Fabricated heat-preservation and decoration combined external wall board and manufacture and construction method thereof

A technology for thermal insulation panels and external wall panels, applied in the field of building materials, can solve problems such as easy entry of heat into the room, damage to wall panels, and aggravation of heat energy flow, saving decoration materials and construction costs, achieving permanent thermal insulation, and increasing the overall the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

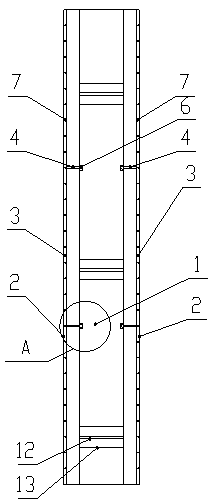

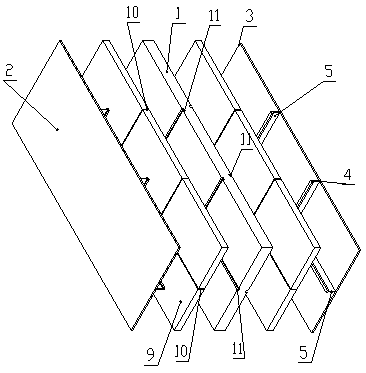

[0057] Such as figure 2 , 3 , Shown in 4 and 5, the left and right sides of insulation board 1 are all provided with insulation board groove 11, and the left and right sides of insulation board are all provided with organic lightweight filler block 9 and formwork 2. The grooves 11 of the heat preservation board 1 are arranged horizontally and vertically on the side of the heat preservation board 1, and the upper side of the heat preservation board 1 is divided into several independent units, and a number of inorganic lightweight filling blocks 9 are bonded to each unit correspondingly. In this embodiment Among them, it is divided into 6 units, so there are 6 inorganic lightweight filling blocks 9, and there are filling block gaps 10 between adjacent inorganic lightweight filling blocks 9, and the width of the insulation board groove 11 is greater than the width of the filling block gap 10 .

[0058] The mesh structure includes a first mesh 6 and a second mesh 7 . The first...

Embodiment 2

[0067] The difference from Embodiment 1 is that the insulation board grooves 11 are not arranged horizontally and vertically on the side of the insulation board 1, but are only arranged horizontally or vertically, and a plurality of insulation board grooves 11 are parallel to each other. 1 The upper side is divided into several independent units.

[0068] The purpose of the present invention is to form a wall, which requires that adjacent assembled thermal insulation and decorative composite exterior wall panels can be engaged with each other to form an integrated structure, so that the overall strength is improved and the thermal insulation effect is better. Therefore, the edges of adjacent exterior wall panels are connected by a mortise and tenon structure.

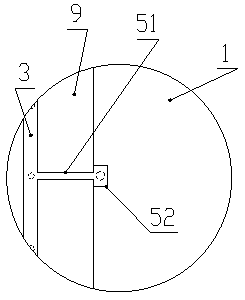

[0069] Mortise and tenon structure includes assembly male structure and assembly female structure; Figure 6~9 As shown, there are four cases:

[0070] Such as Figure 6 As shown, the assembly male head structure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com