Patents

Literature

42results about How to "Meet building requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

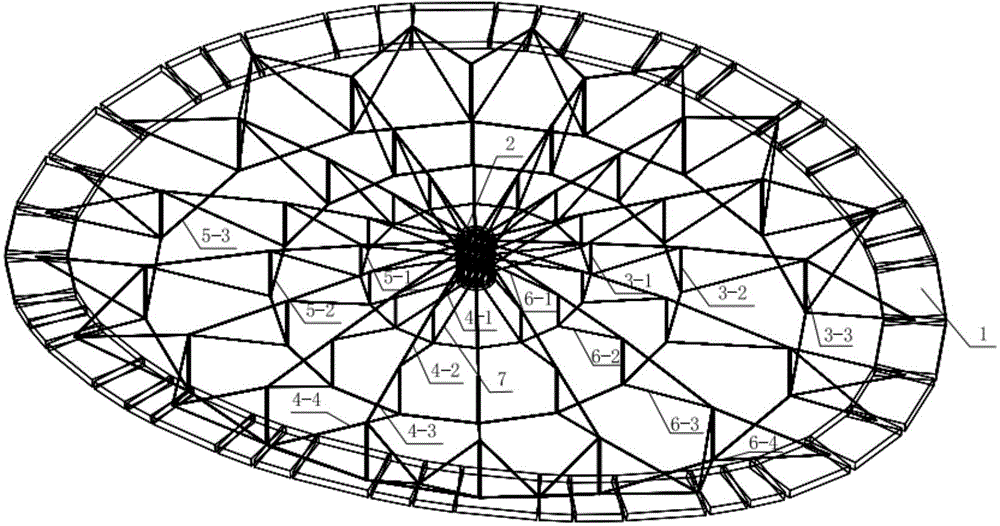

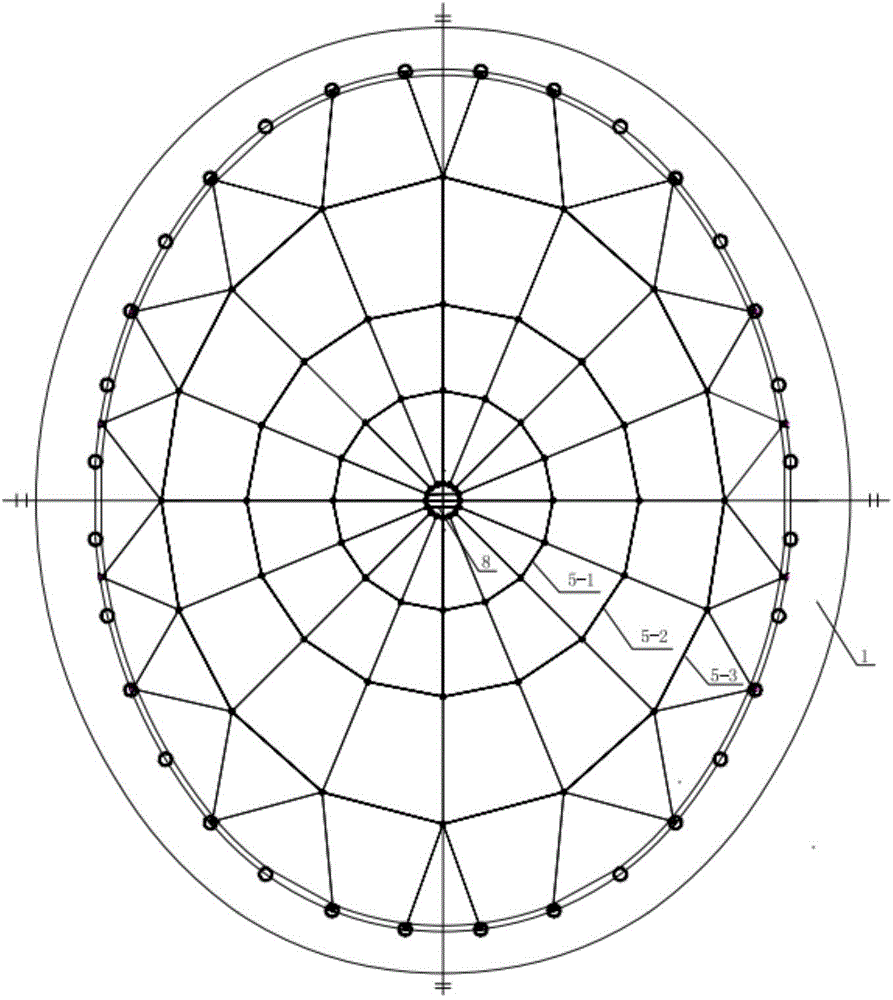

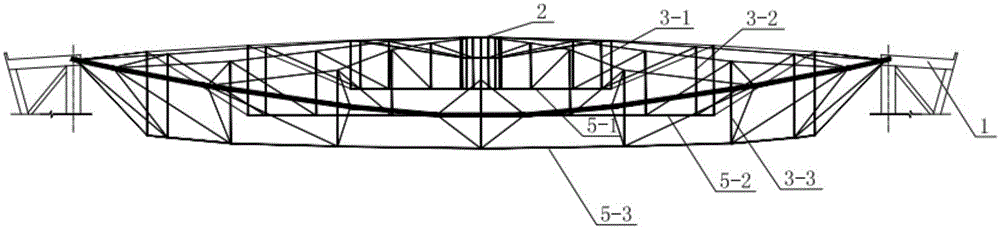

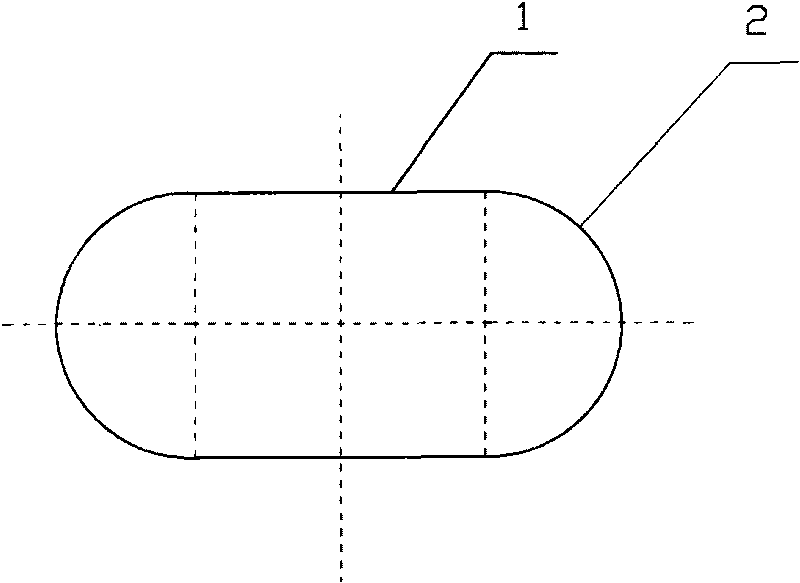

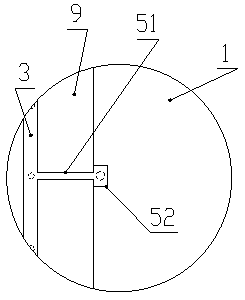

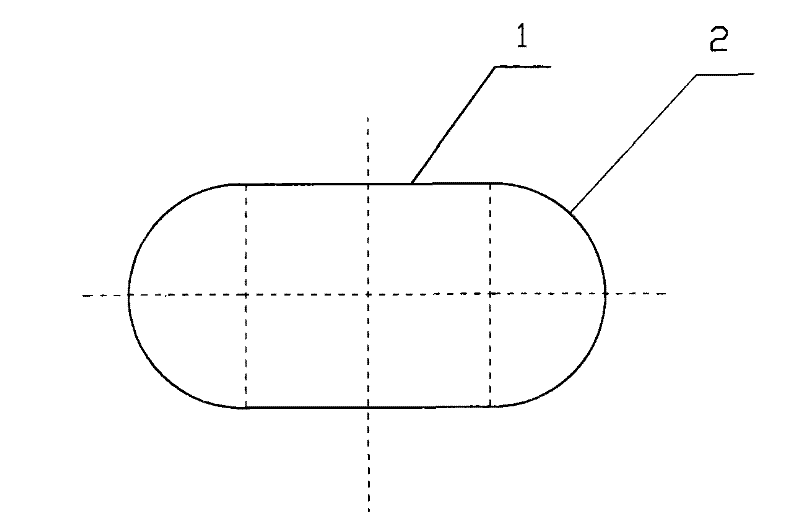

Combined-type cable dome structure for elliptic plane with unequal-height boundary

The invention discloses a combined-type cable dome structure for an elliptic plane with an unequal-height boundary. The combined-type cable dome structure comprises an outer-ring beam arranged on unequal-height capitals of a lower structure. The outer-ring beam adopts a space-curve form which changes along with the elevation of capitals of the lower structure. The horizontal projection of the outer-ring beam is ellipse. An inner-ring beam is arranged above the middle portion of the outer-ring beam. Inhaul cables and ridge cables are arranged on the outermost ring of the outer-ring beam and the inner-ring beam through a levy-type structure, and inhaul cables and ridge cables are arranged within the outermost ring through a Geiger-type structure. A connecting beam for a balancing cable is arranged on the inner-ring beam additionally, and the balancing cable is arranged between the inner-ring beam and the outer-ring beam additionally. The combined-type cable dome structure can be applied to a structural engineering of which unequal-height horizontal projection of the boundary is an ellipse plane, the structure is forced uniformly, and the stability is strong; node structure is simple, the manufacturing cost is low, and construction is convenient; laying requirements of rigid roofing material can be met.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

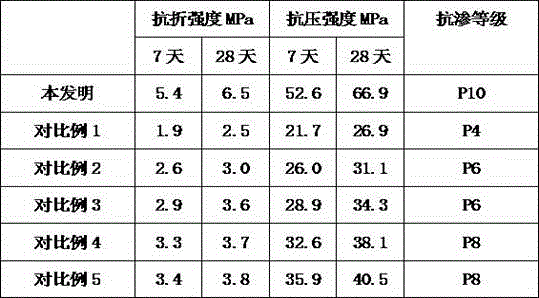

Modified asphalt concrete

The invention discloses a modified asphalt concrete. The modified asphalt concrete is prepared from a binding material, sand, gravel, cocoanut active charcoal, superfine slag powder, waste rubber powder, modified asphalt, hydrotalcite, an additive, an adjuvant and a proper amount of water. The binding material can adsorb stone sand in mortar, a network structure can be formed after gel absorption, all the ingredients can be well bound under the situation of little water, and the situations of separation and water seepage can be reduced. The additive and the adjuvant are added into the concrete formula, the proportion of all the ingredients is adjusted so as to improve the comprehensive performance of the concrete, and the requirements of most buildings can be met. By preparing the modified asphalt concrete with the modified asphalt, the comprehensive performance of the concrete can be further improved, the compressive strength and the flexural strength are improved by 10% or above, the salt resistance and the seepage resistance of the concrete are further improved, development of micro-cracks inside the concrete can be impeded, and the concrete is reinforced and toughened.

Owner:安徽金丰新型建材有限公司

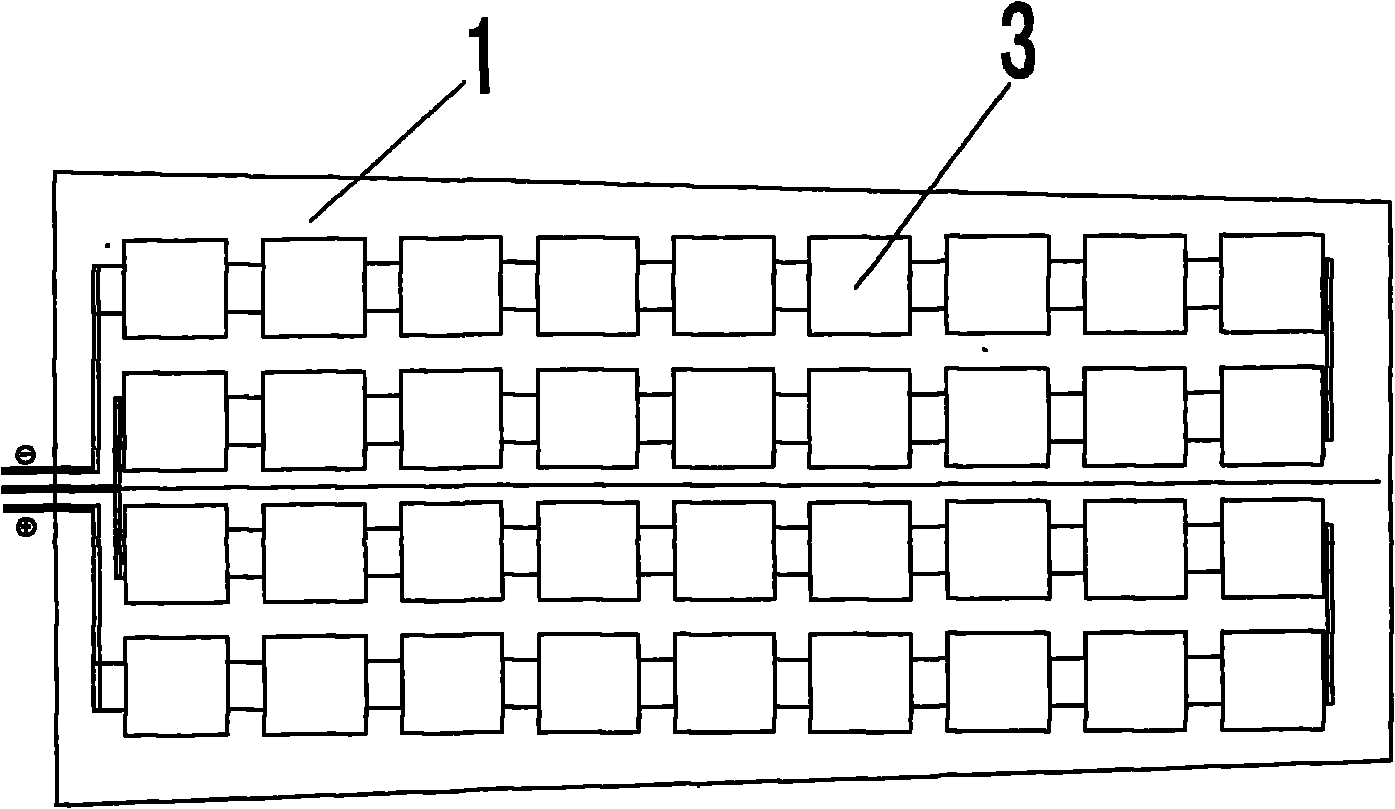

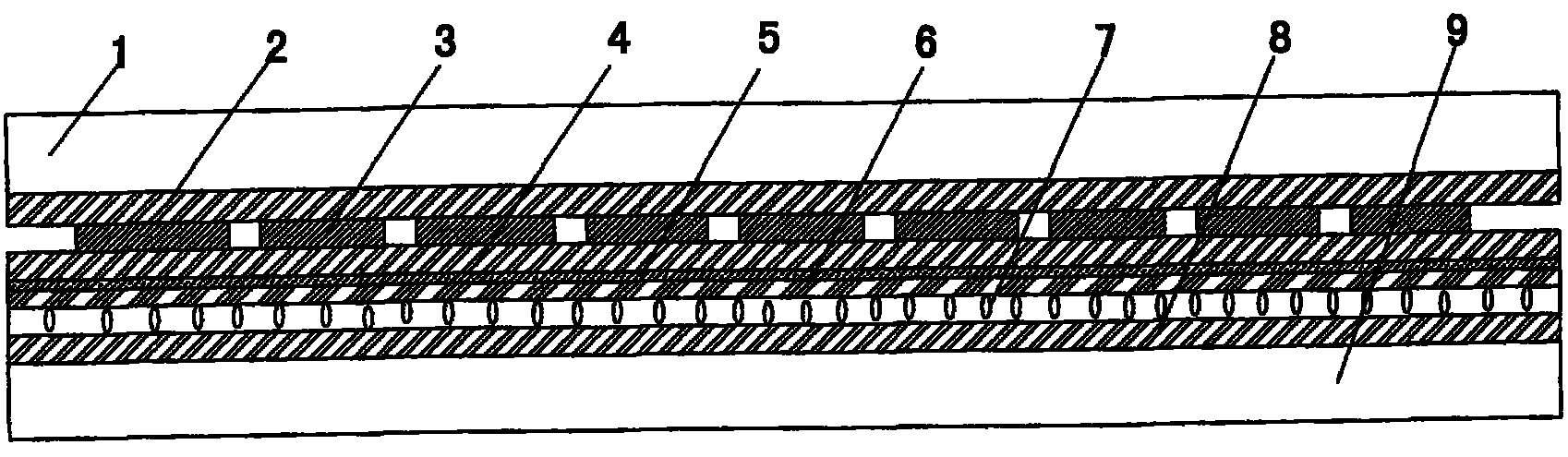

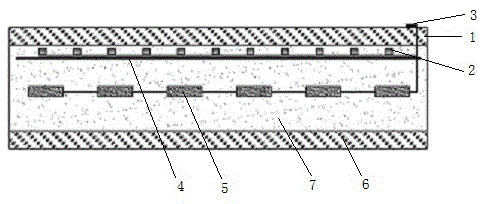

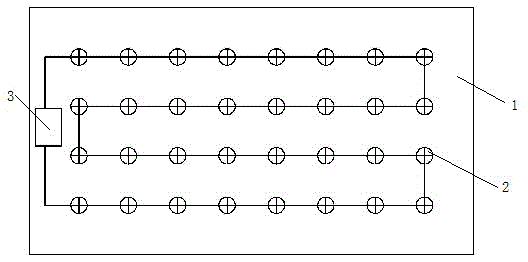

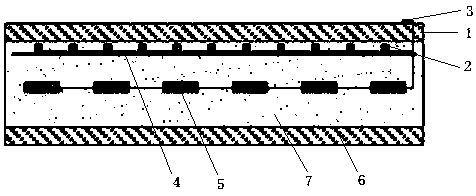

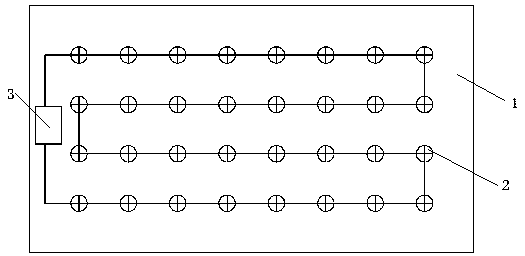

PV-LED (Photovoltaic-Light-Emitting Diode) solar-battery illuminating device and application thereof

InactiveCN102313235AReduce consumptionMeet building requirementsPoint-like light sourceElectric circuit arrangementsChemical energyEnergy source

The invention relates to a PV-LED (Photovoltaic-Light-Emitting Diode) solar-battery illuminating device, which comprises a PV-LED solar-battery assembly, an inverter and a storage battery, wherein the PV-LED solar-battery assembly is formed by laminating and packaging glass, EVA (Ethylene-Vinyl Acetate), a solar-battery pack, the EVA, PET (Polyethylene Terephthalate), an LED lamp group, the EVA, the glass and an auxiliary material, wherein the solar-battery pack is used for outputting the received current generated by sunlight to the inverter, the inverter is used for outputting the current to the storage battery, and the storage battery is used for supplying electricity for the LED lamp group for illumination. In the PV-LED solar-battery illuminating device disclosed by the invention, electricity-generating equipment and illuminating equipment are integrated into the same device, the electricity is generated by utilizing a solar battery under the irradiation of the sunlight at daytime, electrical energy is converted into chemical energy to be stored in the storage battery, and the illumination is supplied for an energy-saving type LED lamp at night, so that the consumption of other energy sources is saved through a circuit design; and double-surface glass packaging is utilized by the device, and the building requirements for both structural strength and heat-preserving performance can be met. The PV-LED solar-battery illuminating device can be combined with buildings to be used as a ceiling or a floor brick; and the PV-LED solar-battery illuminating device not only can be used as a good building material, but also can be used for novel landscape decoration.

Owner:SHANGHAI SOLAR ENERGY S&T

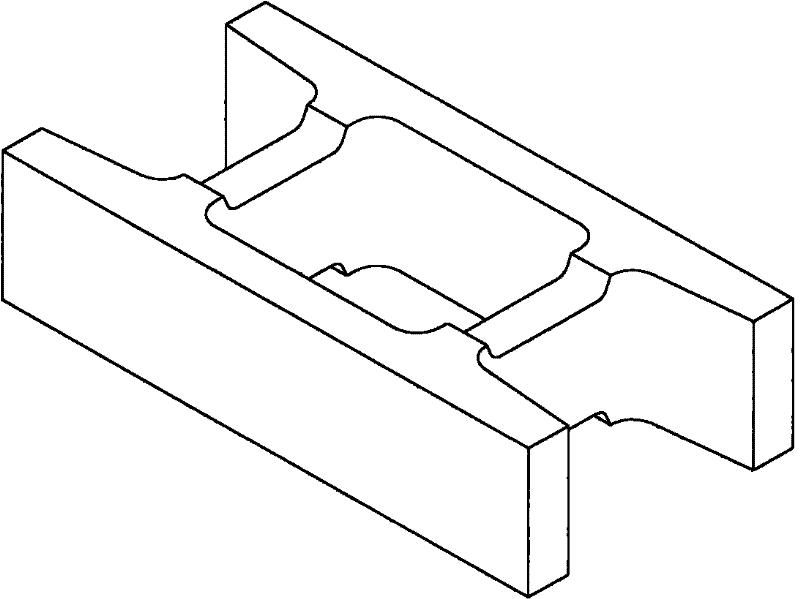

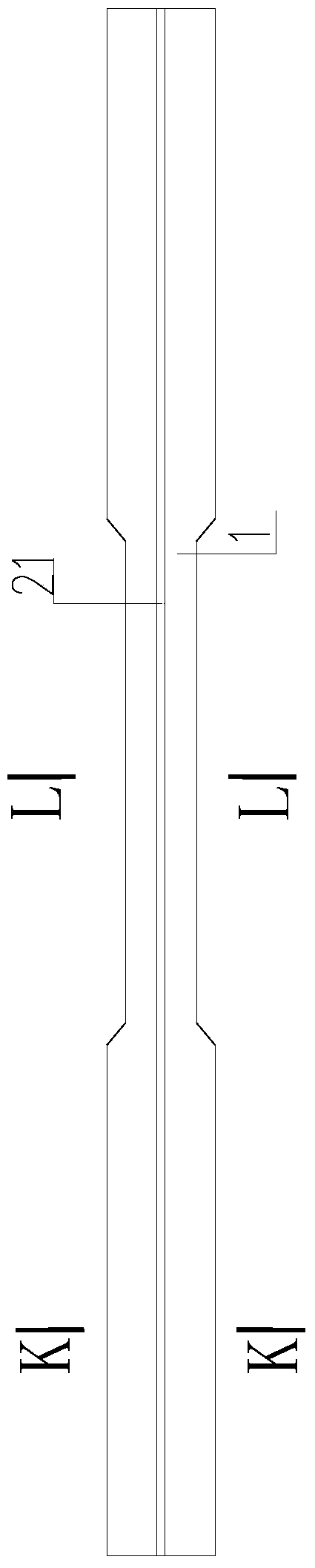

Method for manufacturing steel pattern plate of taper-end concrete pier

ActiveCN101733643AEasy to installExcellent adhesionOther manufacturing equipments/toolsFlame cuttingCost savings

The invention relates to a method for manufacturing a steel pattern plate of a taper-end concrete pier. The method comprises the following steps: calculating circular arc points based on design parameters and marking on a plate, using a flame cutting machine to adjust the curvature radius of the track at the marked cutting points and fixing the track, then cutting the taper-end preliminarily-cut plate into fan-shaped pattern plates, welding the fan-shaped pattern plates two by two to obtain two semi-taper pattern plates, and welding and shaping the straight rectangular plate and the semi-taper pattern plates to obtain a sectional pattern plate. By using the method for making a steel pattern plate of a taper-end concrete pier and a simple tool, a large taper-end steel pattern plate, which can only be finished under specified conditions, can be manufactured and finished under primitive conditions on the construction site; and the pattern plate can be conveniently installed, tightly affixed and quickly erected, thereby ensuring construction quality and speed and completely meeting the construction requirements of piers of such big special shapes. Besides, the pattern plate has the advantages of low manufacturing cost, simple process and significant construction cost saving.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

Material composition for preparing brick and prepared brick

The invention provides a material composition for preparing brick, wherein the material composition contains silica sand, cement, a water reducing agent, redispersible rubber powder and fiber. The strength of the brick prepared from the material composition for preparing brick provided by the invention can reach or exceed the strength of concrete brick (hollow concrete brick), thus the brick can meet building requirement and solves the demands of building bricks in areas short of gravel resources and clay resources, desert areas and other areas (such as Xinjiang area).

Owner:BEIJING RECHSAND SCI & TECH GRP

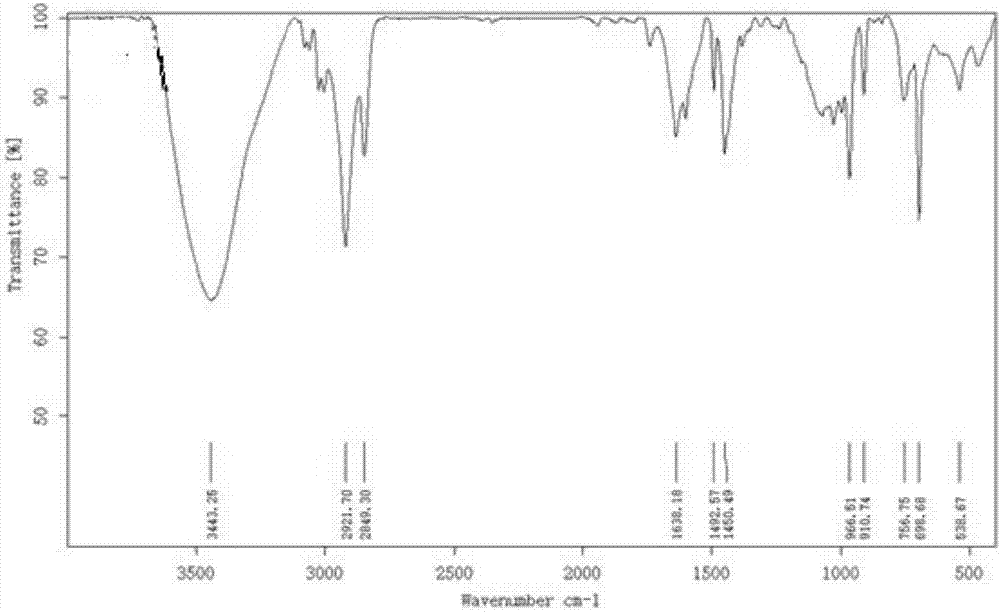

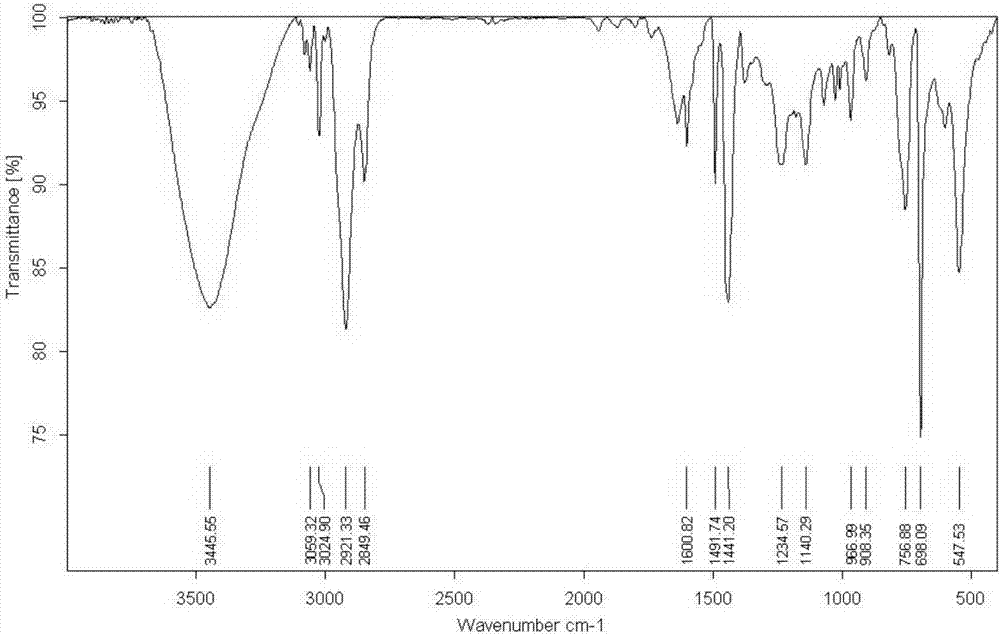

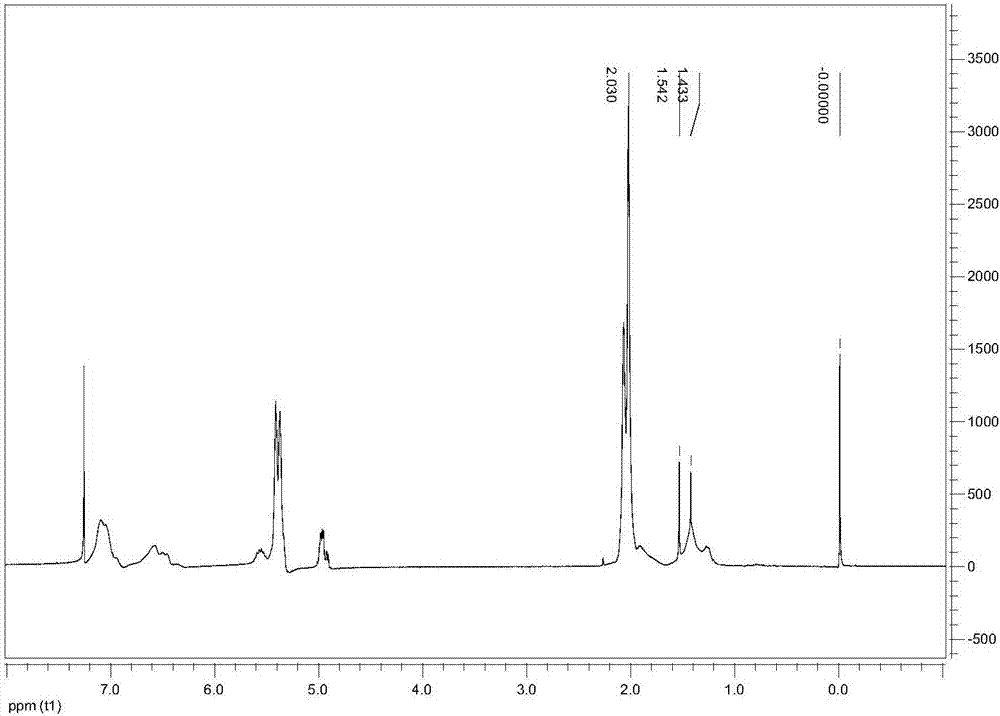

Brominated polymer flame retardant and preparation method thereof

The invention provides a brominated polymer flame retardant and a preparation method thereof and belongs to the field of chemical and constructing material flame retardants. The preparation method comprises the following steps: at 0 DEG C, dripping a certain ratio of diluted bromine into a styrene-butadiene copolymer solution; and reacting by adopting a specific temperature rising mechanism to finally prepare the target brominated polymer flame retardant. The brominated polymer flame retardant provided by the invention has good compatibility with a polystyrene material, a high oxygen index and a good flame retarding effect; the preparation method provided by the invention is simpler and bromine is directly used for carrying out bromine addition, so that introduction of other impurities and byproducts is effectively avoided; and the difficulty of post-treatment is reduced and the cost of a whole synthesizing process is reduced.

Owner:天津天盈新型建材有限公司

PV-LED integrated double-glass module encapsulation method

ActiveCN105552072AMeet building requirementsSolid-state devicesSemiconductor devicesInsulation layerPhotovoltaic industry

The present invention discloses a PV-LED integrated double-glass module encapsulation method. A solar photovoltaic double-glass module and a LED product are perfectly combined, two sheets of glass and an insulation layer are composed, and the back glass of the LED is encapsulated; an interlayer lays solar cells, and Sn-coating copper strip arranged between the solar cells forms a composite layer which is in parallel with and collects the whole component of a lead terminal; and coating is adopted to bond between layers to form a whole module. The PV-LED integrated double-glass module encapsulation method is applied to fields of the photovoltaic industry, the application problem of the combination of a solar photovoltaic module and a LED is solved, and the problems of bubbles in the process of the PV-LED integrated double-glass module manufacture and the damage, the migration and the assignment of the LED lamp bead encapsulation are effectively solved. The PV-LED integrated double-glass module may be modularized and integrated and may take the largest advantage for markets.

Owner:LIANYUNGANG SHENZHOU NEW ENERGY

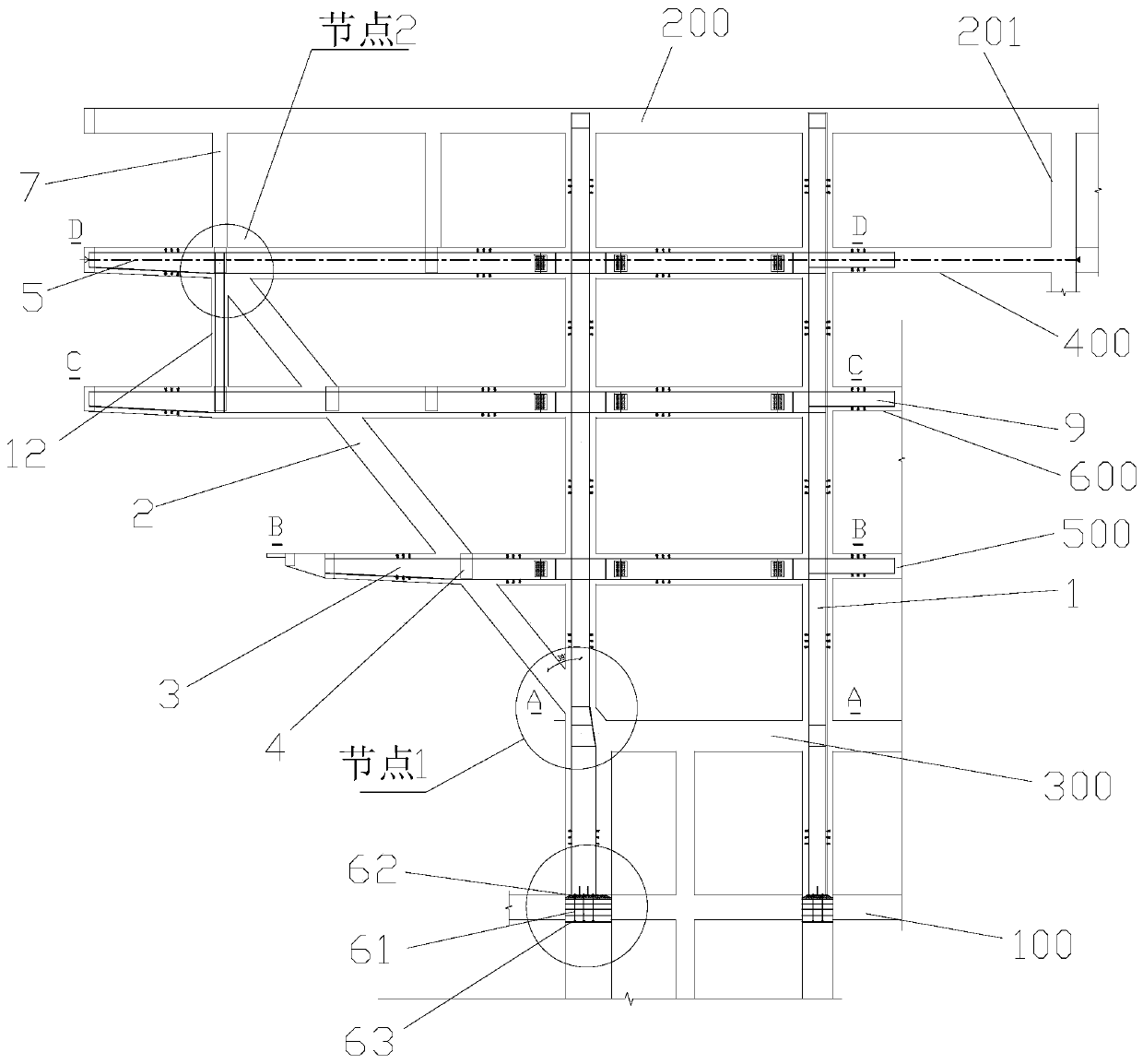

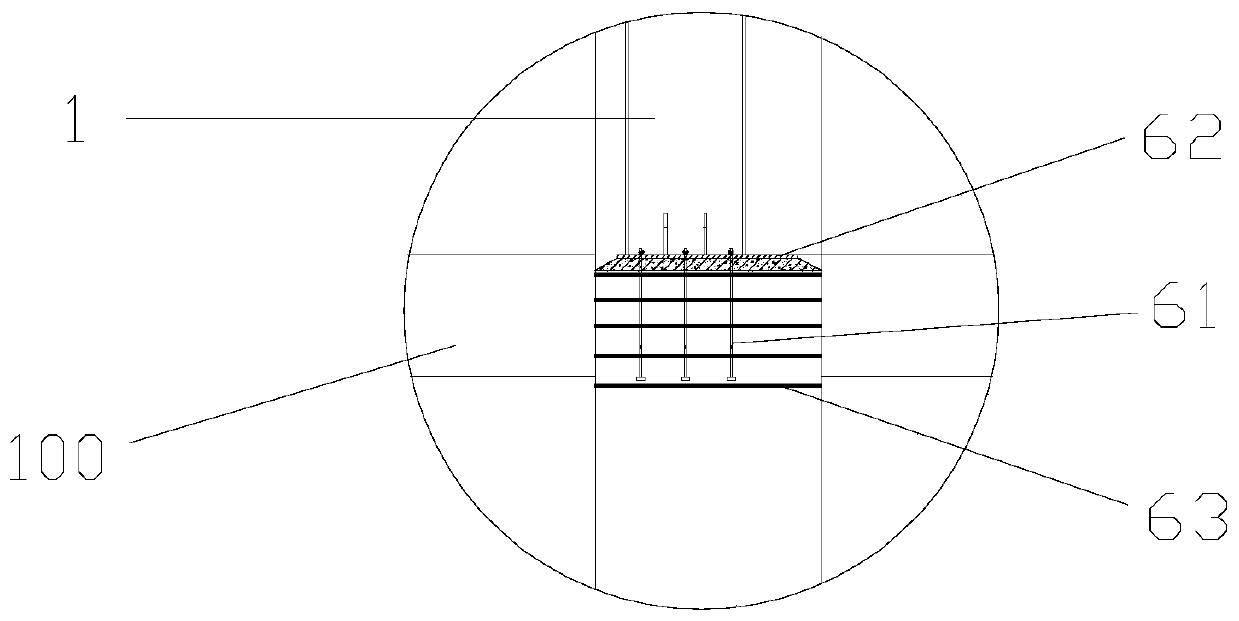

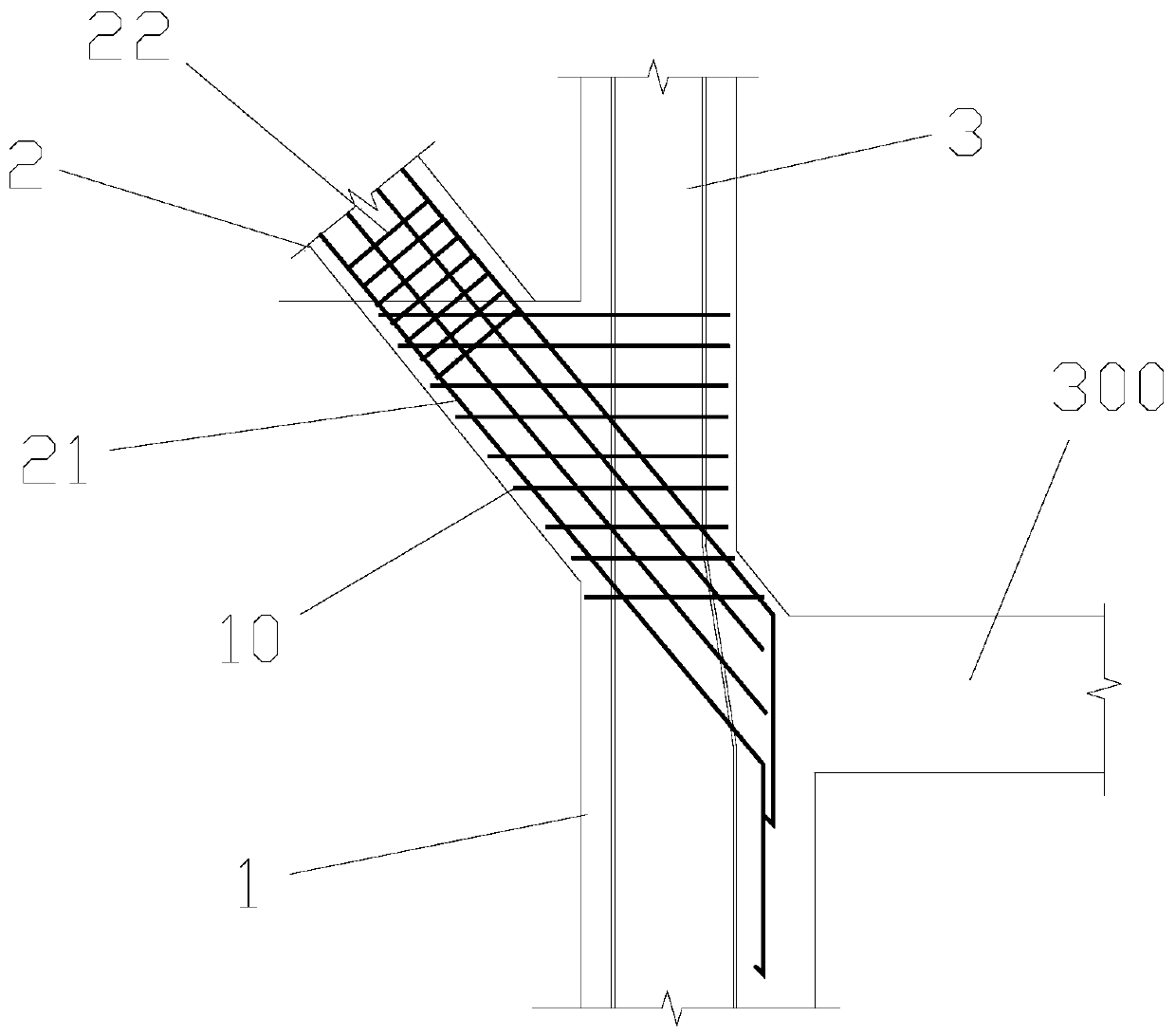

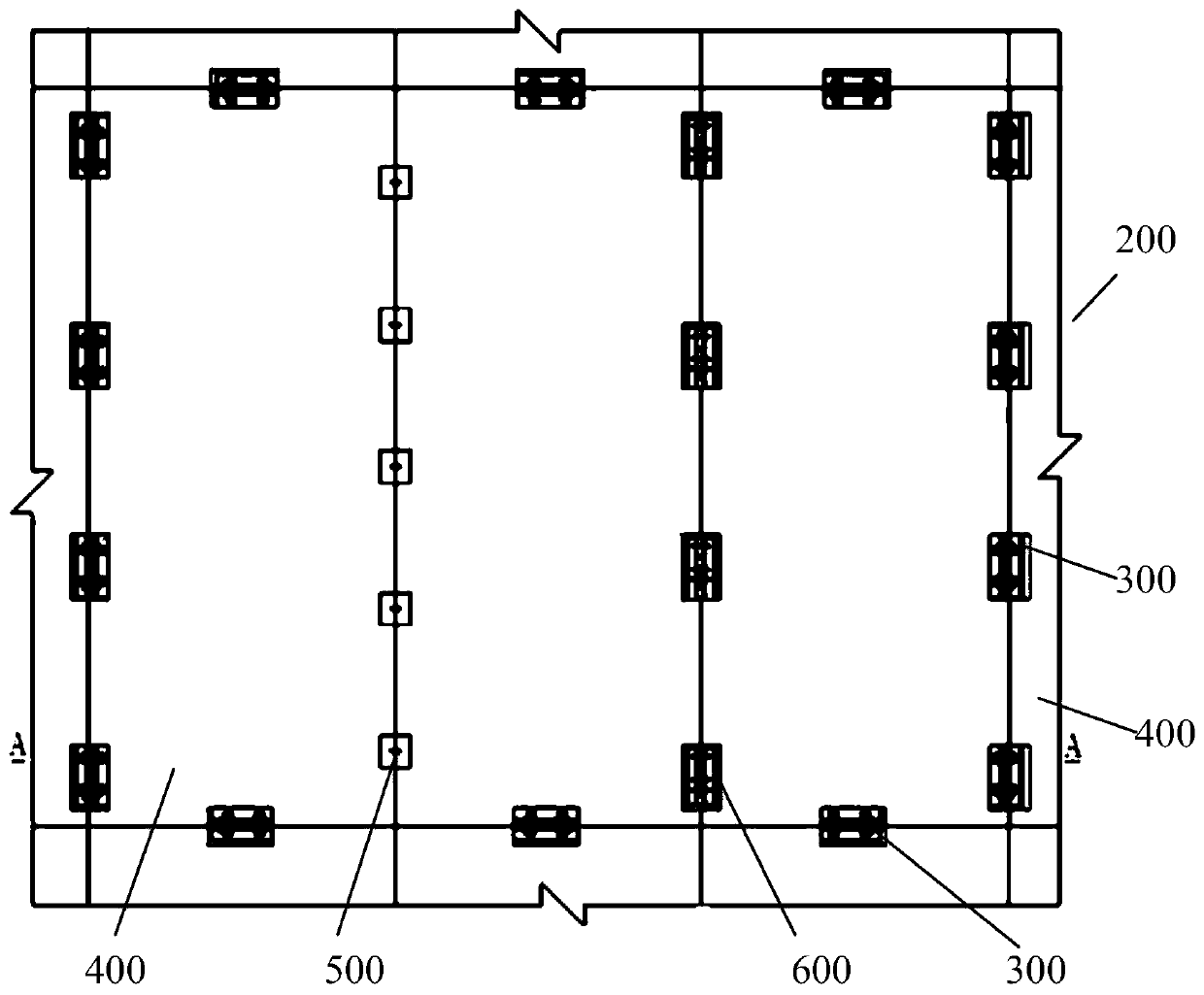

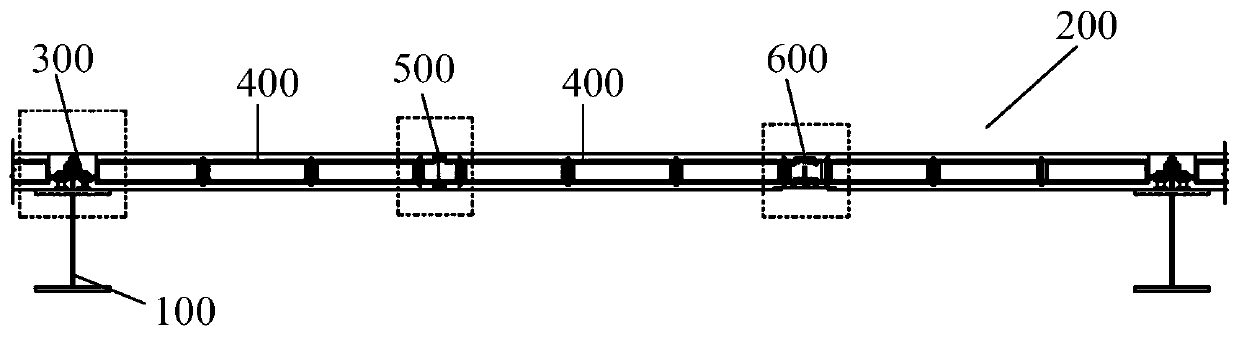

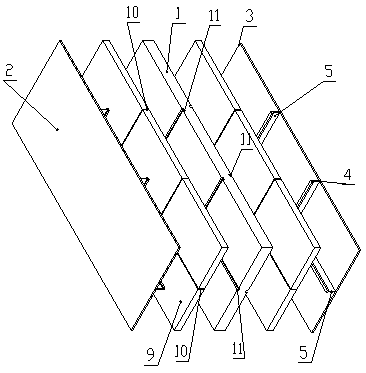

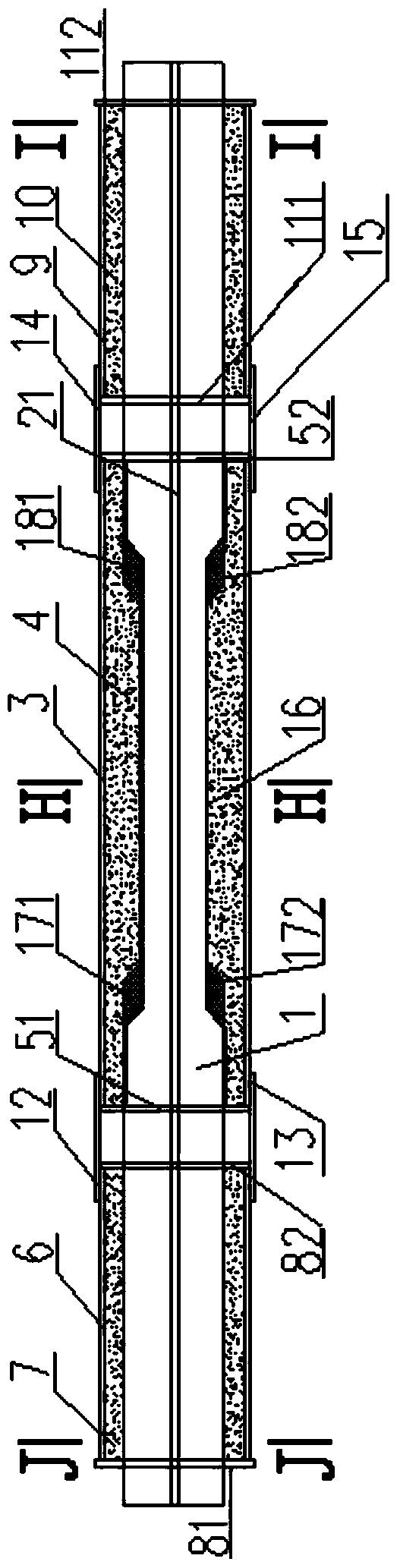

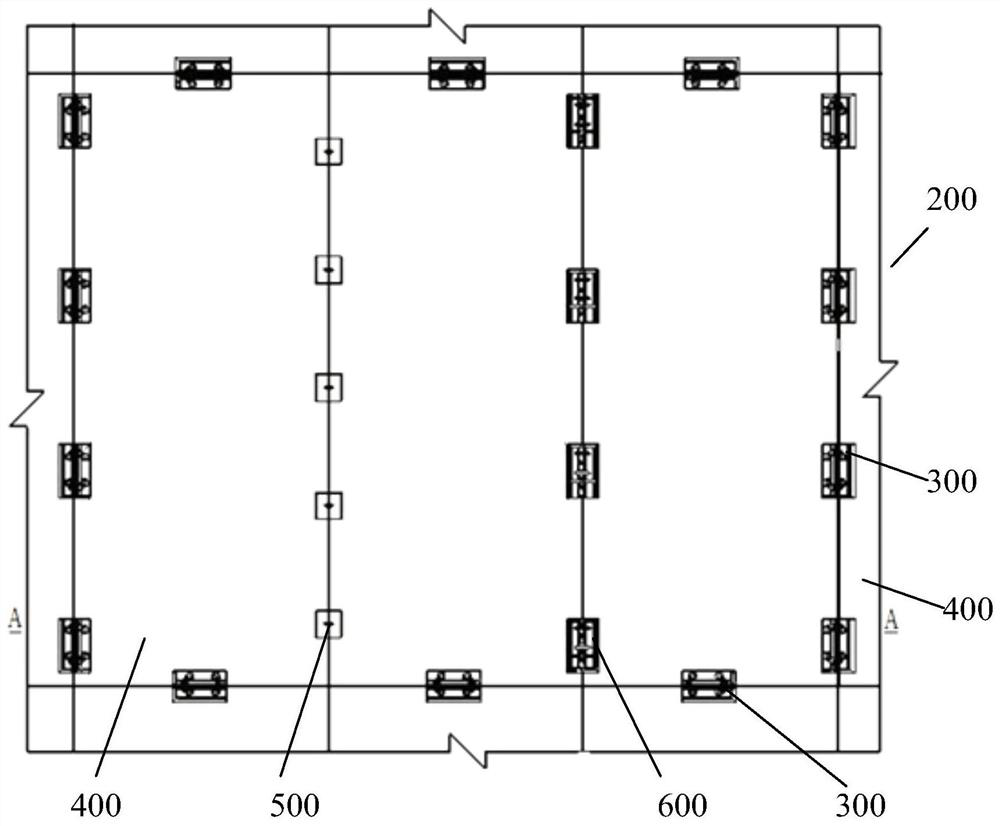

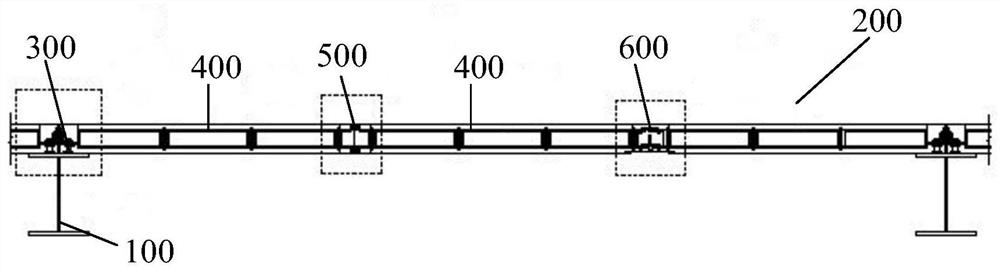

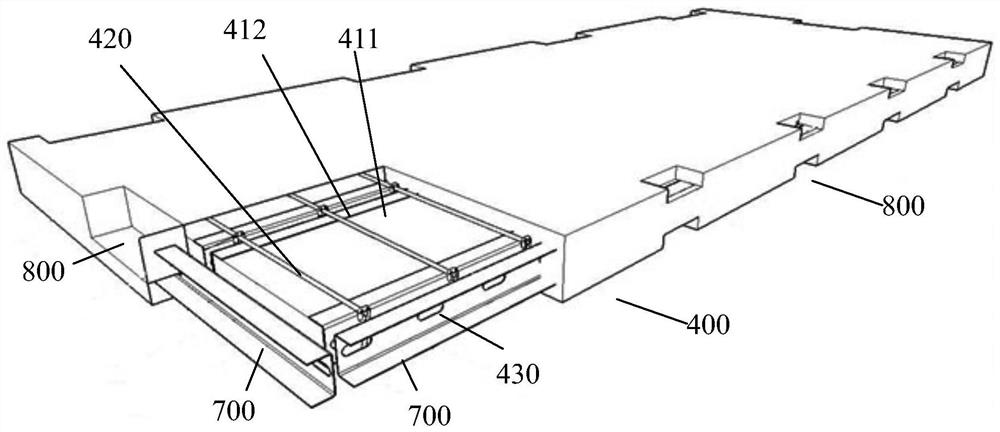

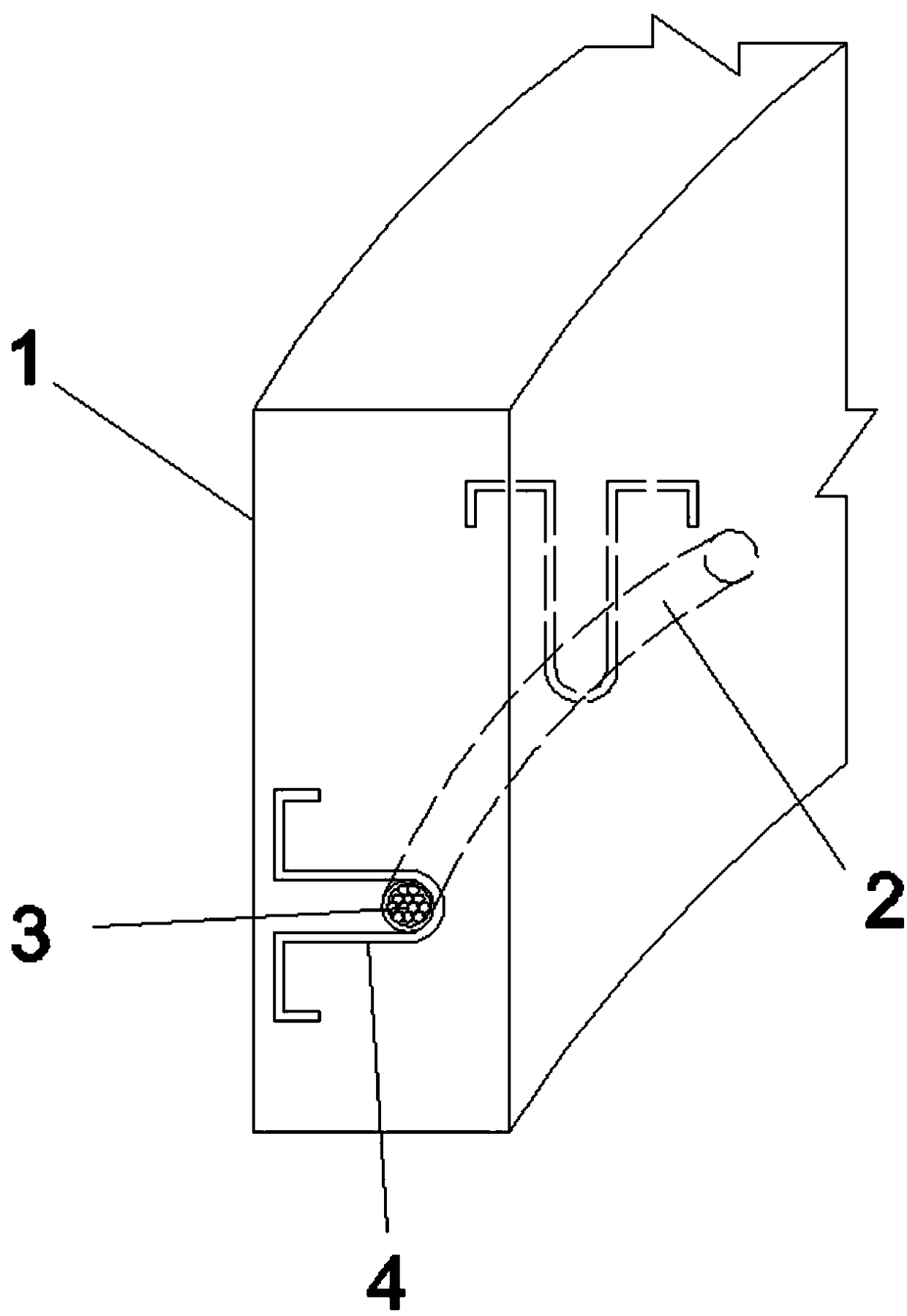

Large-span step-by-step cantilever inclined strut structure based on pull-up and lower-insertion structure and construction method of large-span step-by-step cantilever inclined strut structure

ActiveCN110107075AMeet structural safety and load requirementsImprove indoor space utilizationScaffold accessoriesCantileverPre stress

The invention discloses a large-span step-by-step cantilever inclined strut structure based on a pull-up and lower-insertion structure and a construction method of the large-span step-by-step cantilever inclined strut structure. The large-span step-by-step cantilever inclined strut structure comprises load steel reinforced columns (1), an inclined strut (2), steel reinforced beams (3), tie beams (4) and prestressed tendons (5); the bottoms of the load steel reinforced columns are fixed into a negative layer (100), and the tops of the load steel reinforced columns are fixed to a roof layer (200); the inclined strut is fixed to the load steel reinforced column (1) of a first floor (300), and an inclined strut eccentric angle is formed between the inclined strut and the corresponding load steel reinforced column; the steel reinforced beams are connected through the tie beams and then are disposed on the load steel reinforced columns to form a plurality of floors of a building structure, the inclined strut extends upward in an inclined mode to the top layer and is fixed to the steel reinforced column of each level through the tie beams to form a step-by-step cantilever structure; and the prestressed tendons are anchored on a fixing structural column (201), and the prestressed tendons are arranged in the steel reinforced beams and anchored. According to the large-span step-by-step cantilever inclined strut structure based on the pull-up and lower-insertion structure and the construction method of the large-span step-by-step cantilever inclined strut structure, the architecturalrequirement of the large-span step-by-step inclined shape in the building structure can be met through the construction technology of pull-up and lower-insertion diagonal bracing.

Owner:SICHUAN TAILONG CONSTR GRP CO LTD

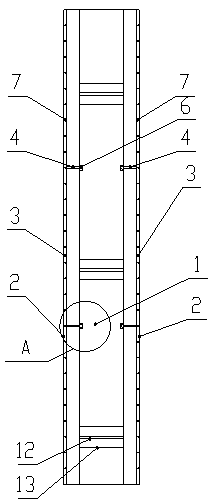

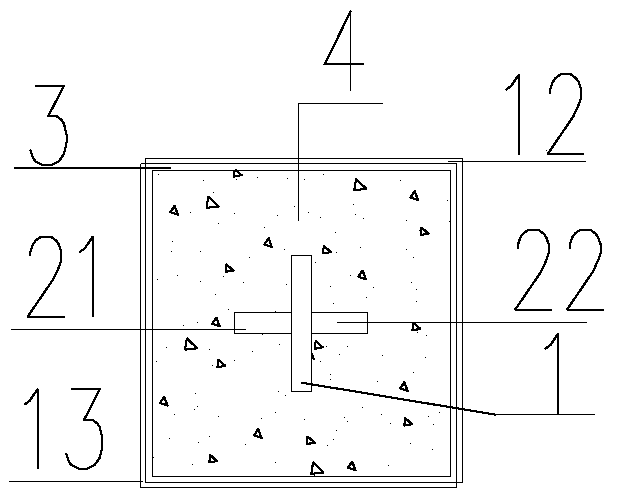

Combination prefabricated shear wall with vertical ECC energy consumption belts and manufacturing method thereof

The invention discloses a combination prefabricated shear wall with vertical ECC energy consumption belts and a manufacturing method thereof. Concrete filled steel tube frame columns are arranged on both sides of a shear wall body; a plurality of parallel partially filled composite core columns are arranged in the shear wall body; and the ECC energy consumption belts fill between the frame columnsand the core columns and between the core columns, and after being assembled with upper and lower frame beams, the combination prefabricated shear wall with the vertical ECC energy consumption beltsis formed. Compared with an ordinary concrete filled steel tube frame shear wall and steel plate shear wall, the combination prefabricated shear wall has large lateral resisting stiffness, high bearing capacity, good energy consumption, stable post-seismic performance, slow degradation of bearing capacity and stiffness, multi-line anti-seismic performance and better performance. The construction is convenient, the degree of prefabrication is high, the layout is flexible, and the combination prefabricated shear wall can be used in high-rise or large-scale complex multi-story buildings.

Owner:CHANGAN UNIV

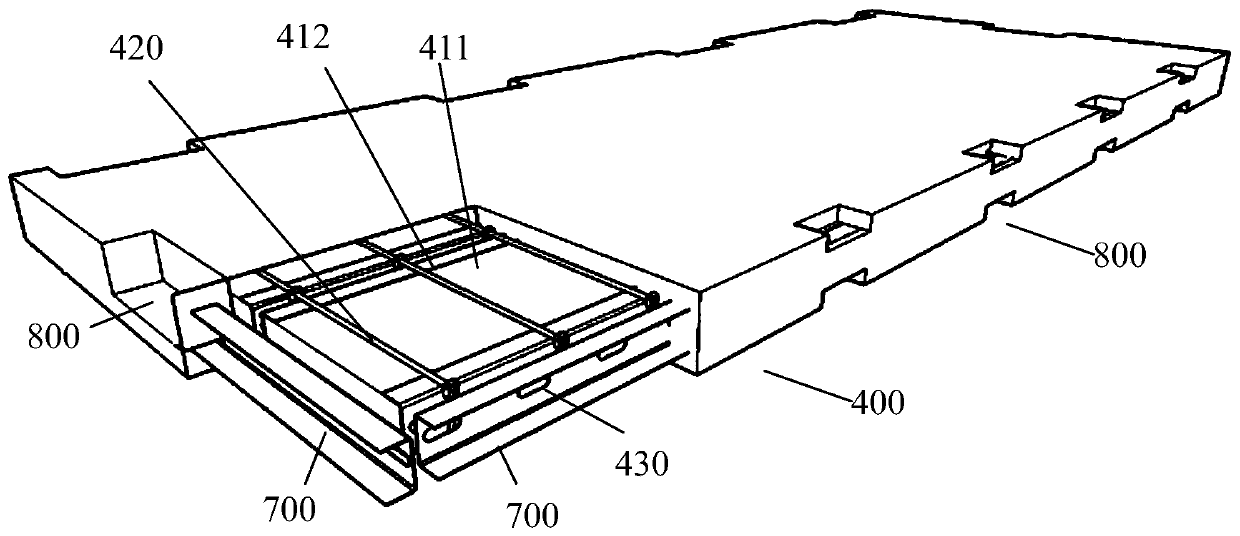

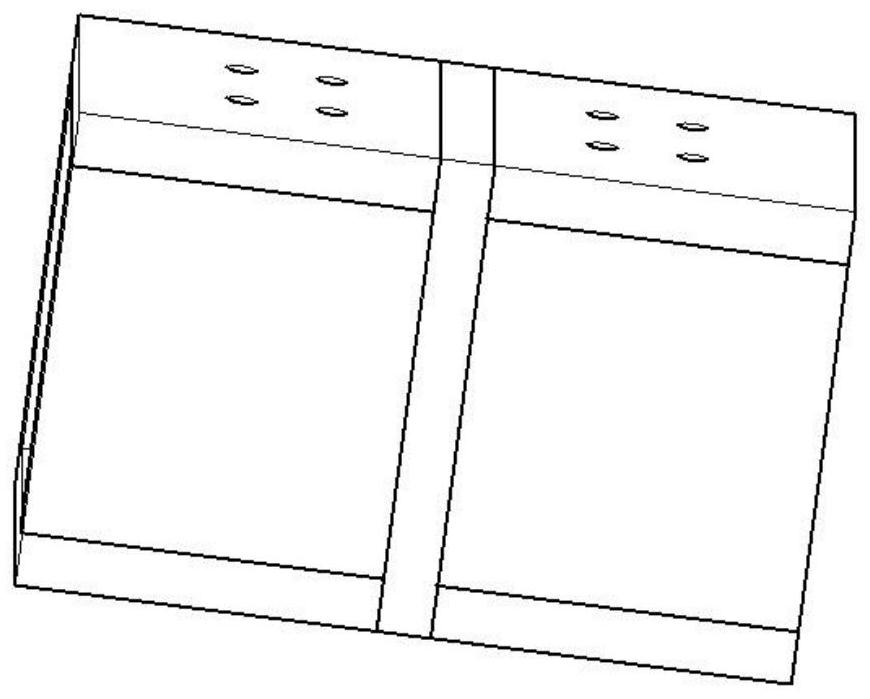

Fabricated type steel concrete composite floor system for steel structure house

The invention provides a fabricated type steel concrete composite floor system for a steel structure house, and belongs to the technical field of architectures. The fabricated type steel concrete composite floor system for the steel structure house comprises a steel beam and a plate body, wherein the plate body is connected with the steel beam through a beam plate connecting piece, the plate bodycomprises at least two precast slabs, every two adjacent precast slabs are connected through a first plate connecting piece or a second plate connecting piece, first type steel for being connected with the beam plate connecting piece, the first plate connecting piece or the second plate connecting piece are pre-buried on the side walls of the precast slabs, connecting piece installation grooves for containing the beam plate connecting piece, the first plate connecting piece or the second plate connecting piece and exposing the first type steel and the connecting parts of the corresponding connecting pieces. According to the fabricated type steel concrete composite floor system for the steel structure house, convenience of construction is improved, and the structure is stable

Owner:河北比穆建筑科技有限公司

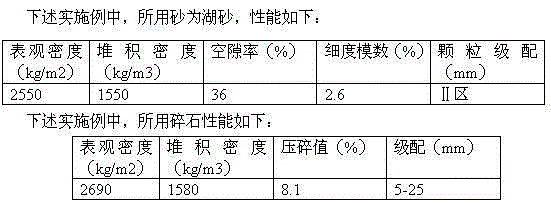

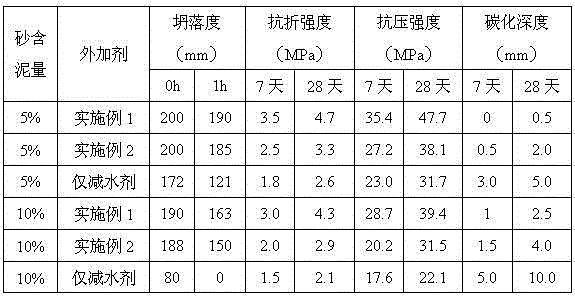

high mud content concrete

ActiveCN104072045BGuaranteed liquidityReduce slump lossSolid waste managementBrickEnvironmental engineering

The invention discloses a concrete with high mud content. The raw materials include: cement, sand, gravel, waste calcined material, admixture and water. The waste calcined material is prepared by the following method: waste concrete and waste bricks Mix according to the mass ratio of 10:3, crush and grind into powder less than 30mm, and set aside; put the powder in water, soak for 2-3 days, then take it out and dry it; put the dried powder at 1000-1100℃ Calcining at lower temperature for 4-5 hours, grinding and sieving after cooling, and taking calcined products with particle diameters of 0.15-3mm and 5-10mm respectively as waste calcined materials. The invention provides a kind of concrete with high mud content, which can use sand with high mud content as raw material, and the concrete with high mud content can still meet the building requirements through the introduction of admixture. In addition, the invention also recycles waste concrete and waste bricks, turns waste into wealth, reduces costs, and has good economic and environmental benefits.

Owner:RIZHAO FEM NEW MATERIAL TECH

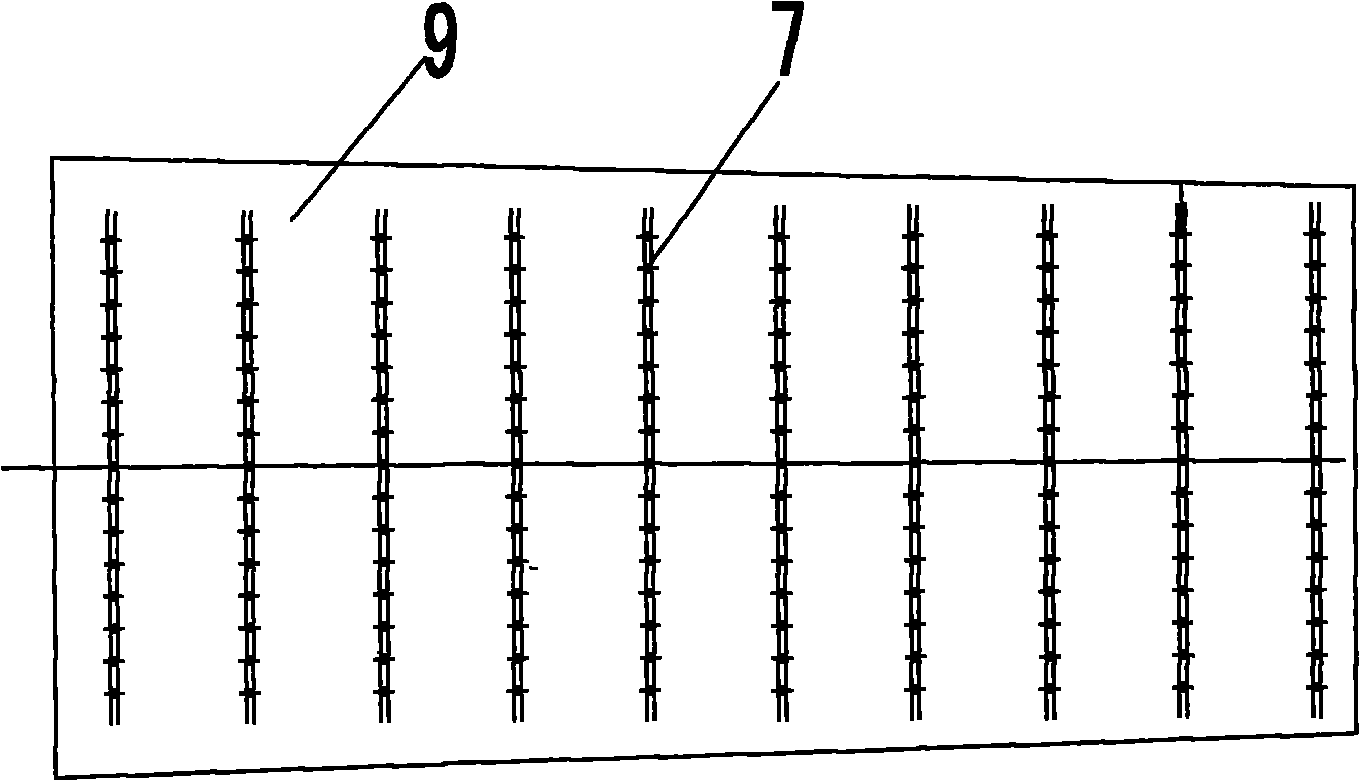

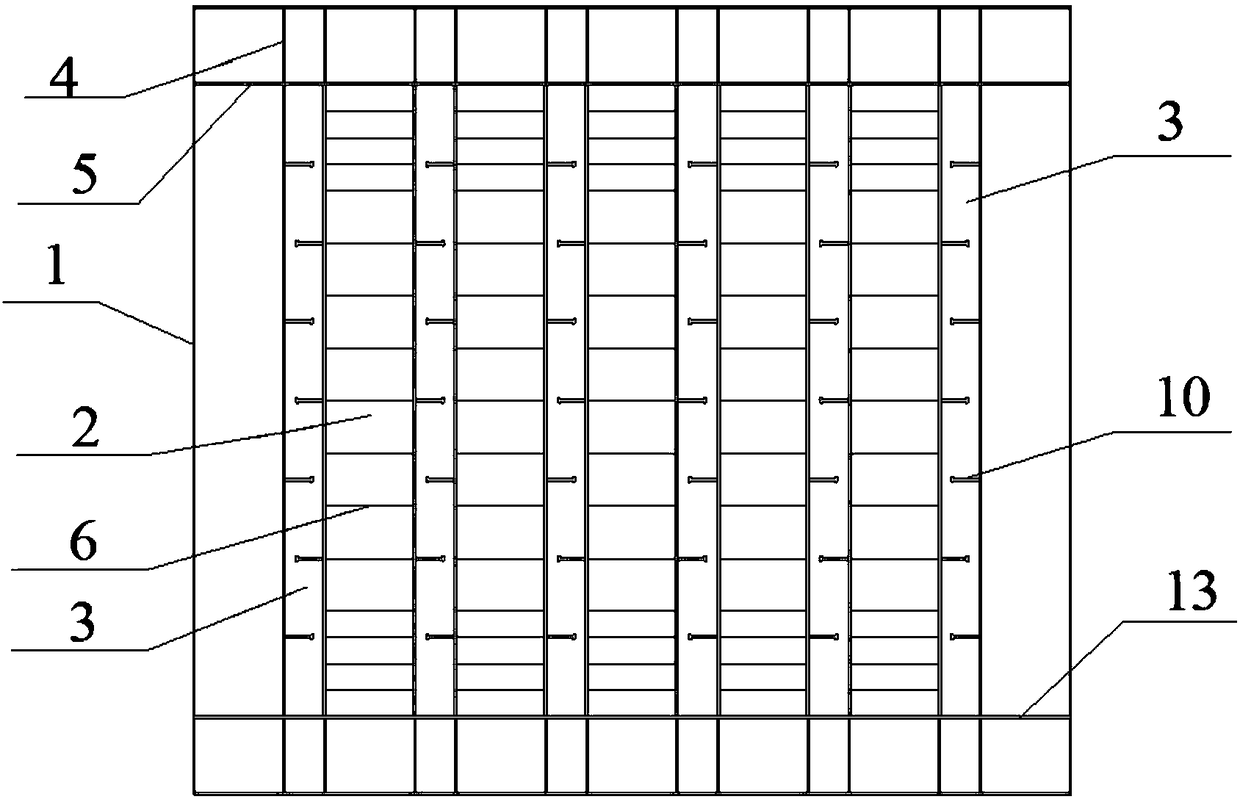

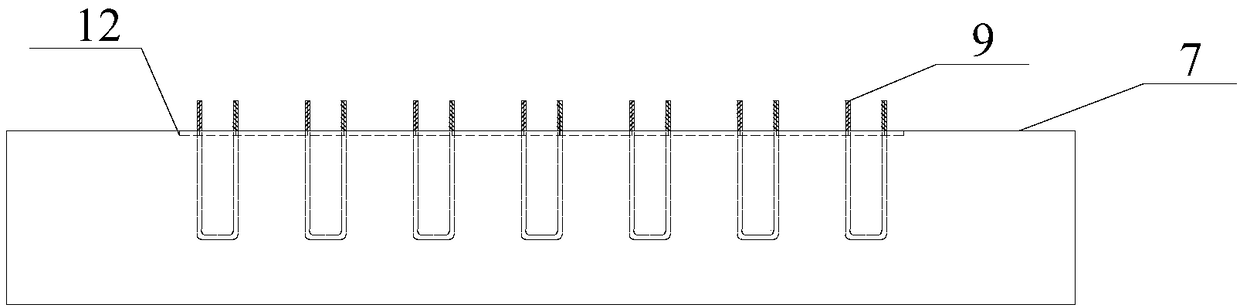

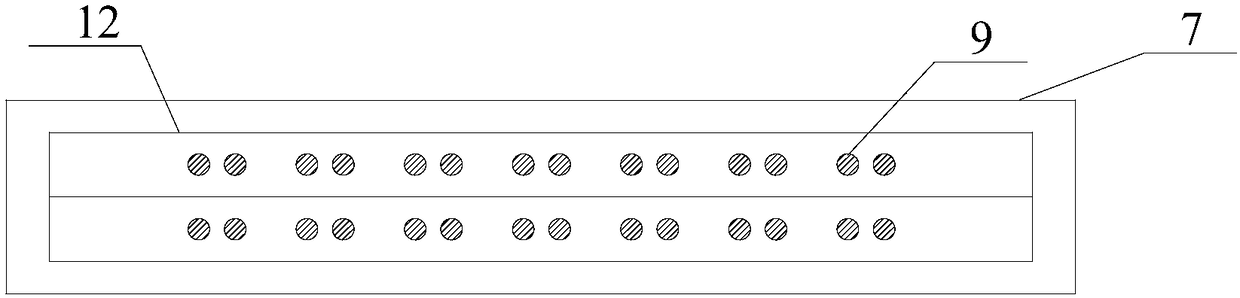

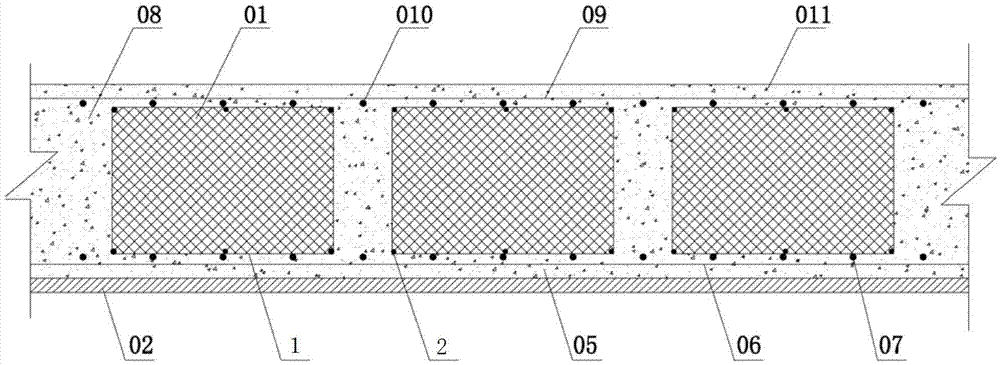

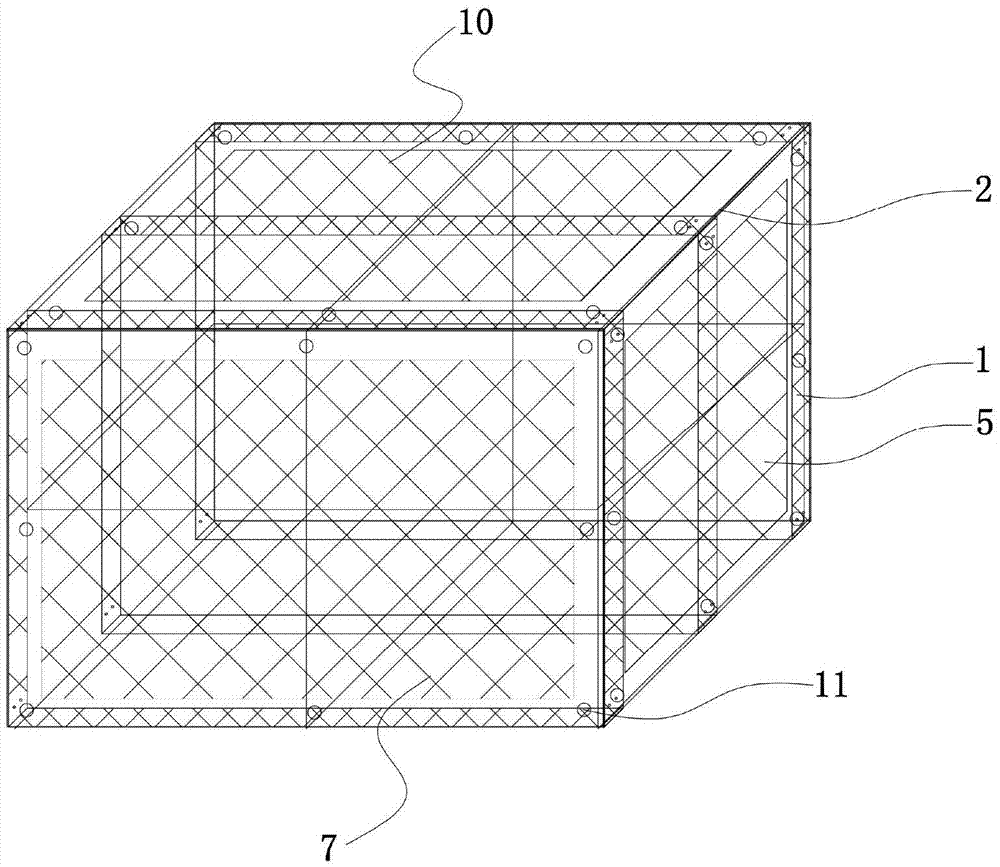

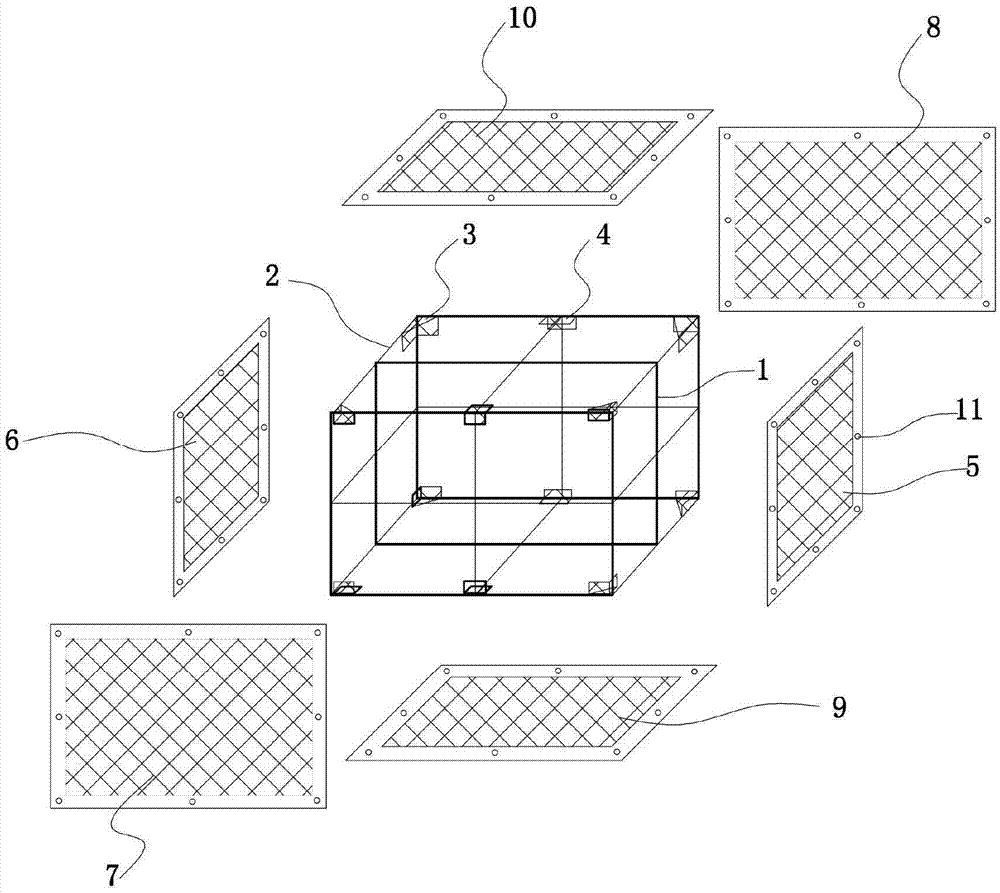

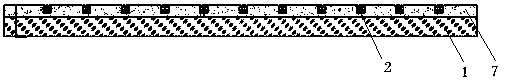

Hollow hidden beam plate structure formed by net pieces and supporting rebar cast-in-place concrete and process

PendingCN106948534AReduce construction proceduresReduce construction difficultyFloorsWeb structureRebar

The invention discloses a hollow hidden beam plate structure formed by net pieces and supporting rebar cast-in-place concrete and a process. The hollow hidden beam plate structure comprises net boxes, a rebar net cloth body and a concrete filling body. The rebar net cloth body comprises an upper layer net cloth body and a lower layer net cloth body which are arranged in an up-down spaced mode. The net boxes are uniformly arranged between the upper layer net cloth body and the lower layer net cloth body at intervals. Outside space of the net boxes are filled with the concrete filling body extending toward the outer sides of the upper layer net cloth body and the lower layer net cloth body. The lower portion of the concrete filling body is supported and shaped through a supporting formwork. The concrete filling body is poured from bottom to top. Air mixed in the concrete filling body is extruded into the net boxes from the two sides of the net boxes and discharged upward through the tops of the net boxes till covers the net boxes, and the net boxes block concrete outside to form a whole hollow hidden beam plate. A hollow or open web structure is formed, supporting rebars takes part in force bearing of the structure to strengthen the building structure, accordingly the construction efficiency is improved, and the energy-saving and environmental-friendly requirement of construction is met.

Owner:刘鹏

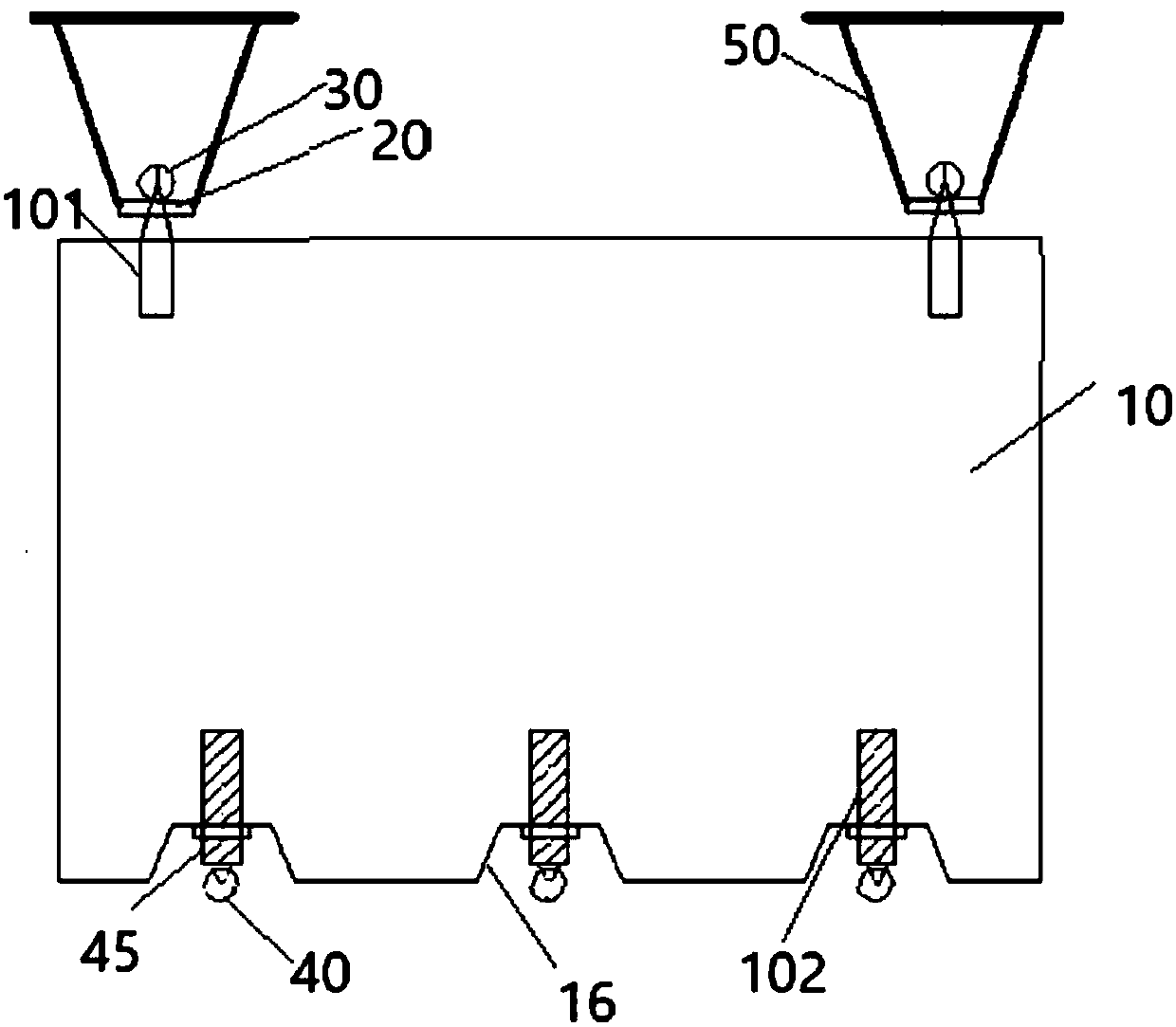

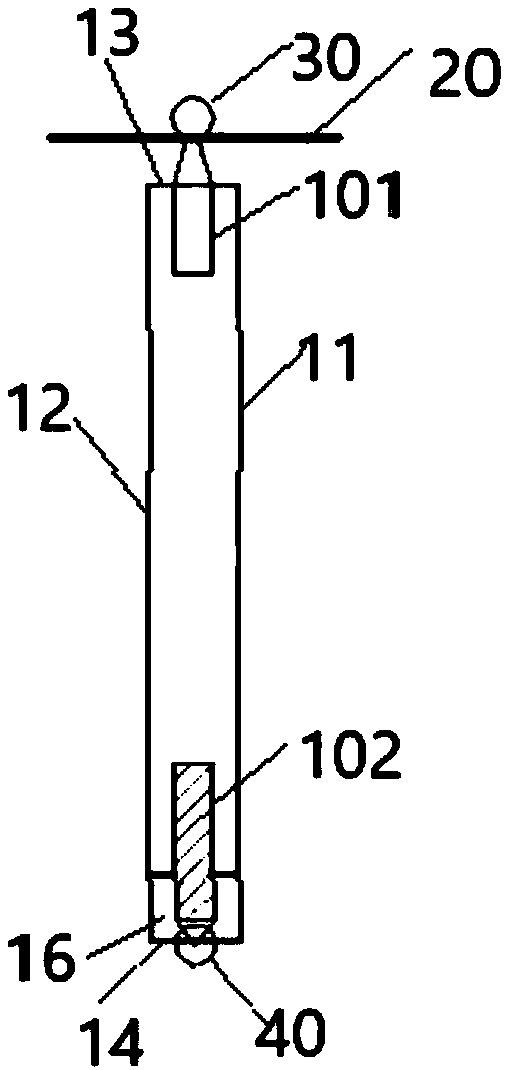

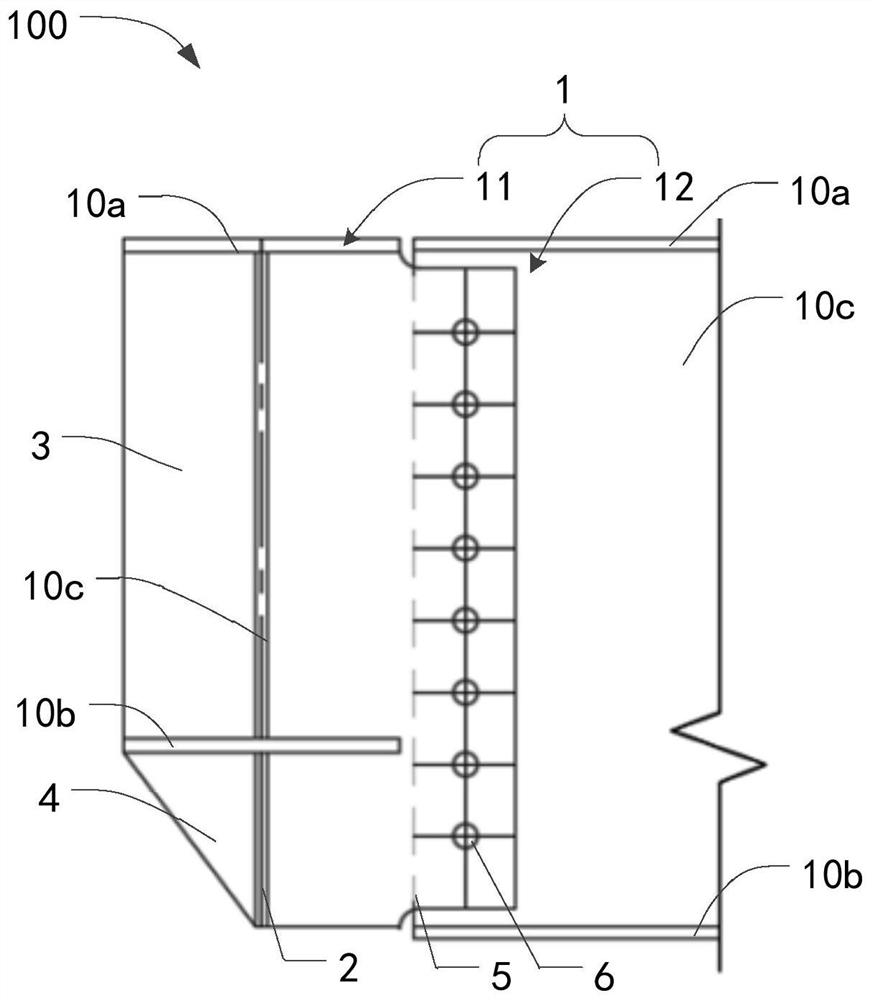

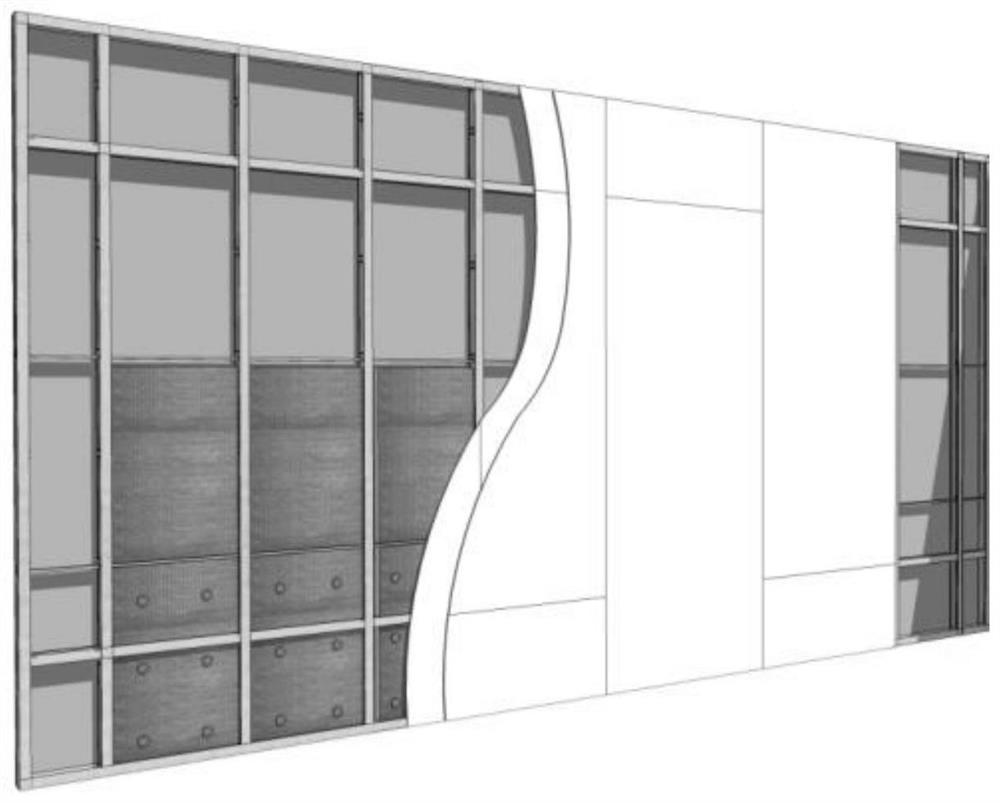

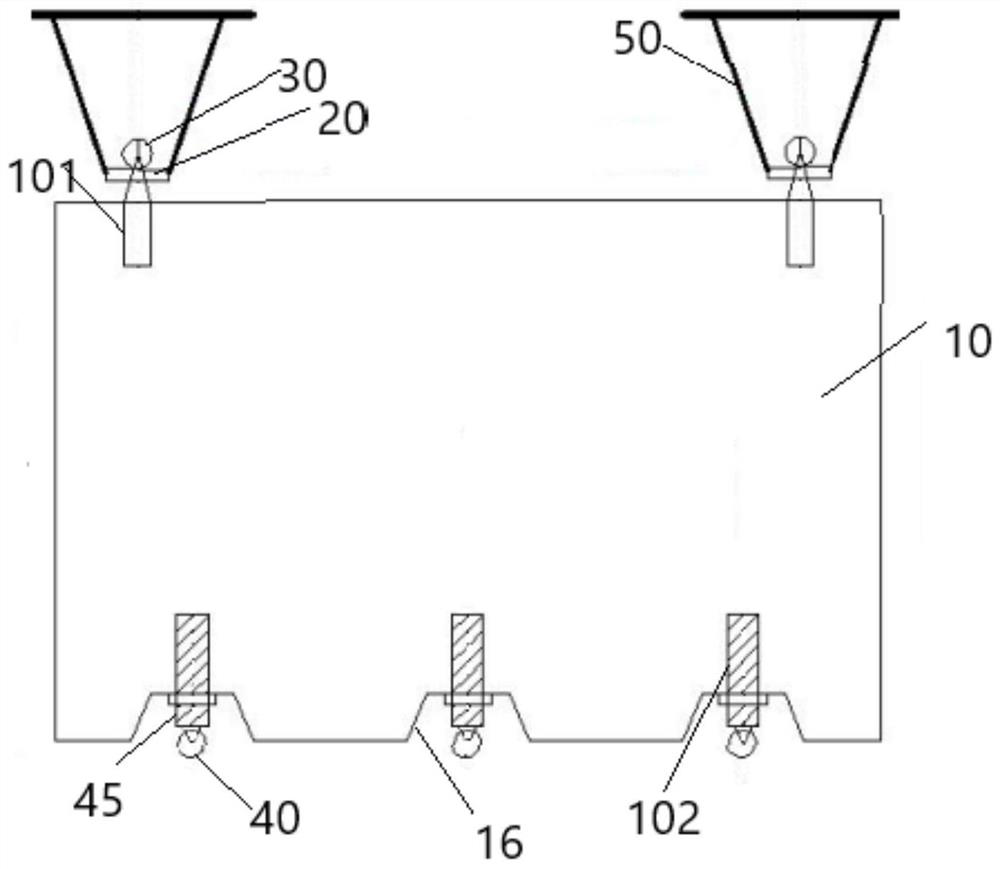

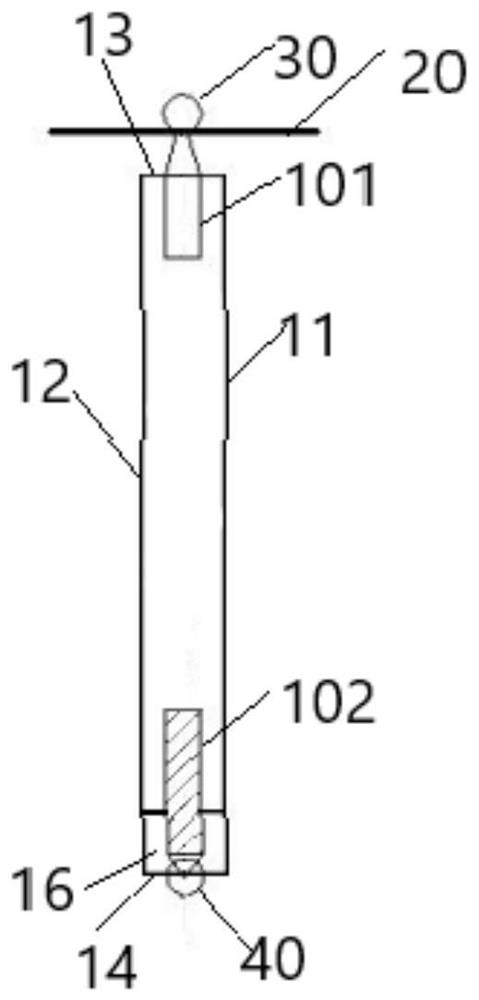

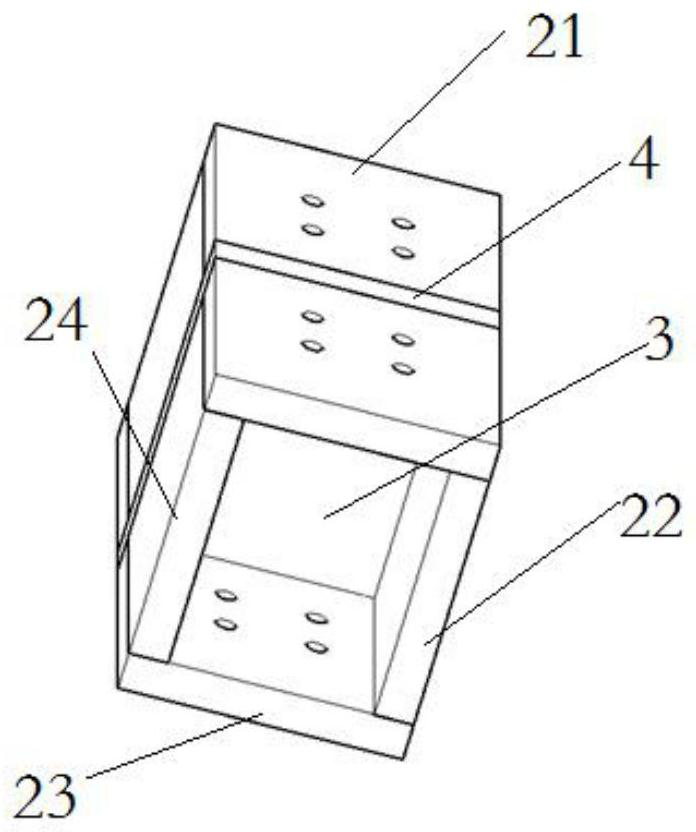

Lightweight movable wall body with gypsum board light-gauge steel frame system

The invention discloses a lightweight movable wall body with a gypsum board light-gauge steel frame system. The lightweight movable wall body with the gypsum board light-gauge steel frame system comprises a movable wall body (10) and at least two guide rails (20) arranged parallel to the top of the movable wall body (10), wherein the movable wall body (10) comprises a frame main body, a first gypsum board (11) and a second gypsum board (12); the first gypsum board (11) and the second gypsum board (12) are used for sealing the frame main body; the frame main body comprises a top plate (13), a bottom plate (14), 3-15 vertical studs and 3-15 horizontal core-through beams; the top plate (13) is provided with at least two universal rolling wheels (30); the at least two universal rolling wheels(30) are separately and correspondingly connected to the at least two guide rails; the universal rolling wheels (30) slide along the guide rails; and the bottom plate (14) is evenly provided with at least three load-bearing rolling wheels (40) at equal intervals.

Owner:肇庆北新建材有限公司

Fabricated heat-preservation and decoration combined external wall board and manufacture and construction method thereof

InactiveCN108301554AReduce processShorten the construction periodCeramic shaping plantsBuilding componentsEngineeringBlocking layer

A fabricated heat-preservation and decoration combined external wall board comprises a heat-preservation board, an inorganic light-weight filling block layer, a mesh structure and a connecting rod, wherein heat-preservation board grooves are formed in the left side and the right side of the heat preservation board, light-weight filling blocks and mold shells are arranged on the left and right sides of the heat-preservation board, and the heat-preservation board grooves are arranged crosswise on the side surfaces of the heat-preservation board in the transverse direction and the longitudinal direction, and the side surfaces of the heat-preservation board are divided into a plurality of independent units. The inorganic light-weight filling block layer comprises the inorganic light-weight filling blocks, the inorganic light-weight filling blocks are correspondingly adhered to the units, filling block gaps are arranged between the adjacent inorganic light-weight filling blocks, and the width of each heat-preservation board grooves is larger than the width of each filling block gap. The mesh structure comprises a first mesh and a second mesh. The fabricated heat-preservation and decoration combined external wall board can be used not only for building external walls but also for various types of walls such as internal walls, the construction speed is high, heat preservation and durability are achieved, and a decorative layer of a wall surface can save decoration materials and construction cost.

Owner:郑州中誉佳联实业有限公司 +1

Preparation technology of inorganic foaming partition plate

InactiveCN108214919ALow priceReduce manufacturing costConstruction materialSurface layering apparatusFiberGlass fiber

The invention relates to a preparation technology of an inorganic foaming partition plate. The preparation technology comprises the following steps that magnesium chloride and water are mixed, prepared to be bittern and added into a stirring machine, and PP fiber is added into the bittern; caustic-burned magnesia powder and modifying agent are added and continue to be stirred for 30s; efficient chemical foaming agent is added, the mixture continues to be stirred to be uniform, and slurry with completely-dissolved solid materials and uniform liquid surface foams is prepared; the bottom layer ofa die is coated with a plastic film, a layer of glass fiber gridding cloth is fully laid on the film on the bottom layer of the die, the prepared slurry is rapidly poured into the die, the surface ofthe die is also coated with a layer of glass fiber gridding cloth after the die is filled and coated with a layer of plastic film again, the die is locked, and standing is carried out at indoor temperature for 24h; and the die is removed, the upper surface, lower surface and periphery of the cured partition plate are each spread with a layer of anti-crack mortar. According to the technology, operation is easy, operation steps are simplified, building requirements are met, and meanwhile working efficiency is improved. The inorganic foaming partition plate prepared through the technology is lowin cost, and the manufacturing cost of enterprises is reduced.

Owner:宜宾市叙州区伍益砖厂

Method for preparing light high-strength fire-proof plate

The invention provides a method for preparing a light high-strength fire-proof plate. The method comprises the following steps: (1), selecting a chemical exciting agent, and mixing the chemical exciting agent and coal ash residues to obtain a mixture of the chemical exciting agent and the coal ash residues; (2), adding natural or artificial inorganic light aggregate into the mixture to obtain a batch; and (3), adding water into the batch, fully stirring, adding the water and batch mixture into a template, pressing the template to form a plate by pressure, maintaining the plate in environmental temperature and manufacturing the light high-strength fire-proof plate with the density of 0.60g-1.60g / cm<3>, the compressive strength of 5.2MPa-15MPs and the thermal conductivity of 0.2-0.7W / m*K. The invention has the benefits that the coal ash residue resource can be fully utilized; the manufacture light high-strength fire-proof plate can play not only a heat-insulating fireproof role but also a decorative role, reduces the architectural ornament procedure and cost, and conforms to the energy-saving and low-carbon requirements on building; and the method is simple, the source of raw materials is wide, the cost is lower, and industrialized popularization and application are permitted.

Owner:EAST CHINA UNIV OF SCI & TECH

Admixture concrete

The invention belongs to the technical field of concrete and specifically relates to admixture concrete. the admixture concrete comprises the following raw materials (by weight): 100 parts of cement,30-35 parts of fly ash, 30-35 parts of blast furnace slag, 14-16 parts of ceramic waste, 30-35 parts of broken stone, 35-40 parts of waste concrete, 1-5 parts of an additive, and 10-30 parts of a lightweight filler. According to the admixture concrete, fly ash, blast furnace slag and other industrial waste residues can be utilized to avoid environmental pollution. In comparison with common concrete, the admixture concrete has the following advantages: use amount of cement is reduced; costs are reduced; and early strength performance of concrete is improved.

Owner:淮安市冰青建设工程管理有限公司

Preparation method of cement concrete

The invention belongs to the technical field of concrete and specifically relates to a preparation method of cement concrete. the preparation method comprises the following steps: fetching waste concrete and ceramic waste, crushing, and grinding into a powder with the particle size being less than 30 mm for later use; immersing the powder into water, taking out and drying; calcining the dried powder at 900-1100 DEG C, cooling, grinding, screening to obtain a waste calcined material; uniformly mixing the waste calcined material with cement, crushed stone, an admixture, water and a lightweight filler, pouring, carrying out vibration compaction, and maintaining to obtain the concrete. During the preparation process of the concrete, part of building waste concrete is added to respectively replace part of sand and crushed stone after processed, thus changing waste into valuable things and lowering the cost. The invention provides a preparation method of concrete with high mud content. Sandwith high mud content can be used as a raw material of the concrete; and with the introduction of the admixture, the concrete with high mud content still can meet building requirements.

Owner:淮安市冰青建设工程管理有限公司

Process for preparing bricks from sludge

InactiveCN109053143AAvoid crackingMeet building requirementsSludge treatment by de-watering/drying/thickeningCeramic materials productionBrickSludge

The invention discloses a process for preparing bricks from sludge. The sludge is filtered more than once with a filter screen of 80-160 meshes to filter out silt-like solid impurities in the sludge.The process fully utilizes the sludge in a sewage treatment plant, which not only solves the problem of sludge pollution treatment of the sewage treatment plant, but also is beneficial to environmental protection, and relates to comprehensive utilization of resources; and the prepared baking-free bricks have high strength and good durability.

Owner:南京胜仁市政建设有限公司

Assembling type building material and preparation method thereof

The invention discloses an assembling type building material and a preparation method thereof. According to the assembling type building material, plant wastes containing lignose and cellulose such asplant straws are used as a main raw material, and quartz sand and sodium hydroxide are subjected to reaction to generate a sodium silicate type substance; then urea is added to enhance the viscosityof the sodium silicate type substance, so as to form an adhesive; then the assembling type building material is prepared by mixing, filling pores of the plant wastes with the quartz sand, molding, carrying out surface spraying and ageing. The assembling type building material prepared by the preparation method has the advantages of light weight, low shrinkage rate, good heat preservation and insulation performance and the like, and can be completely used for various buildings including low-rise, mid-rise and high-rise buildings.

Owner:鲁兵 +1

Cement concrete

The invention belongs to the technical field of concrete, and in particular relates to a cement concrete. The cement concrete includes the following raw materials (by weight): 30-35 parts of cement, 14-16 parts of ceramic waste, 30-35 parts of crushed stone, 35-40 parts of waste concrete, 1-5 parts of an admixture, and 10-30 parts of a lightweight filler. Part of building waste concrete is added into the concrete formula to replace part of sand and crushed stone after processed, thus changing waste into valuable things and lowering the cost. The invention provides a concrete with high mud content. Sand with high mud content can be used as a raw material of the concrete; and with the introduction of the admixture, the concrete with high mud content still can meet building requirements.

Owner:淮安市冰青建设工程管理有限公司

PV-led integrated double glass module packaging method

ActiveCN105552072BMeet building requirementsSolid-state devicesSemiconductor devicesInsulation layerPhotovoltaic industry

The present invention discloses a PV-LED integrated double-glass module encapsulation method. A solar photovoltaic double-glass module and a LED product are perfectly combined, two sheets of glass and an insulation layer are composed, and the back glass of the LED is encapsulated; an interlayer lays solar cells, and Sn-coating copper strip arranged between the solar cells forms a composite layer which is in parallel with and collects the whole component of a lead terminal; and coating is adopted to bond between layers to form a whole module. The PV-LED integrated double-glass module encapsulation method is applied to fields of the photovoltaic industry, the application problem of the combination of a solar photovoltaic module and a LED is solved, and the problems of bubbles in the process of the PV-LED integrated double-glass module manufacture and the damage, the migration and the assignment of the LED lamp bead encapsulation are effectively solved. The PV-LED integrated double-glass module may be modularized and integrated and may take the largest advantage for markets.

Owner:LIANYUNGANG SHENZHOU NEW ENERGY

Sleeve Buckling Restrained Brace

ActiveCN104929259BImprove economyIncrease stiffnessShock proofingBuckling-restrained braceEngineering

Owner:上海研深信息科技有限公司

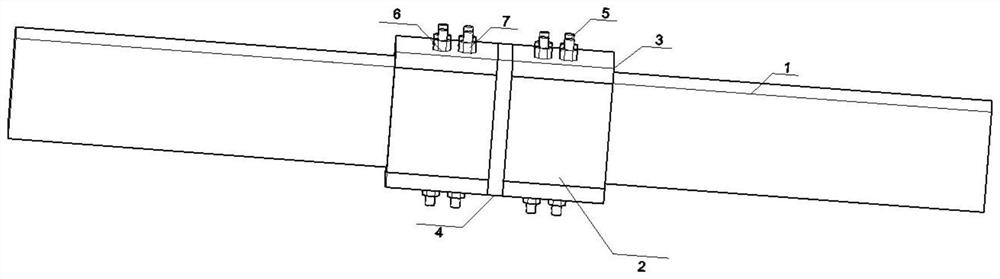

Steel beam connecting structure and method

InactiveCN113187103ASolve the problem of not matchingIncrease stiffnessBuilding constructionsClassical mechanicsFlange

The invention discloses a steel beam connecting structure and method. According to the steel beam connecting method, a height compensation connecting plate is arranged on a lower flange plate of a main beam, so that the problem that the beam height of the main beam cannot be matched with the beam height of a secondary beam is solved, and the joint connection under the condition that the height of the secondary beam is larger than that of the main beam is achieved; and a rectangular stiffening plate and a triangular stiffening plate are arranged at a node position, so that the rigidity of the steel beam structure is improved, the building requirements are met, and the safety of the building structure is ensured.

Owner:NANJING YANGTZE RIVER URBAN AGCHITECTURAL DESIGN

A lightweight movable wall with gypsum board light steel keel system

The invention discloses a lightweight movable wall body of a gypsum board light steel keel system, comprising: a movable wall body (10) and at least two guide rails (20) arranged in parallel on the top of the movable wall body (10). The movable wall body (10) includes a keel body and a first gypsum board (11) and a second gypsum board (12) for closing the keel body, and the keel body includes a sky keel (13), a ground keel (14), 3- 15 vertical keels and 3 to 15 transverse piercing keels. Wherein, the sky keel (13) is provided with at least two universal rollers (30), at least two universal rollers (30) are respectively connected with at least two guide rails, and the universal rollers (30) slide along the direction of the guide rails, At least three load-bearing rollers (40) are evenly arranged on the ground keel (14).

Owner:肇庆北新建材有限公司

A prefabricated steel-concrete composite floor applied to steel structure buildings

The invention provides a fabricated type steel concrete composite floor system for a steel structure house, and belongs to the technical field of architectures. The fabricated type steel concrete composite floor system for the steel structure house comprises a steel beam and a plate body, wherein the plate body is connected with the steel beam through a beam plate connecting piece, the plate bodycomprises at least two precast slabs, every two adjacent precast slabs are connected through a first plate connecting piece or a second plate connecting piece, first type steel for being connected with the beam plate connecting piece, the first plate connecting piece or the second plate connecting piece are pre-buried on the side walls of the precast slabs, connecting piece installation grooves for containing the beam plate connecting piece, the first plate connecting piece or the second plate connecting piece and exposing the first type steel and the connecting parts of the corresponding connecting pieces. According to the fabricated type steel concrete composite floor system for the steel structure house, convenience of construction is improved, and the structure is stable

Owner:河北比穆建筑科技有限公司

Method for manufacturing steel pattern plate of taper-end concrete pier

ActiveCN101733643BEasy to installExcellent adhesionOther manufacturing equipments/toolsFlame cuttingCost savings

The invention relates to a method for manufacturing a steel pattern plate of a taper-end concrete pier. The method comprises the following steps: calculating circular arc points based on design parameters and marking on a plate, using a flame cutting machine to adjust the curvature radius of the track at the marked cutting points and fixing the track, then cutting the taper-end preliminarily-cut plate into fan-shaped pattern plates, welding the fan-shaped pattern plates two by two to obtain two semi-taper pattern plates, and welding and shaping the straight rectangular plate and the semi-taper pattern plates to obtain a sectional pattern plate. By using the method for making a steel pattern plate of a taper-end concrete pier and a simple tool, a large taper-end steel pattern plate, which can only be finished under specified conditions, can be manufactured and finished under primitive conditions on the construction site; and the pattern plate can be conveniently installed, tightly affixed and quickly erected, thereby ensuring construction quality and speed and completely meeting the construction requirements of piers of such big special shapes. Besides, the pattern plate has the advantages of low manufacturing cost, simple process and significant construction cost saving.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

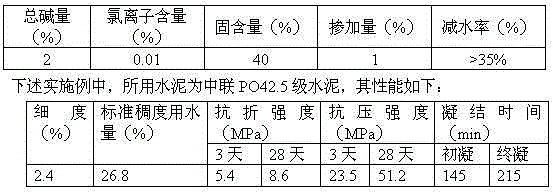

Efficient water-reducing agent and preparation method thereof

The invention relates to the technology of concrete admixtures, and provides an efficient water-reducing agent and a preparation method thereof. The efficient water-reducing agent is prepared from the following raw materials in parts by weight: 100 parts of prenyl alcohol polyoxyethylene ether, 0.8-1.2 parts of hydrogen peroxide, 0.14-0.19 part of thioglycollic acid, 6-9 parts of acrylic acid, 0.06-0.20 part of ascorbic acid and 173-247 parts of water. According to the preparation method, the preparation condition can be fulfilled only by simply regulating the temperature, and the preparation process is simple and convenient to implement; and the prepared efficient water-reducing agent is in accordance with construction requirements.

Owner:SHENYANG LIANHE CHEM TECH CO LTD

Building structure key component connecting joint and construction method thereof

PendingCN114575450AImprove securityIncreased durabilityStrutsSolid waste managementArchitectural engineeringStructural engineering

The invention provides a building structure key component connecting joint and a construction method thereof.The building structure key component connecting joint comprises an upper connecting face, a lower connecting face, a left connecting face and a right connecting face, the upper connecting face, the lower connecting face, the left connecting face and the right connecting face are connected end to end to form a barrel-shaped unit, and the section of the barrel-shaped unit is of a rectangular structure matched with the section of a prefabricated component; the barrel-shaped unit is used for inserting the end parts of the prefabricated parts into the barrel-shaped unit, so that the front and rear prefabricated parts are connected; the barrel-shaped unit is formed by integrally pouring a fiber cement-based composite material; the fiber cement-based composite material is prepared from the following raw materials: cement, fly ash, sand, water, fibers and a water reducing agent. The connecting joint is simple in structure, reasonable in design, convenient to use, simple in installation process and high in efficiency.

Owner:成都托启新材料科技有限公司

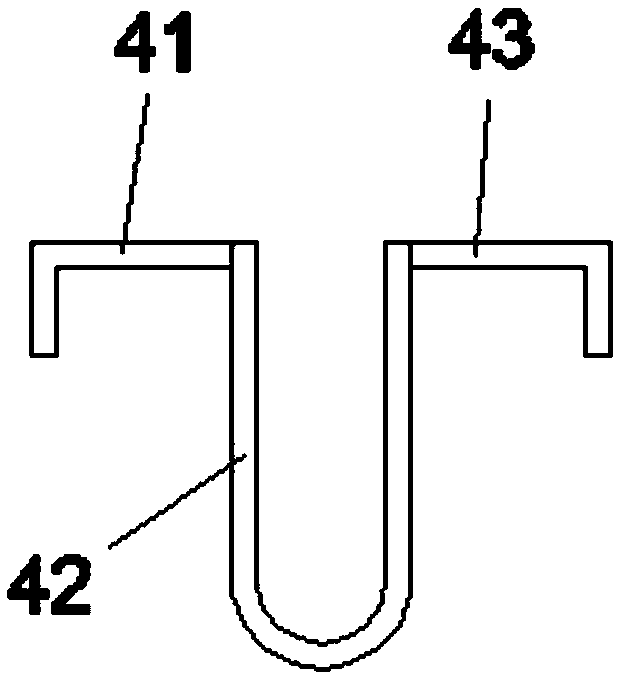

Construction structure and construction method of a cast-in-situ box girder prestressed steel tendon

The invention discloses a construction structure and a construction method of a cast-in-situ box girder prestressed steel tendon. The construction structure further comprises a bellows, a prestressedsteel bundle and a plurality of limit bars, wherein the limit bars are fixed on the frame bars, the bellows is arranged in the limit bars, and the bellows is sleeved on the prestressed steel bundle; the construction structure comprises a box girder skeleton steel bar, a prestressed steel bundle and a plurality of limit bars. The limiting steel bar comprises a left section, a middle section and a right section, wherein the left section and the right section are L-shaped, the middle section is U-shaped, the bellows is located in the middle section, and the left section and the right section arewelded on the skeleton steel bar. The opening direction of the middle section of the limiting steel bar is away from the curvature center of the bellows at the limiting steel bar. The invention can limit the curvature of the bellows and the steel bundle inside the bellows at the bending position of the box girder, so that the curvature of the box girder meets the building requirements, the structure is simple, safe and reliable, the installation is convenient, the engineering progress is accelerated, the construction period is shortened, and the construction cost is saved.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com