Pulping method of food processor

A food processing machine and pulping technology, which is applied to heating devices, cooking utensils, household utensils, etc., can solve the problems of reducing the user experience of the food processing machine, uneven temperature of the slurry, unrealistic and other problems, so as to improve the user experience and user satisfaction, improved accuracy, and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

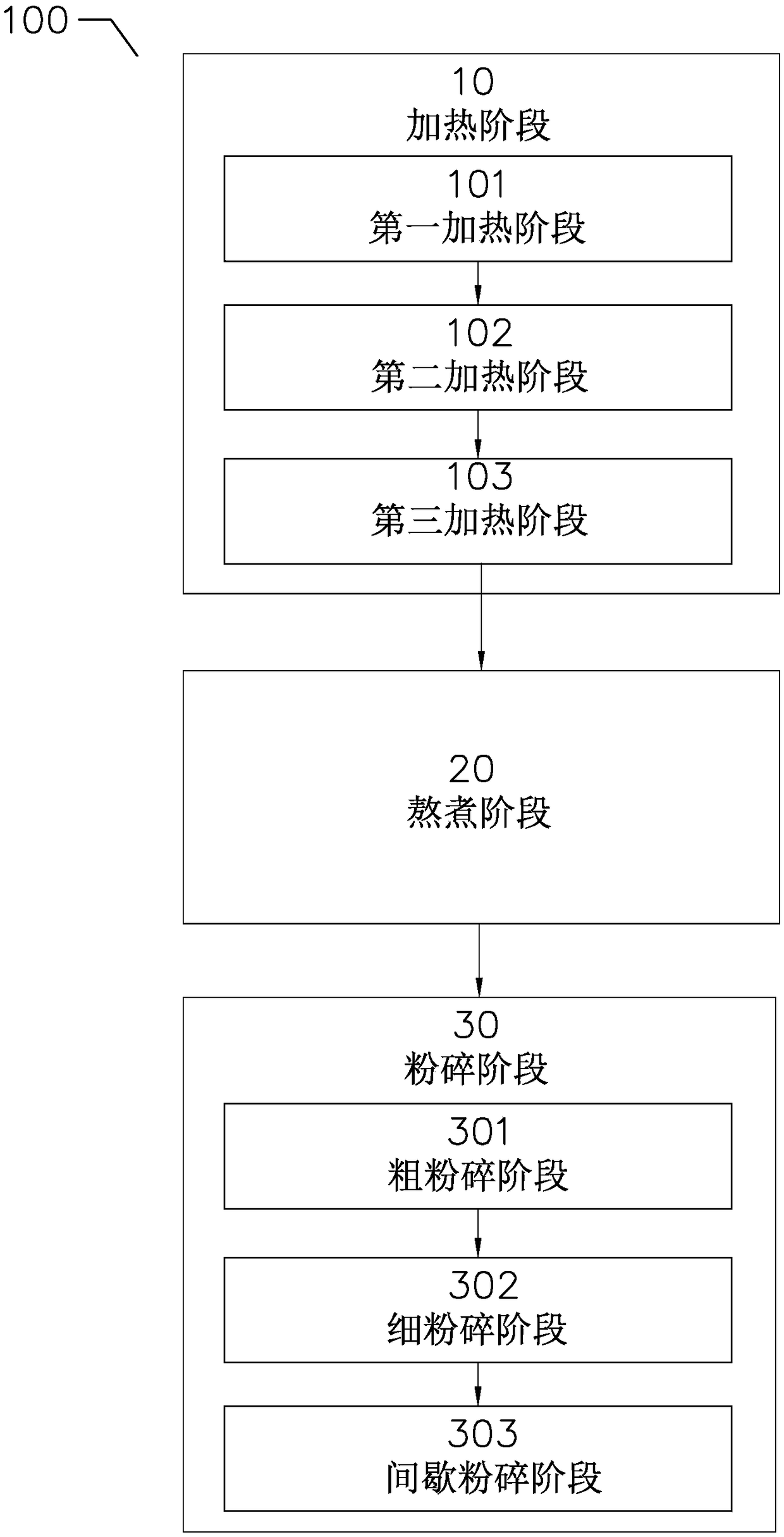

[0031] Such as figure 1 As shown, the present invention provides a pulping method 100 for a food processor, the food processor includes a machine base, a stirring cup, a pulverizer, a control board, a motor electrically connected to the control board, a heating device and a temperature detection device, and the control board Control motor and heating device to carry out corresponding work. The food processing machine is also equipped with a corresponding display device for the user to operate and remind the user. After the user performs a corresponding operation on the food processing machine, the food processing machine starts to execute the corresponding workflow according to the user's operation. For the pulping process of the food processor, it has three major pulping stages, which are the heating stage 10: the control board cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com