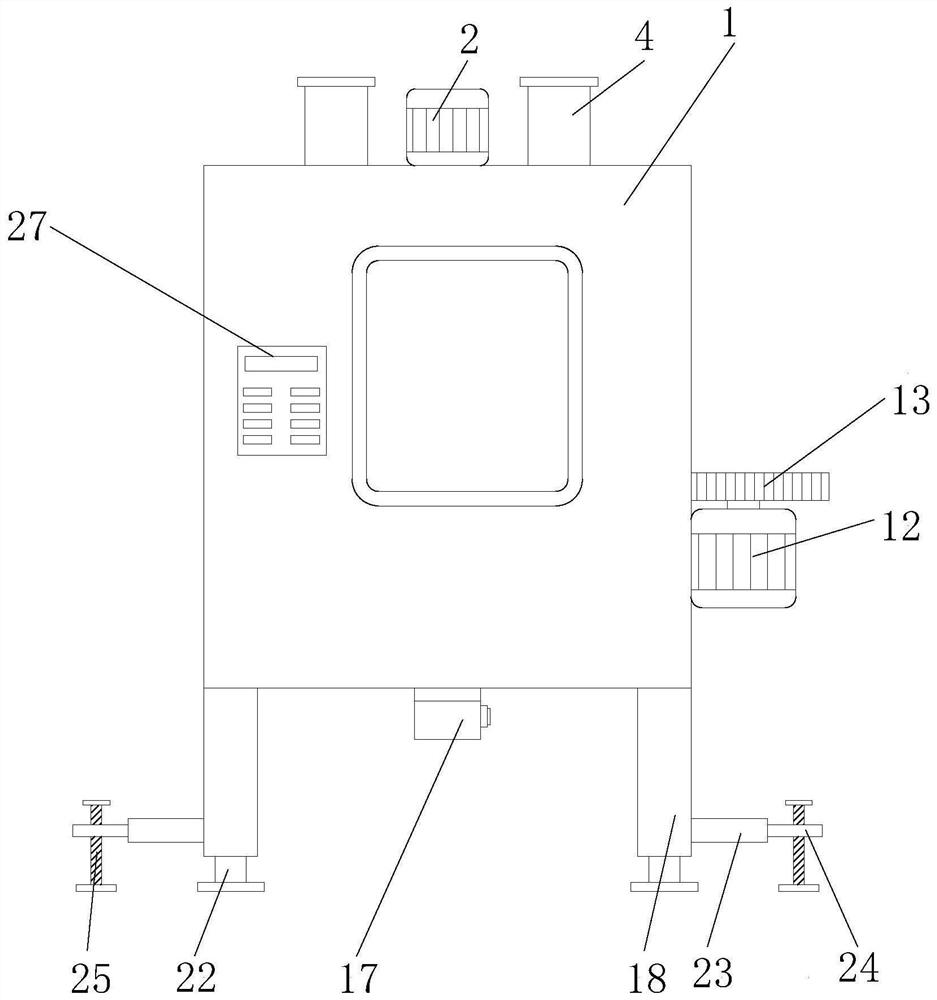

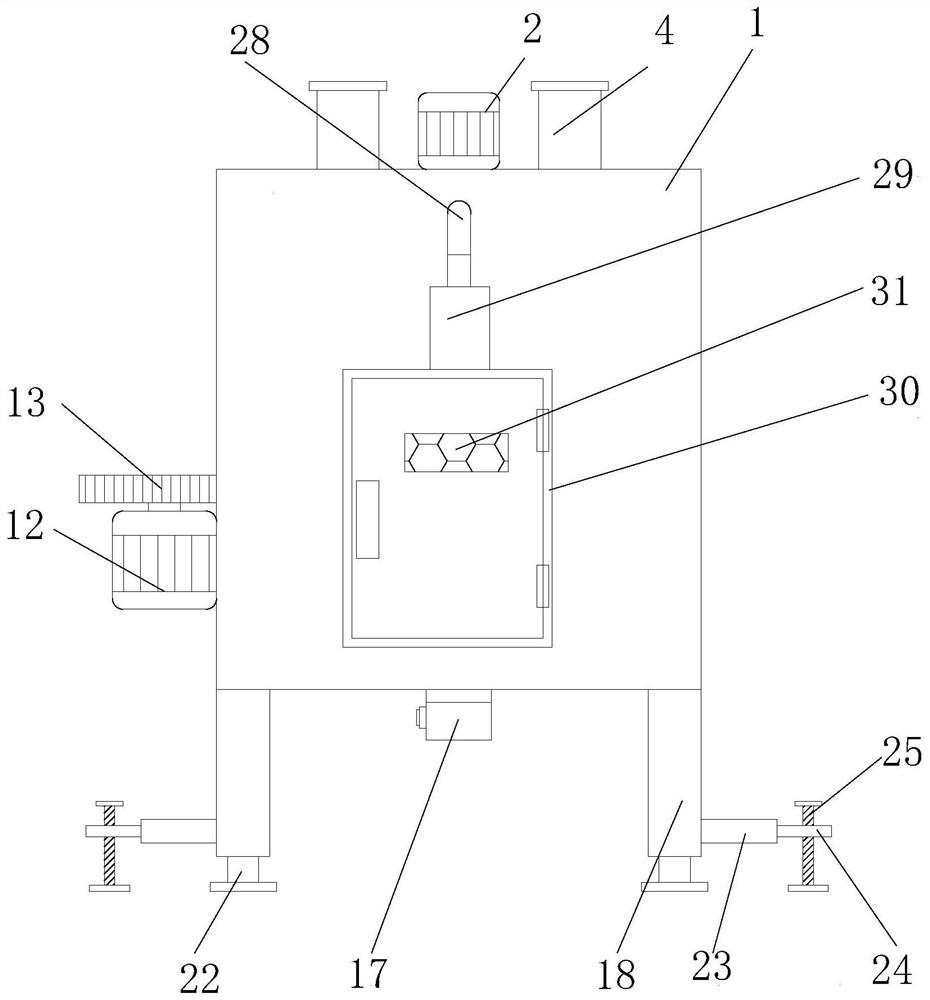

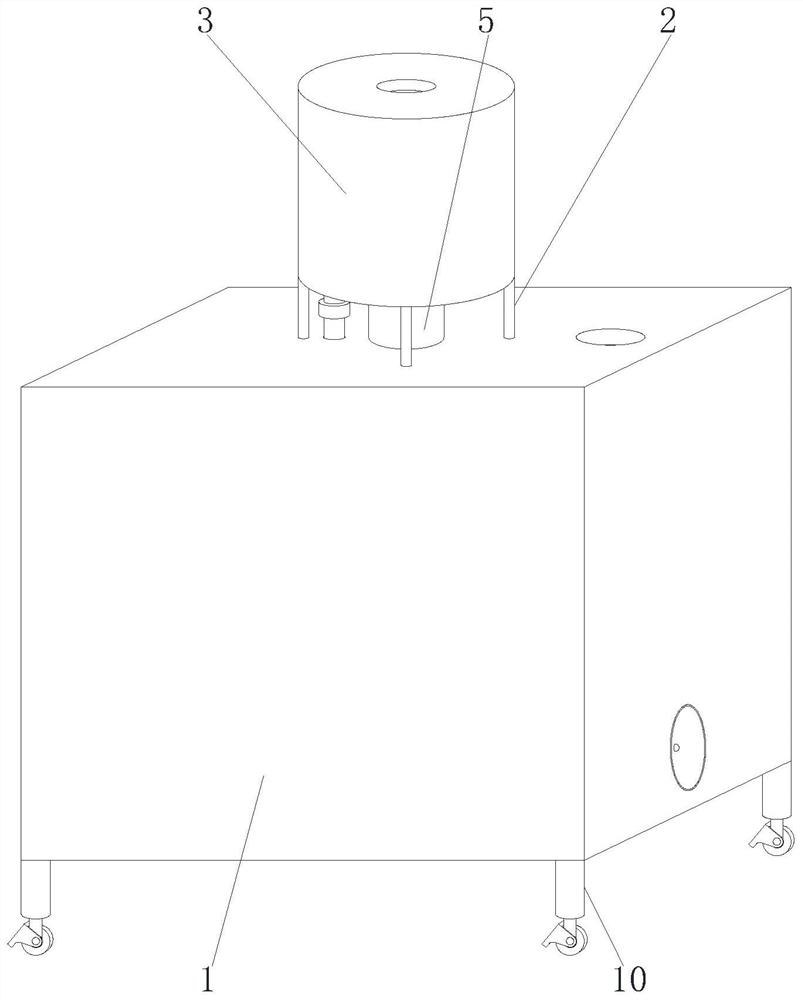

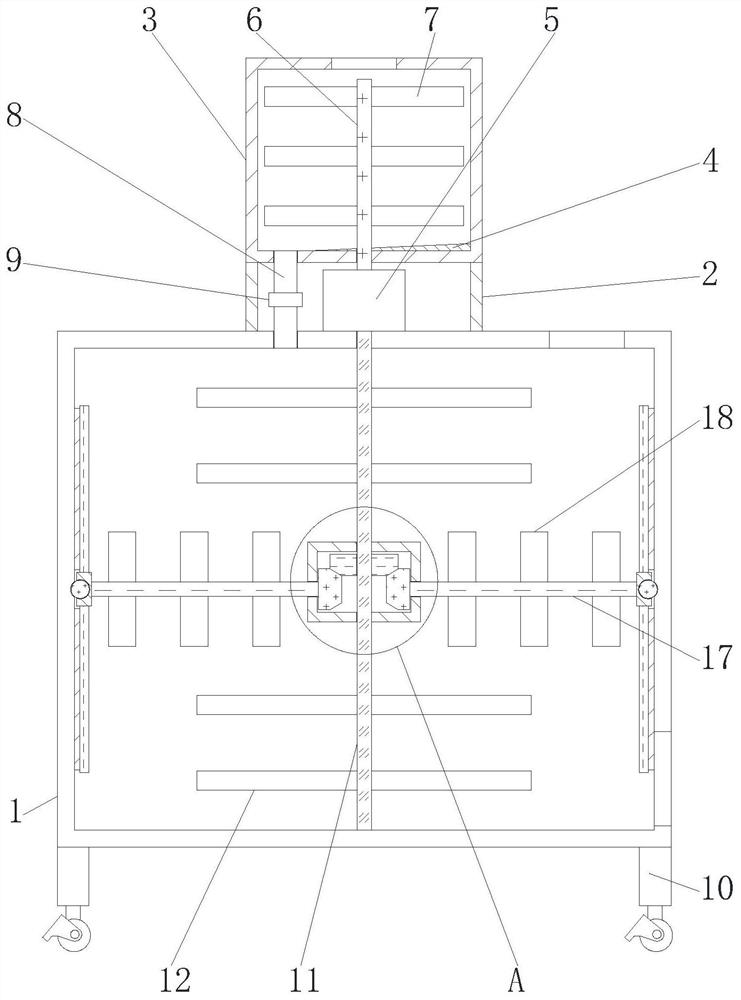

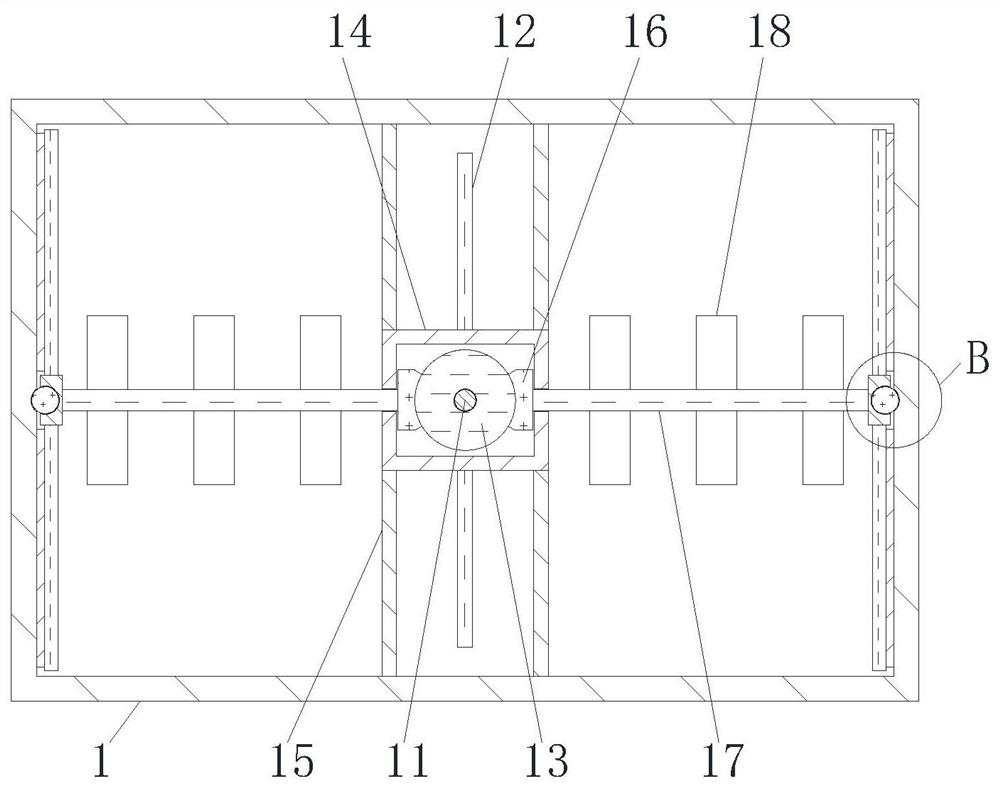

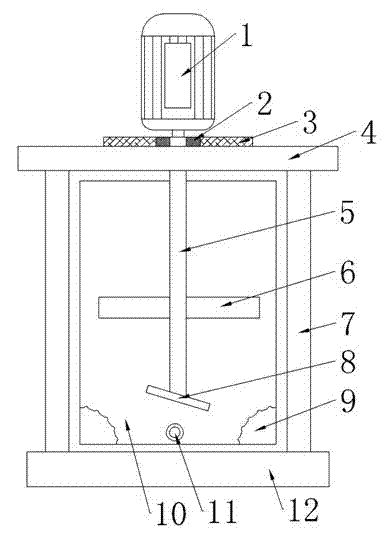

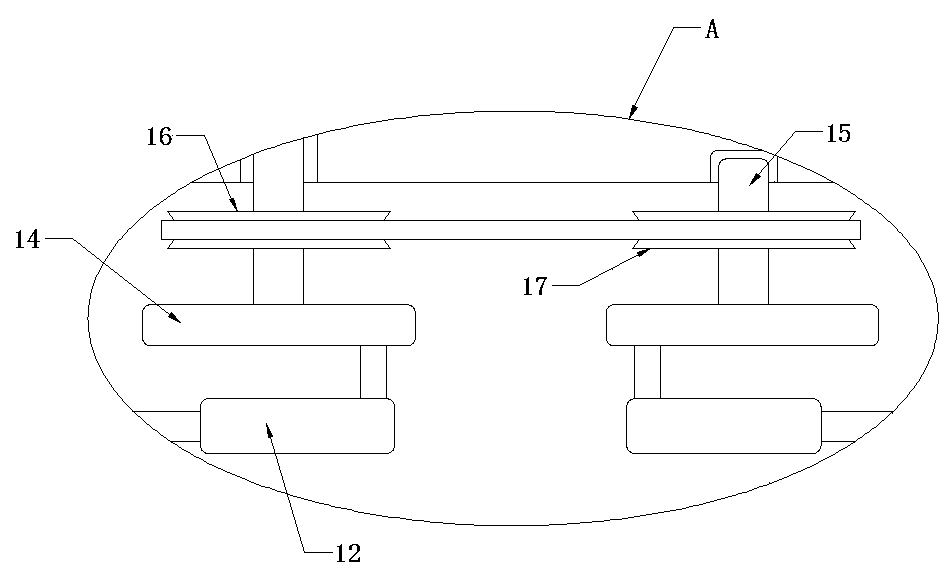

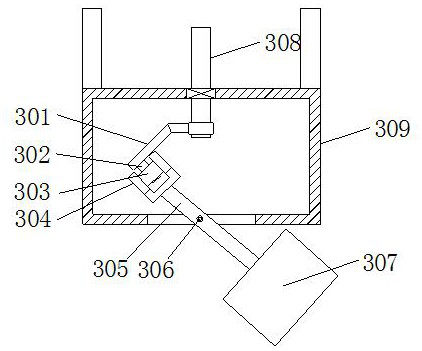

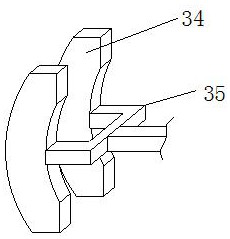

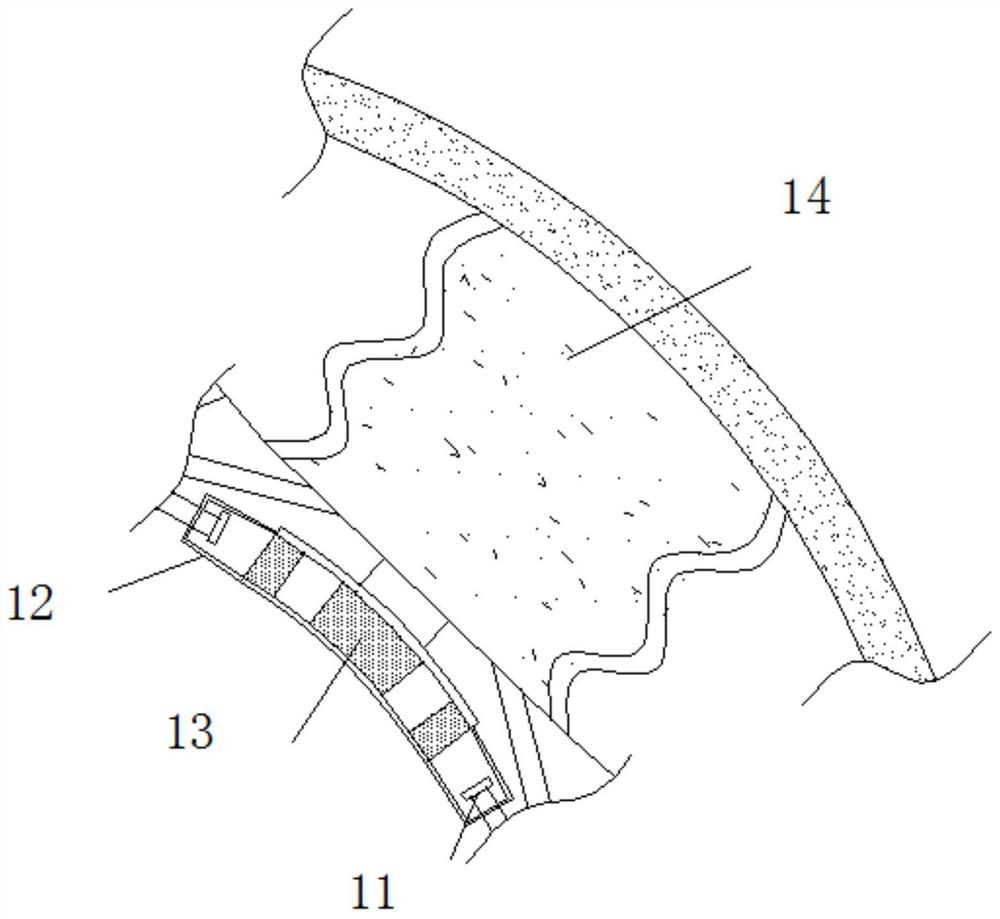

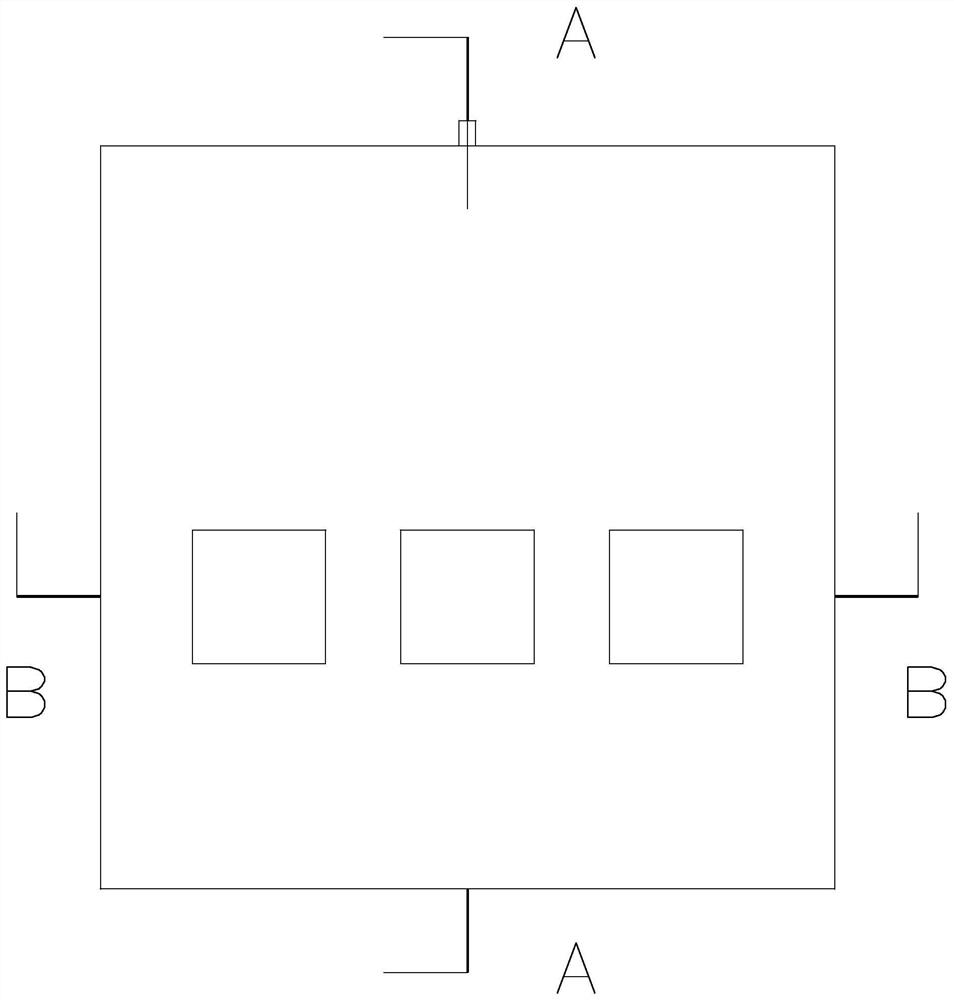

Double-side-rack type concrete mixing equipment

InactiveCN108214910AReduce stirring efficiencyStir wellCement mixing apparatusArchitectural engineering

Owner:南宁腾宁商品混凝土有限公司

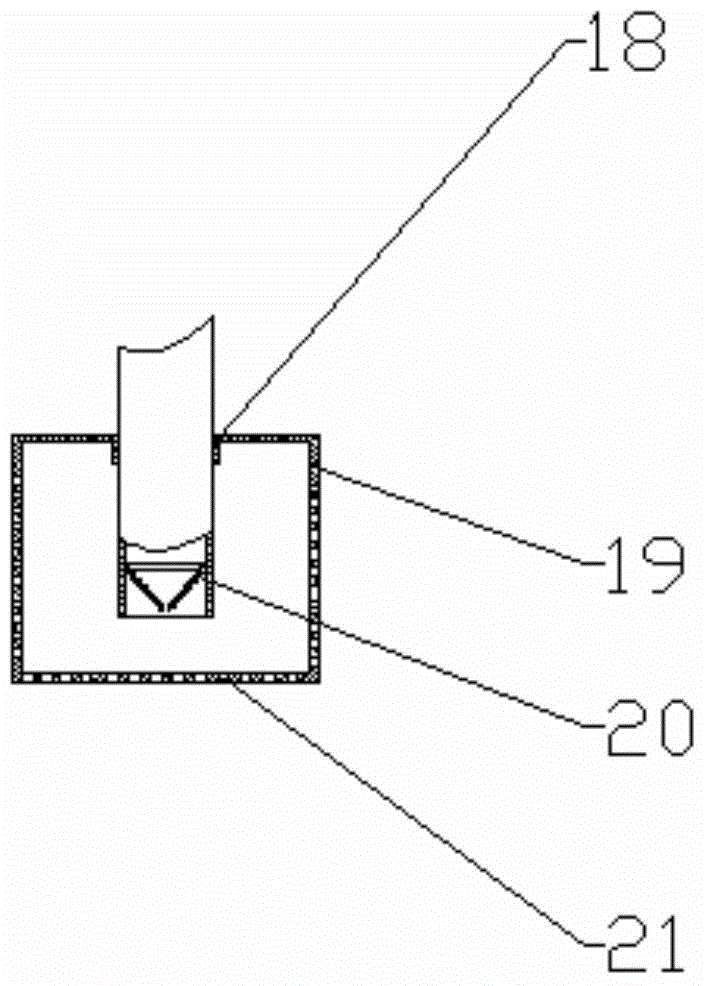

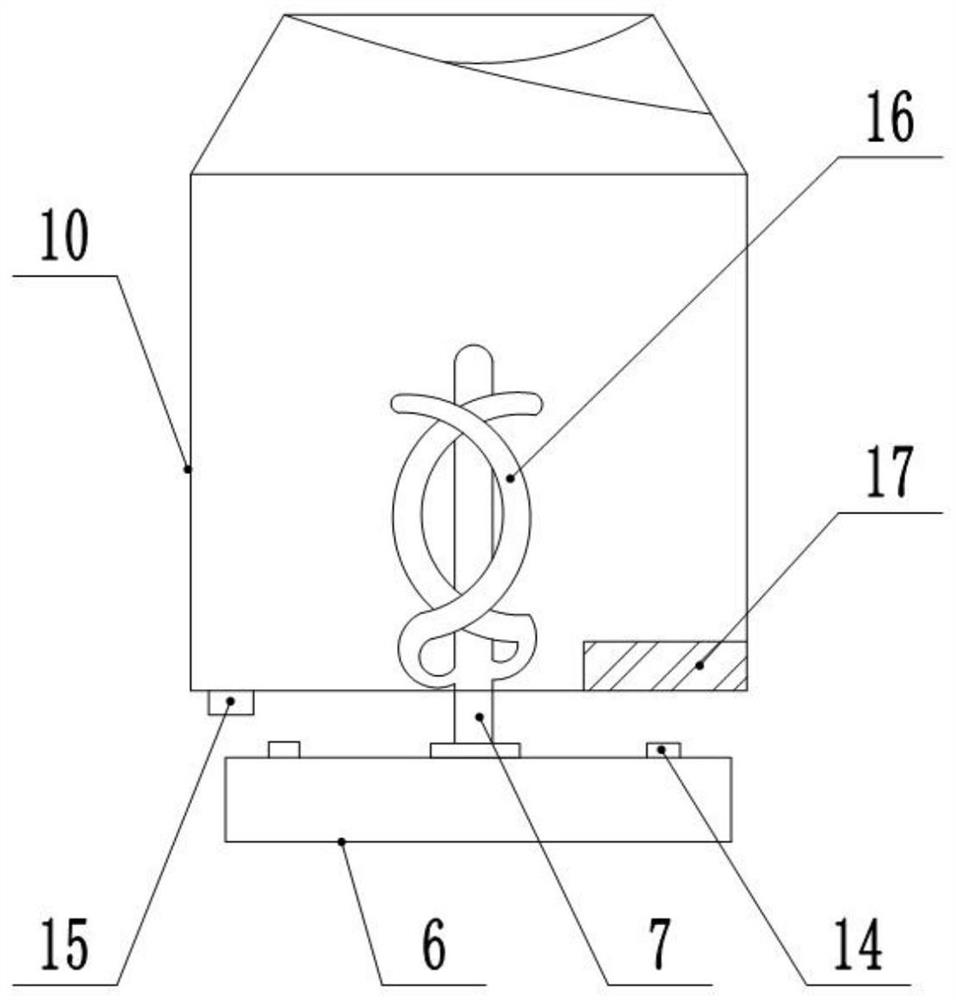

Efficient and even stirring equipment for simply and conveniently separating nonferrous metals

InactiveCN106474957AStir wellImprove stirring efficiencyShaking/oscillating/vibrating mixersRotary stirring mixersNonferrous metalEngineering

The invention relates to stirring equipment, in particular to efficient and even stirring equipment for simply and conveniently separating nonferrous metals. The efficient and even stirring equipment for simply and conveniently separating nonferrous metals is simple and convenient to operate and can stir evenly and has a carrying effect. In order to solve the technical problem, the invention provides the efficient and even stirring equipment for simply and conveniently separating the nonferrous metals. The efficient and even stirring equipment for simply and conveniently separating the nonferrous metals further comprises a frame, a roller, a first belt pulley, a flat belt, a first bearing block, a second rotating shaft, a second belt pulley, a second bearing block, a first bevel gear, a rotating motor and the like. The roller can rotate. The lower part of the right wall of the frame is connected with a handle in a welding mode. The effect of separating the adhered nonferrous metals is achieved. Meanwhile, by the handle and the roller, the whole equipment can stir the nonferrous metals and can carry the nonferrous metal, and therefore, the labor is saved.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

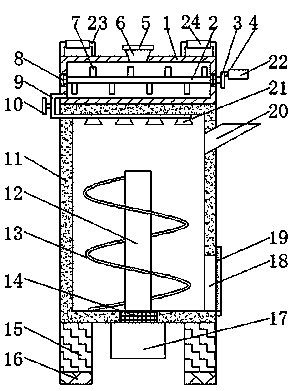

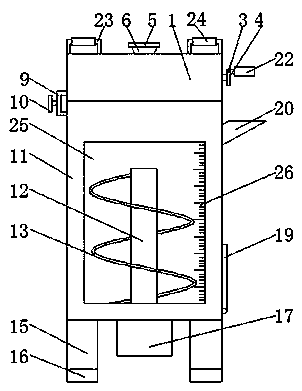

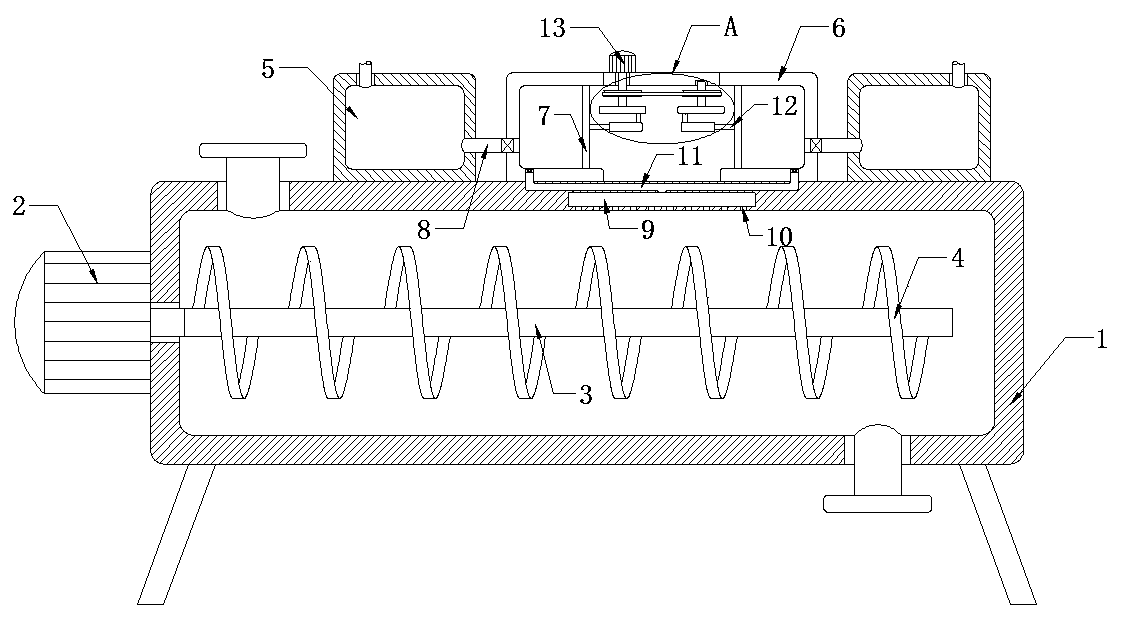

Stirring device for vegetable seeds

InactiveCN108465425AStir wellImprove stirring efficiencyRotary stirring mixersTransportation and packagingSpiral bladeEngineering

The invention discloses a stirring device for vegetable seeds. The device comprises a first stirring box, the bottom surface of the first stirring box is fixedly connected with two symmetrical supporting legs, the upper part of the right side surface of the first stirring box fixedly communicates with a first material inlet, the lower part of the right side surface of the first stirring box is provided with a material outlet, the lower part of the right side surface of the first stirring box is fixedly hinged with a material outlet door matched with the material outlet through hinges, and themiddle part of the inner bottom wall of the first stirring box is fixedly inlaid with a first bearing. According to the stirring device for the vegetable seeds disclosed by the invention, through arrangement of a second stirring rod, under action of a hand wheel and stirring blades, different pesticides in a second stirring box can be fully mixed, and drug properties of pesticides are played in amaximization manner; and through arrangement of spraying heads and a spiral blade, under action of a pipeline, a stirring motor and a first stirring rod, the vegetable seeds in the first stirring boxcan be sprayed while being turned up and down, so that the vegetable seeds are in full contact with the pesticides, stirring efficiency is high, and stirring is uniform.

Owner:WUXI IGROWTHS TECH CO LTD

Silver ion antibacterial fabric and application thereof

PendingCN112921434ANot easy to fall offLong-lasting antibacterial and deodorant effectArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentSpinningSilver ion

The invention discloses a silver ion antibacterial fabric and application thereof. A preparation method of the silver ion antibacterial fabric comprises the following steps of S1, weighing the following raw materials in parts by weight of 50-60 parts of polyacrylonitrile, 100-120 parts of a solvent and 130-150 parts of water; S2, putting polyacrylonitrile and the solvent serving as raw materials into a mixing and stirring device, and stirring at the temperature of 80-90 DEG C for 2-3 hours to obtain a mixture; S3, after silver is purified through an electrolytic method, putting silver into water to be subjected to micro-electrolysis, releasing anions, and obtaining a colorless and transparent silver ion water solution; S4, putting the mixture into the silver ion water solution, adjusting the stirring speed, stirring until the color of the solution becomes light yellow, and carrying out a vacuumizing treatment process on the stock solution to obtain a fiber stock solution; and S5, performing emulsion spinning on the fiber stock solution to obtain nascent fibers, and performing water washing, drafting, oiling and curling post-processing procedures to form the silver ion antibacterial fabric.

Owner:刘国成

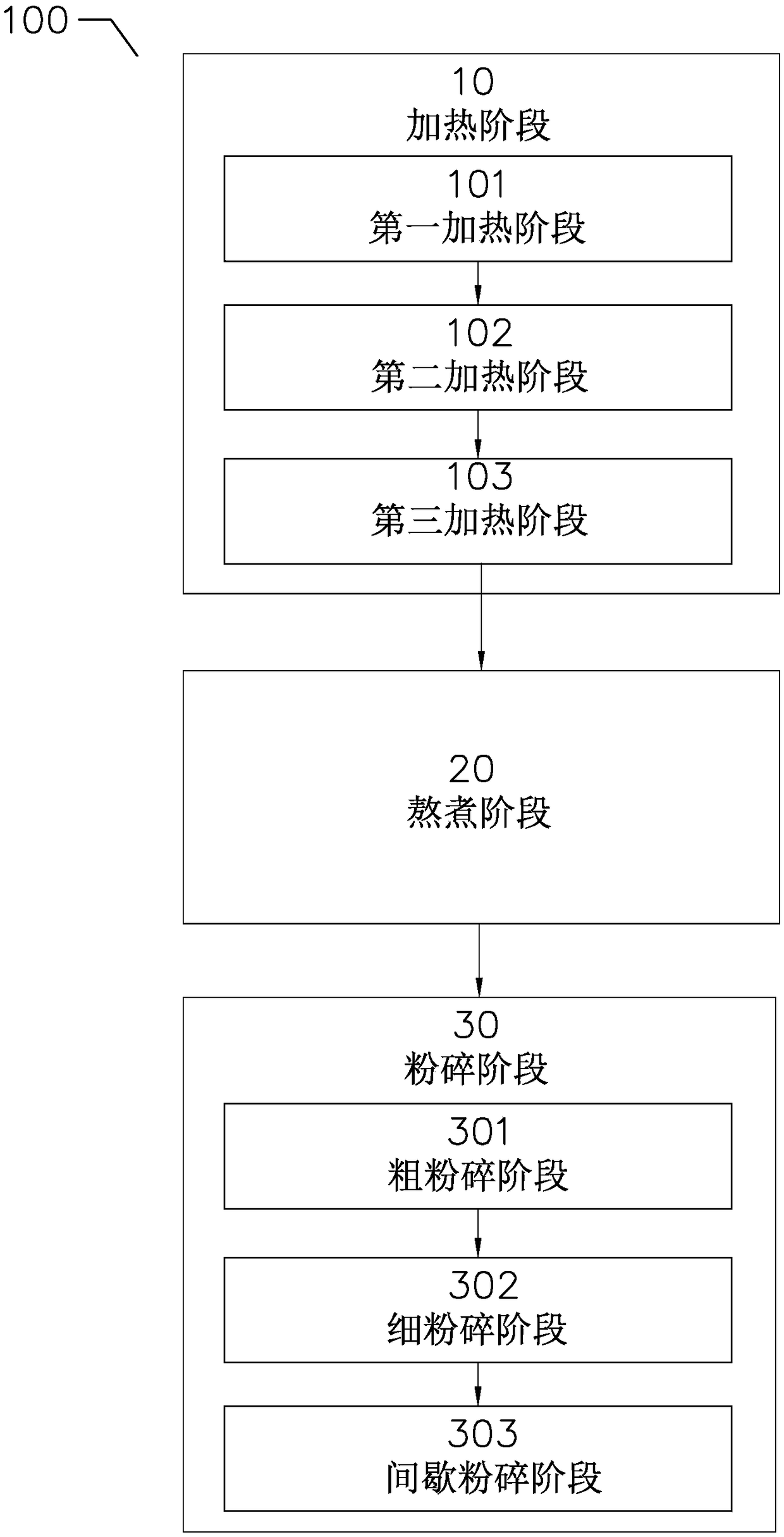

Pulping method of food processor

Owner:JOYOUNG CO LTD

Plastic processing stirring device

PendingCN114378969ASolve the phenomenon of uneven mixingReduce stirring efficiencyNon-rotating vibration suppressionGear wheelDamping function

The plastic processing stirring device comprises a shell, the top of the shell is fixedly connected with a first motor, and the output end of the first motor penetrates into an inner cavity of the shell and is fixedly connected with a spiral rotating shaft. According to the invention, the spiral rotating shaft, the circular mounting barrel, the rotating barrel, a gear ring, a gear, a first through hole, a first bevel gear, a third stirring rod, a supporting column, a damper, a spring, a first limiting plate, an extension box, an extension plate, a threaded supporting rod, a first bearing, a second bevel gear and a second limiting plate are cooperatively used; the plastic processing and stirring device solves the problems that an existing plastic processing and stirring device is generally single in plastic stirring structure in the using process, so that the phenomenon of non-uniform stirring is likely to occur in the stirring process, meanwhile, the stirring efficiency is reduced, the device generally does not have a damping function in the stirring process when the device works, and the stirring efficiency is reduced. And certain inconvenience can be caused to the use of a user.

Owner:张家港市三塑机械有限公司

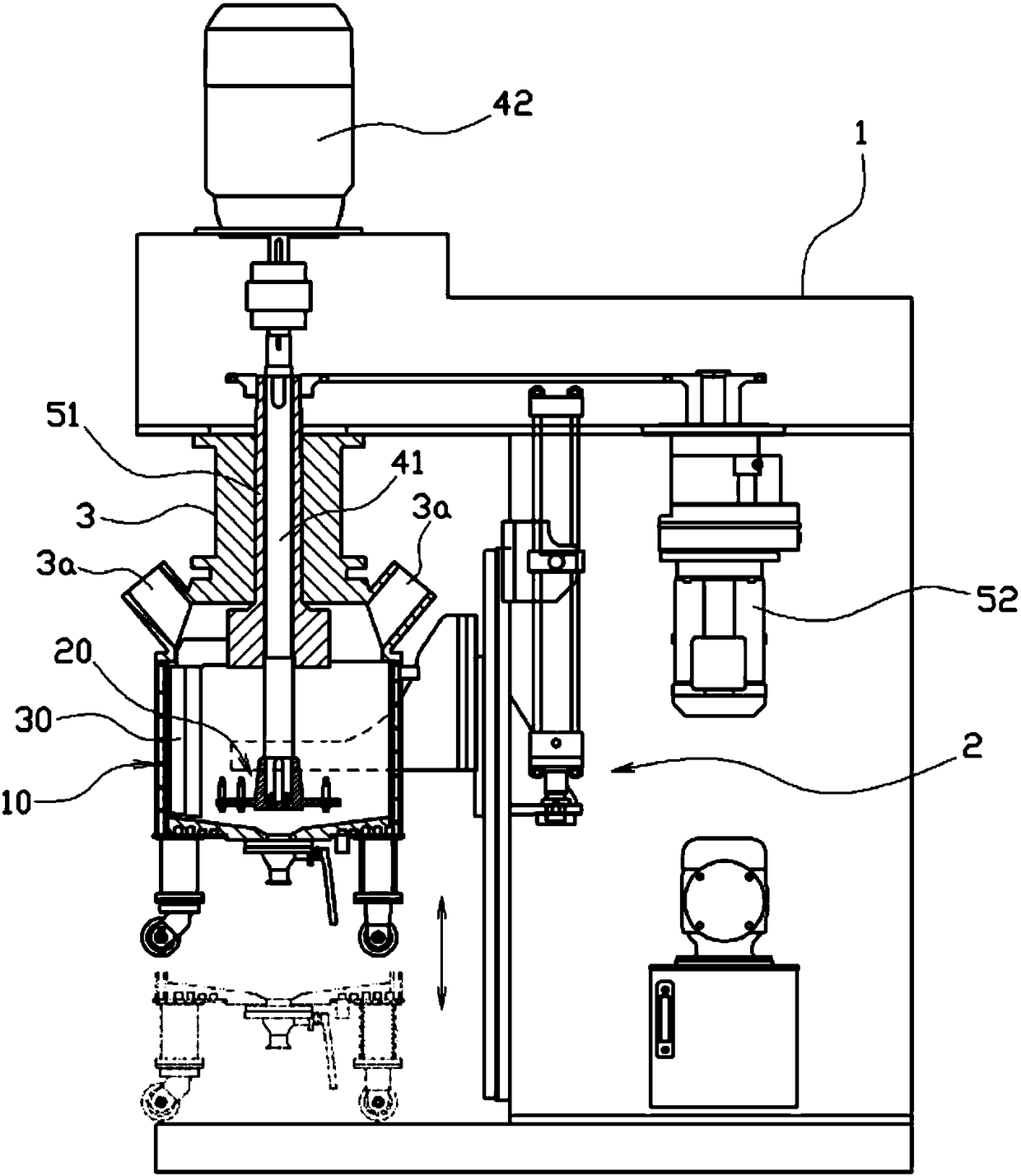

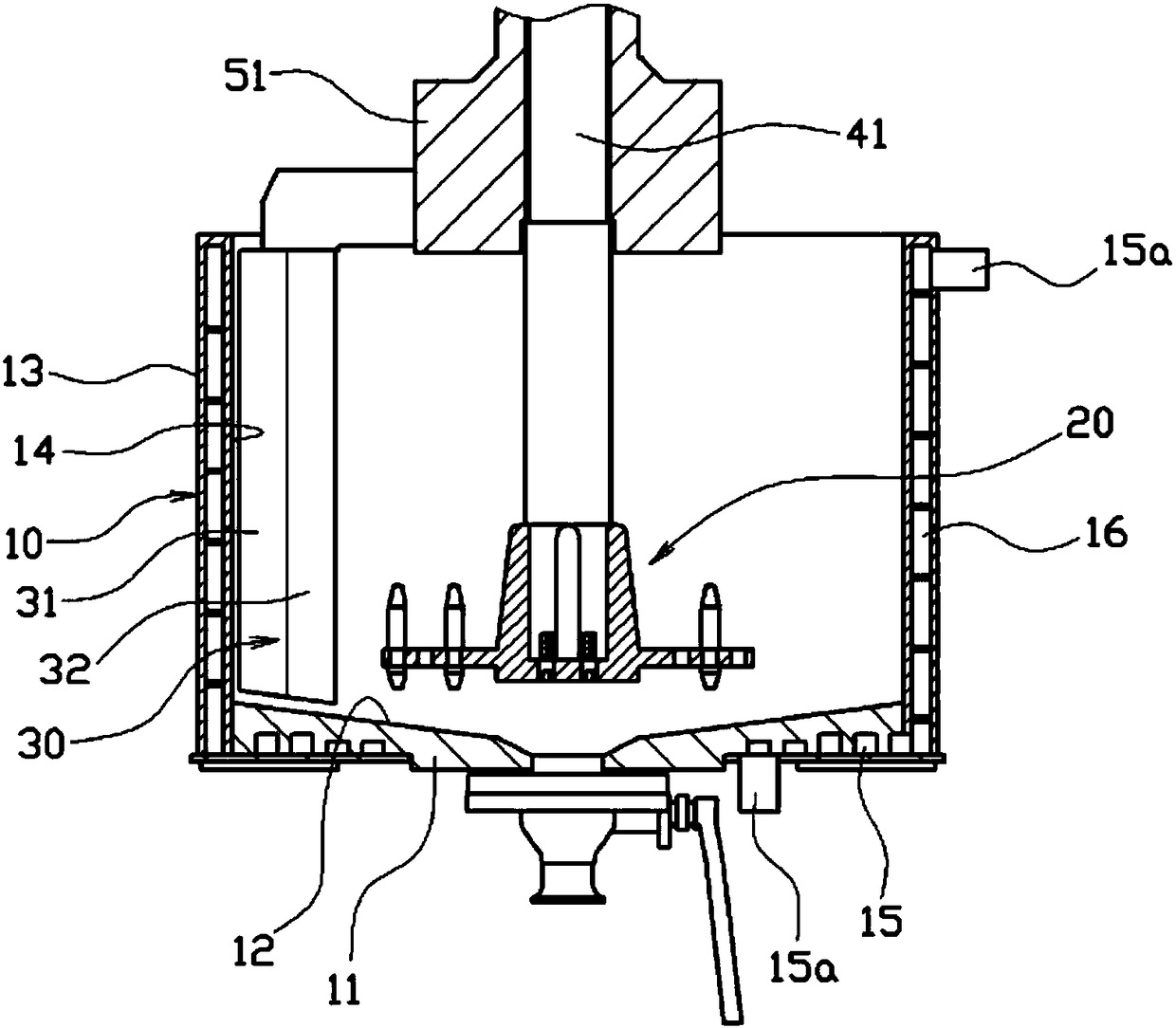

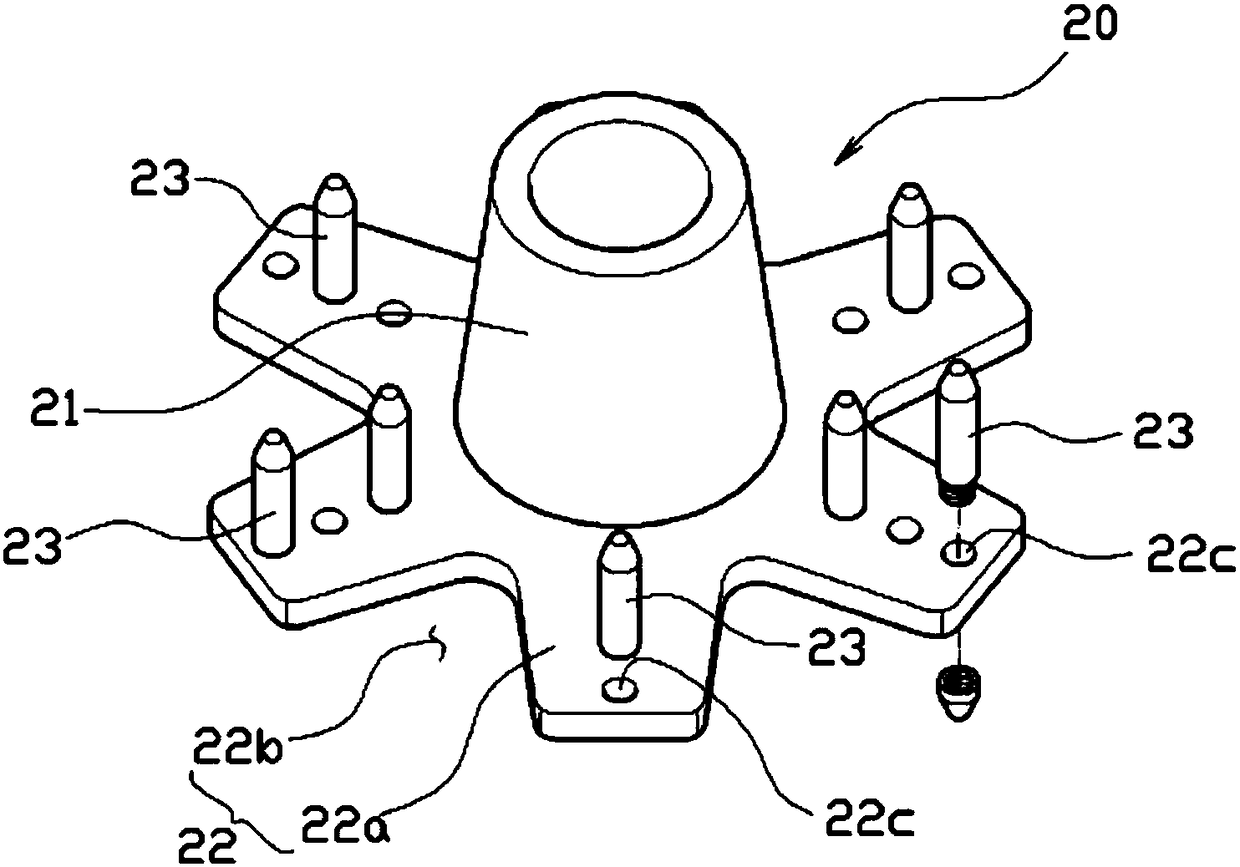

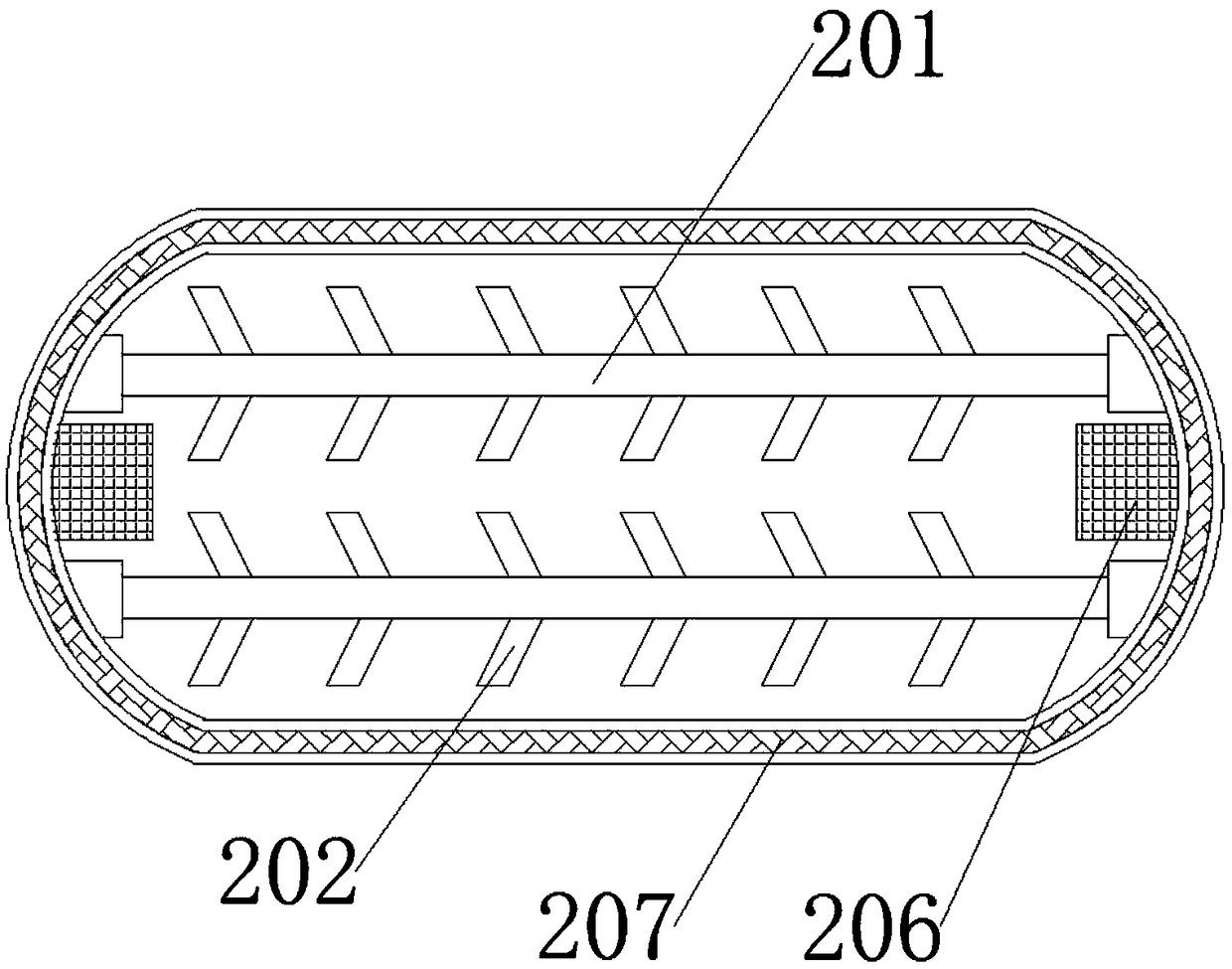

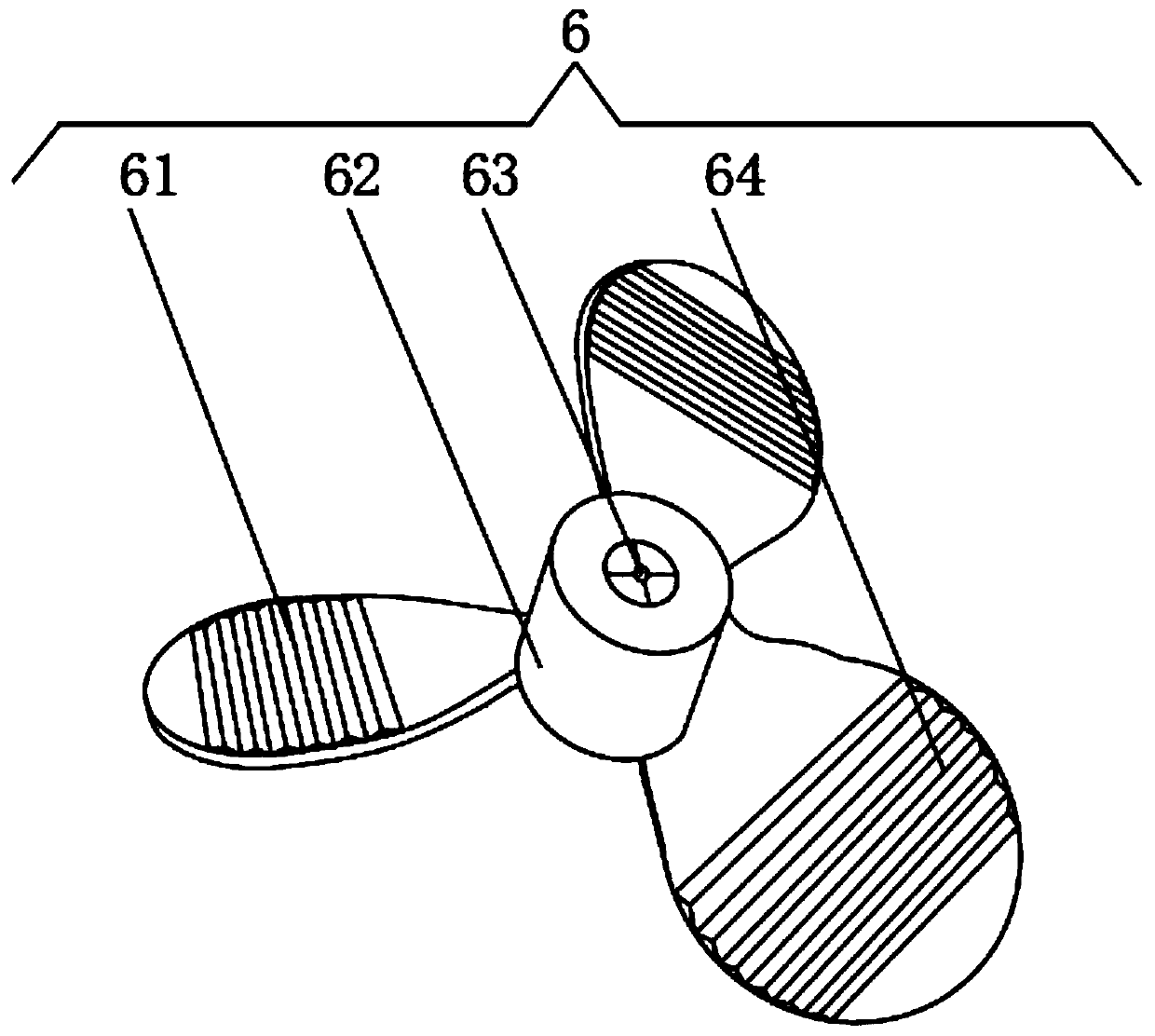

Slurry mixer for battery electrode

ActiveCN108325420ASimple structureReduce rotational loadFinal product manufactureRotary stirring mixersLow speedMixed materials

According to the present invention, provided is a slurry mixer for a battery electrode which allows an agitator to separately have a high-speed agitator and a low-speed agitator to input a mixed material at the same time so as to uniformly disperse and mix the same, and allows the configuration of the high-speed agitator to be maximally simplified to minimize a rotating load so as to be able to set a high-speed rotation of an electric motor, thereby improving the productivity by greatly shortening an agitation time of slurry. The slurry mixer for the battery electrode of the present inventioncomprises: a container for accommodating a mixed material consisting of a liquid material and a powdery material, and having a bottom portion formed with an inclined bottom surface and a side wall portion formed with an inner circumferential surface erected from an edge portion of the inclined bottom surface; a high-speed agitator for flowing and agitating the mixed material, and having an inclined cylindrical portion, a plurality of radially-arranged agitating pieces, a rotating plate having agitating grooves alternately arranged, and a plurality of agitating rods fixed to the agitating pieces of the rotating plate; a high-speed electric motor for rotating the high-speed agitator; a low-speed agitator having a blade surface for separating the mixed material attached onto the inner circumferential surface of the container therefrom and a swirling surface for moving the mixed material located at an edge portion in the container to the center; and a low-speed electric motor for rotatingthe low-speed agitator.

Owner:TSI CO LTD

Efficient grinding fluid stirrer

PendingCN113209878AImprove stirring efficiencyReduce stirring efficiencyShaking/oscillating/vibrating mixersTransportation and packagingEngineeringAgitator

The invention provides an efficient grinding fluid stirrer which comprises a shell and a power shell; the power shell is fixedly arranged at the upper end of the shell, a plurality of supports are evenly distributed at the side end of the shell in the circumferential direction, and a stirring cavity, a filtering cavity and a feeding cavity are formed in the shell; the power shell is rotationally connected with a first rotating shaft; the first rotating shaft penetrates through the shell and enters the interior of the stirring cavity; and a stirring rod is arranged at the lower end of the first rotating shaft, a plurality of blades are symmetrically arranged on the left side and the right side of the stirring rod, and a stirring assembly is fixedly connected to the bottom end of the stirring rod. The technical problems that in the stirring process, stirring is carried out in the same direction through the stirring rod, the needed stirring time is long, raw materials at the bottom of a stirring chamber are usually difficult to stir, the grinding fluid mixing efficiency is low, then the raw materials at the bottom of the stirring chamber cannot be evenly mixed, the raw material mixing effect is poor, and the use effect of the grinding fluid is influenced are solved through the stirring assembly.

Owner:SHENZHEN COFUN GRINDING MATERIALS CO LTD

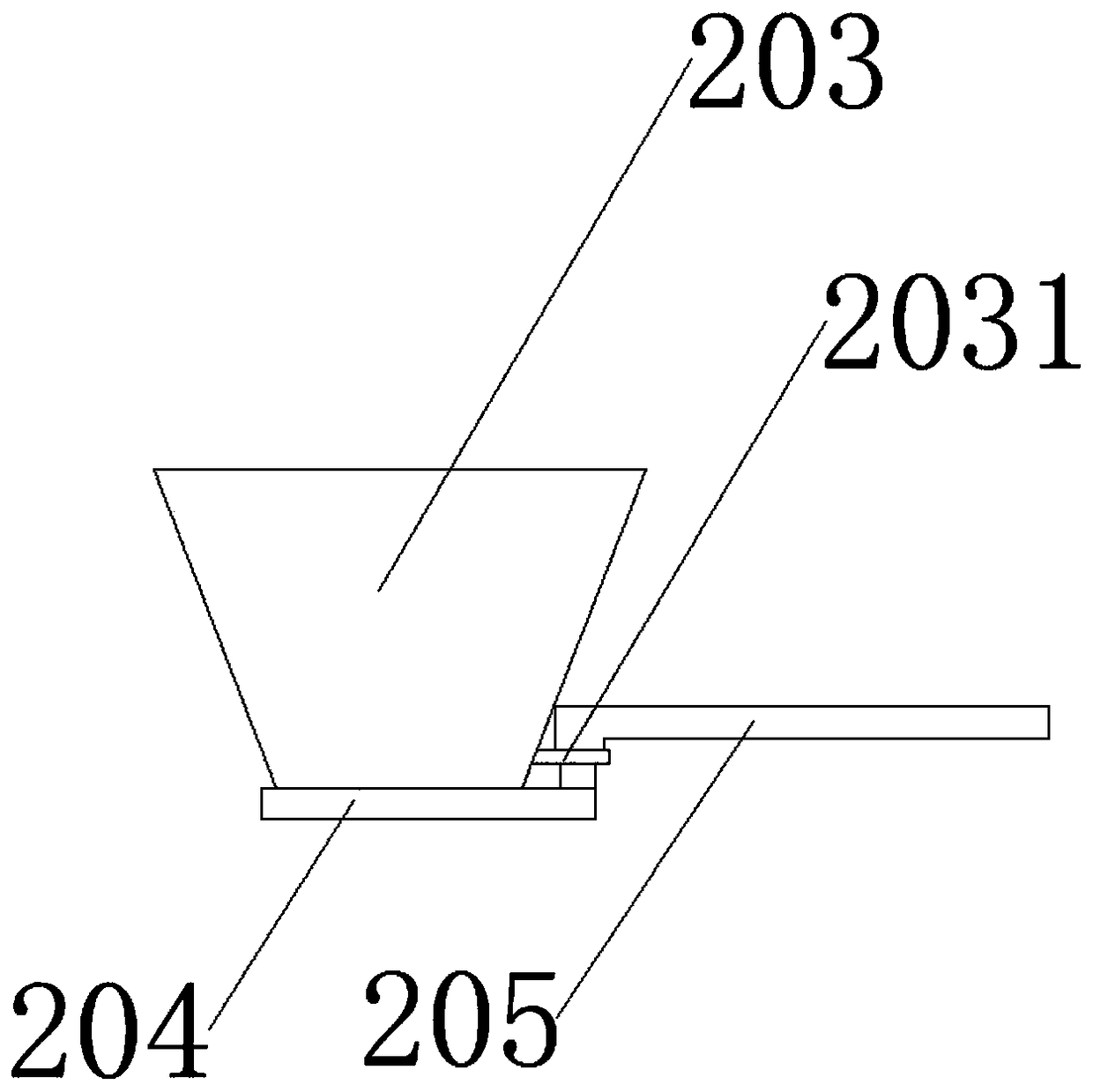

Production device of PVC plastic ground mat and improved process thereof

PendingCN113665017AGood mixing effectShorten mixing timeHollow article cleaningProcess engineeringPlasticizer

The invention discloses a production device of a PVC plastic ground mat and an improved process thereof. The production device comprises a material mixing shell and a feeding structure; the feeding structure comprises a supporting column; the supporting column is fixedly connected to the top of the material mixing shell; the top end of the supporting column is fixedly connected with a feeding shell; the bottom of an inner cavity of the feeding shell is fixedly connected with a guide plate; the top of the material mixing shell is fixedly connected with a dual-axis motor; one output end of the dual-axis motor is fixedly connected with a feeding stirring shaft; the side surface of the feeding stirring shaft is fixedly connected with feeding stirring blades; the bottom of the feeding shell is fixedly connected with a communicating pipe; the communicating pipe is provided with an electromagnetic valve; and the communicating pipe is fixedly connected with the top of the material mixing shell. The dual-axis motor and other structures can drive the feeding stirring blades and other structures to rotate, the feeding stirring blades can be used for mixing and stirring plasticizers and other additives, so that the multiple additives are mixed uniformly, then the uniformly mixed additives are added into raw materials, the raw material stirring and mixing time is shortened, and the raw material mixing effect is better.

Owner:宣以龙

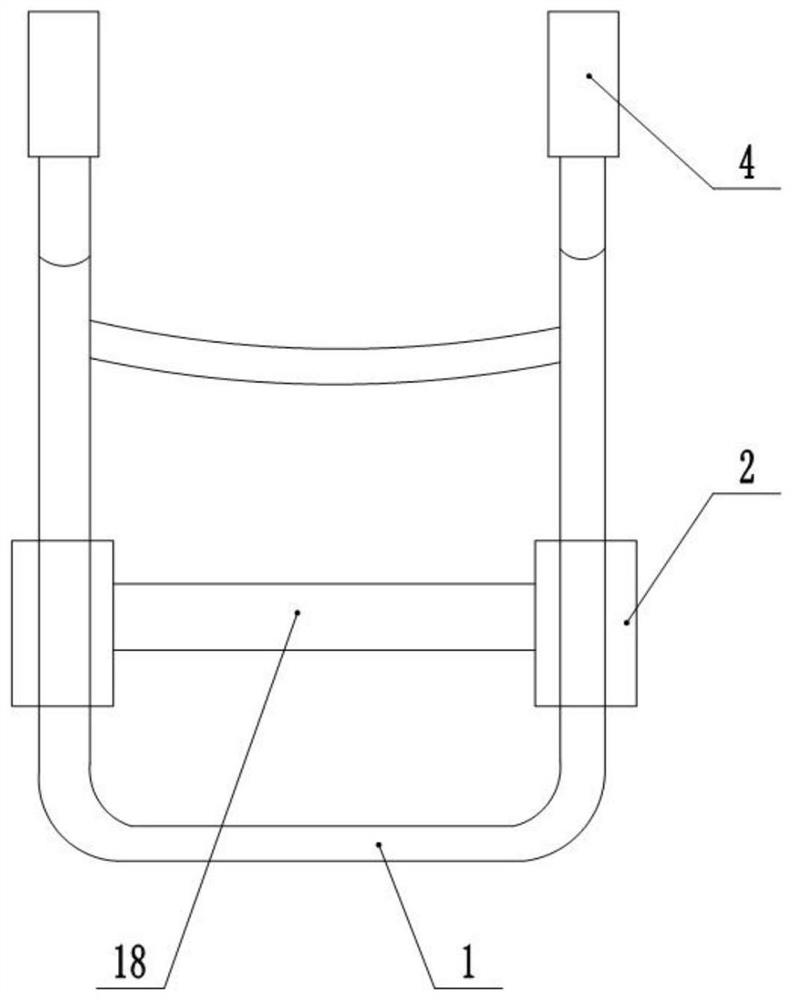

Simple vertical stirrer

The invention discloses a simple vertical stirrer comprising a bracket, a stirring shaft and a stirring barrel, wherein the bracket is in bilateral symmetry, a beam is arranged on the upper part of the middle of the bracket, is provided with a ceramic base plate and is provided with a stirring motor through the ceramic base plate, and an output shaft of the stirring motor is connected to the stirring shaft; the stirring barrel is located below the beam in the middle of the bracket, and the bottom edge of the stirring barrel is provided with a circle of arc bulges on which a plurality of convex hulls are uniformly distributed; and in addition, the stirring shaft is also provided with two groups of stirring blades, the stirring blades at the upper part are vertically arranged relative to the stirring shaft, and the stirring blades at the lower part are arranged on the end face of the stirring shaft and are formed into an included angle of 60-75 DEG together with the stirring shaft. The simple vertical stirrer is simple in process, convenient to process, low in cost and good in stirring effect.

Owner:广西中盟机械有限责任公司

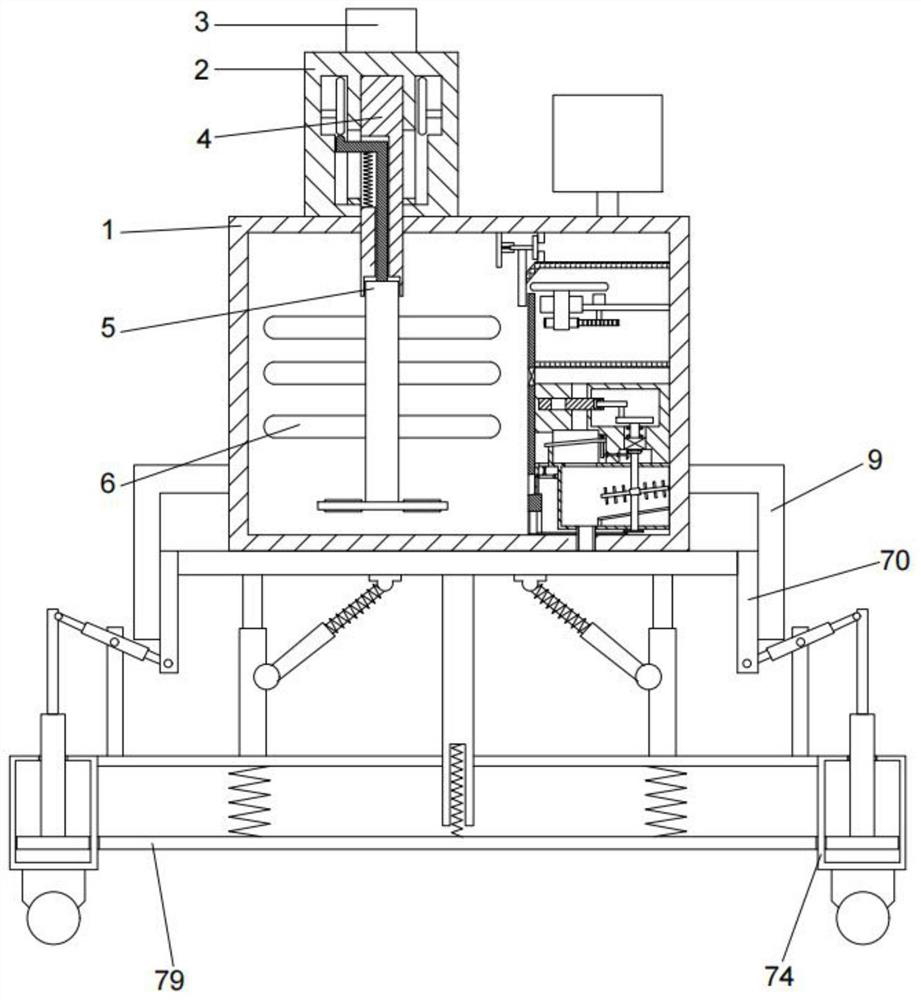

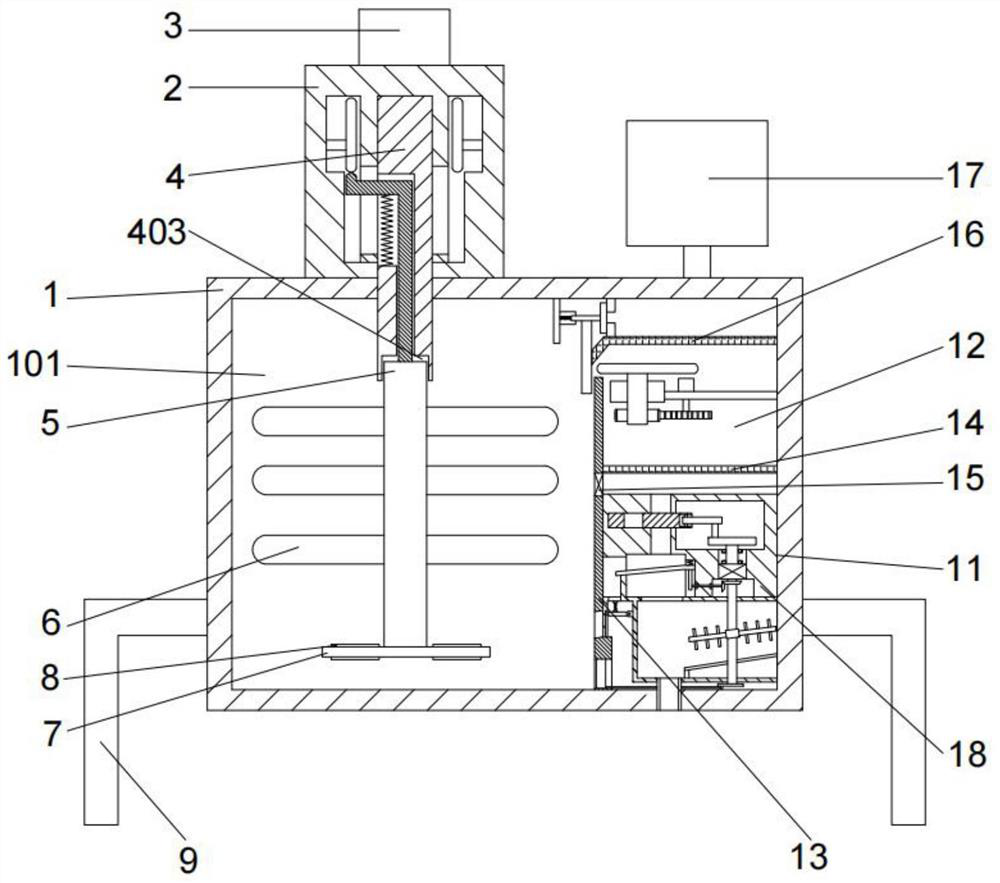

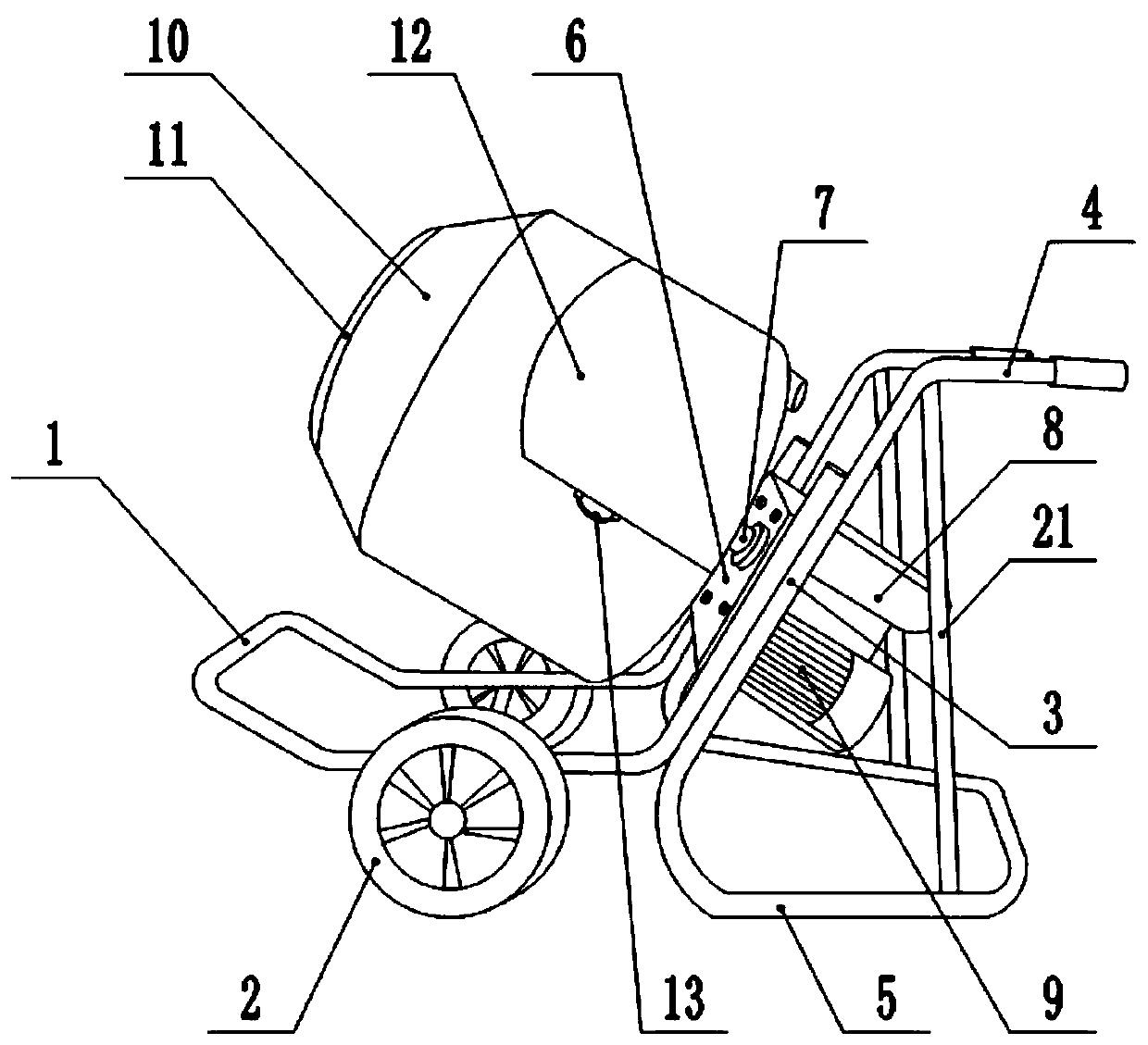

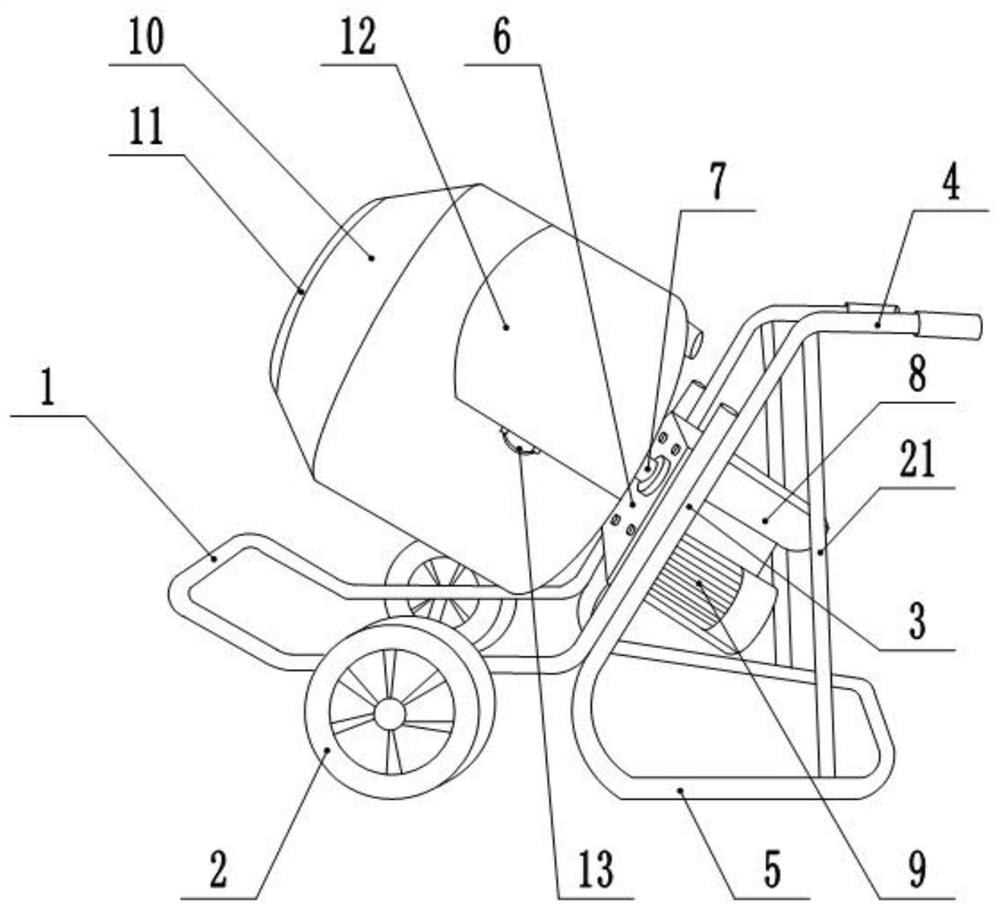

Concrete mixing equipment for water engineering construction

ActiveCN110666964AImprove shock absorptionEasy to moveCement mixing apparatusVehicle frameArchitectural engineering

The invention discloses concrete mixing equipment for water engineering construction. The concrete mixing equipment comprises a frame and a fixed rear seat. Wheels are arranged at the position, closeto the middle, of one side of the frame. A handle is fixedly mounted on the outer surface of the rear end of the frame. A handrail is fixedly mounted at one end of the handle. A supporting frame is fixedly mounted at the other end of the handle. An axle is arranged between the wheels. A rotating shaft is fixedly mounted on the outer surface of the front end of the fixed rear seat. A motor protection shell is fixedly mounted on the inner side of the handle. An electromotor is fixedly mounted on the outer surface of the lower end of the motor protection shell. A tank body is arranged at one endof the rotating shaft. The concrete mixing equipment for water engineering construction has the beneficial effects that the concrete mixing equipment for water engineering construction can be moved conveniently, the mixing efficiency can be improved, the interior of the equipment can be cooled, the structure is simple, and use is convenient.

Owner:SHANDONG WATER CONSERVANCY CONSTR ENG CO LTD

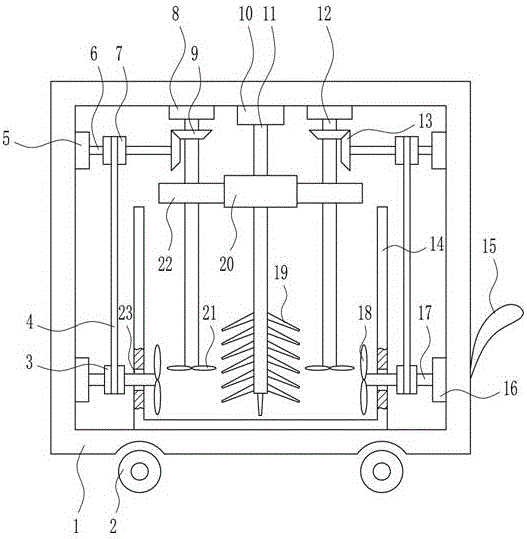

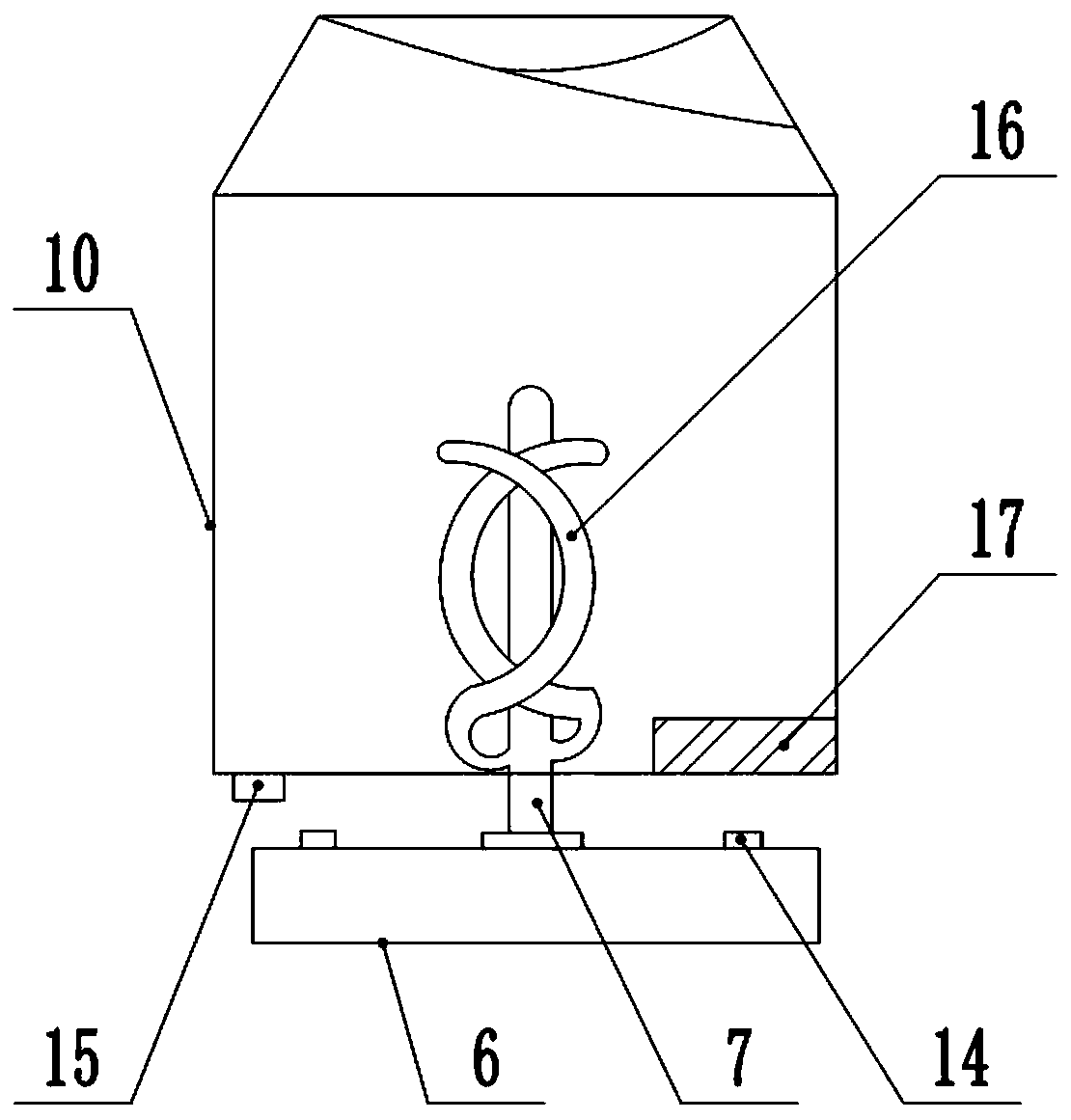

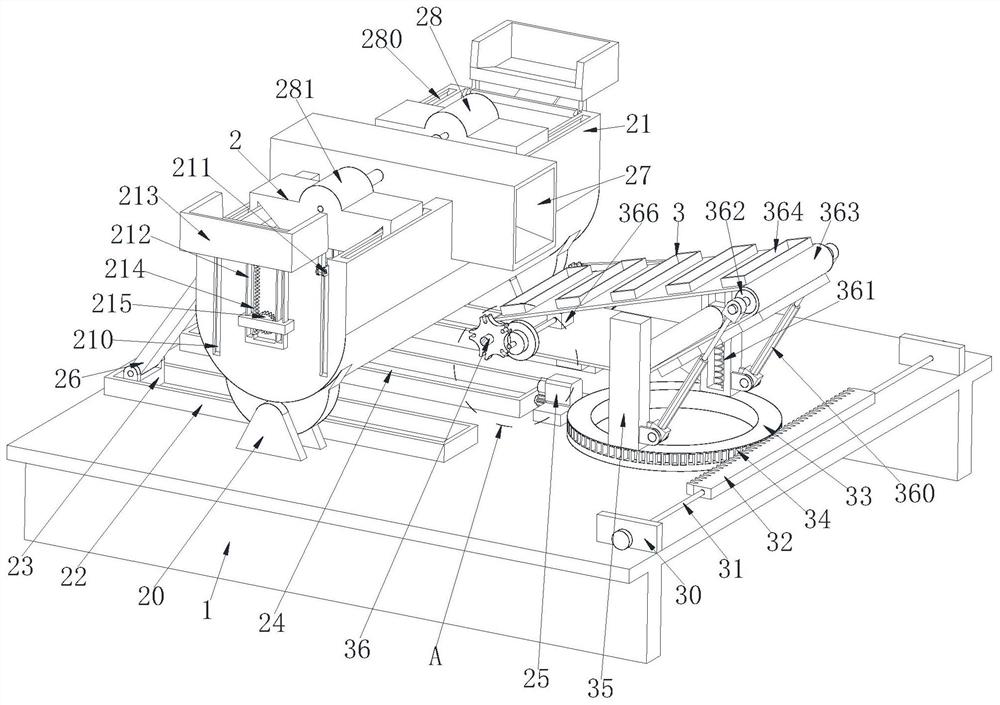

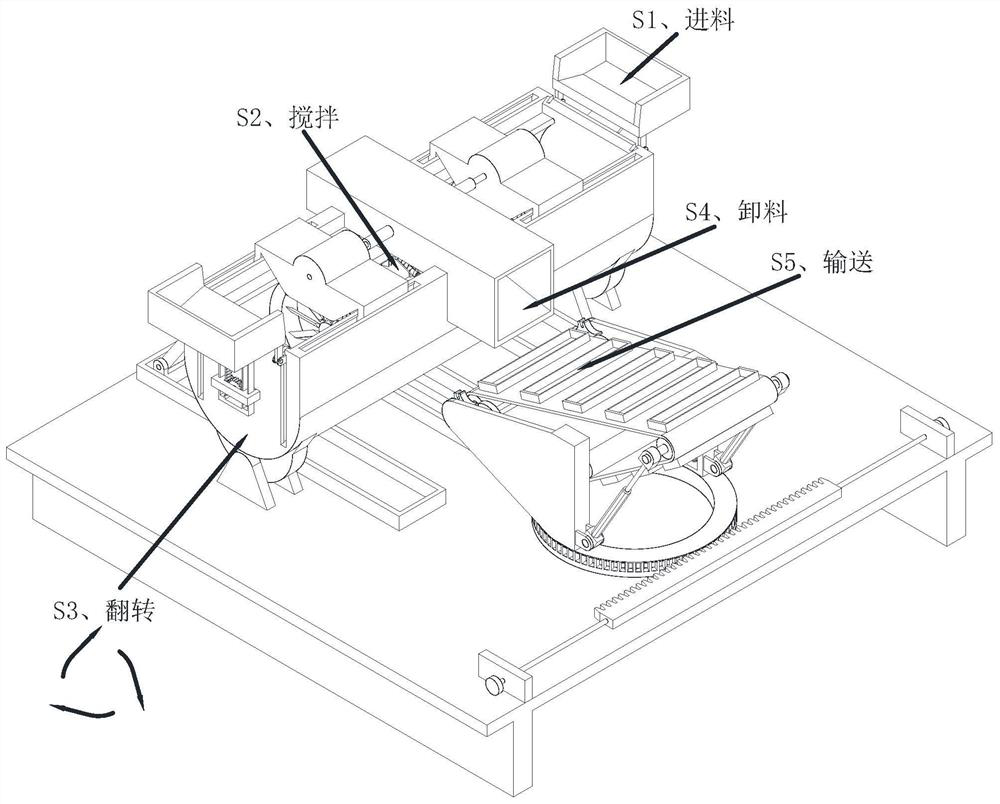

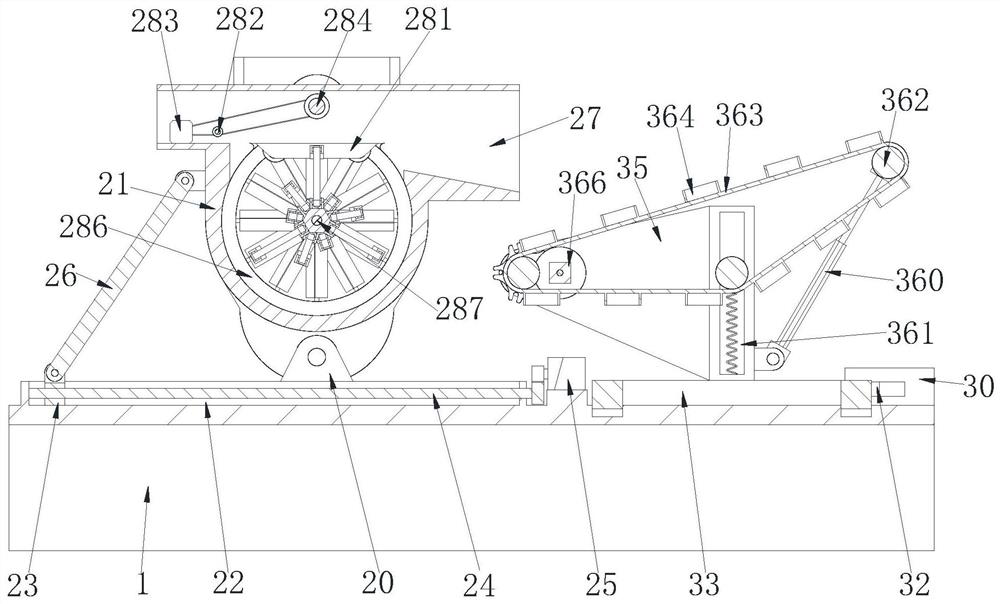

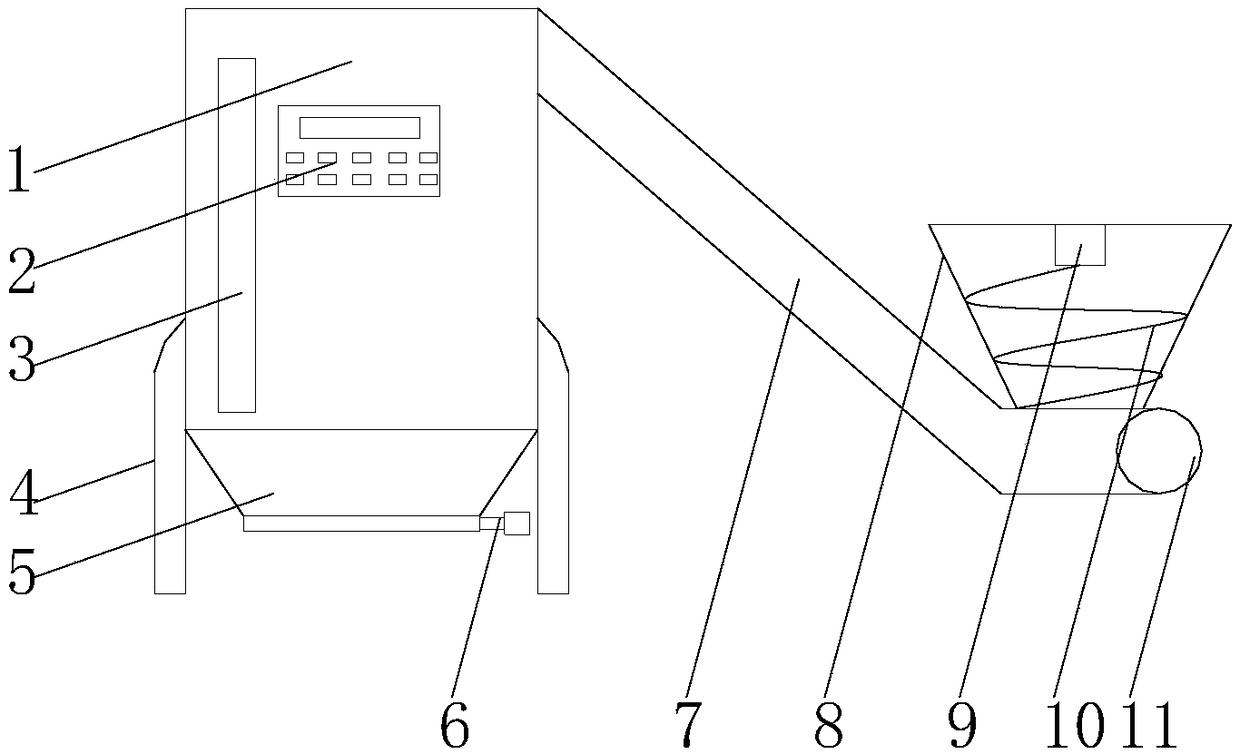

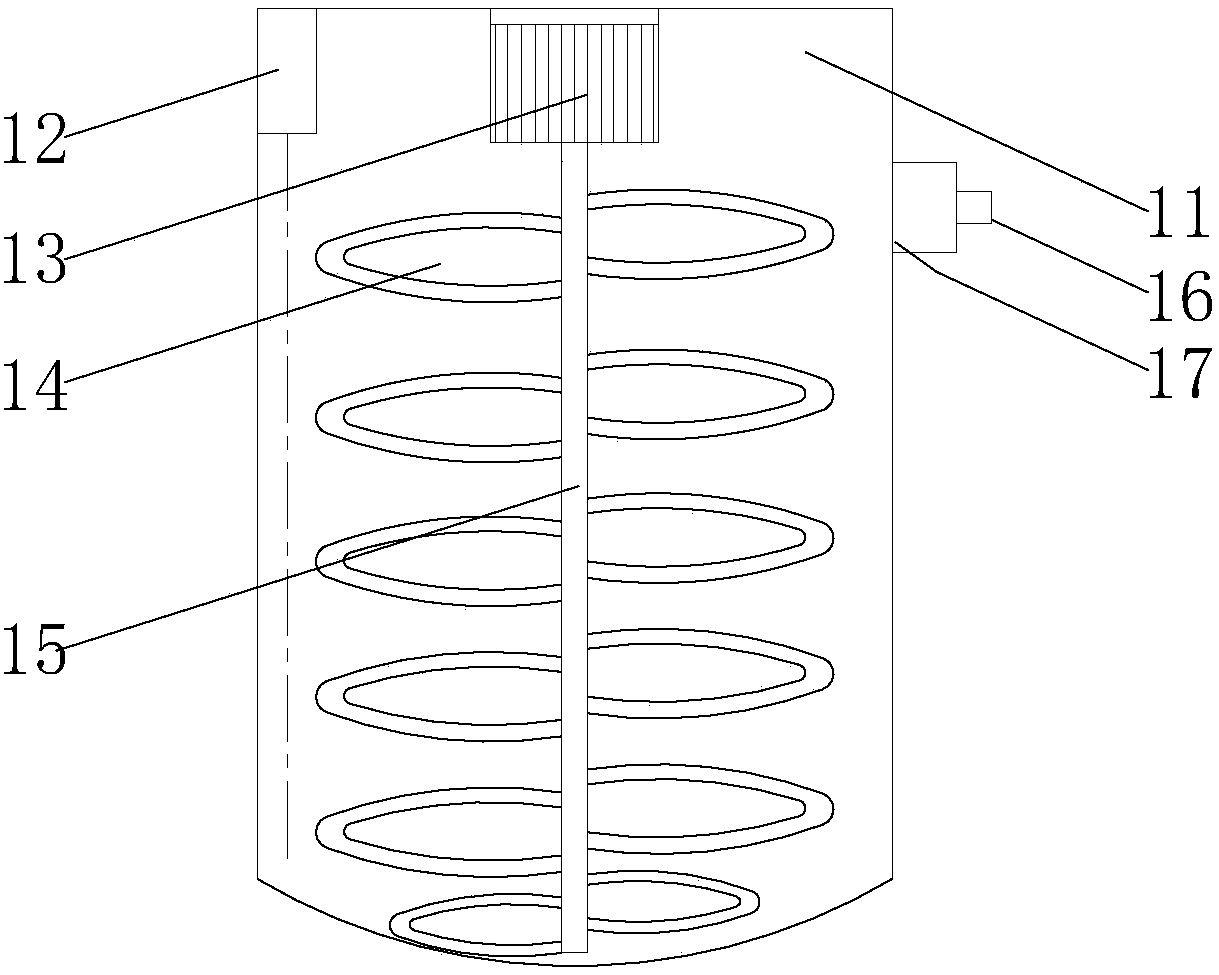

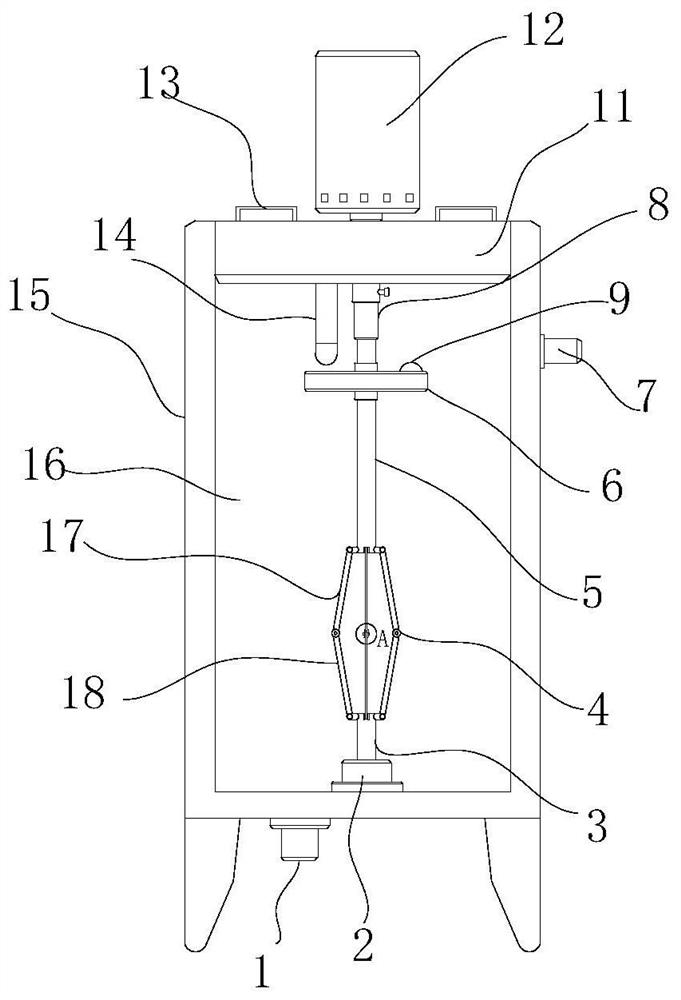

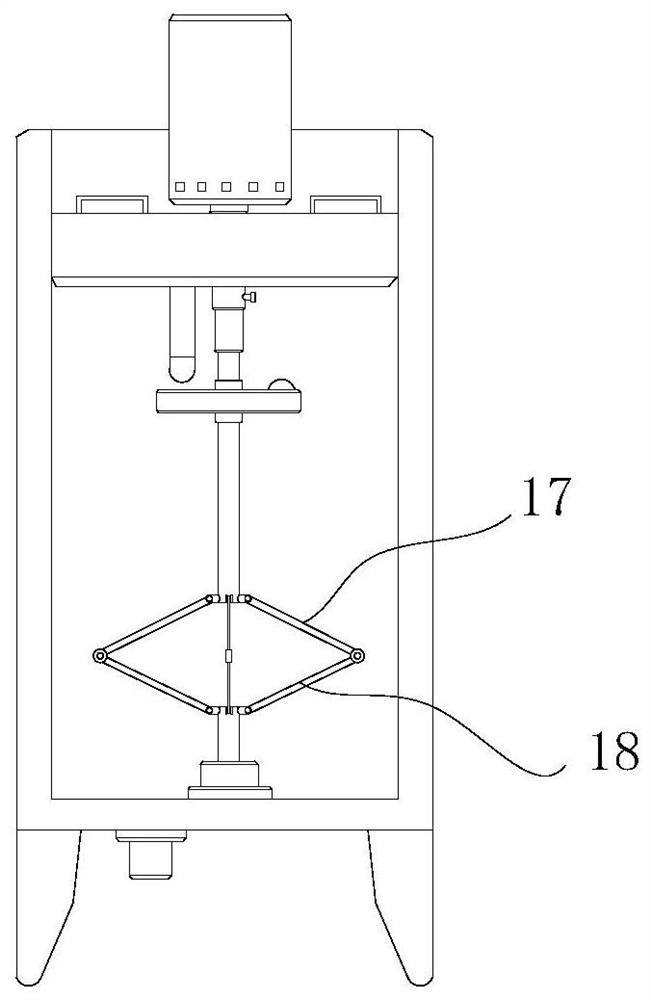

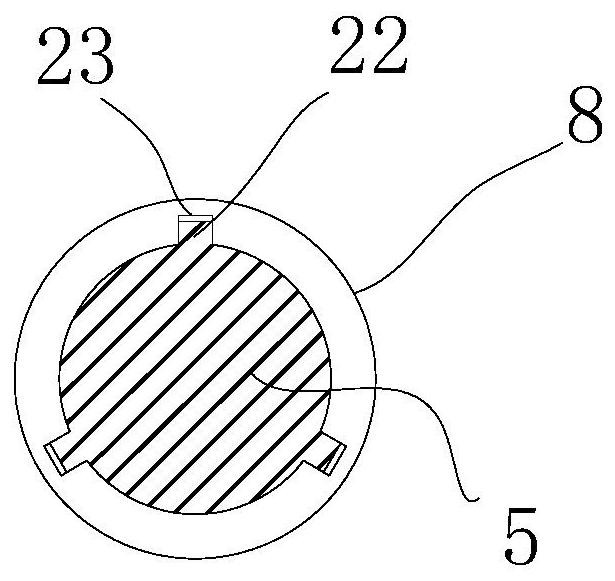

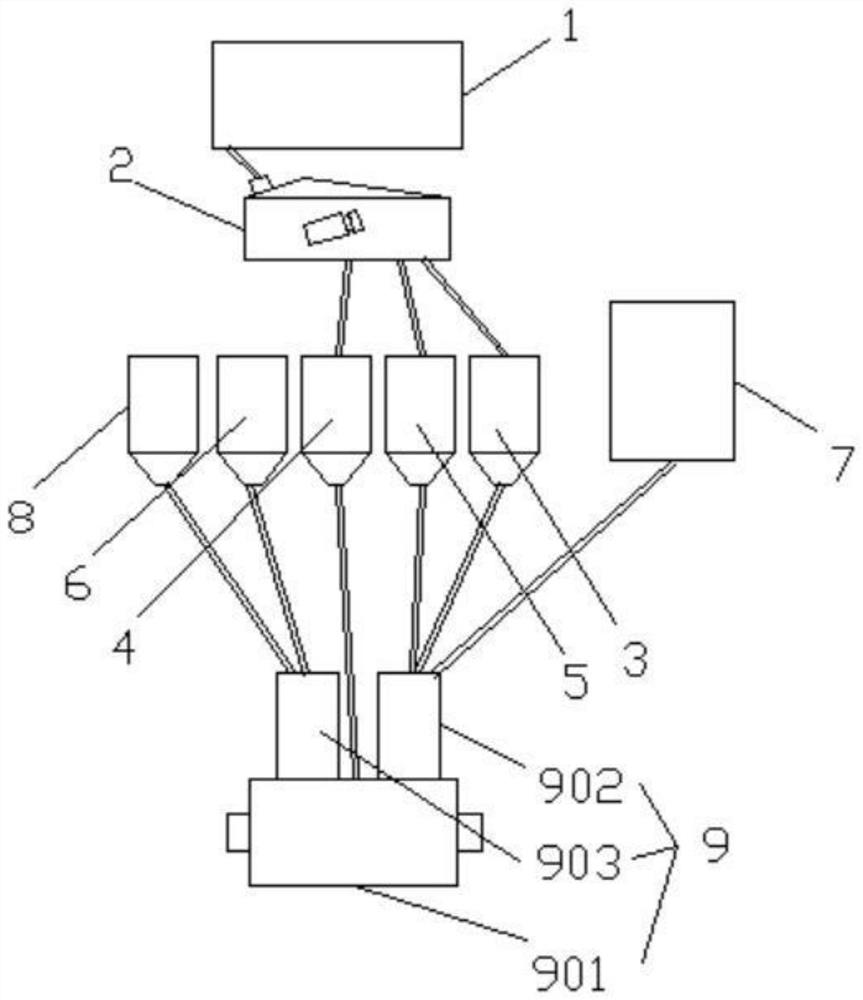

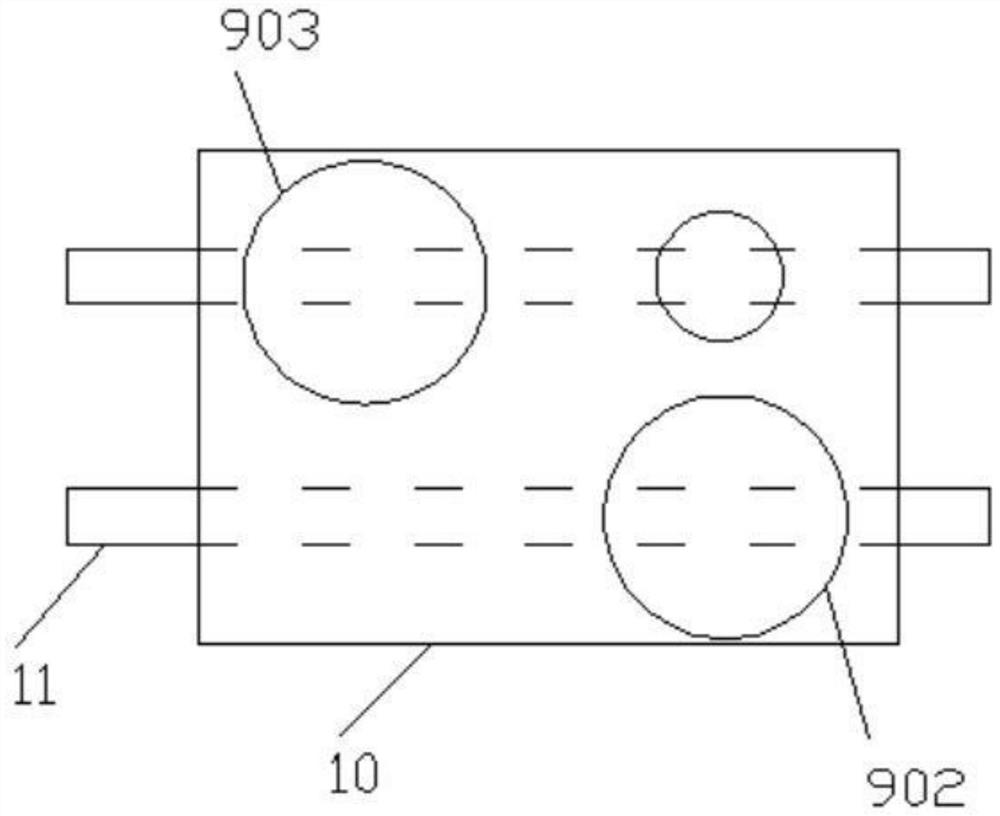

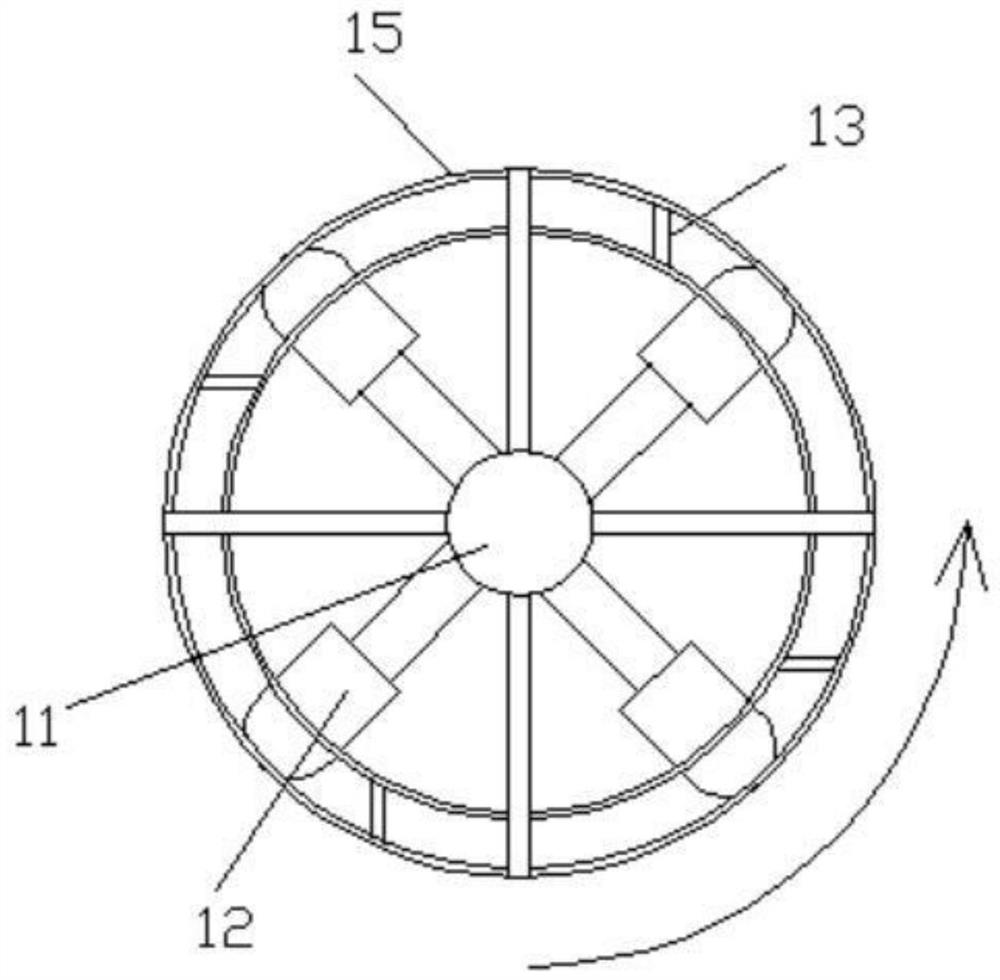

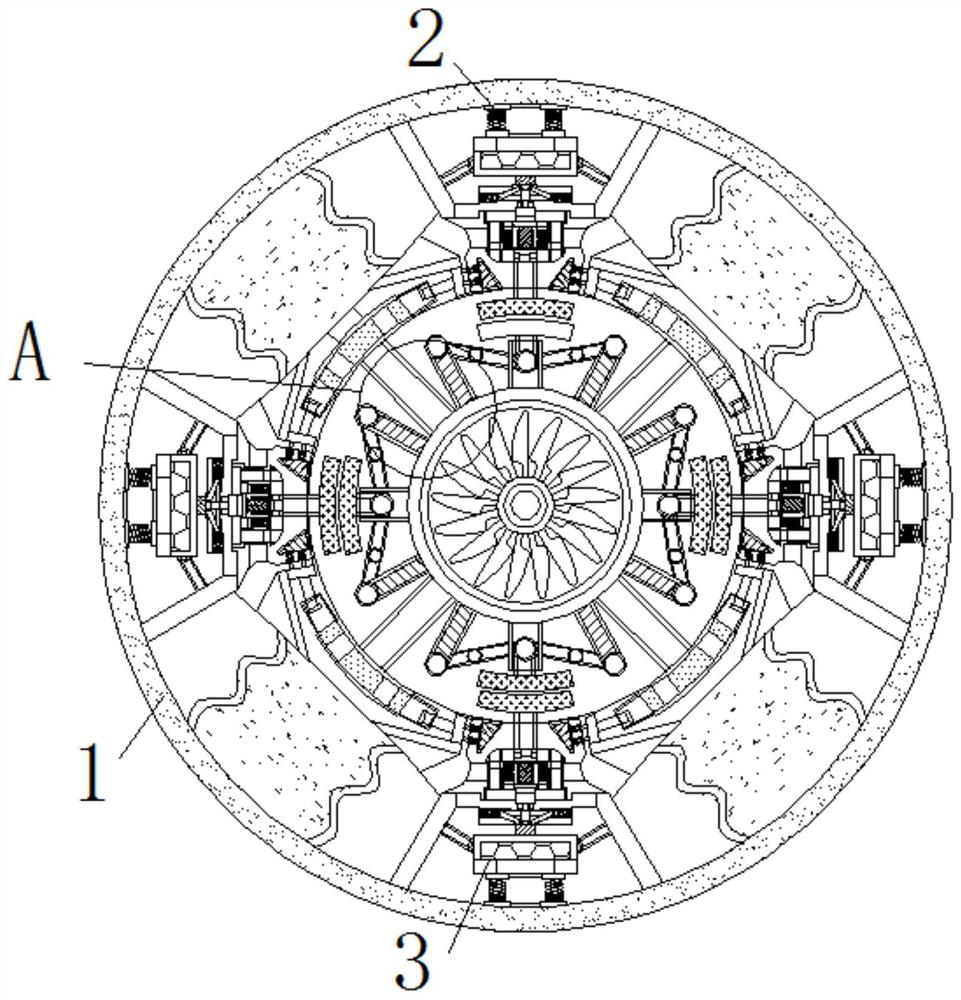

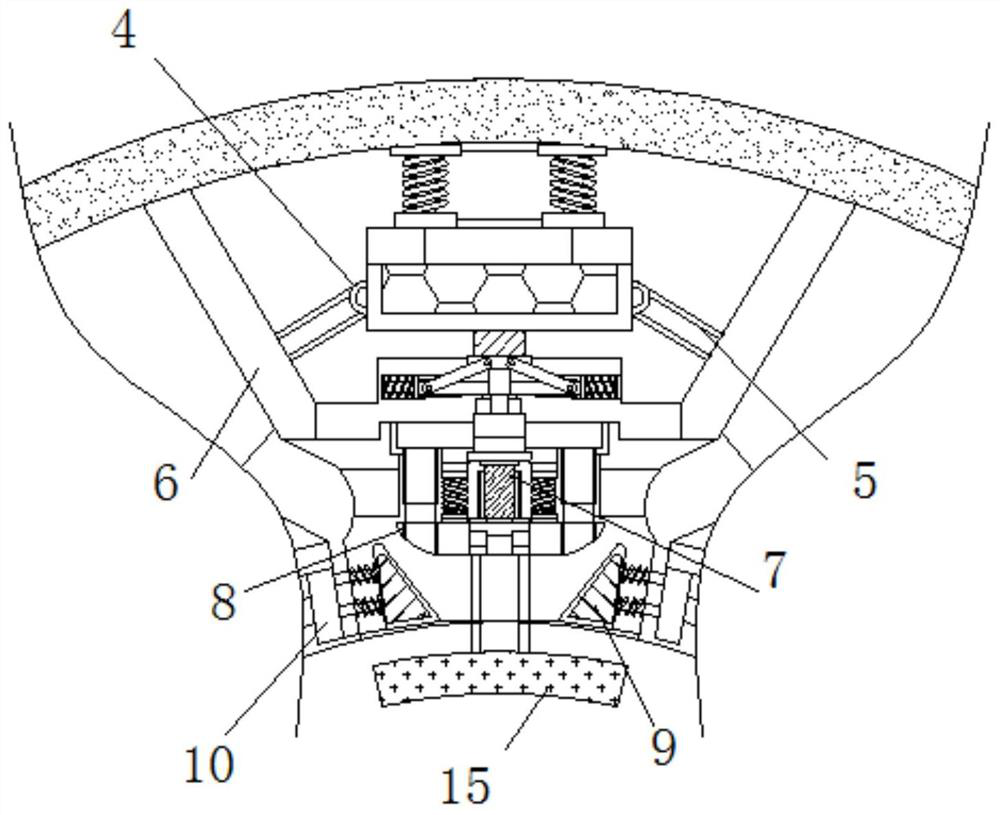

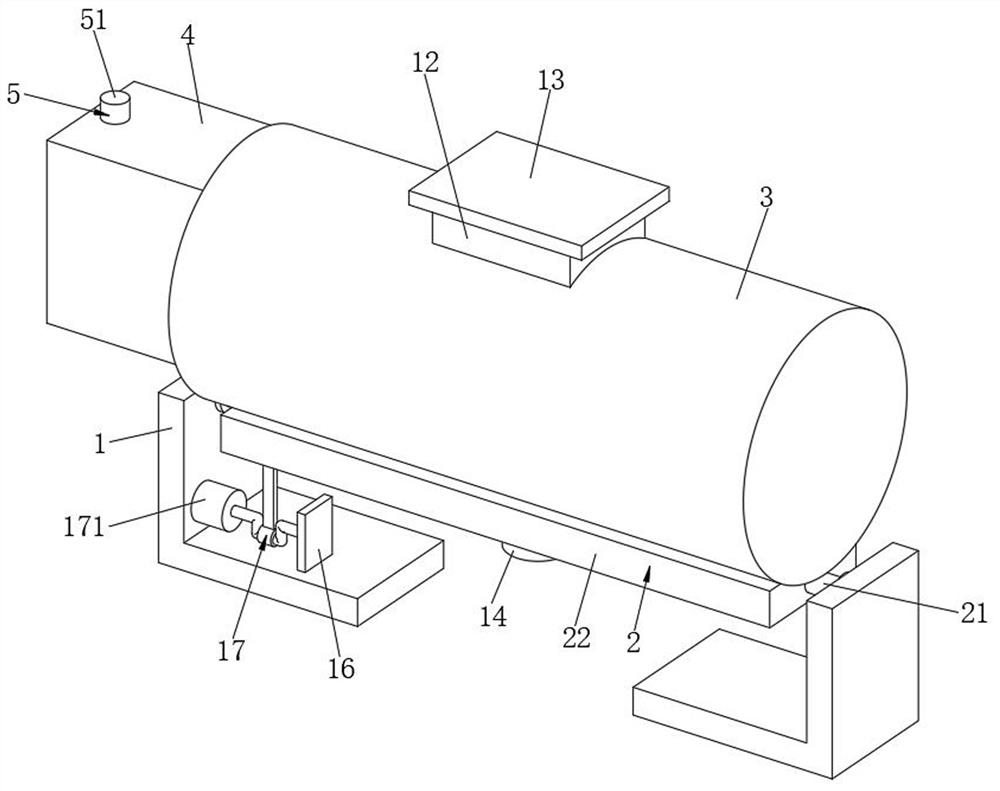

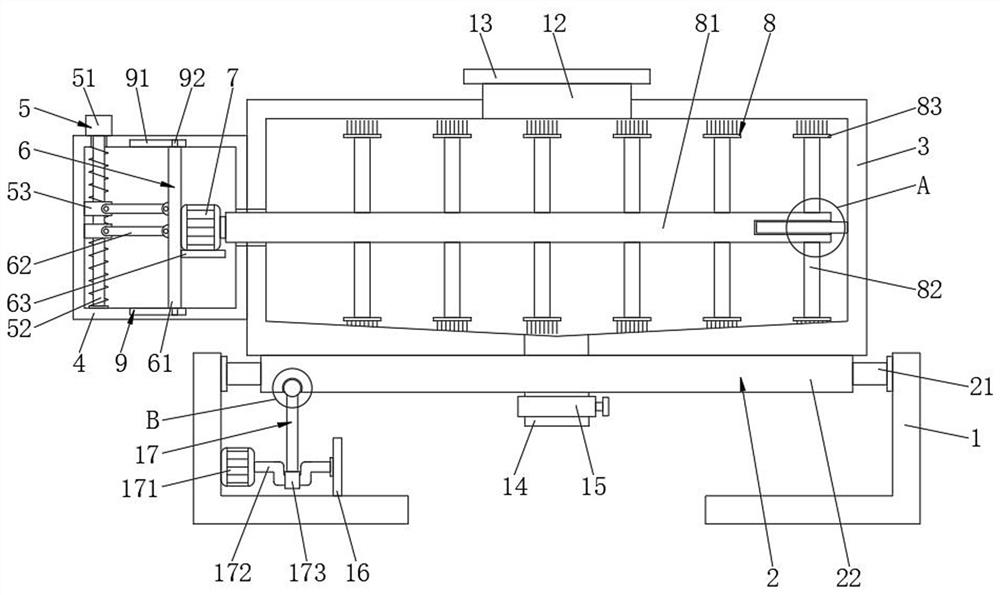

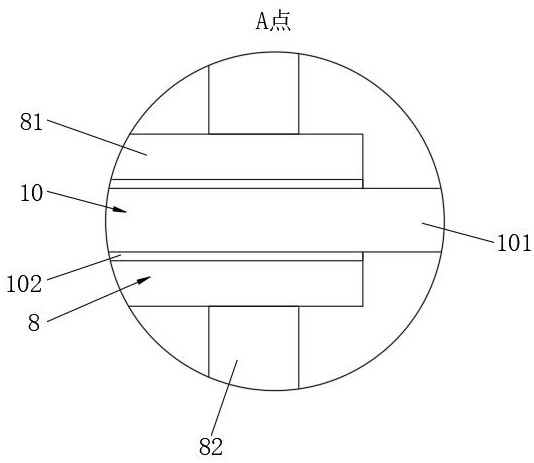

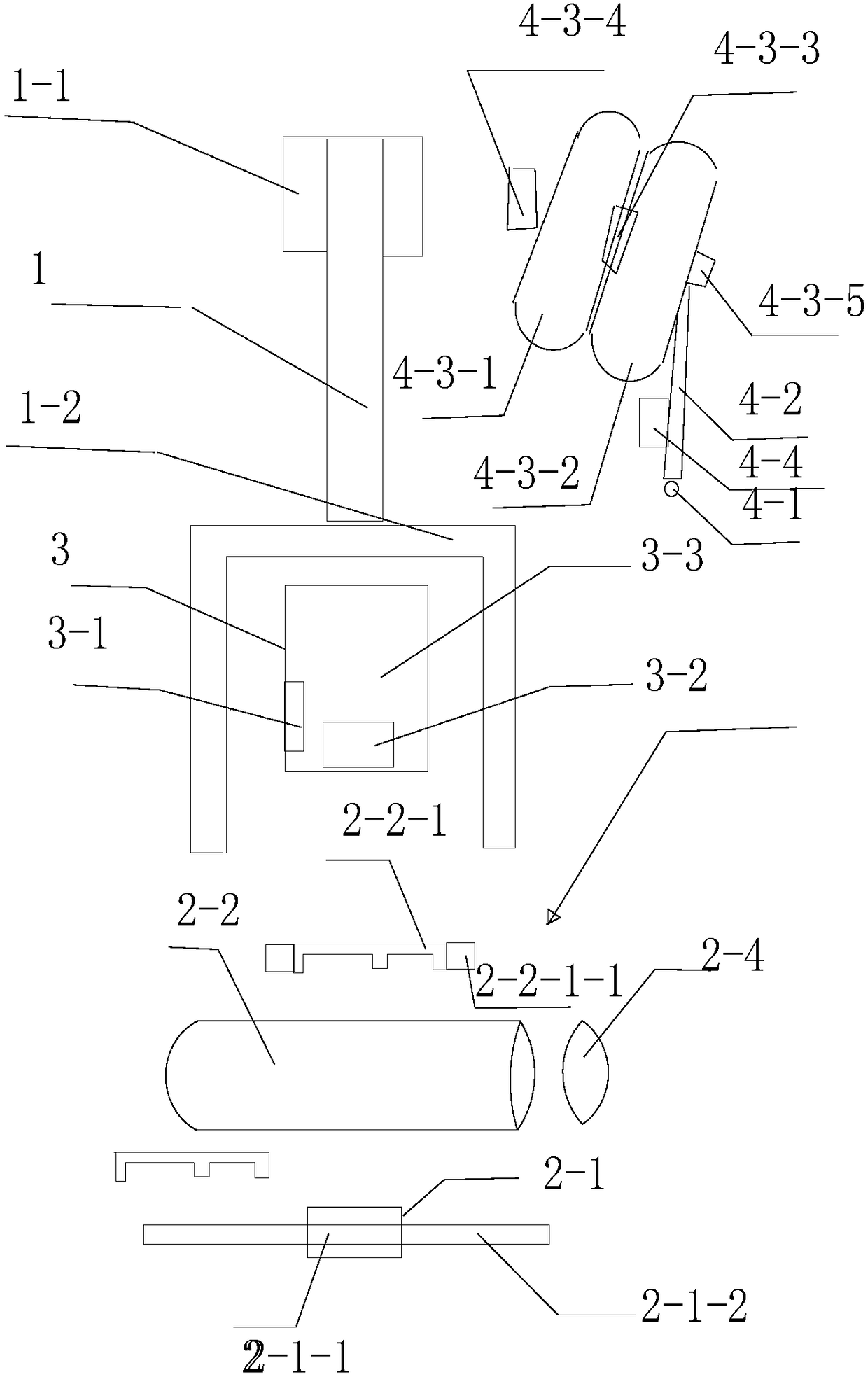

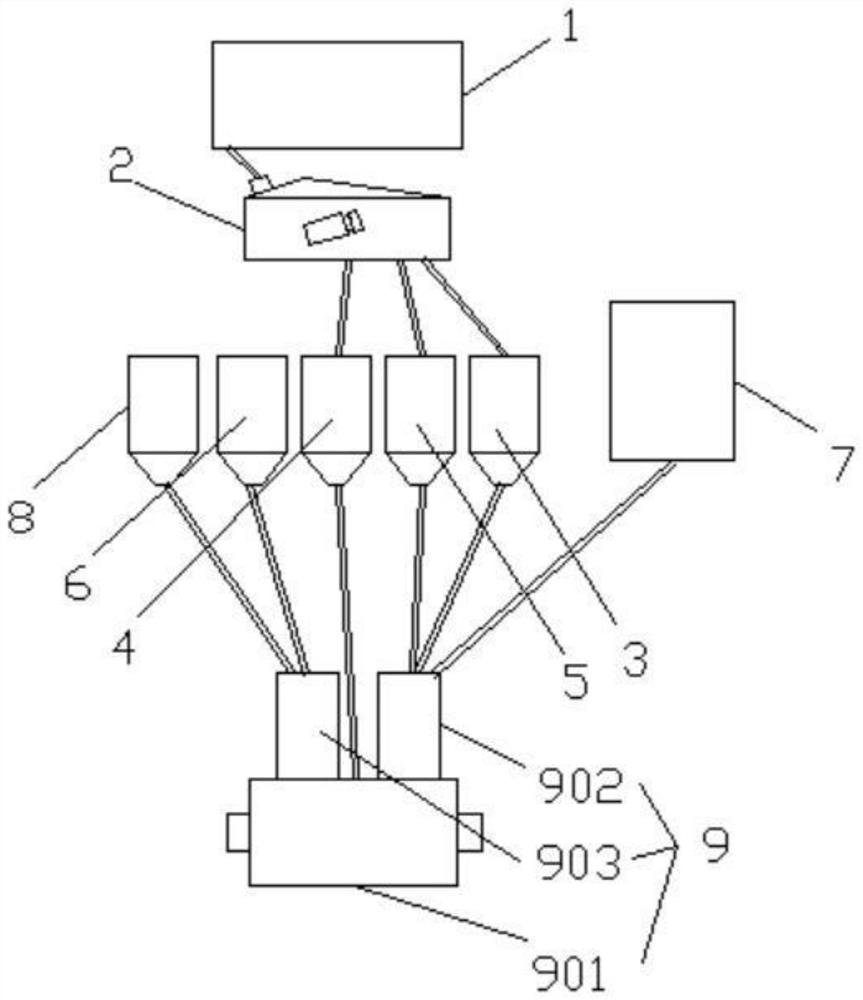

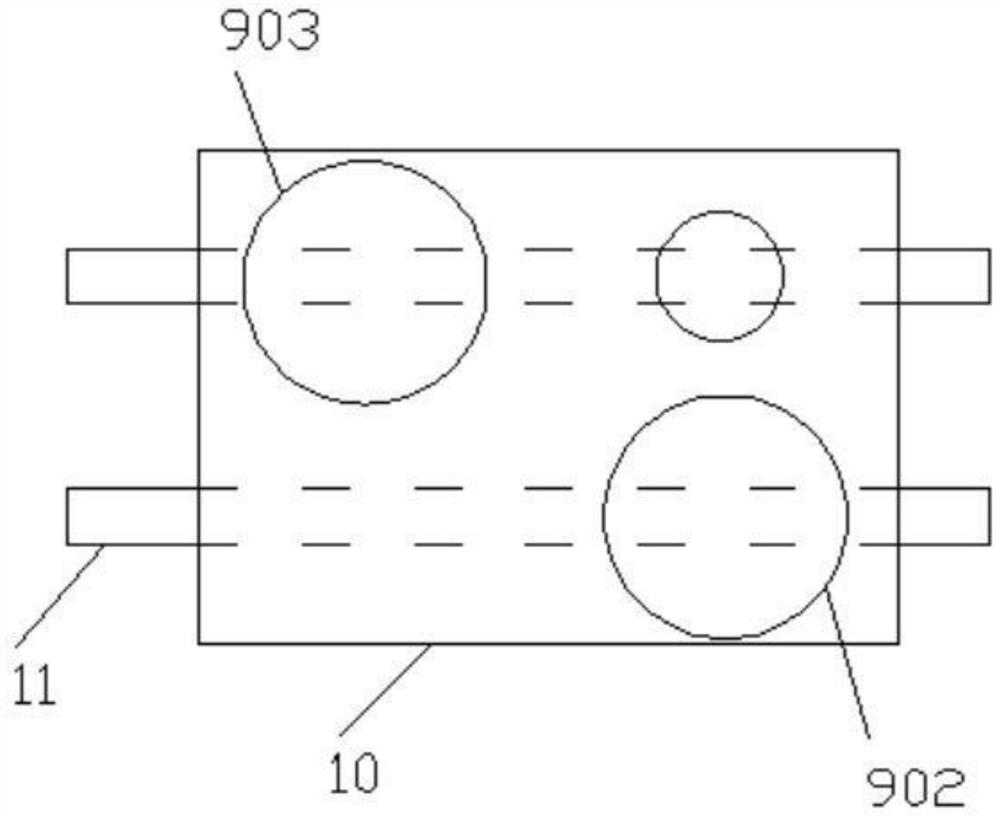

Stirring and conveying integrated system for commercial concrete

ActiveCN113232159AReduce stirring efficiencyLabor intensiveDischarging apparatusMixing operation control apparatusArchitectural engineeringMechanical engineering

The invention relates to a stirring and conveying integrated system for commercial concrete. The stirring and conveying integrated system for the commercial concrete comprises a base, a stirring device and a conveying device, and the stirring device and the conveying device are sequentially arranged on the upper surface of the base in the width direction of the base. The stirring and conveying integrated system for the commercial concrete can solve the current existing problems that when stirring is carried out on the concrete through existing stirring equipment, the stirring mode is too simple and single, cement, aggregate and water are difficult to fully and uniformly mix and stir, concrete raw materials need to be manually shoveled into a stirring tank for multiple times in the feeding operation, and therefore higher labor intensity is brought to workers, and the concrete stirring efficiency is reduced; and when conveying is carried out on the stirred concrete through the existing conveying equipment, the amount of the concrete conveyed each time is difficult to control, so that the concrete is conveyed too much or too little, and the smooth progress of construction is influenced.

Owner:广东丰业电力器材有限公司

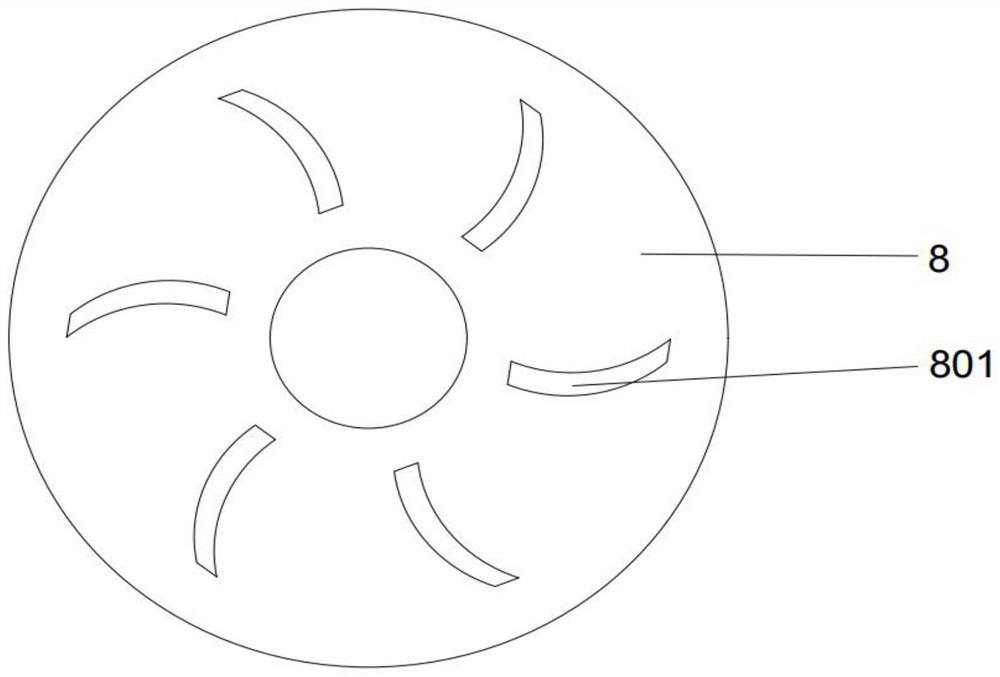

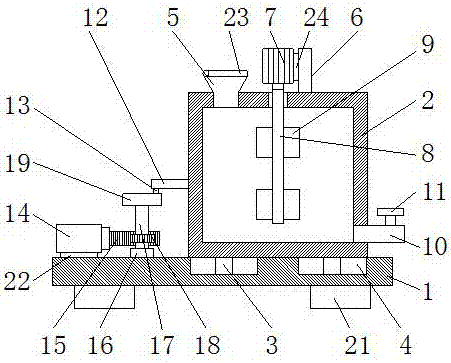

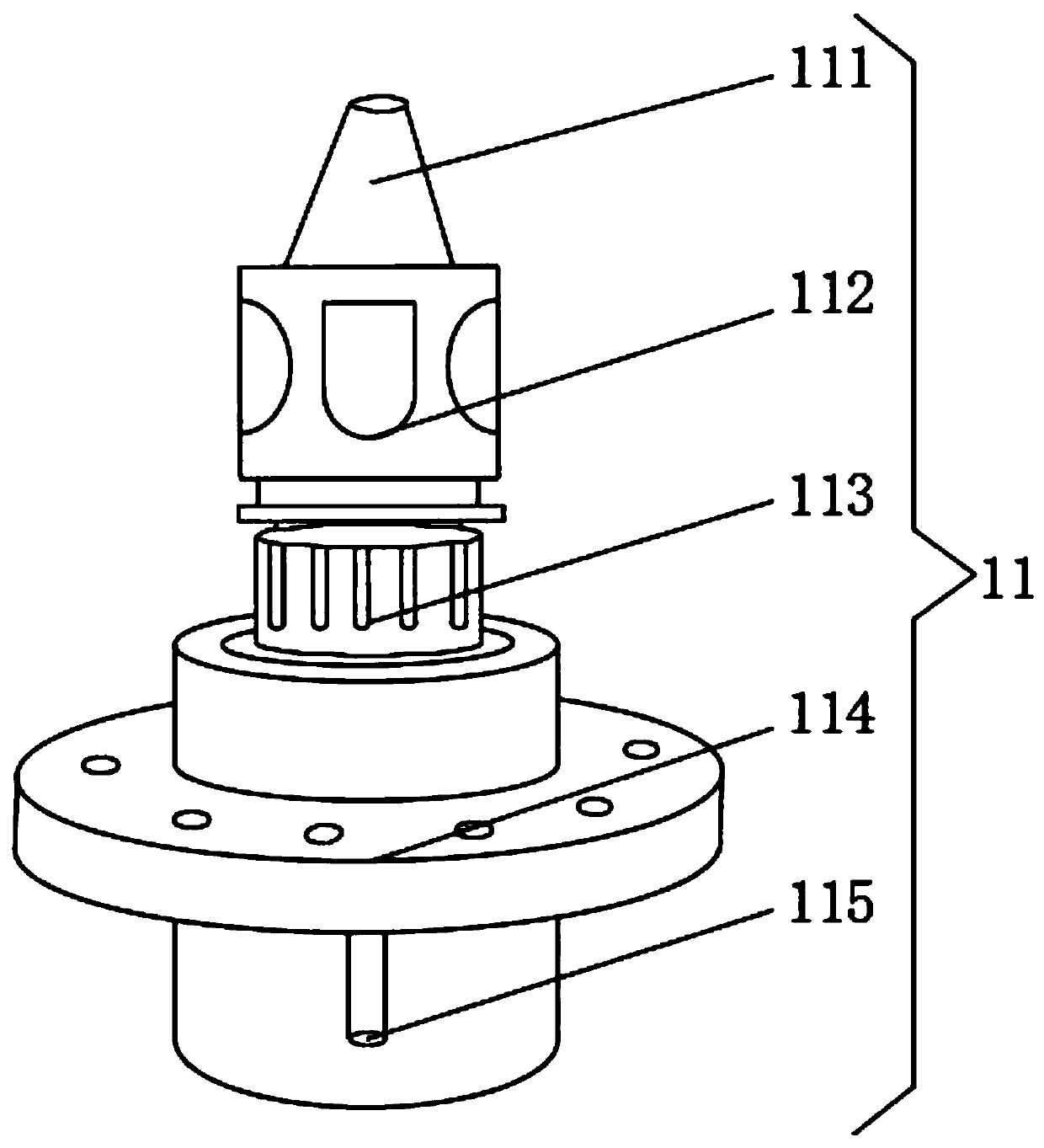

Novel stirring and lifting device for pharmaceutical equipment

InactiveCN110711508AExtend the mixing timeAvoid Manual JoiningRotary stirring mixersTransportation and packagingCircular discPharmaceutical drug

The invention discloses a novel stirring and lifting device for pharmaceutical equipment. The device comprises a stirring barrel, wherein liquid storage tanks are symmetrically and fixedly connected to the upper end of the stirring barrel, and a liquid pumping device for pumping medicine liquid in the liquid storage tanks into the stirring barrel is mounted on the stirring barrel. According to thedevice, a sliding plug cylinder, a sliding plug, a telescopic rod, a disc and a second motor are arranged, so that the second motor rotates to enable the sliding plug to move back and forth in the sliding plug cylinder; the medicine liquid in the liquid storage tanks is pumped into an arc-shaped cavity, and sprayed through liquid outlets; manual addition of the liquid medicine, which causes too-long stirring time of medicine, and reduced stirring efficiency is prevented; the telescopic rod is adjusted to control the adding amount of the medicine liquid, the adding amount of different types ofthe medicine liquid can be conveniently adjusted, and the situation that the adding amount of the medicine liquid cannot be accurately judged due to the fact that the adding amount of the medicine liquid is manually controlled is avoided.

Owner:神木市四妹子农产品开发有限公司

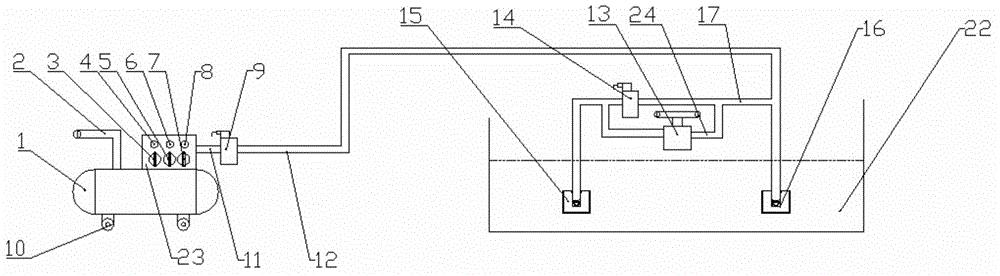

Ceramic fibrofelt air mixer

InactiveCN105561850APrevent slurry backflowImprove air agitation efficiencyTransportation and packagingMixersCeramicEngineering

The invention belongs to the technical field of ceramic fibrofelt processing equipment and relates to a ceramic fibrofelt air mixer. The ceramic fibrofelt air mixer comprises an air compressor, the air compressor is provided with a compressed air outlet, the compressed air outlet is provided with an electromagnetic stop valve A, the compressed air outlet is connected to a compressed air inlet A through a gas pipe A, the pipe A is connected to the compressed air inlet A through a gas pipe B, an electromagnetic stop valve B is arranged between the gas pipe B and the compressed air inlet A, the gas pipe B is provided with a manual globe valve in parallel through a gas pipe C, the compressed air inlet A and the compressed air inlet B are arranged in a melt tank, filter covers are arranged outside the compressed air inlet A and the compressed air inlet B, a seal ring is arranged between the filter covers and the compressed air inlets A and B, each one of the filter covers is provided with several filtering apertures and a backflow-prevention rubber ring is arranged in the port of each one of the compressed air inlets A and B.

Owner:天津市广盛源新型建材科技有限公司

Stirring device for production of biodegradable films

InactiveCN107415075AEfficient mixing effectReduce stirring efficiencyPulp and paper industryBiodegradable polymer

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

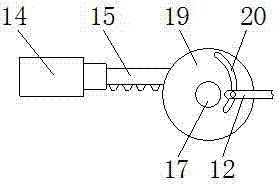

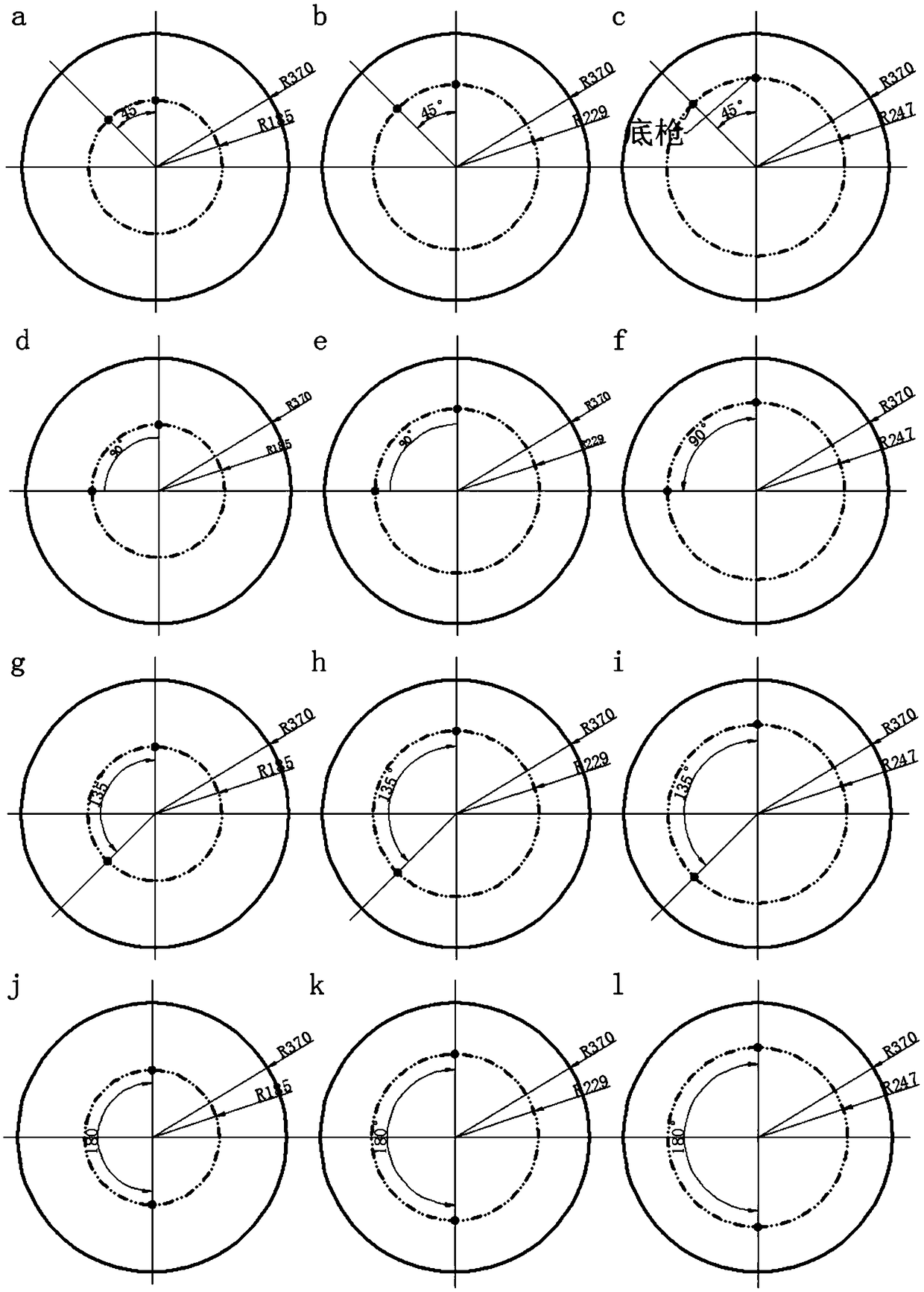

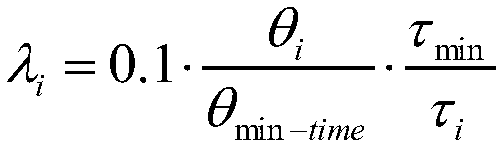

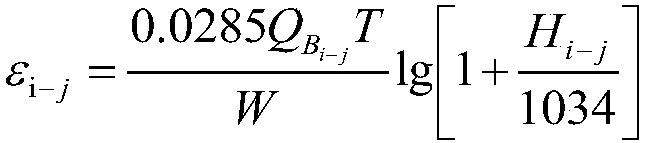

A method for predicting the minimum mixing time of ladle

ActiveCN109472090AIncrease coverageSmall geometryDesign optimisation/simulationSpecial data processing applicationsPredictive methodsTime data

The invention discloses a prediction method for the lowest mixing time of a ladle, which establishes a prediction formula for the mixing time based on the mixing time data tested by a hydraulic modeland the geometrical characteristics of the model to predict and estimate the lowest mixing time of the hydraulic model. The blending time prediction formula is applied to the actual ladle prediction by comparison. The invention provides a new formula for predicting the lowest mixing time of the ladle, which has high accuracy; Used in laboratory research or industrial technology to reduce duplication of effort in obtaining data. At the same time, the invention further deduces the factors influencing the lowest mixing time of the ladle, and determines the physical meaning of the formula.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

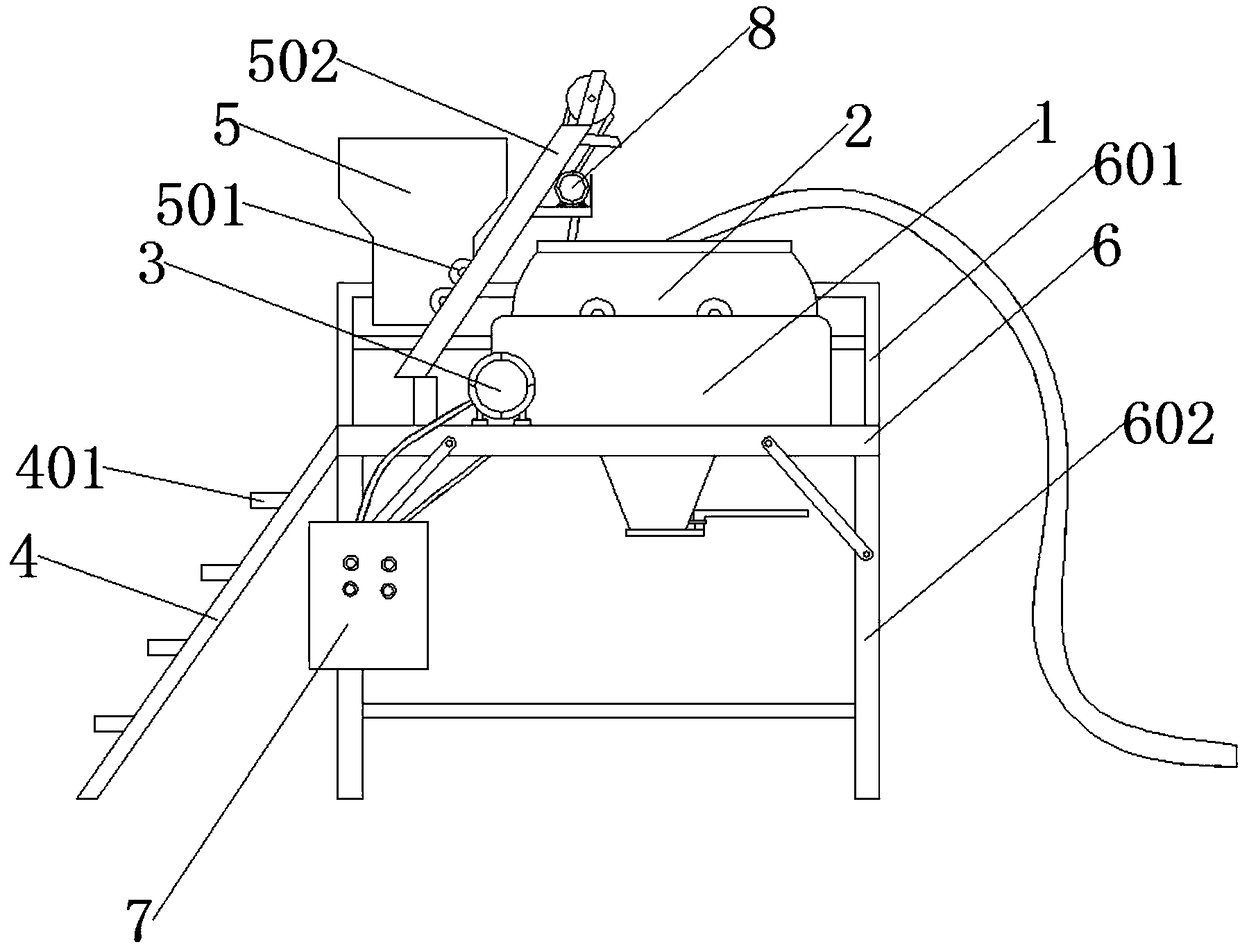

Quantitative stirring machine used for building

InactiveCN108162183AEasy mixing ratioEasy to unloadDischarging apparatusMixing operation control apparatusSpiral bladePulp and paper industry

The invention discloses a quantitative stirring machine used for a building. The quantitative stirring machine used for the building comprises a stirring barrel, a controller, a conveying belt, a material discharging hopper and a distance measurement sensor; the controller is mounted at the outer wall of the stirring barrel and a steel plate glass window is mounted at one side of the controller; astirring motor is fixed at the upper end of the interior of the stirring barrel and the stirring motor is rotationally connected with a connecting rod by a rotary shaft; a stirring paddle is fixed atthe exterior of the connecting rod; the distance measurement sensor is arranged at the interior of the stirring barrel at one side of the stirring motor and the distance measurement sensor is electrically connected with the controller by a wire; the left end of the conveying belt is connected with a material feeding port of the stirring barrel and a material discharging hopper is mounted on the other end of the conveying belt; a material discharging motor is fixed at the upper end of the material discharging hopper by a supporting frame and the material discharging motor is rotationally connected with spiral blades; a water pouring port is arranged at the upper end of the stirring barrel and an electronic control valve is mounted in the water pouring port. The machine is capable of realizing quantitative material feeding, convenient to control the ratio of a mixture, high in stirring quality and convenient to use.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

Steam heating type stirrer used for concrete stirring

InactiveCN108943392AEfficient mixingSolve the relatively low stirring efficiencyDischarging apparatusCement mixing apparatusHeating powerSteam heating

The invention provides a steam heating type stirrer used for concrete stirring. The steam heating type stirrer comprises a supporting table, a stirring barrel and a main motor. A top plate is seamlessly welded to the bottom end of the supporting table. The main motor is arranged at the front end of the left side of the supporting table. Supporting rods are seamlessly welded to the four corners ofthe bottom end of the top plate. An operation box is fixedly connected to the front ends of the left sides of the supporting rods through bolts. Two long strips are seamlessly welded to the left sideof the top plate. A pedal is fixed between the two long strips. The stirring barrel is arranged between the positions of the supporting table in an embedded manner. Heating power supply boxes are arranged on the left side and the right side in the stirring barrel. A steam heating layer is arranged on the inner wall of the stirring barrel in an embedded manner. The steam heating type stirrer used for concrete stirring has wide practicality, is high in stirring efficiency, sufficient in stirring and convenient to use and has high promotional value.

Owner:天津市裕昇建筑工程有限公司

concrete mixer

ActiveCN108972886BAdjust the mixing widthDifferent mixing effectsCement mixing apparatusCouplingElectric machinery

The invention discloses a concrete mixer, comprising a mixer shell, the upper end surface of the mixer shell is open, the inner wall of the opening end is provided with an internal thread, the opening end is threaded into a rotating cover, and the outer wall of the rotating cover engages with the internal thread of the opening end, so that A driving motor is installed on the top of the rotating cover, the motor shaft of the driving motor is connected to a connecting rod through a coupling, a first rotating rod is telescopically loaded into the connecting rod, and the top of the first rotating rod is telescopically loaded into the In the connecting rod, at the bottom of the first rotating rod, more than one first stirring blade is arranged around the first rotating rod. The present invention can use the height of the rotating cover relative to the mixer shell to adjust the angle between the first stirring piece and the second stirring piece, and then adjust the stirring width of the whole stirring piece, and realize the lifting type opening and closing stirring during stirring, Stirring efficiency is greatly reduced. When not in use, the entire stirring rod is in the shape of a "one", which is easy to carry and clean.

Owner:天门市天安建材有限公司

Pavement asphalt mixture preparation method and device

ActiveCN111676772AReduce stirring efficiencyExtend the mixing timeRoads maintainenceRoad surfaceAsphalt

The present invention relates to a pavement asphalt mixture preparation method, which comprises: 1) screening aggregates to obtain a coarse material, an intermediate material and a fine material, wherein the particle size of the coarse material is not less than 10 mm, the particle size of the fine material is not more than 1 mm, and the particle size of the intermediate material is between 10 mm and 1 mm; 2) drying the asphalt, partially melting to obtain liquid asphalt, and powdering the residual asphalt to obtain powdery asphalt; 3) preheating the coarse material, adding liquid asphalt, stirring the components, adding the fine material, and stirring the components to obtain a coarse prefabricated material; 4) mixing and stirring the powdery asphalt and mineral powder to obtain an asphaltand mineral powder mixture, and 5) mixing the coarse prefabricated material, the intermediate material and the asphalt and mineral powder mixture, uniformly stirring the components, and heating and stirring the mixture. The invention aims to solve the problem of separation during preparation of the asphalt mixture.

Owner:段真巍

Raw material mixing device for constructional engineering

PendingCN112156670AReduce stepsReduce the amount usedRotary stirring mixersTransportation and packagingElectric machineryManufacturing engineering

The invention discloses a raw material mixing device for constructional engineering, relates to the field of constructional engineering, and provides the following scheme for solving the problem thatan existing raw material mixing device is poor in mixing efficiency: the raw material mixing device comprises a mixing box, a raw material storage box is fixedly mounted at the upper end of the mixingbox, and a feeding pipe is fixedly mounted at and communicates with the lower end of the raw material storage box; the lower end of the feeding pipe penetrates through the material mixing box and extends into the material mixing box, a material blocking mechanism is fixedly installed on the rear end face in the material mixing box through a fixing rod, a speed reducer is fixedly installed at therear end of the material mixing box, a double-shaft motor is fixedly installed at the rear end of the speed reducer, and the front end of an output shaft of the double-shaft motor is connected with aninput shaft of the speed reducer; the mixing device disclosed by the invention is high in mixing efficiency, good in effect, simple to operate, low in processing cost and high in practicability.

Owner:湖南傲创科技有限公司

Special feed quantitative mixing device for Shanxiang pigs

InactiveCN112156694AAchieve hybridAvoid damageRotating receptacle mixersFeeding-stuffAnimal scienceBlocking layer

The invention relates to the technical field of animal husbandry breeding, and provides a special feed quantitative mixing device for Shanxiang pigs, which comprises a body, the inner wall of the bodyis elastically connected with a spring, one end of the spring away from the body is movably connected with a pressure block, and the outer wall of the pressure block is movably connected with a rolling ball. According to the special feed quantitative mixing device for the Shanxiang pigs, when a pressure block rotates to the upper half circle, the pressure block stretches a spring and drives a push rod to move, at the moment, the rolling ball and a supporting plate keep the pressure block stably moving without deviating from a rail, the pressure block drives a pushing device to move, and the pushing device pushes inclined blocks to the two sides through extrusion; the inclined blocks enable a pushing column to push a blocking layer, the blocking layer communicates with a raw material box and a stirring bin, every time the blocking layer is communicated, two raw materials are sequentially introduced into the stirring bin, the two kinds of feed are firstly mixed and sequentially rotatedfor sequential and quantitative feeding to be mixed, and when the pressure block rotates to the lower half circle, the pressure block is opposite to the pressure block, and gravity is used for sequential mixing and quantitative feeding.

Owner:湖南侗湘生态农业股份有限公司

High-speed stirring device for new material production

InactiveCN112403360AAvoid stickingExtension of timeShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionElectric machine

The invention discloses a high-speed stirring device for new material production. The high-speed stirring device comprises two supporting frames and a stirring box, a swing mechanism is arranged on the inner side of each supporting frame, a shell is fixedly connected to the left side of the stirring box, a reciprocating mechanism is arranged at the top of the shell, and a moving mechanism is arranged in an inner cavity of the shell. A first motor, a second motor and a motor are started, the first motor drives a stirring rod and stirring blades to rotate to stir new materials, the motor finallydrives the stirring rod and the stirring blades to reciprocate left and right, the inner wall is cleaned while reciprocating stirring is conducted, and the purpose of being good in stirring effect isachieved; the high-speed stirring device for new material production has the beneficial effect of being good in stirring effect, new materials are stirred in a left-right reciprocating mode, the inner wall of the stirring box is cleaned while stirring is conducted, the stirring box is shaken, and the stirring efficiency is further improved.

Owner:孙国林

Concrete mixing equipment for hydraulic engineering construction

ActiveCN110666964BChange trajectoryAvoid overall overheatingCement mixing apparatusVehicle frameArchitectural engineering

The invention discloses concrete mixing equipment for water engineering construction. The concrete mixing equipment comprises a frame and a fixed rear seat. Wheels are arranged at the position, closeto the middle, of one side of the frame. A handle is fixedly mounted on the outer surface of the rear end of the frame. A handrail is fixedly mounted at one end of the handle. A supporting frame is fixedly mounted at the other end of the handle. An axle is arranged between the wheels. A rotating shaft is fixedly mounted on the outer surface of the front end of the fixed rear seat. A motor protection shell is fixedly mounted on the inner side of the handle. An electromotor is fixedly mounted on the outer surface of the lower end of the motor protection shell. A tank body is arranged at one endof the rotating shaft. The concrete mixing equipment for water engineering construction has the beneficial effects that the concrete mixing equipment for water engineering construction can be moved conveniently, the mixing efficiency can be improved, the interior of the equipment can be cooled, the structure is simple, and use is convenient.

Owner:SHANDONG WATER CONSERVANCY CONSTR ENG CO LTD

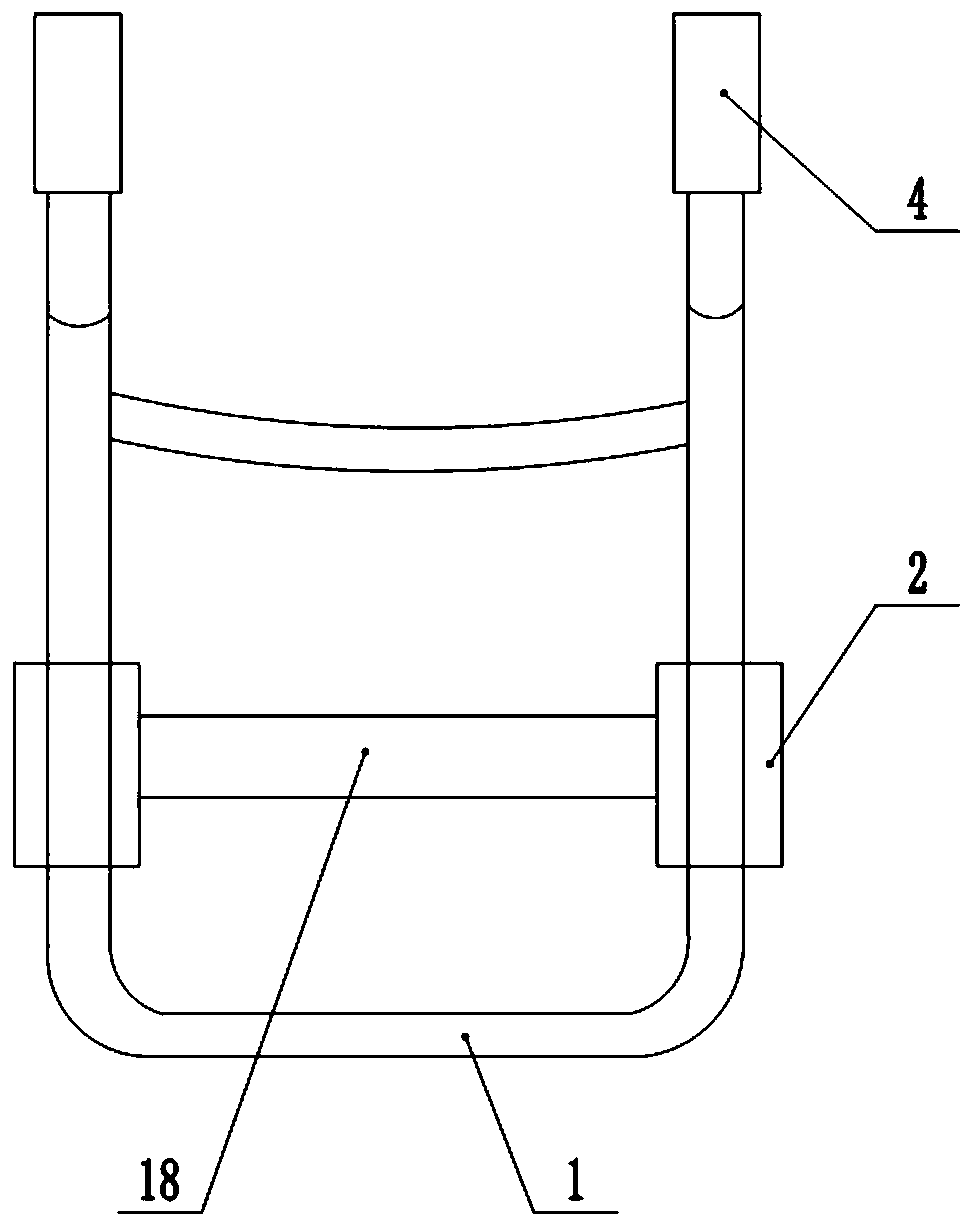

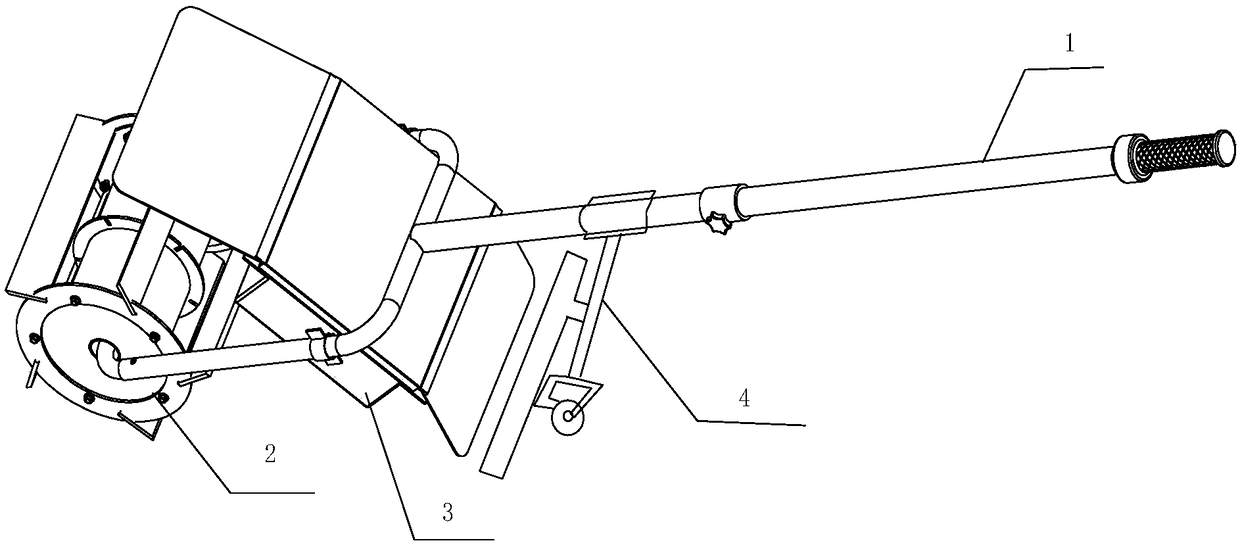

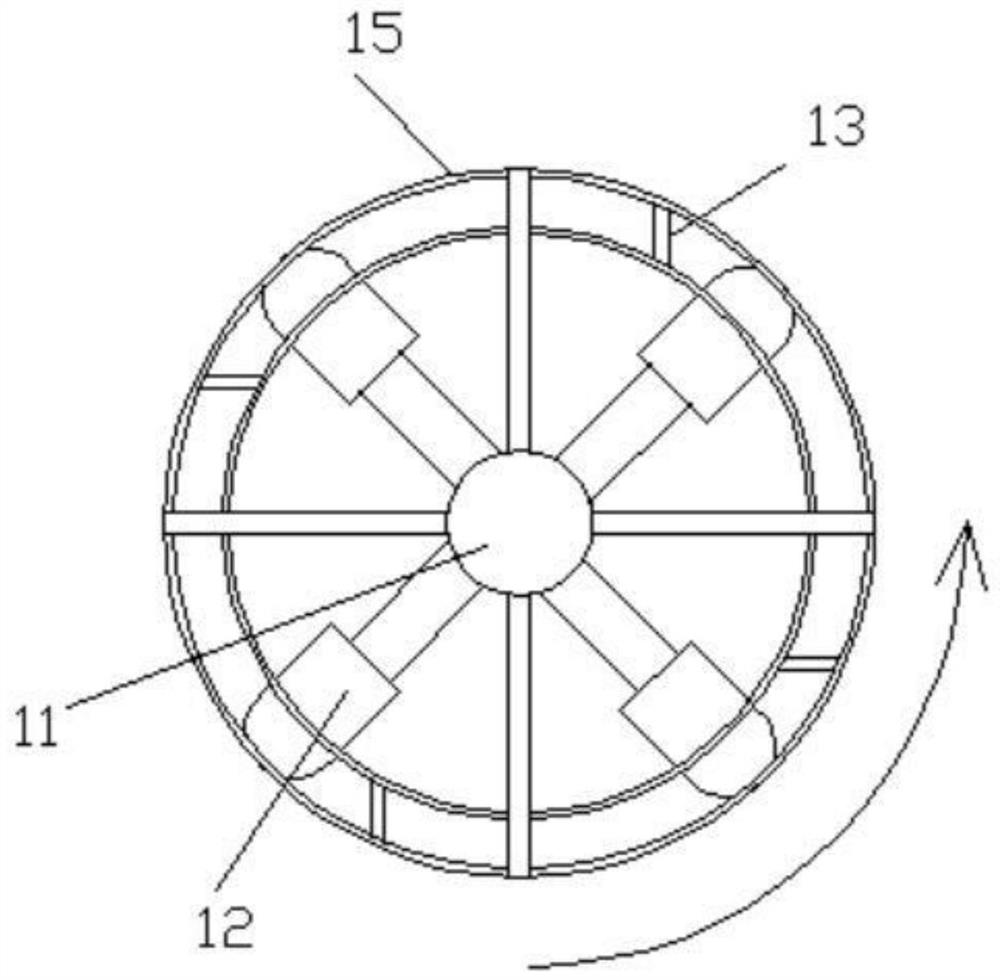

Labour-saving stirring robot

InactiveCN109304129AImprove stirring efficiencyEasy to carryTransportation and packagingMixer accessoriesPulp and paper industryRobot

The invention discloses a labour-saving stirring robot. The labour-saving stirring robot comprises a folding type rod, and a stirring device body, wherein one end of the folding type rod is a controlhandle, and the other end of the folding type rod is a U-shaped rod; the stirring device body comprises a motor, a roller, an electrical appliance control box and an adjustable type travelling wheel device. The labour-saving stirring robot adopts a roller blade type stirring head, and turns over the conventional rotary blade type stirring way, so that stirring efficiency is greatly improved. The labour-saving stirring robot is provided with the adjustable type travelling wheel device, so that the stirring machine can freely travel without being held by force, and therefore, labour is saved, labour intensity is greatly reduced; and moreover, the adjustable type travelling wheel device is convenient to dismount, and is simple in structure.

Owner:唐七零

Stirring equipment for glass formula raw materials

InactiveCN110624436AWell mixedEfficient mixingTransportation and packagingRotary stirring mixersReducerEngineering

The invention discloses stirring equipment for glass formula raw materials. The stirring equipment comprises a speed reducer, wherein a rotating shaft device is arranged at the upper end of the speedreducer, a motor is arranged at the upper end of the rotating shaft device, a rack is arranged at the lower end of the speed reducer, and a stirring body is arranged at the lower end of the rack. According to the stirring equipment for glass formula raw materials, a stirrer device and a hydraulic cleaning device are arranged, wherein the hydraulic cleaning device has good cleaning effect on the inner wall, has high efficiency is high, and can effectively treat the inner wall of the stirring equipment, perform disinfection and sterilization, reduce machine core consumption, reduce power operation, and make the inner wall to be cleaned efficiently and rapidly; and dirt can be generated on the inner wall in the original stirring process, the stirring tooth buckles are additionally arranged onthe stirrer device so as to efficiently, rapidly and uniformly stir the coating material and achieve advantages of low energy consumption, simple operation, safe use, complete raw material mixing andimproved uniformity of stirred materials.

Owner:蚌埠市昆宇机械加工厂

A pavement asphalt mixture preparation device

ActiveCN111676772BReduce stirring efficiencyExtend the mixing timeRoads maintainenceEngineeringRoad surface

The present invention relates to a preparation method of pavement asphalt mixture, which comprises the following steps: 1) sieving the aggregate to obtain coarse material, medium material and fine material, the particle size of the coarse material is not less than 10 mm, the particle size of the fine material is not greater than 1 mm, and the medium material is not greater than 1 mm. The particle size of the material is between 10mm and 1mm; 2) Dry the asphalt, melt part of it to obtain liquid asphalt, and powder the remaining asphalt to obtain powdered asphalt; 3) After the coarse material is preheated, add liquid asphalt for stirring, and then add fine material for stirring , to obtain a rough prefabricated material; 4) mixing and stirring the powdered asphalt and the ore powder to obtain an asphalt ore powder mixture; 5) mixing the coarse prefabricated material, the medium material and the asphalt ore powder mixture, stirring evenly, and then heating and stirring. The purpose of the present invention is to solve the segregation problem during asphalt mixture preparation.

Owner:段真巍

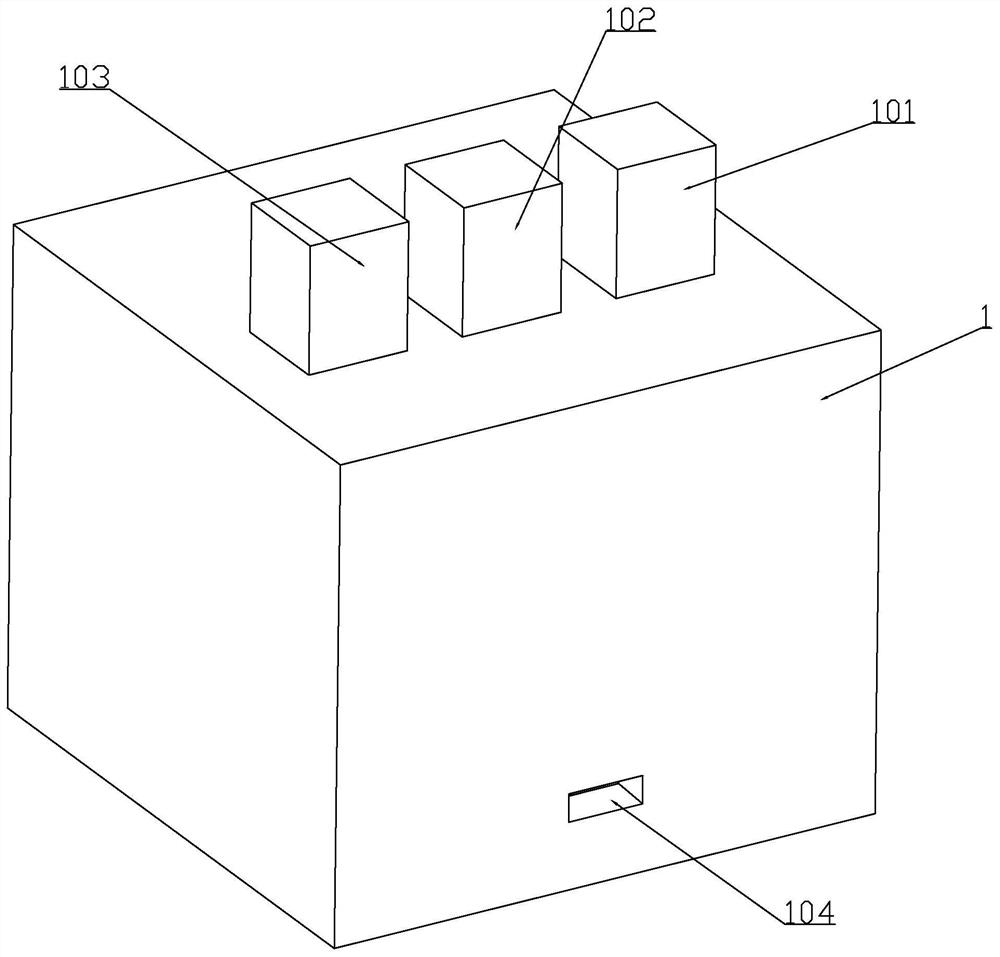

Efficient stirring method for building concrete

InactiveCN113427630APrevent running outMeet building requirementsHollow article cleaningCement mixing apparatusArchitectural engineeringSewage

The invention relates to the technical field of building construction machinery, in particular to an efficient stirring method for building concrete, and particularly relates to an efficient concrete stirring device. The efficient concrete stirring device comprises a box body, a stone feeding box body is fixedly arranged in the middle of the upper end face of the box body, and a fine sand feeding box body is arranged on one side of the stone feeding box body. A cement powder feeding box body is arranged on the side, away from the fine sand feeding box body, of the stone feeding box body, a concrete discharging channel is formed in one end of the box body, a stirring component is arranged above the box body in the direction away from the concrete discharging channel, a water set component is arranged above the stirring component in the direction away from the concrete discharging channel, and a cleaning component is arranged below the stirring component. Sewage recycling components are arranged on the two sides of the cleaning component. Cement, fine sand and stones can be efficiently stirred into concrete, the stirring component and the interior of the box body are cleaned in time, residues are discharged in time, and sewage is treated and reused for shock absorption.

Owner:冯锐强

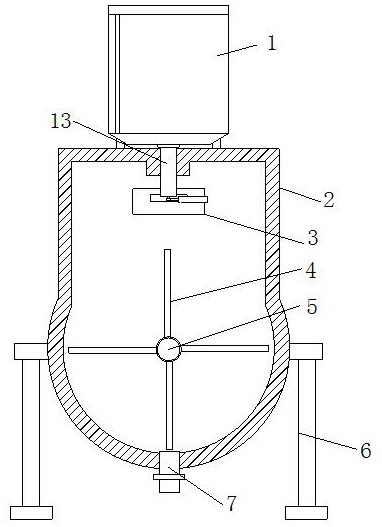

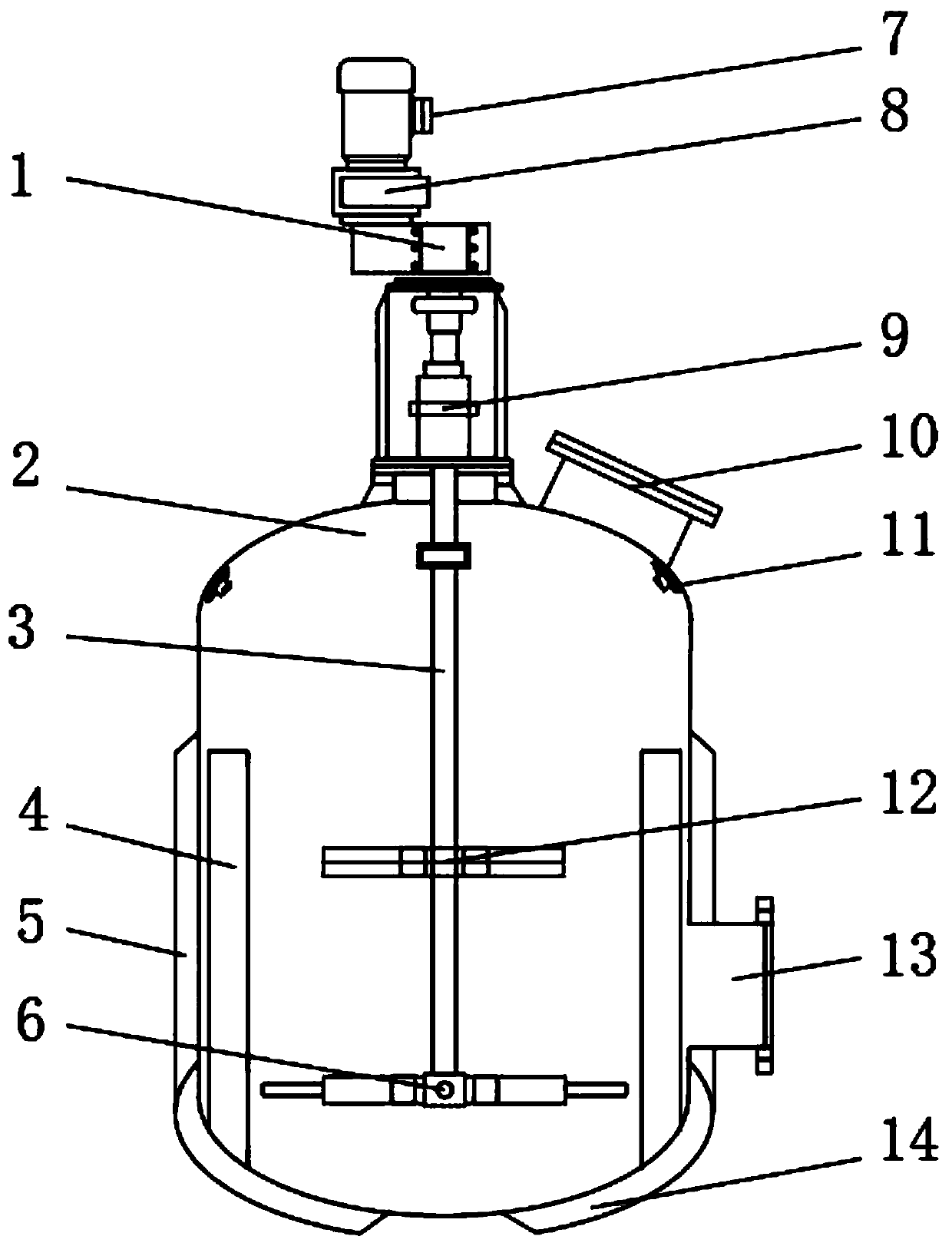

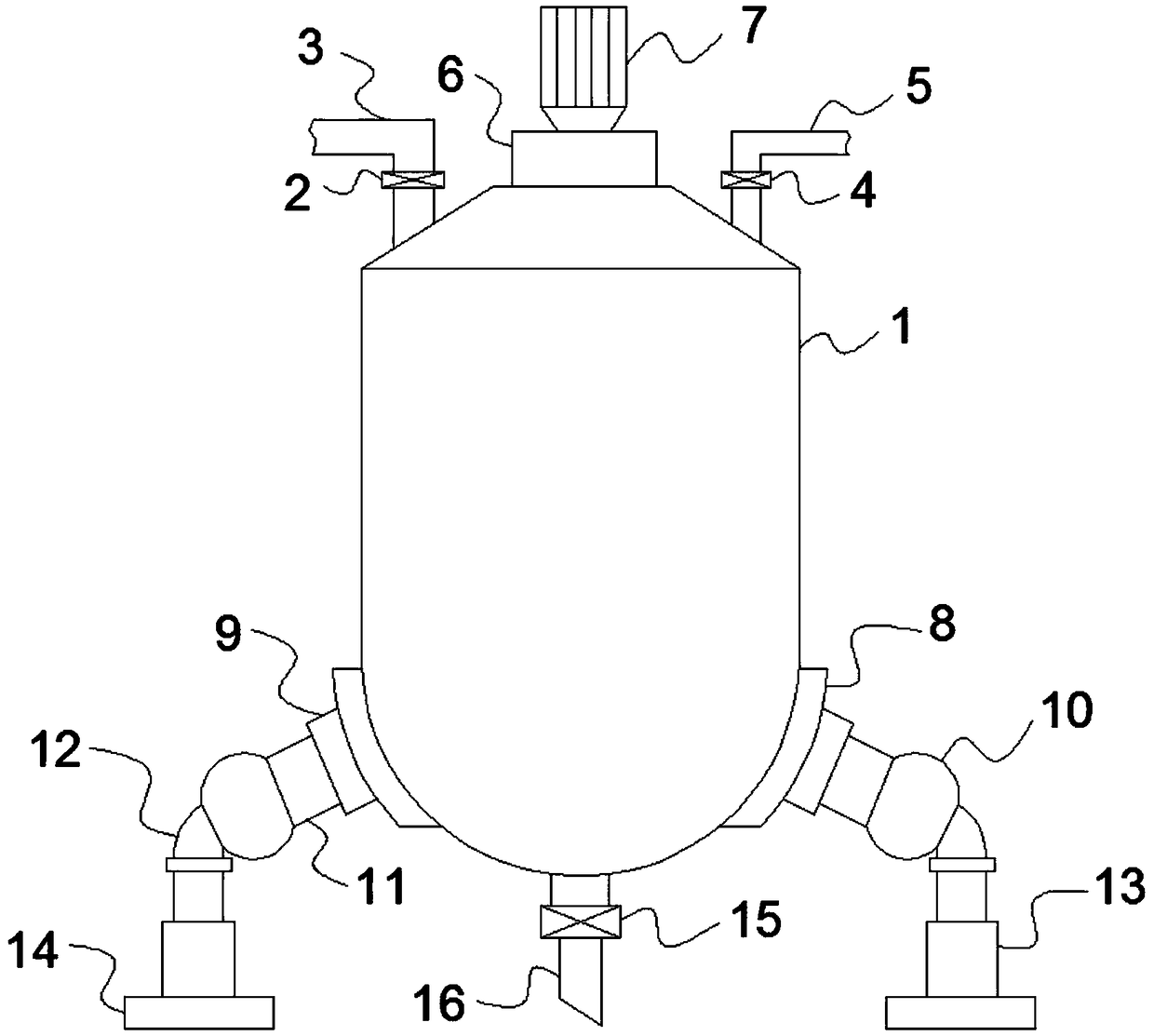

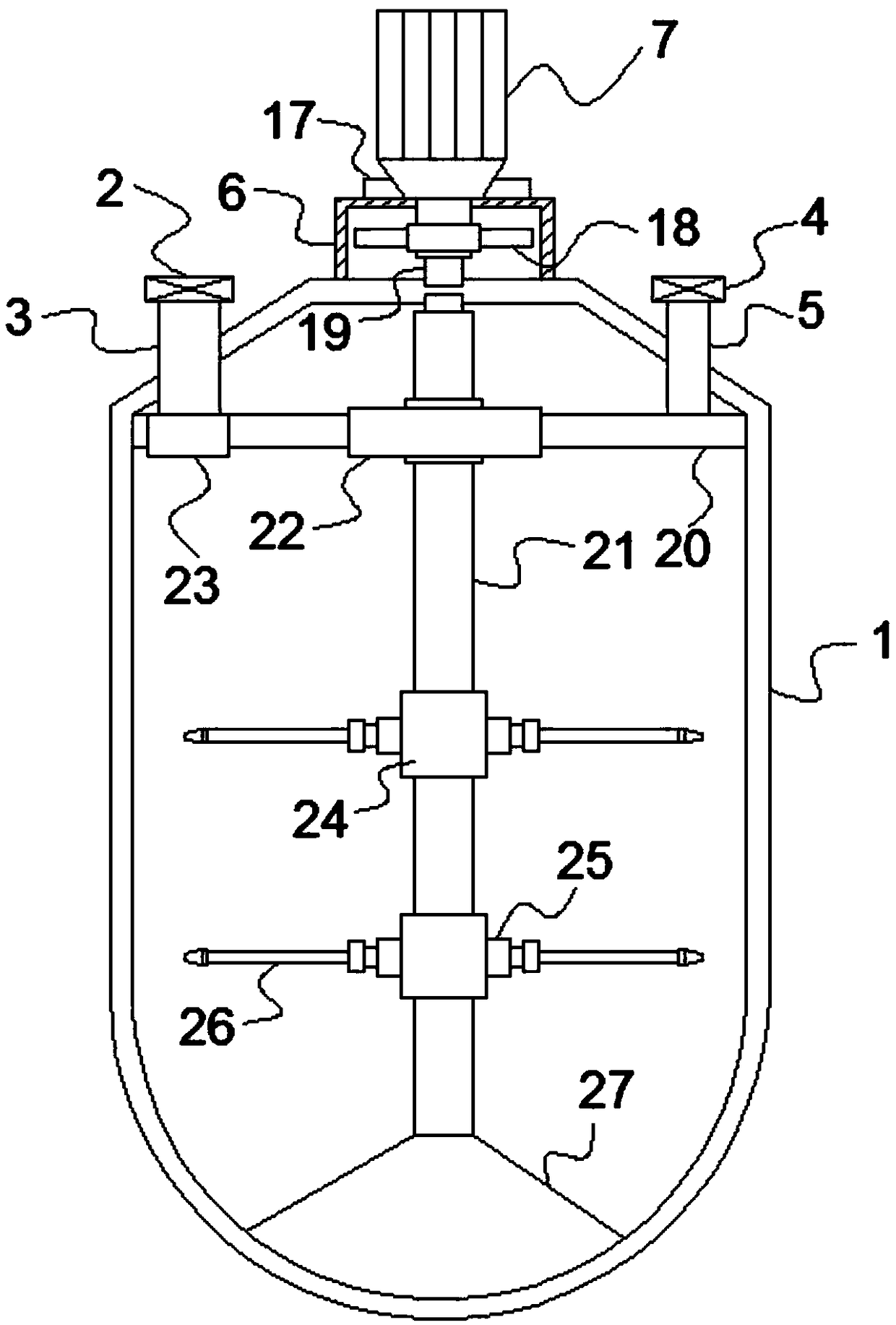

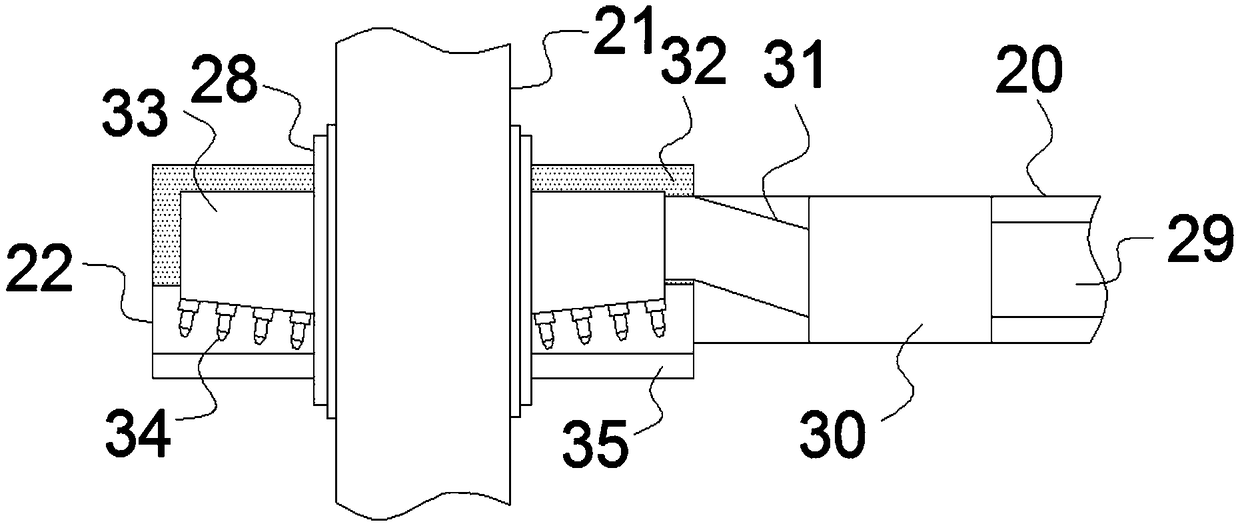

Efficient reaction still for cosmetic production

ActiveCN109364861AAbandon efficiencyAbandon the situationChemical/physical/physico-chemical stationary reactorsFeed devicesInlet valveEngineering

The invention relates to the technical field of the cosmetic production, and specifically relates to an efficient reaction still for cosmetic production. The efficient reaction still comprises a reaction still body, wherein a thick liquid inlet pipe and a thin liquid inlet pipe penetrate through the left side and the right side of the top of the reaction still body correspondingly; a thick liquidinlet valve and a thin liquid inlet valve correspondingly penetrate through the lower parts of the outer walls of the thick liquid inlet pipe and the thin liquid inlet pipe on the left side and the right side; a motor base is arranged at the center of the top of the reaction still body; a servo motor penetrates through the center of the top of the motor base; supporting plates are symmetrically and cooperatively fixed at the outer walls of the left side and the right side of the bottom of the reaction still body; a support block is arranged at the middle of the outer wall of each supporting plate; a round drum type connector is arranged under each support block; bases are symmetrically arranged on the left side and the right side of the bottom of the reaction still body; and a shock-absorption damper is fixed at the center of the top of the base. The efficient reaction still disclosed by the invention can effectively overcome the defect that the traditional reaction still for cosmeticproduction in the prior art is low in production efficiency and short in service life.

Owner:江苏鑫昊空调设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com