Patents

Literature

44results about How to "Lightweight construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

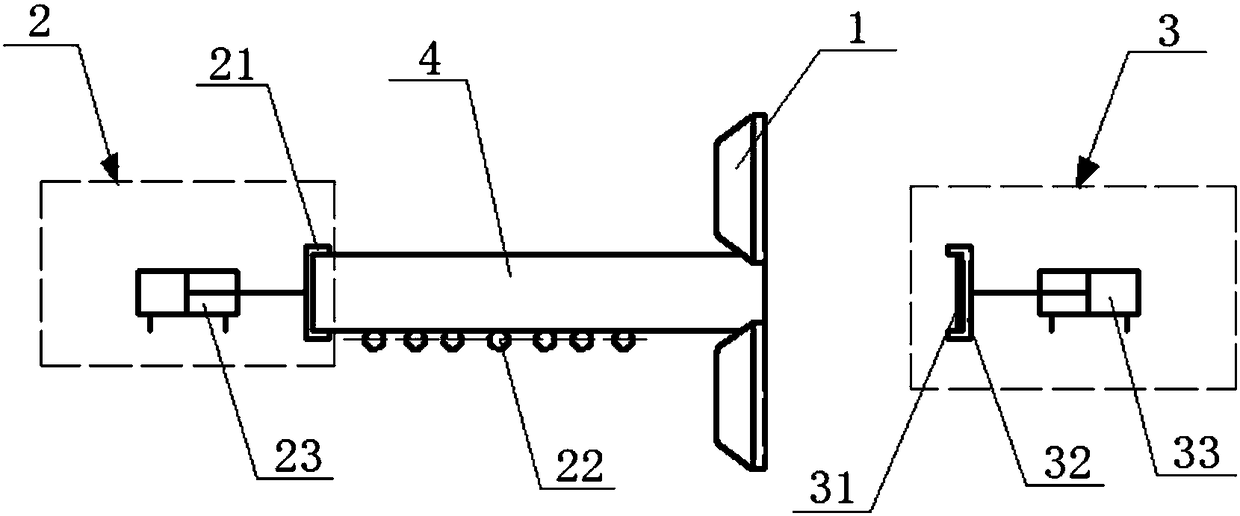

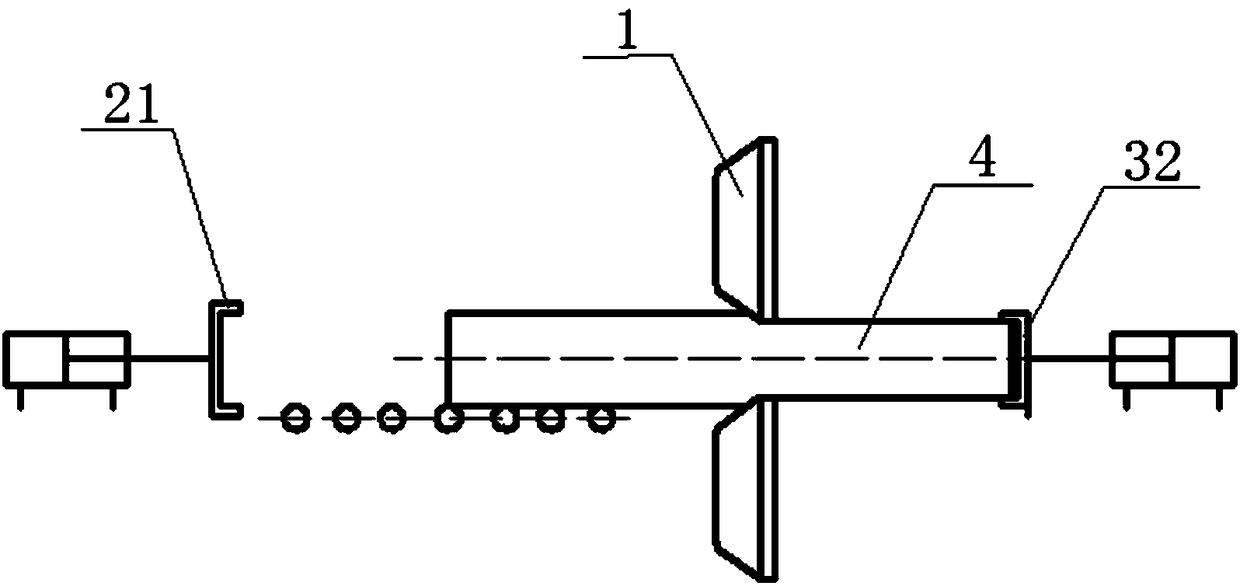

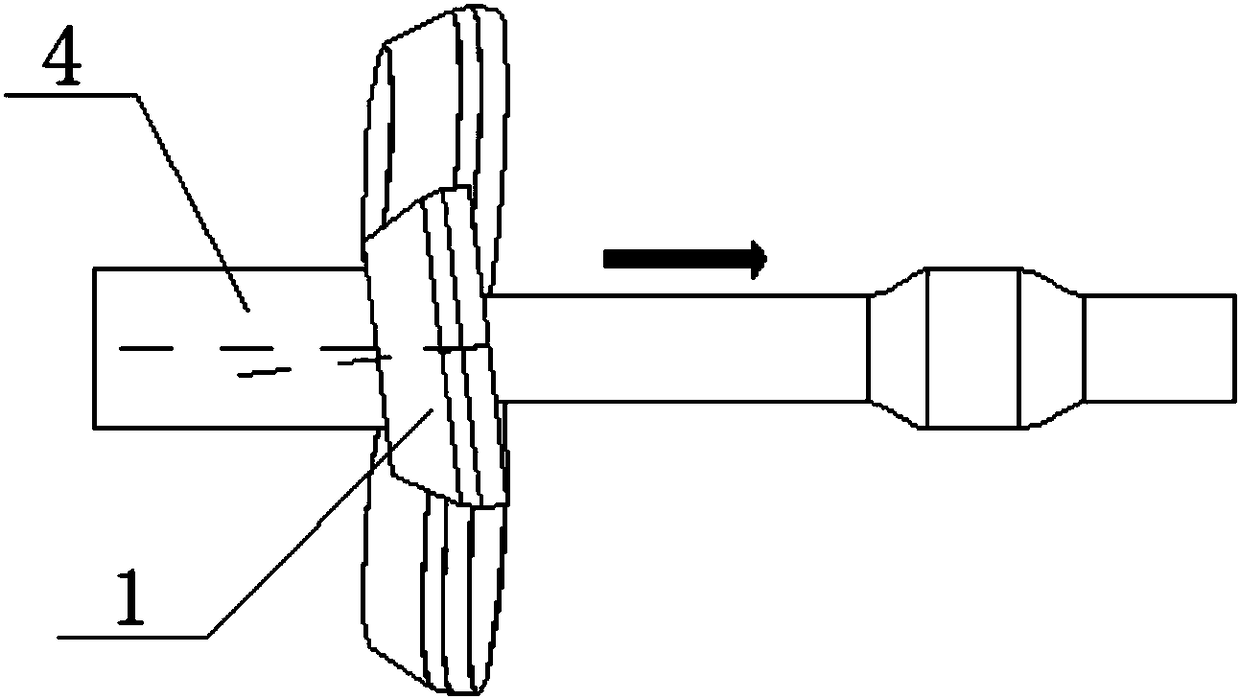

Three-roller inclined rolling forming method of rail vehicle axles

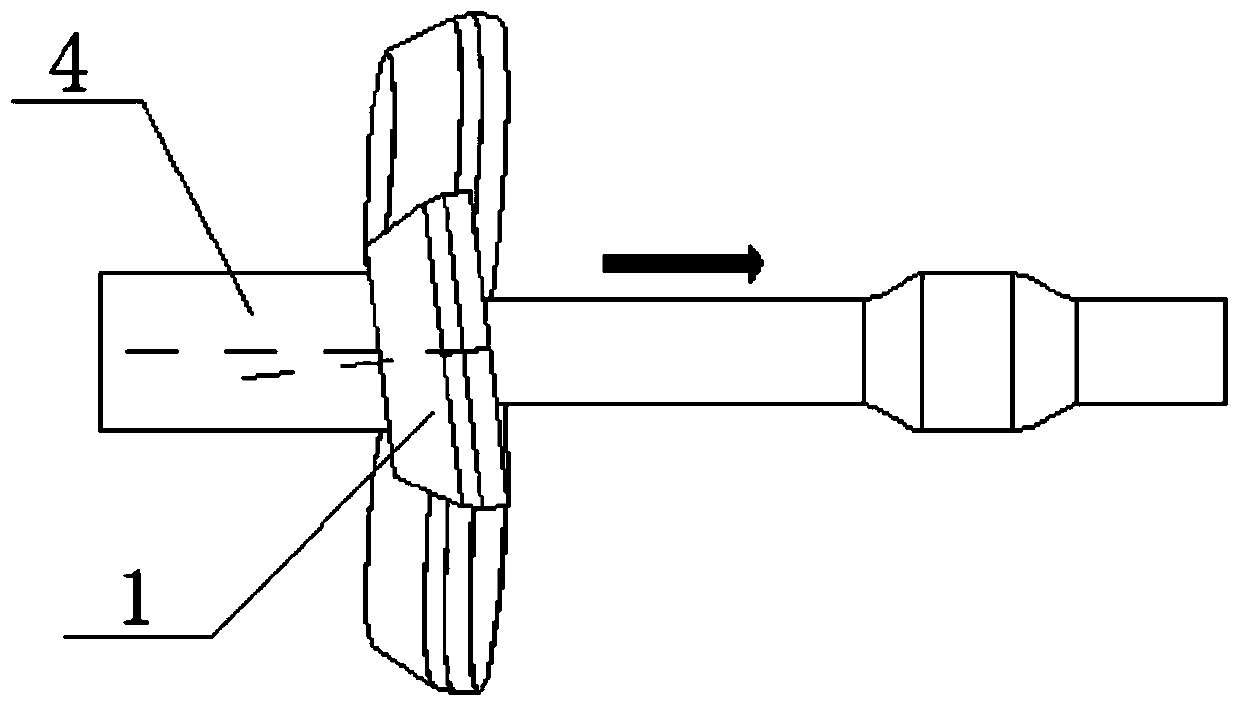

The invention discloses a three-roller inclined rolling forming method of rail vehicle axles. The method is characterized in that rods are heated and fed into a three-roller inclined rolling machine through an axial pushing device; three inclined rollers are engaged with the rods at the same time, and drive the rods to rotate; meanwhile, the axial pushing device pushes the rods to axially move ata constant speed; a radial driving mechanism controls radial movement of the inclined rollers according to diameter requirements of rail vehicle axles needing to be machined; when the rods axially move to contact with an axial guide device, the axial guide device tows the rods to continuously move axially at a constant speed; meanwhile, the rods are deviated from the axial pushing device; and after machining is finished, large-diameter long step shafts-rail vehicle axles are obtained. The method has the advantages of simple mold manufacturing, uniform distribution of force on the surfaces of rolled parts, capability of effectively reducing wear of the rollers in the inclined rolling process, capability of realizing light construction of the rolling machine and effective prolonging of the service life of the rolling machine.

Owner:NINGBO UNIV

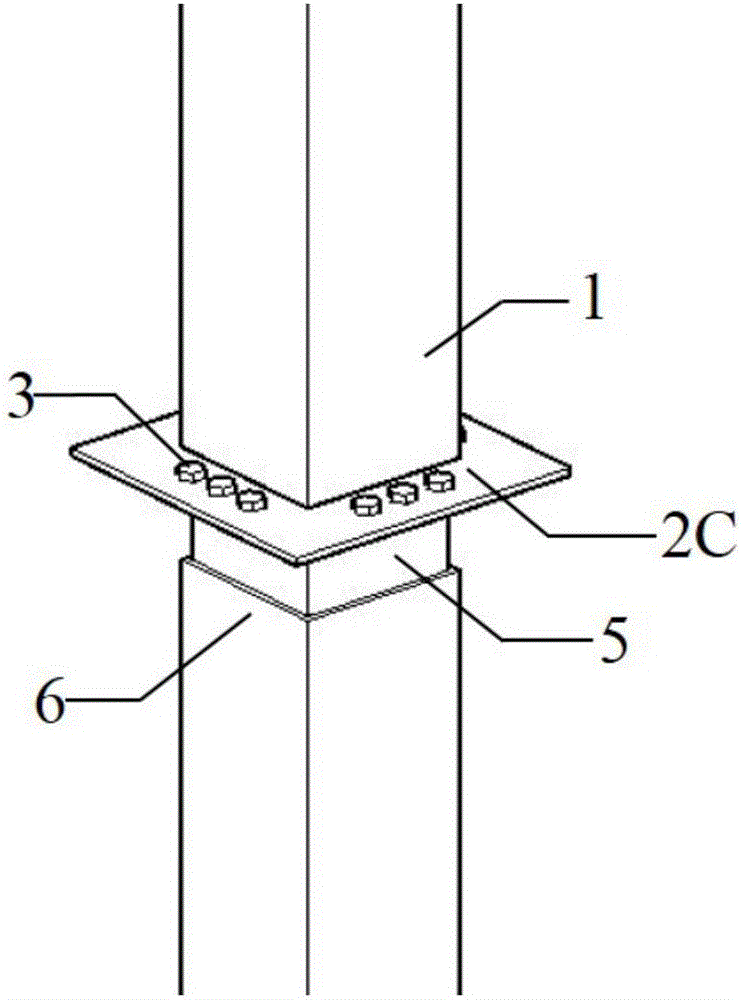

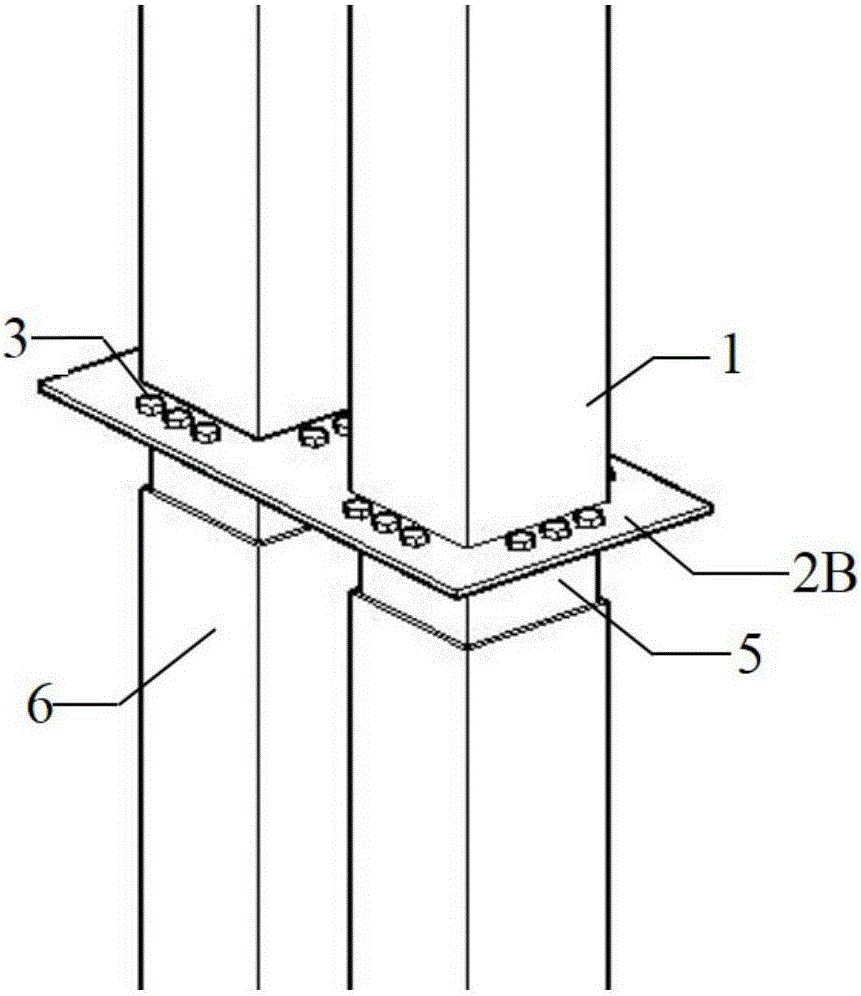

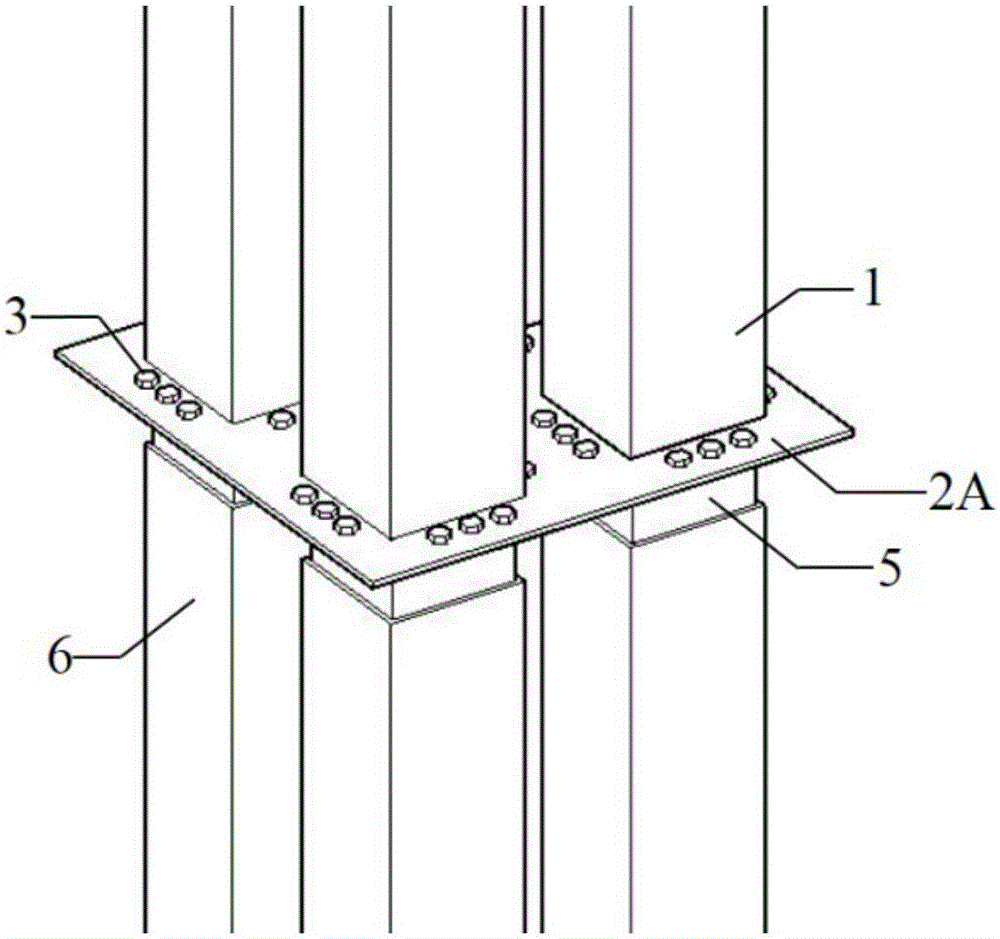

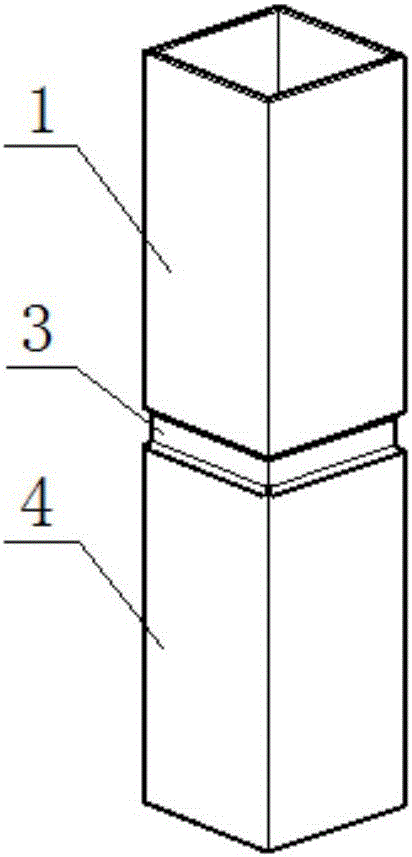

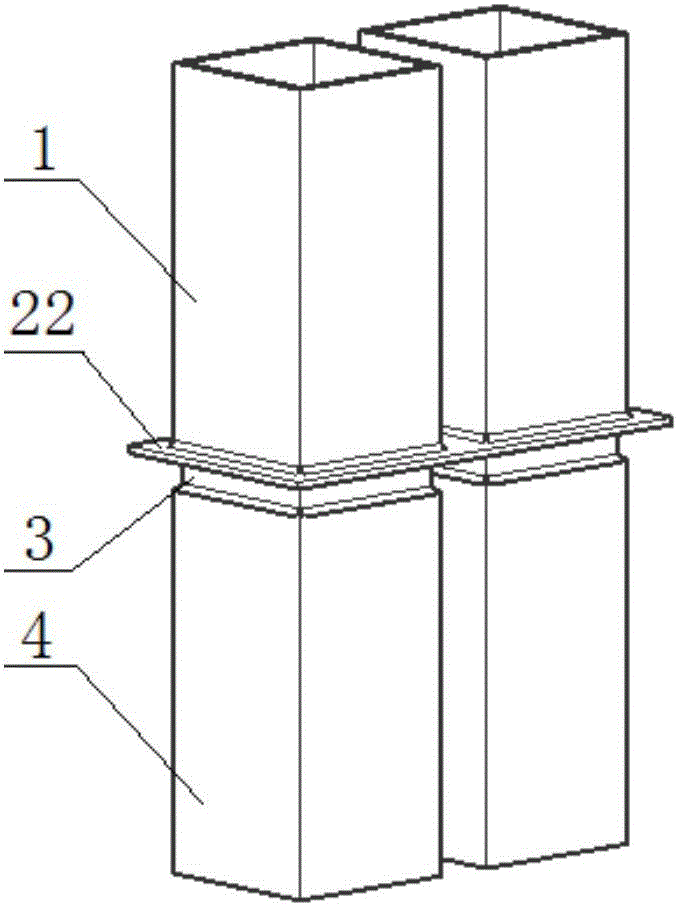

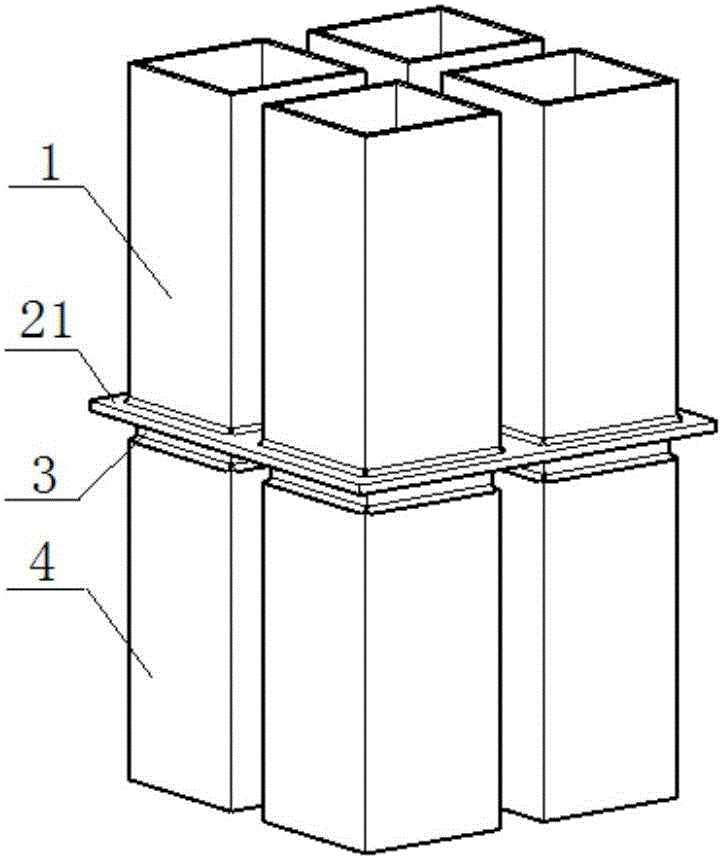

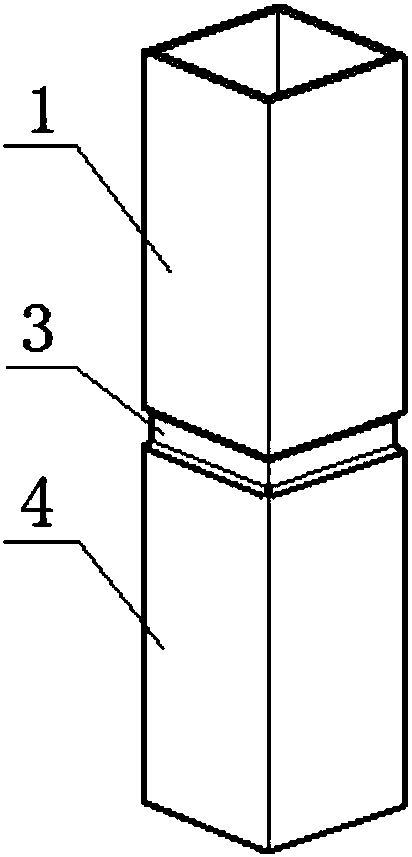

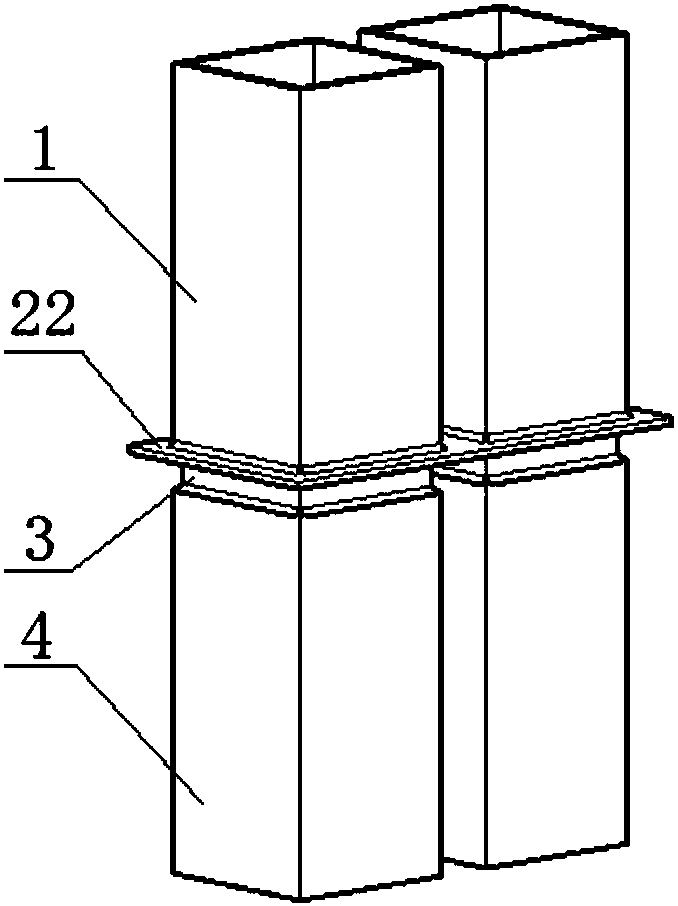

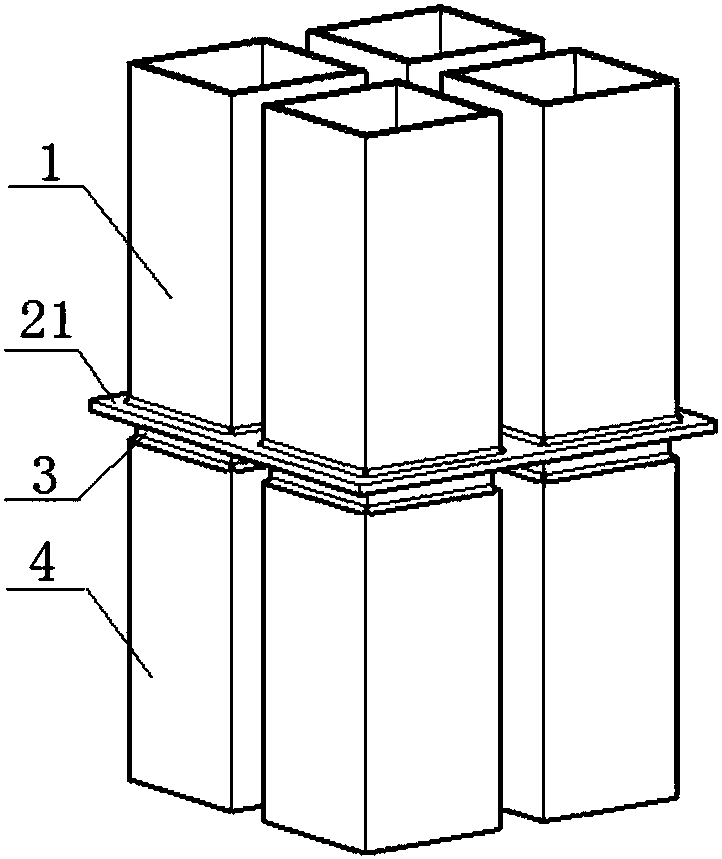

Connecting device for connecting modular steel frames and connecting method of connecting device

ActiveCN106522374AReduce processShorten construction timeBuilding constructionsSteel frameBearing surface

The invention relates to a connecting device for connecting modular steel frames. The connecting device at least comprises first square steel tube columns and second square steel tube columns. The ends of the first square steel tube columns and the ends of the second square steel tube columns are hollow. The first square steel tube columns and the second square steel tube columns are connected through inner sleeves, the inner sleeves are in clearance fit with the first square steel tube columns and the second square steel tube columns, positioning blocks and bearing steel angles are arranged on the peripheral rings of the inner sleeves, the positioning blocks are located below the bearing steel angles, the lower edges of the positioning blocks are parallel to column openings of the first square steel tube columns, and the bearing surfaces of the bearing steel angles are parallel to column openings of the second square steel tube columns. The modular steel frames are partially machined in a factory in advance and then constructed on a construction site, the procedures of site construction are greatly reduced, the construction time is shortened, and the environment on site is not excessively influenced; the modular steel frames are welded to the inner sleeves, the firmness degree between the frames is greatly enhanced, and the risk caused by screw or bolt looseness is avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Modular steel frame connection device and connection method thereof

ActiveCN106522363AOmit fixed wayReduce on-site construction proceduresBuilding constructionsEngineeringSteel frame

The invention relates to a modular steel frame connection device. the modular steel frame connection device at least comprises a first square steel tubular column and a second square steel tubular column which are internally hollow and are connected through an inner sleeve. The inner sleeve is in clearance fit with the second square steel tubular column. the periphery of the inner sleeve is annularly provided with locating blocks parallel to the column opening of the first square steel tubular column and the column opening of the second square steel tubular column. the modular steel frame connection device further comprises a connection plate provided with an assembly hole matched with the inner sleeve. modular steel frames are connected in an inner sleeve mode, the fixing mode of screws or bolts is omitted, procedures of site construction are omitted, and the construction time is shortened. the modular steel frames and inner sleeves are welded, the firm degree between the frames is enhanced, and risks caused by loosening of the screws or the bolts are avoided. The modular steel frames are partially machined in a factory in advance and then constructed in a construction site, so that the site construction time is shortened greatly, and too many influences on the site environment are avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

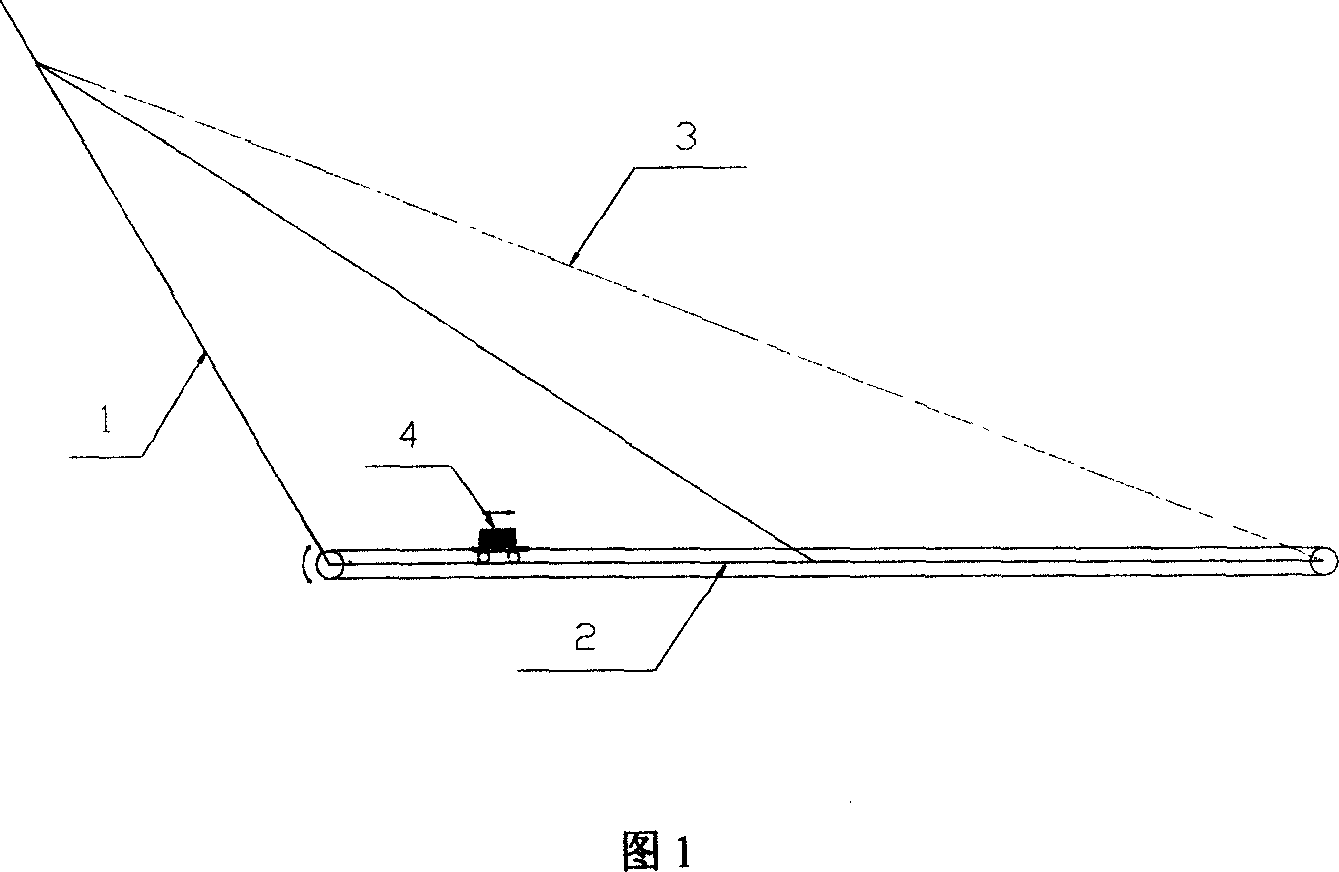

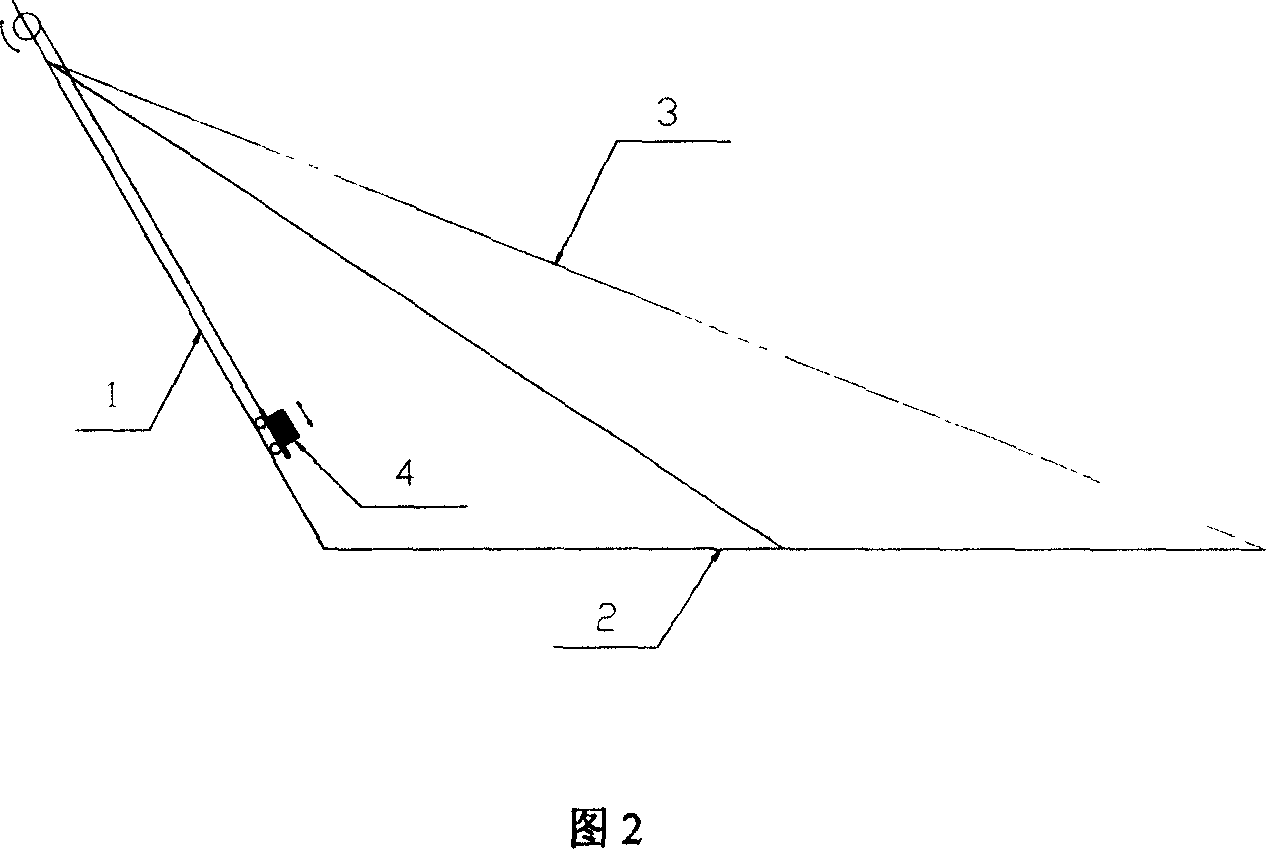

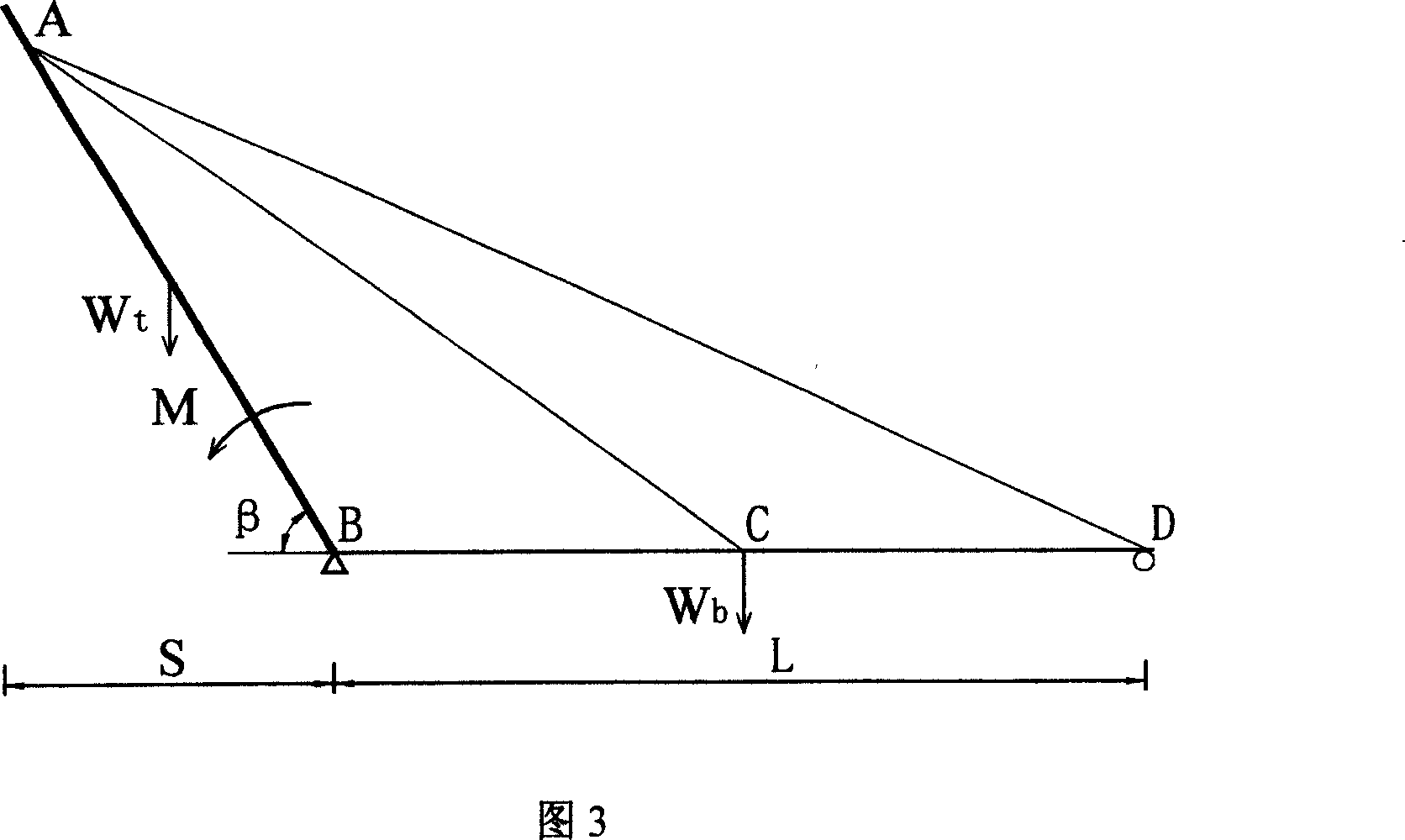

Light bascule opening bridge

The present invention relates to a light-type vertically-turning opening bridge. It includes a main frame, said main frame is composed of oblique tower and bridge floor, said oblique tower is connected with one end of said bridge floor, and said one end where the oblique tower and bridge floor are mutually connected is set on the base seat and is turnably connected with said base seat, between said oblique tower and bridge floor an oblique guy rope is set and two ends of said oblique guy rope are respectively connected with said oblique tower and bridge floor, on the main frame a balance weight block is set, and said balance weight block can be slidden on said main frame.

Owner:SOUTHEAST UNIV

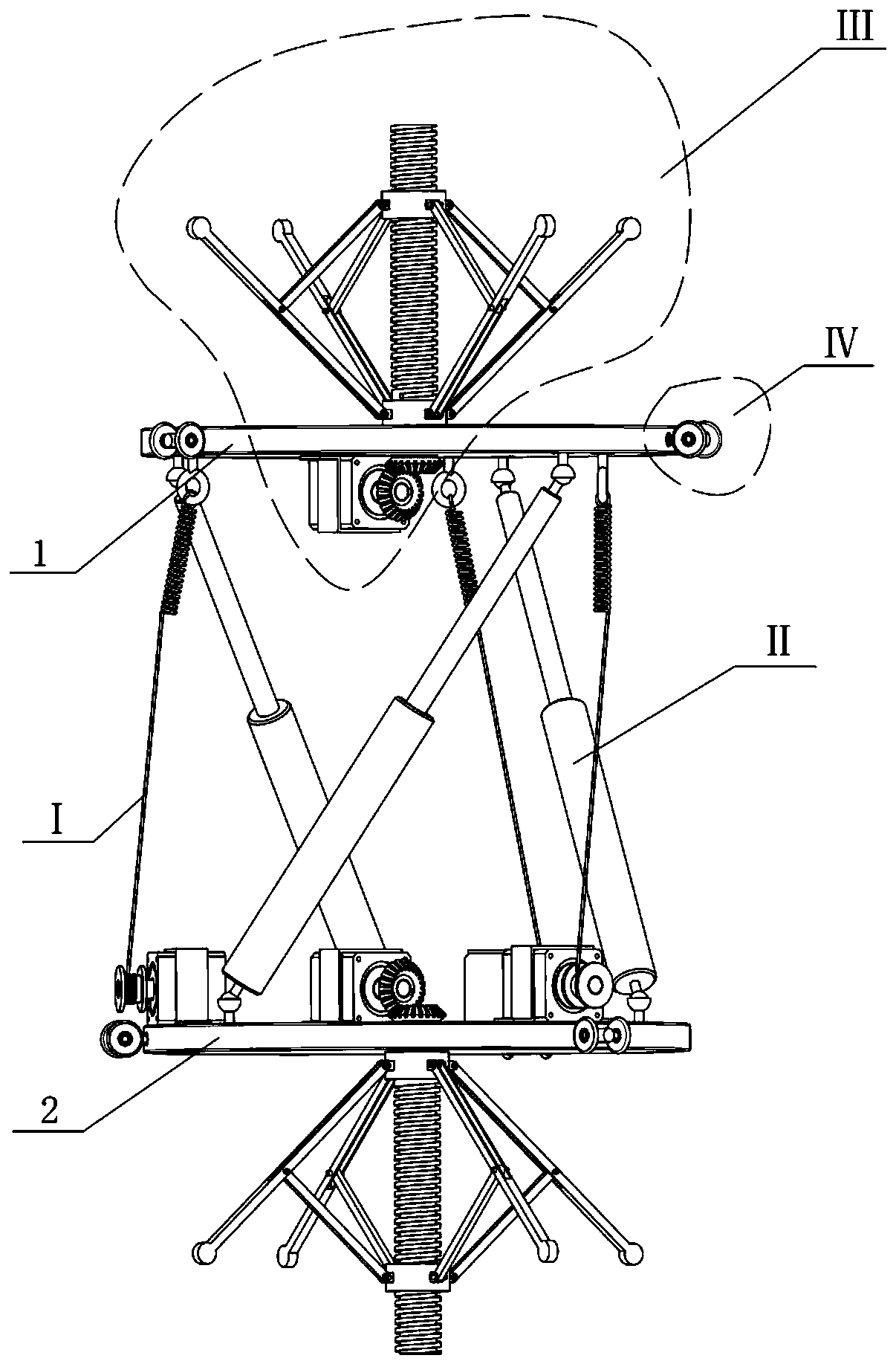

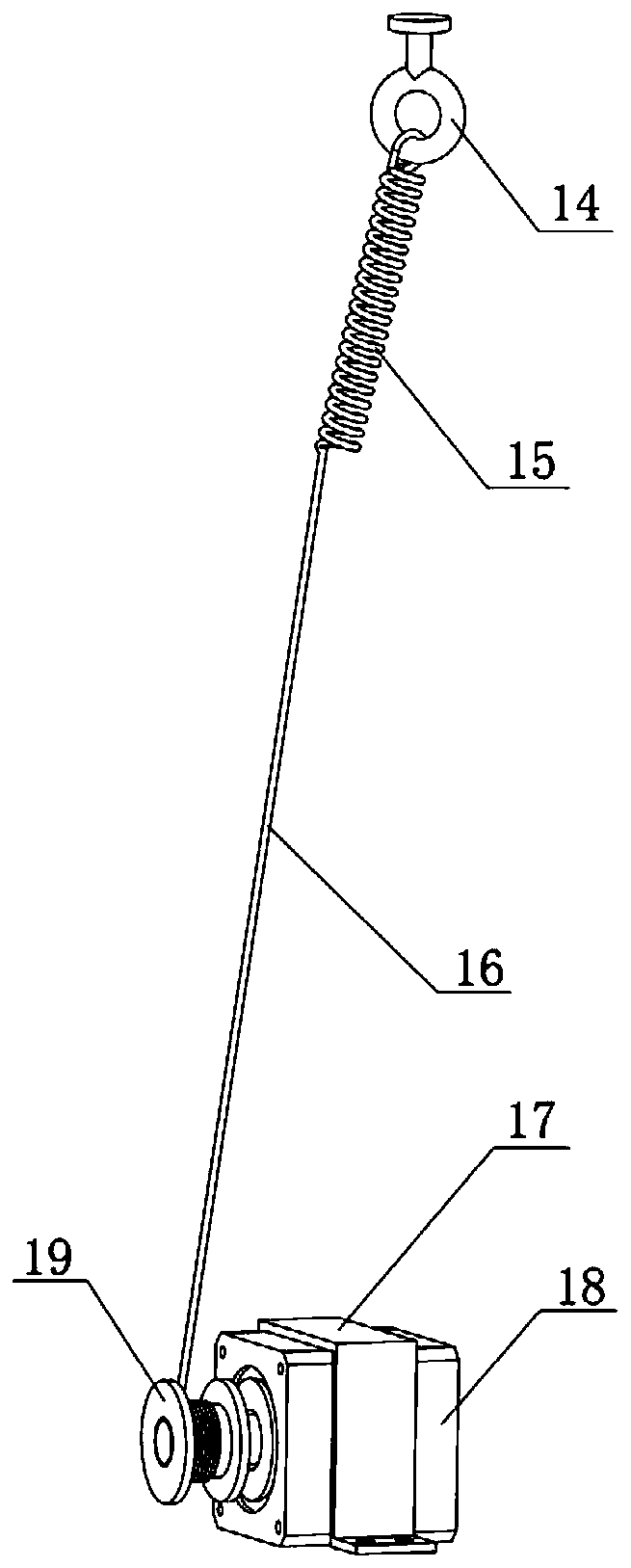

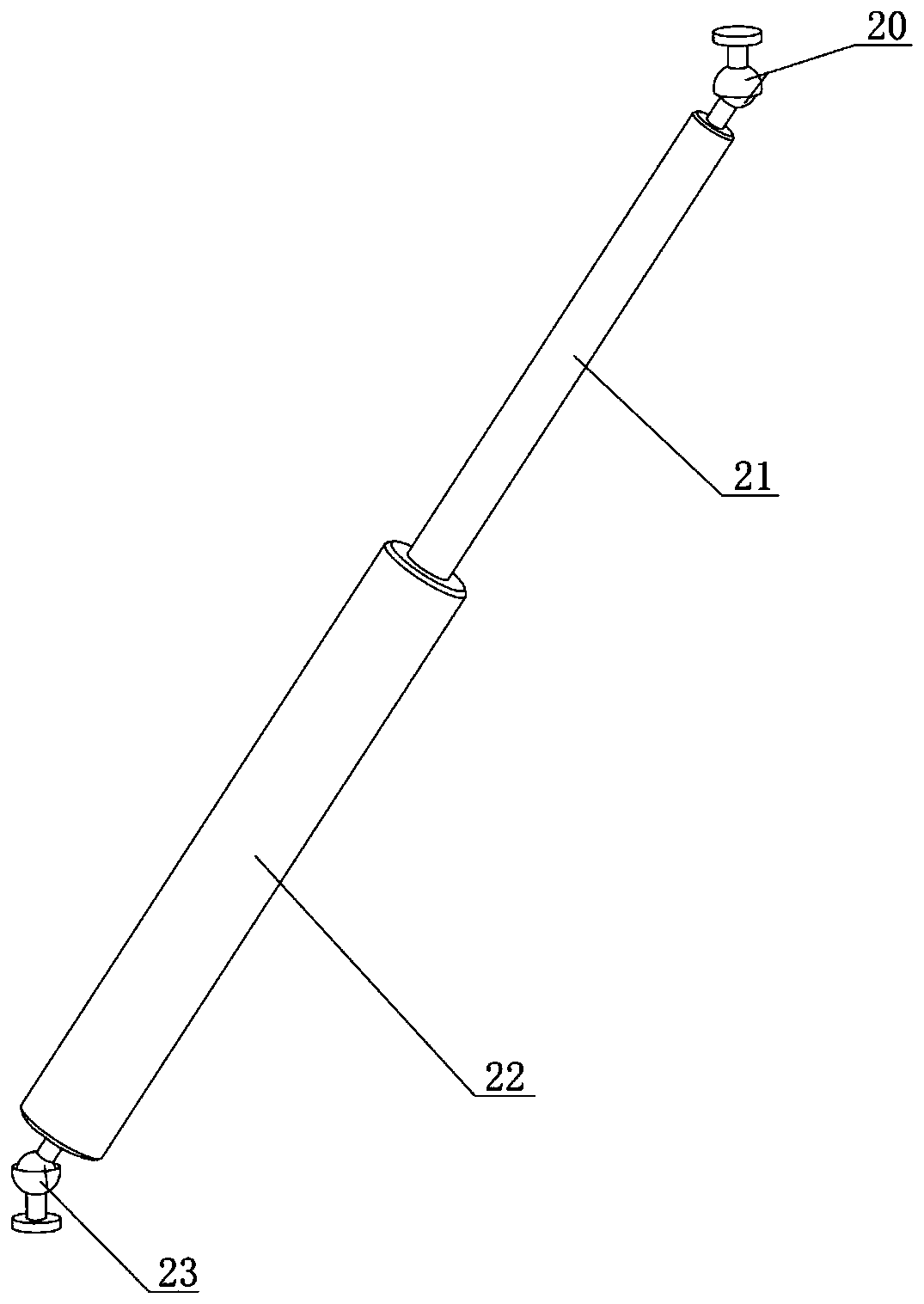

Stretch-draw integrated pipeline robot

The invention provides a stretch-draw integrated pipeline robot comprising platforms arranged in pairs. The platforms include the upper platform and the lower platform. Multiple flexible supporting chains and multiple rigid supporting chains are arranged between the upper platform and the lower platform in a supporting manner. Stretch-out and draw-back devices are installed on the upper side faceof the upper platform and the lower side face of the lower platform correspondingly. Auxiliary slide wheel devices are evenly distributed on the peripheral face of the upper platform, and auxiliary slide wheel devices are evenly distributed on the peripheral face of the lower platform. The stretch-draw integrated pipeline robot is reasonable in structural design, has the capacity of climbing and suspending in a vertical pipeline and can bear large loads; and the stretch-draw integrated pipeline robot is small in structural mass and capable of being folded, the size of the upper platform and the size of the lower platform can be changed along with the size of the pipeline, the movement component inertia force is low, and the pipeline adaptability is high.

Owner:CHANGZHOU UNIV

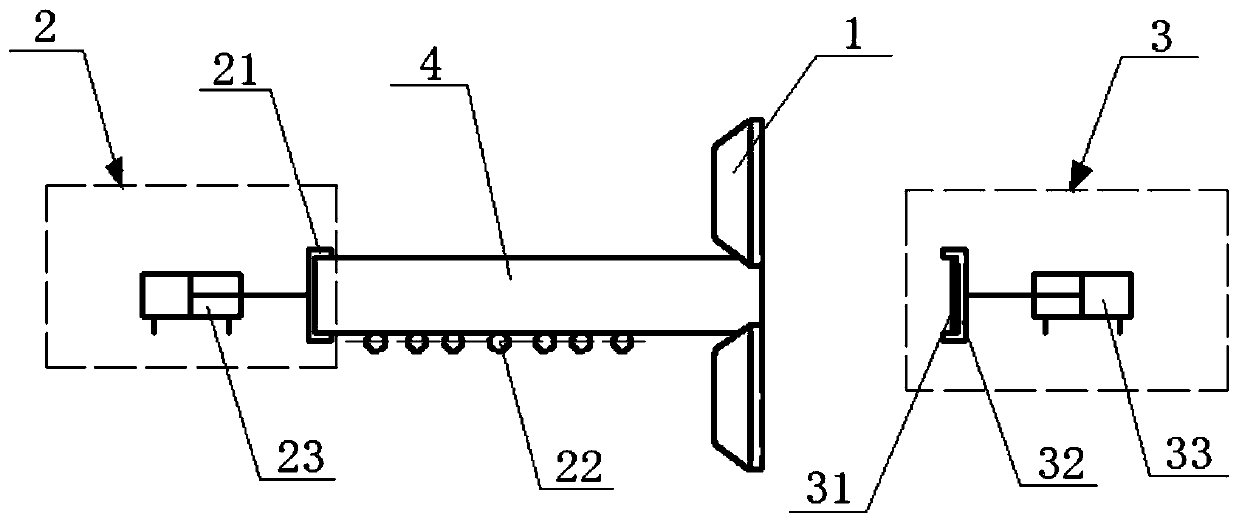

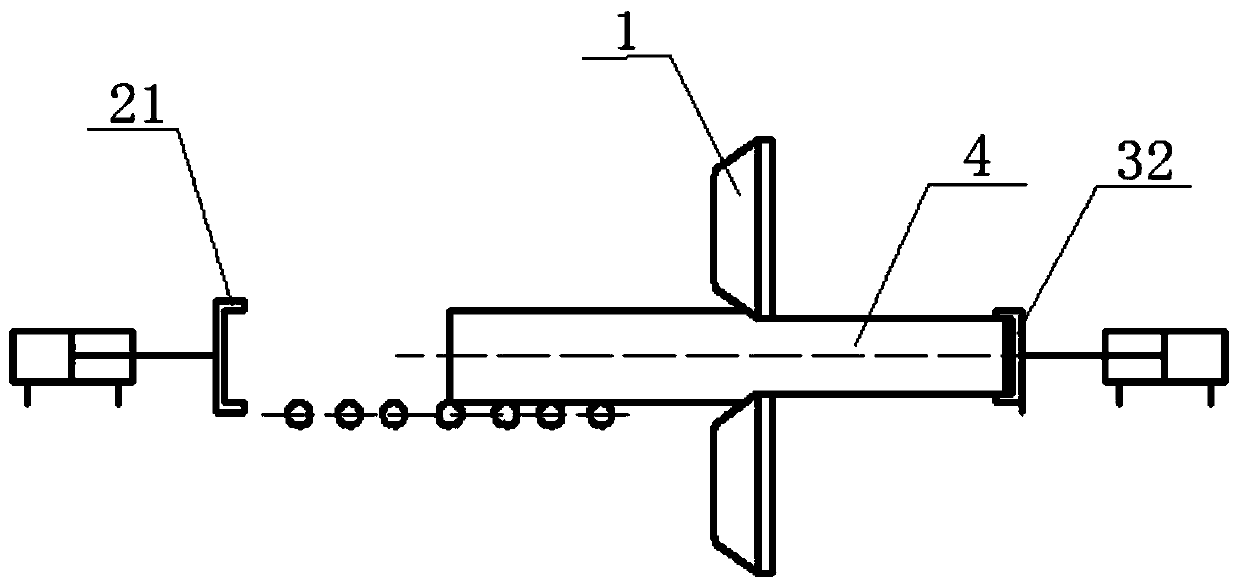

Cross-member for the base region of a motor vehicle body shell structure, a method for producing a cross-member and a motor vehicle body shell structure

ActiveCN105189256AImprove stabilityHigh mechanical strengthUnderstructuresSuperstructure subunitsMaterials scienceMagnesium alloy

The invention relates to a cross-member (3, 5) for the base region of a motor vehicle body shell structure (1), characterised in that at least some sections of said cross-member (3, 5) comprise a light metal or light metal alloy, preferably aluminium or an aluminium alloy, or preferably magnesium or a magnesium alloy, and in that at least some sections of this are produced by forging.

Owner:梅赛德斯-奔驰集团股份公司

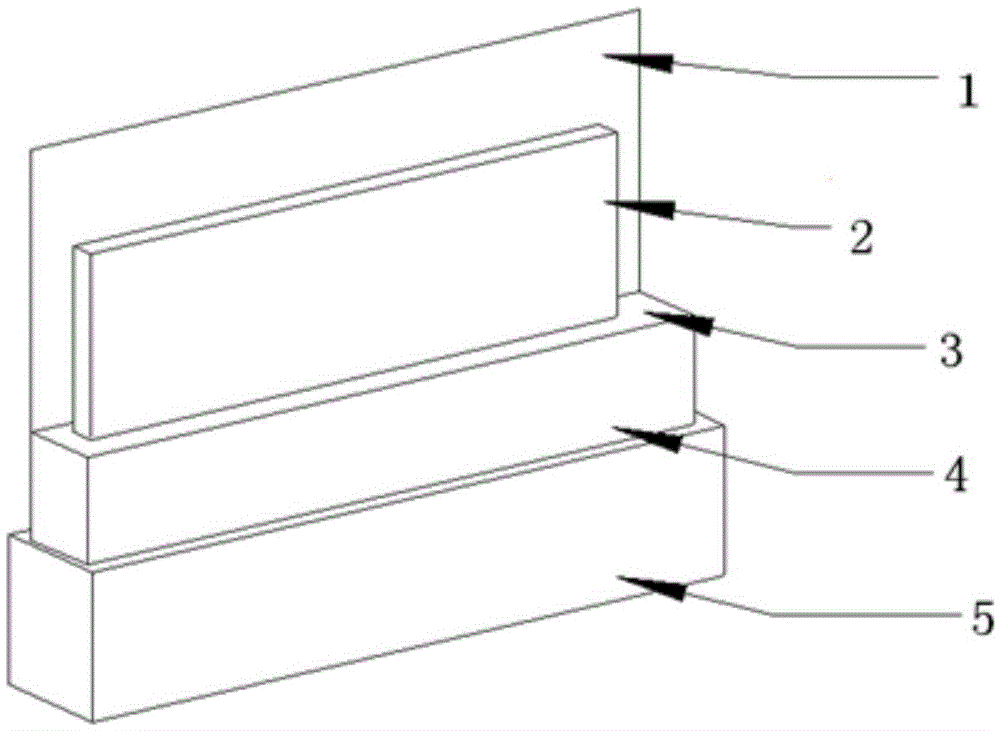

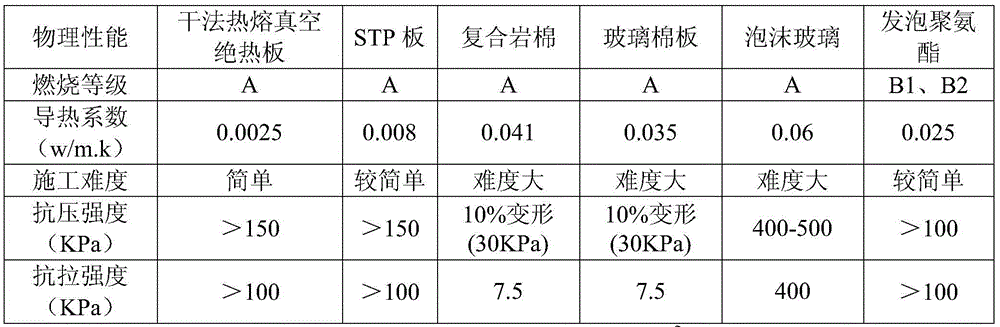

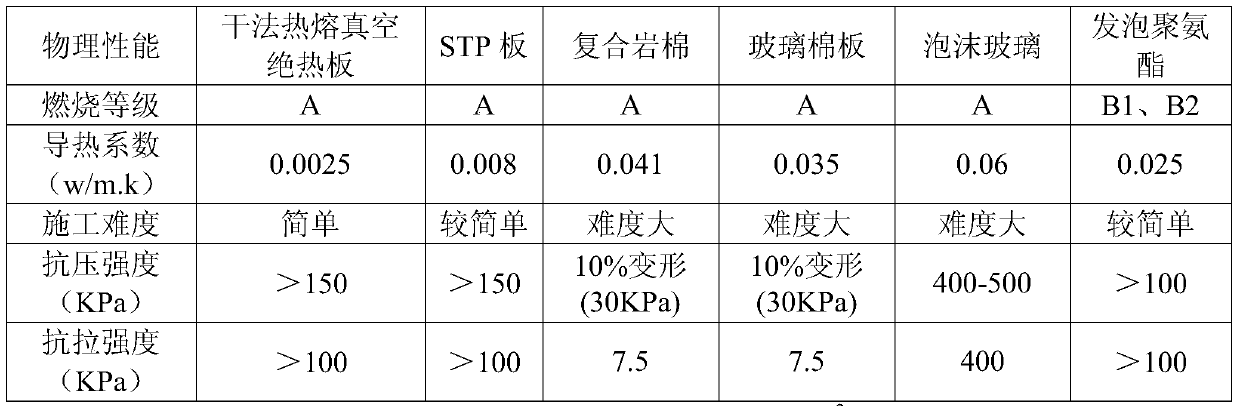

Vacuum thermal insulation board derivative for inner wall and preparation method of derivative

ActiveCN105421602APerformance lightweightImprove performanceClimate change adaptationInsulation improvementAluminum foilProtection layer

The invention discloses a vacuum thermal insulation board derivative for an inner wall. The vacuum thermal insulation board derivative is composed of a bonding layer, a thermal insulation layer, a packing layer, a protection layer and a decorative finish layer, the bonding layer is made of aluminum foil, the thermal insulation layer is a vacuum thermal insulation board, the packing layer is made of hard foamed plastic, the protection layer is of a metal frame structure, and the decorative finish layer is made of flame retardant kraft paper. The vacuum thermal insulation board derivative for the inner wall is a material suitable for a thermal insulation system in the inner wall, the vacuum thermal insulation board derivative for the inner wall is good in thermal insulation effect, easy and convenient to construct, short in construction period, high in safety and low in cost, and a series of problems existing in the thermal insulation system of the inner wall are effectively solved.

Owner:CHONGQING ZAISHENG TECH CORP

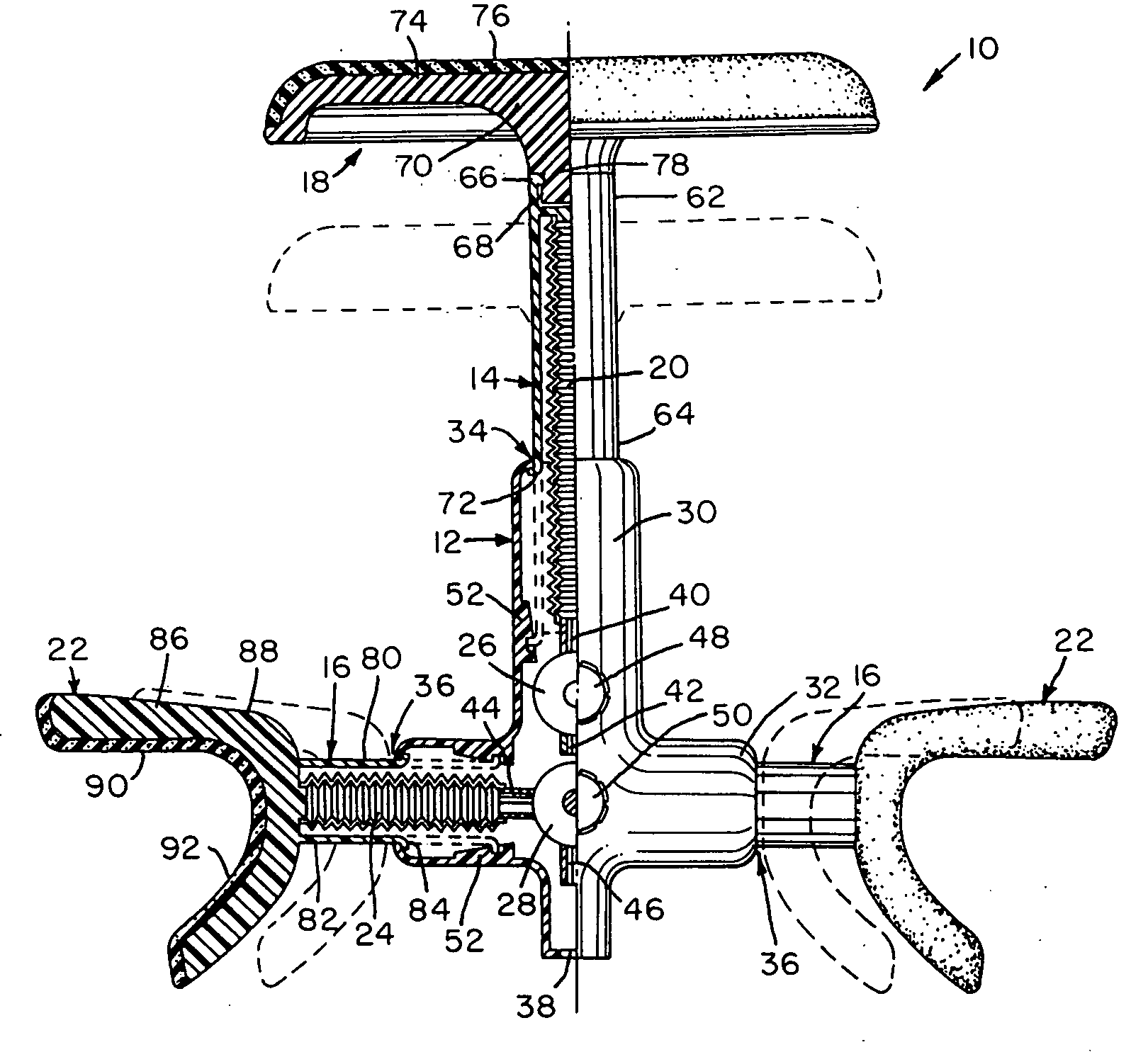

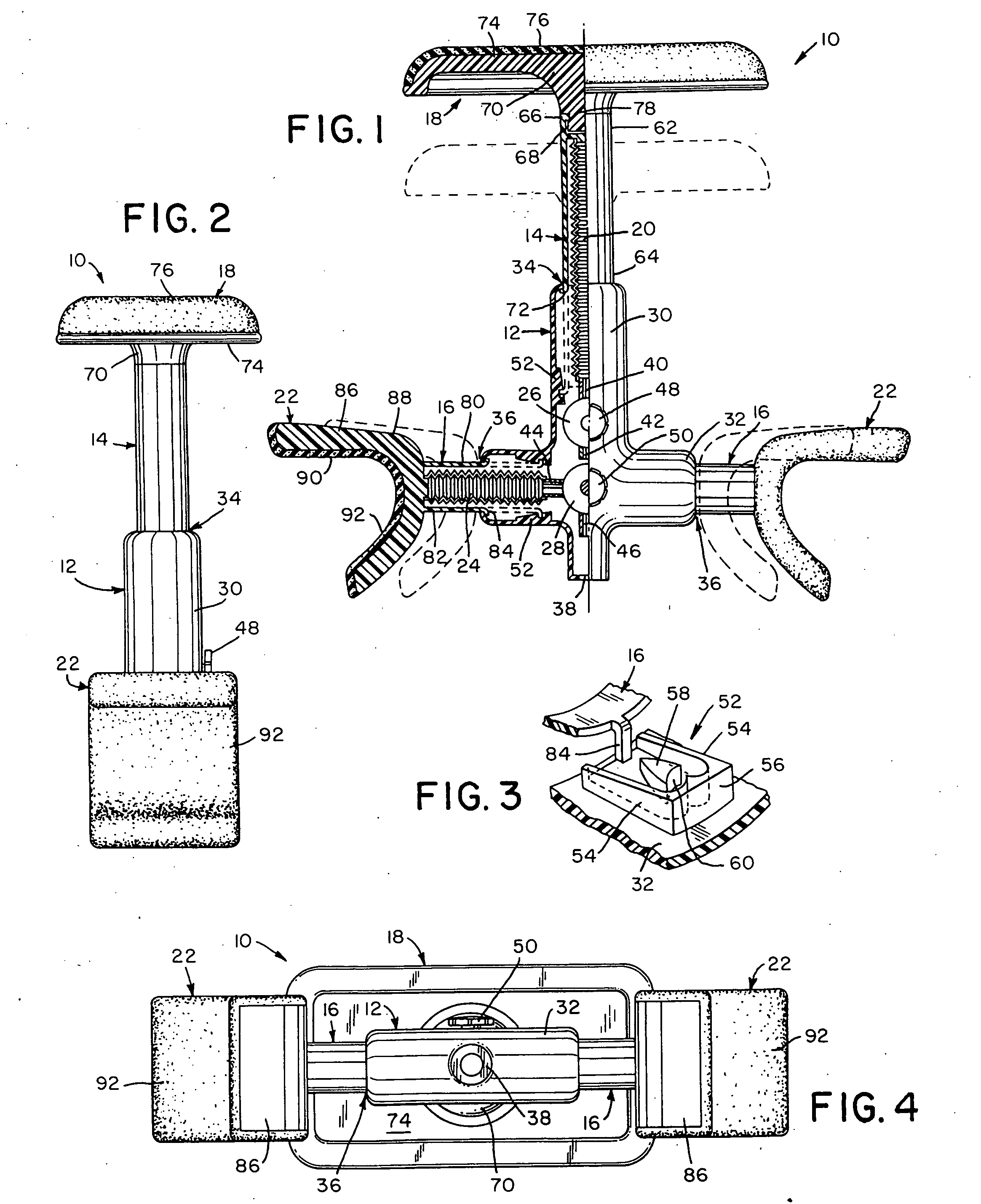

Exercise device

InactiveUS20050255974A1Lightweight constructionInexpensive to manufactureMuscle exercising devicesPhysical exerciseEngineering

An exercise device including a hollow body having openings into which a user may repeatedly push vertical and horizontal legs. The vertical leg has a saddle at its top for engagement with the chest of a user and contains a bellows for resisting the user's efforts to push the vertical leg into the hollow body with his chest. The horizontal legs have cradles at their outer ends for engaging the thighs of a user and contain bellows for resisting the user's efforts push the horizontal legs into the hollow body with his thighs. Valves associated with the bellows permit the force required to push the vertical and horizontal legs into the hollow body to be varied

Owner:GAULT RODERICK L

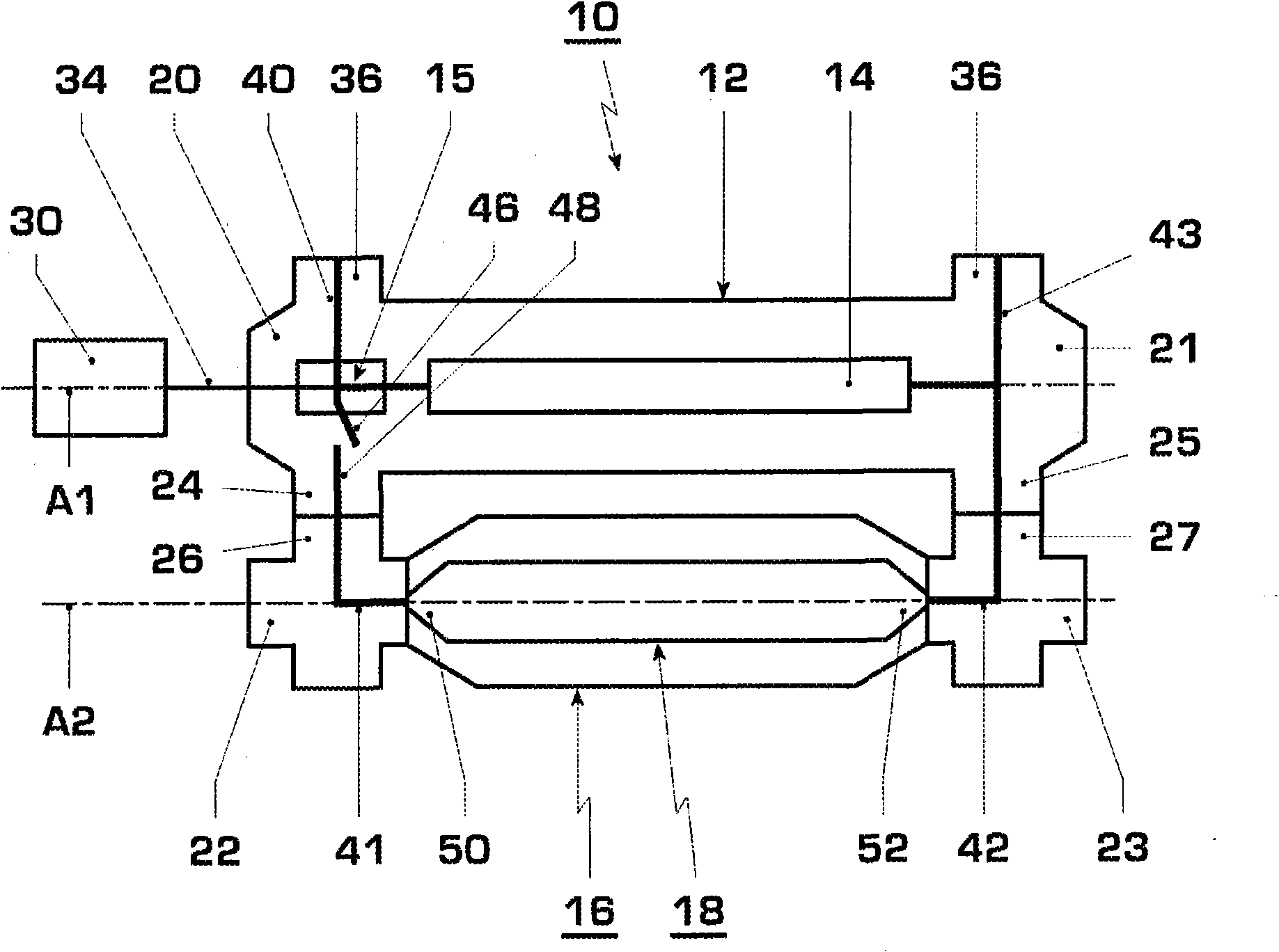

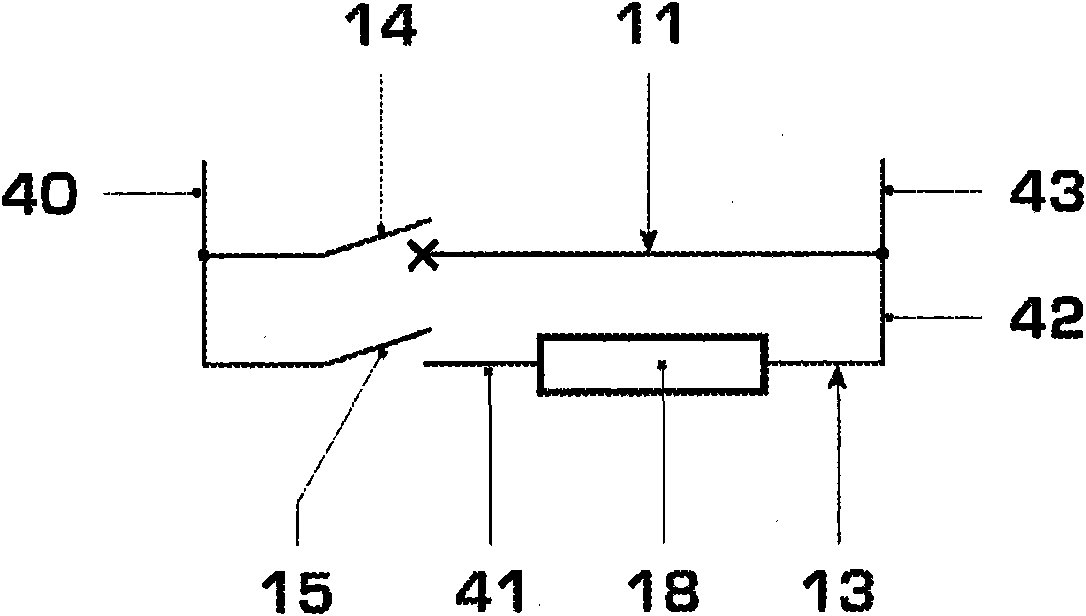

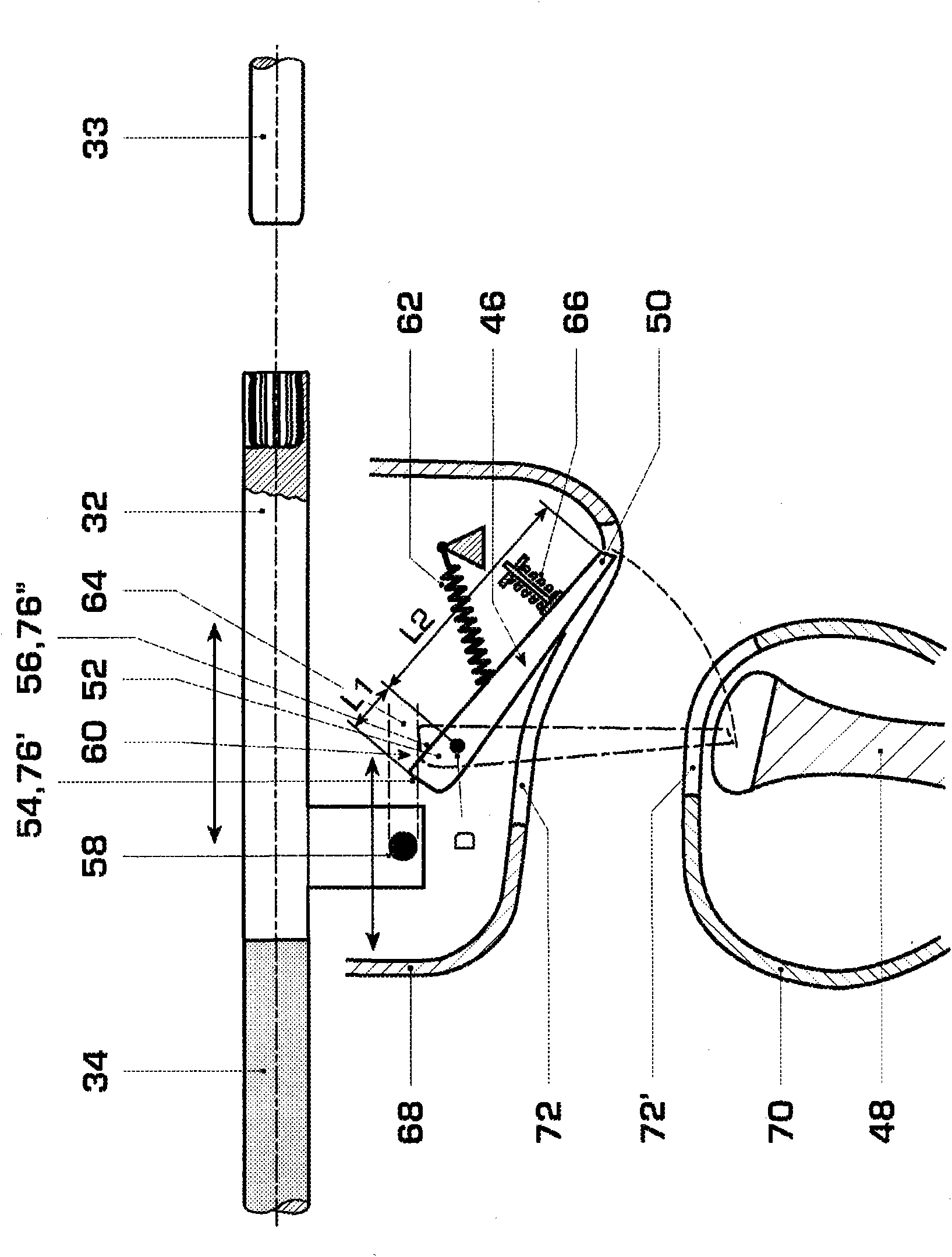

High-voltage power switch having a switch for engaging a starting resistor

ActiveCN101855694AControl closureControl the moment of opening againSwitchgear arrangementsHigh-tension/heavy-dress switchesEngineeringHigh pressure

The invention relates to a high-voltage power switch having an interrupter unit (14), a starting resistor (18), and a switch (15) connected in series with the starting resistor (18). The interrupter unit (14) comprises a first interrupter contact (32) displaceable along an axis (A1) and driven, acting together with a second interrupter contact (33) disposed on the axis (A1) to open and close the high-voltage power switch. The switch (15) comprises a switch contact (46) pivotable about a pivot axis (D), the pivoting motion of which is coupled to the motion of the first interrupter contact (32) along the axis (A1) by means of a link motion (60).

Owner:HITACHI ENERGY SWITZERLAND AG

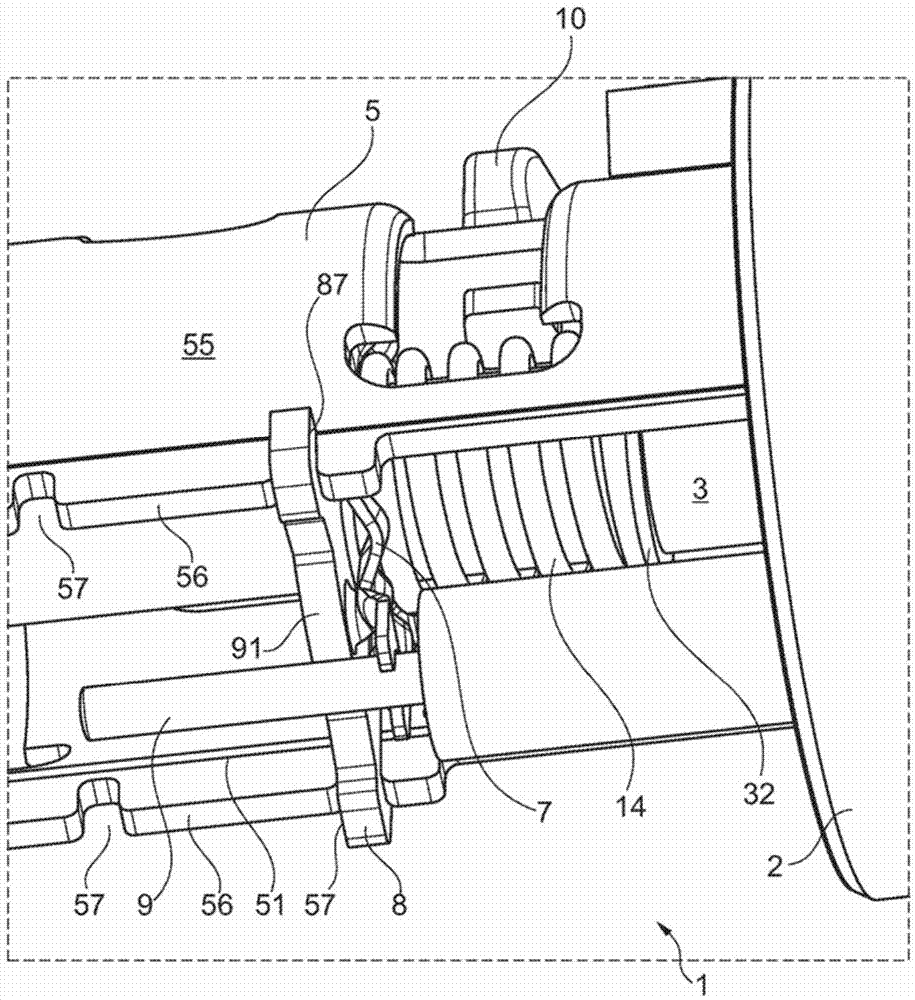

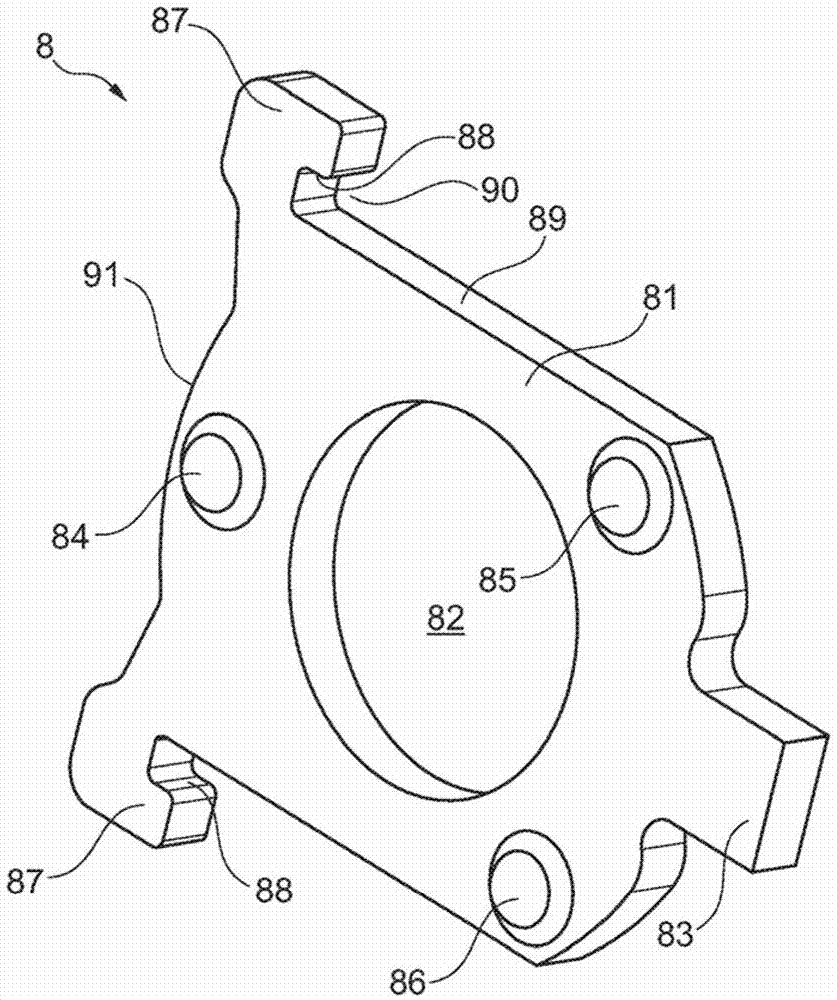

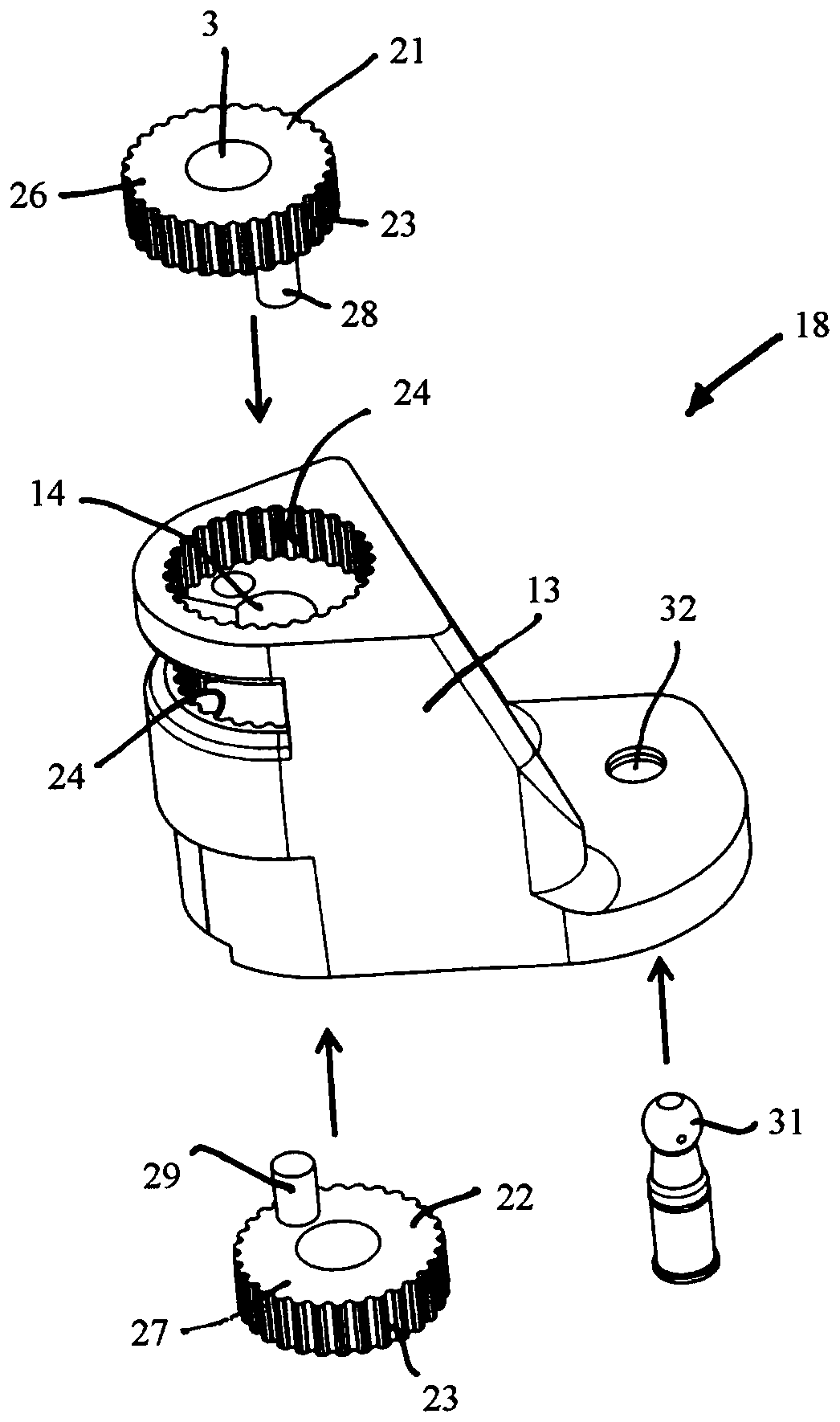

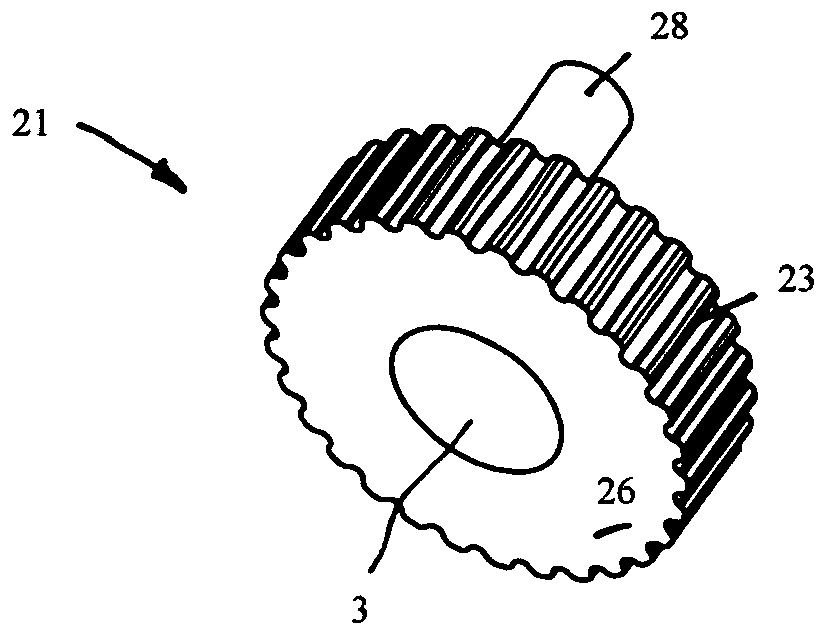

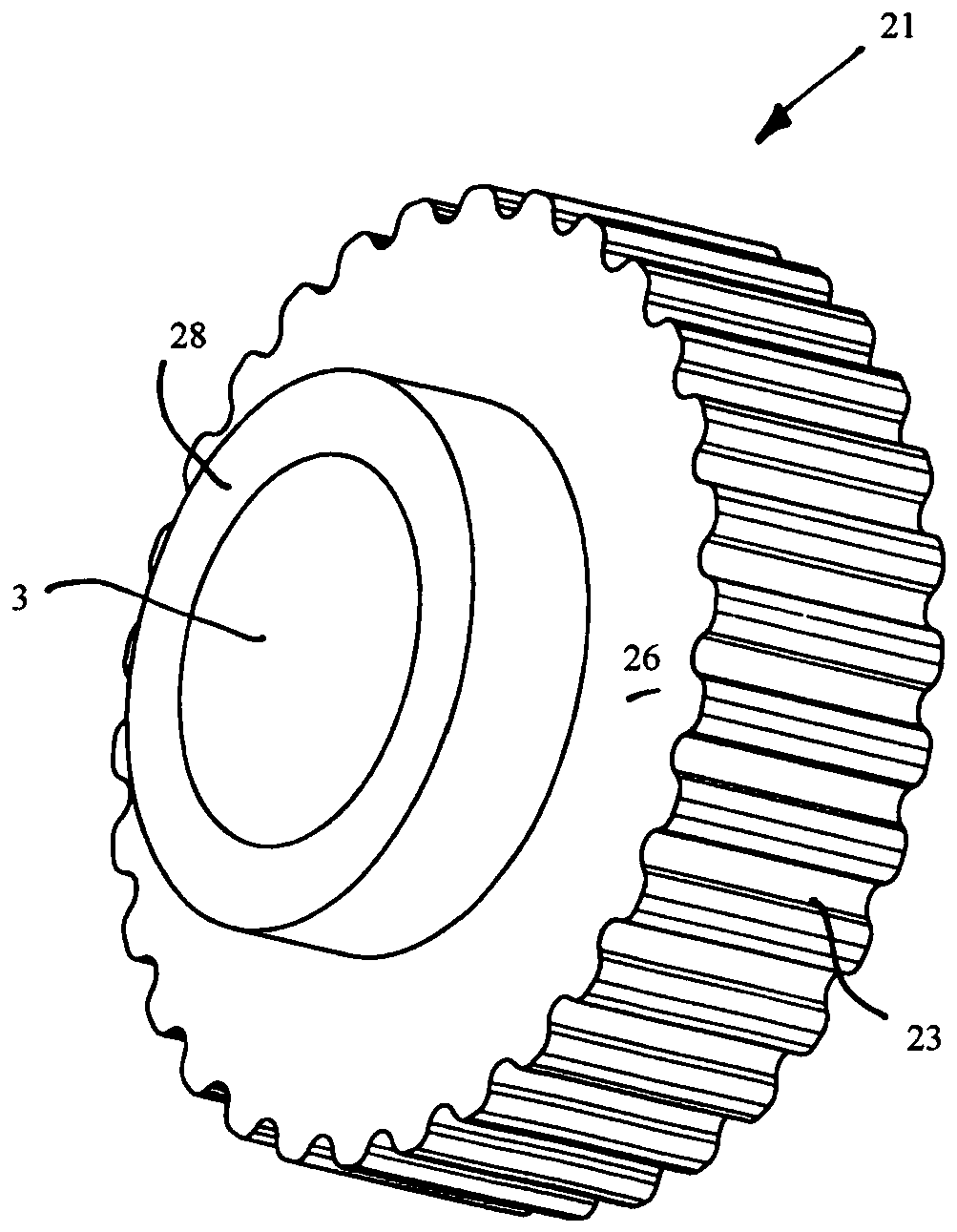

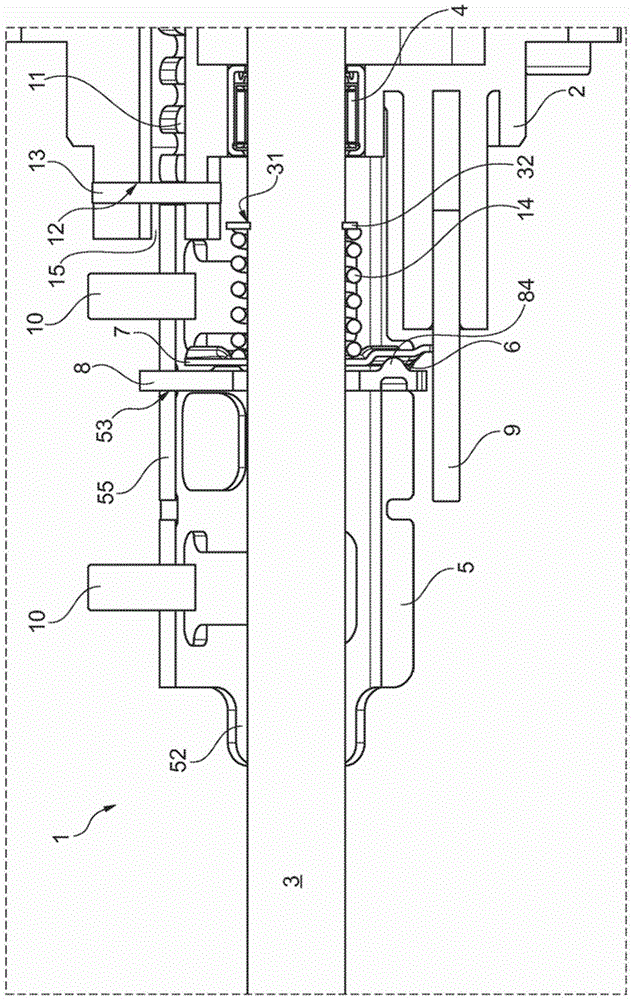

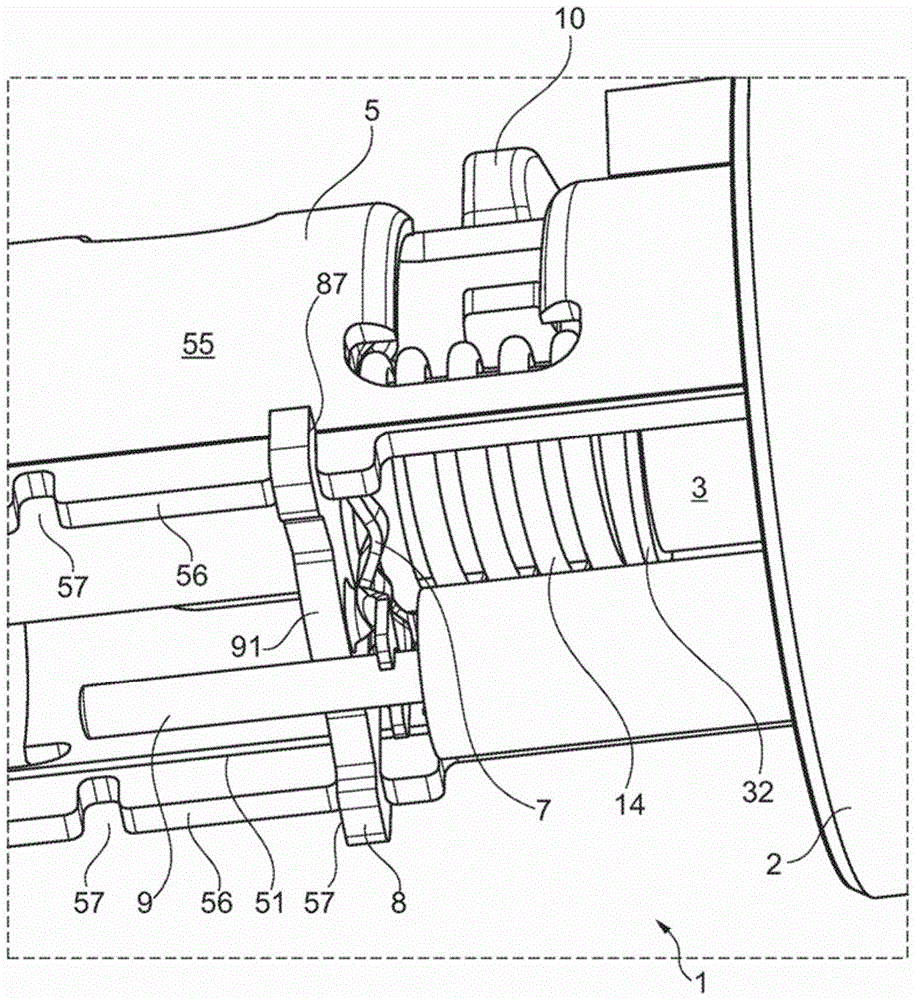

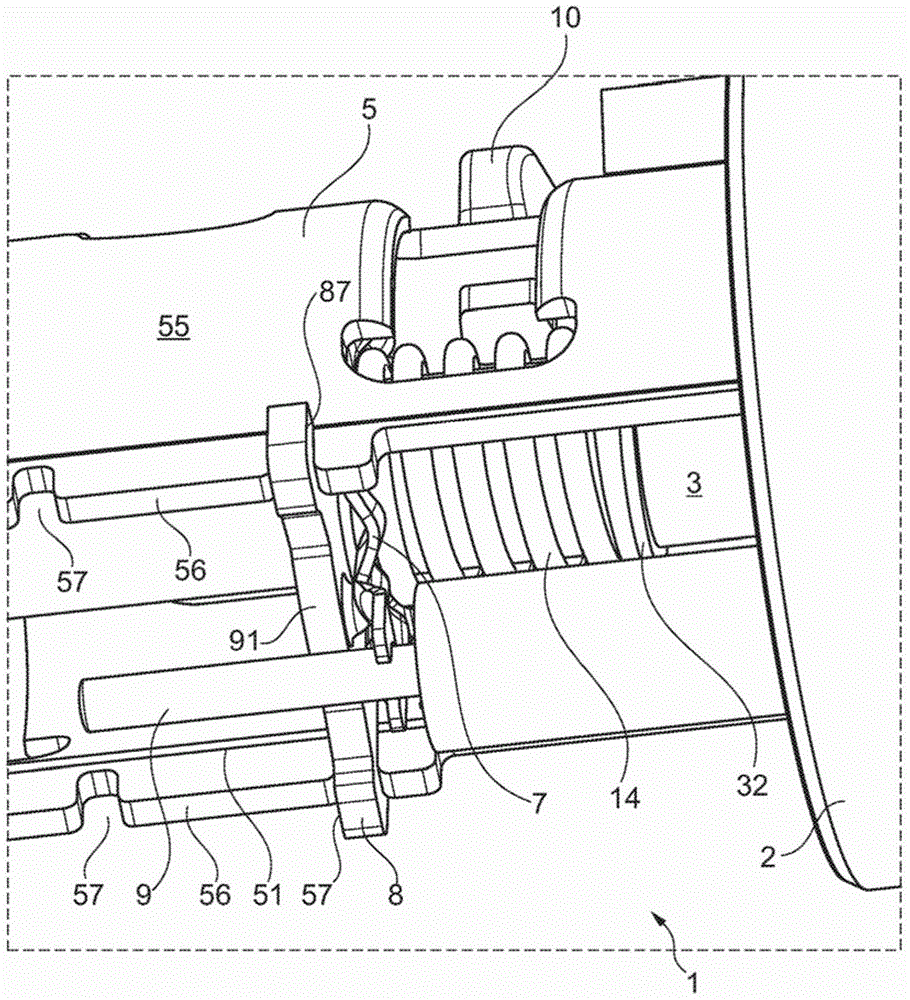

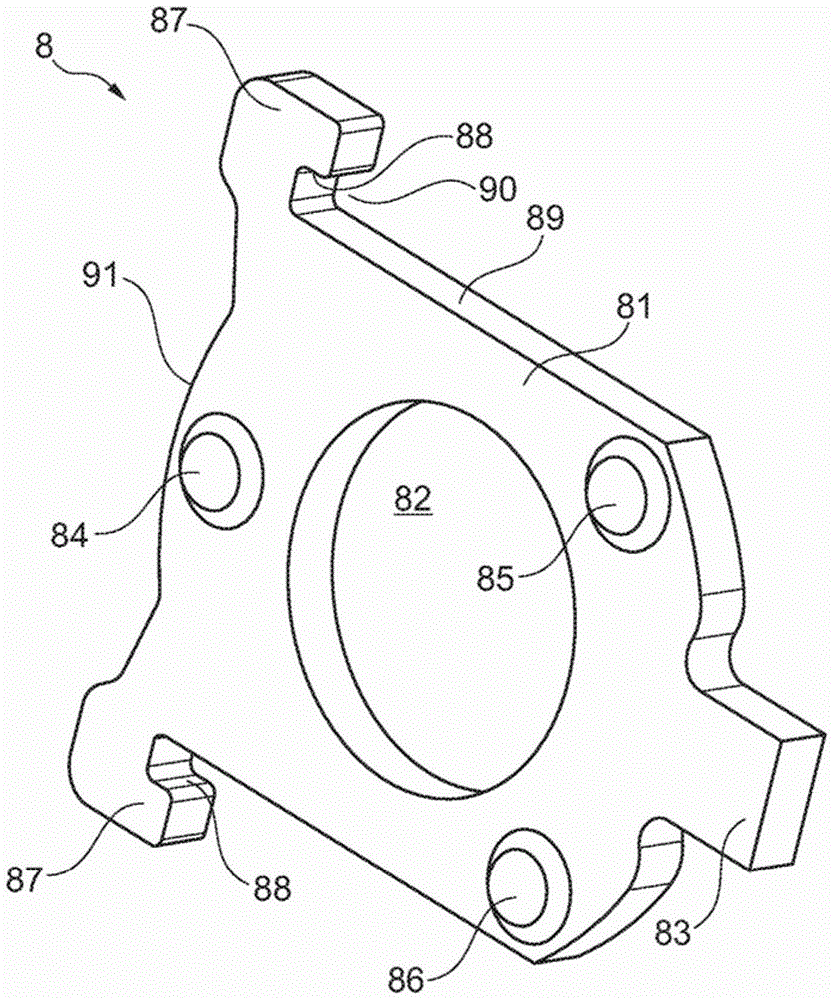

Shifting device of a motor vehicle change-speed gearbox

InactiveCN104769337AReduce in quantityCompact structureGearing controlEngineeringMechanical engineering

Owner:SCHAEFFLER TECH AG & CO KG

A three-roll skew rolling forming method for a railway vehicle axle

The invention discloses a three-roll cross-rolling forming method for railway vehicle axles, which is characterized in that the bar is heated, and the bar is sent into a three-roll cross-rolling machine through an axial pushing device, and three cross-rollers are simultaneously engaged with the bar , and drive the bar to rotate. At the same time, the axial pusher pushes the bar to move axially at a constant speed. The radial drive mechanism controls the radial movement of the skew roll according to the diameter of the railway vehicle axle to be processed. When it moves to contact with the axial feeding device, the axial feeding device pulls the bar and continues to move axially at a constant speed, and at the same time the bar is separated from the axial pushing device, and a long step with a large diameter is obtained after processing Axle—the railway vehicle axle; the advantage is that the mold is simple to manufacture, and the force is evenly distributed on the surface of the rolled piece, which can effectively reduce the wear of the roll during the skew rolling process, enable the rolling mill to carry out lightweight construction, and effectively increase the service life of the rolling mill.

Owner:NINGBO UNIV

Indoor floor leveling mortar and construction method thereof

The invention relates to a light-weight indoor floor leveling mortar, which comprises the following components in proportion by weight: 30-35 ordinary portland cement, 4-5 hydrated lime, 5-8 light aggregate, 55-60 heavy aggregate (ordinary river sand) and 1.0 compound additive, wherein the light aggregate is an inorganic vitrified hollow cellular material of which the fineness is lower than 100 meshes; and the compound additive can be prepared by mixing 0.1 part by weight of dispersible latex powder, 0.3 part by weight of cellulose ether, 0.5 part by weight of water reducing agent and 0.1 part by weight of coagulant agent. The construction method comprises the following steps: watering the mortar with water which is 30-50% of the mortar in weight, mechanically or manually mixing until the mortar and water are evenly mixed and achieve the viscosity, and carrying out mechanical spray coating or manual construction. The mortar of the invention has light weight, self-leveling performance, good smoothness, easy toweling, rapid construction, simple and practical process, low cost of unit area and popularization value, is favorable to mechanized construction, lightens the load quantity of a building body, improves the safety earthquake-resistant performance of the construction, achieves leveling thickness rapidly once, and is very suitable for leveling the floor of the bottom surface of a light weight floor material, such as a wood floor and the like.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

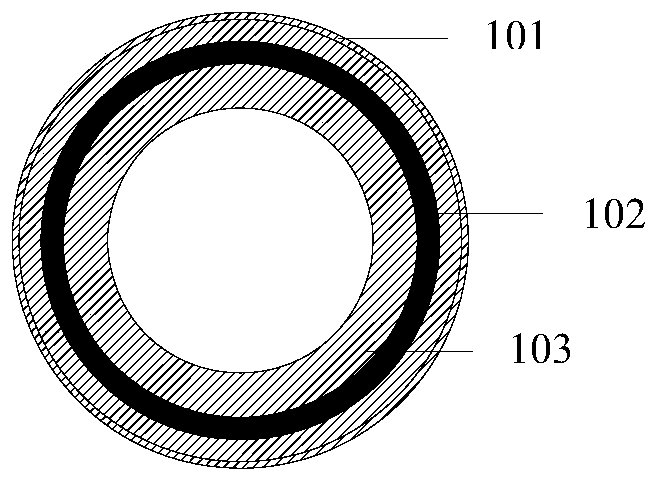

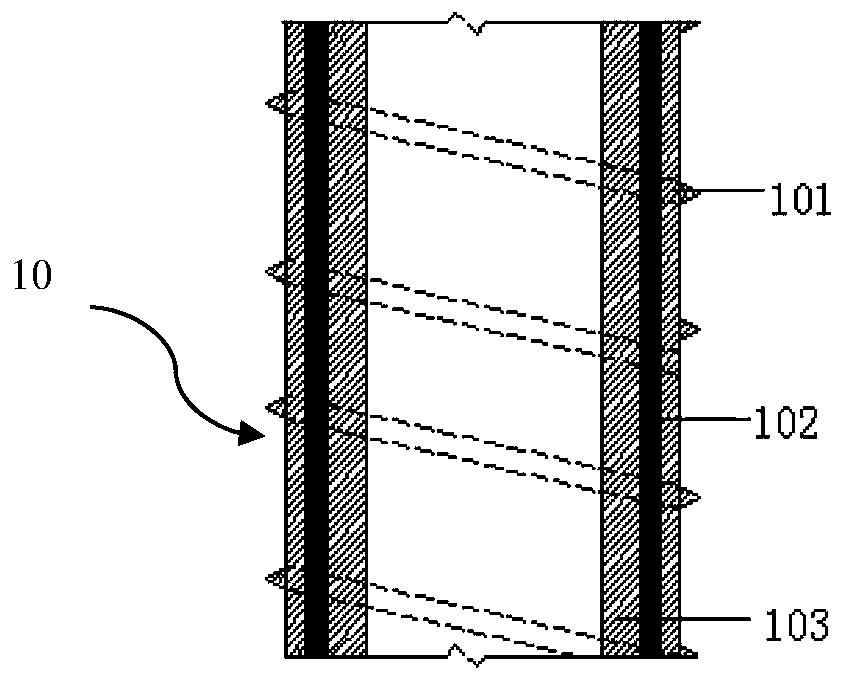

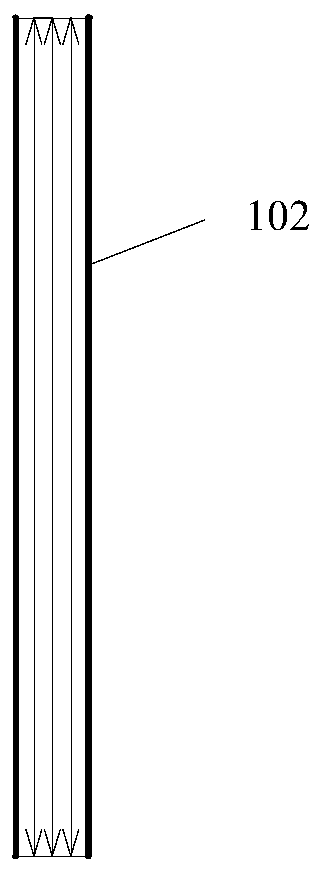

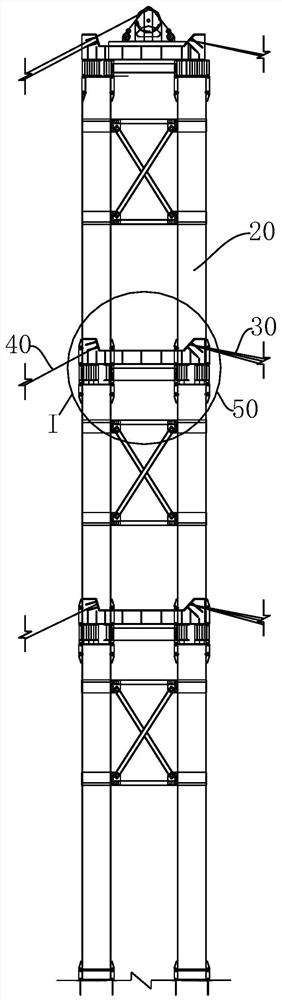

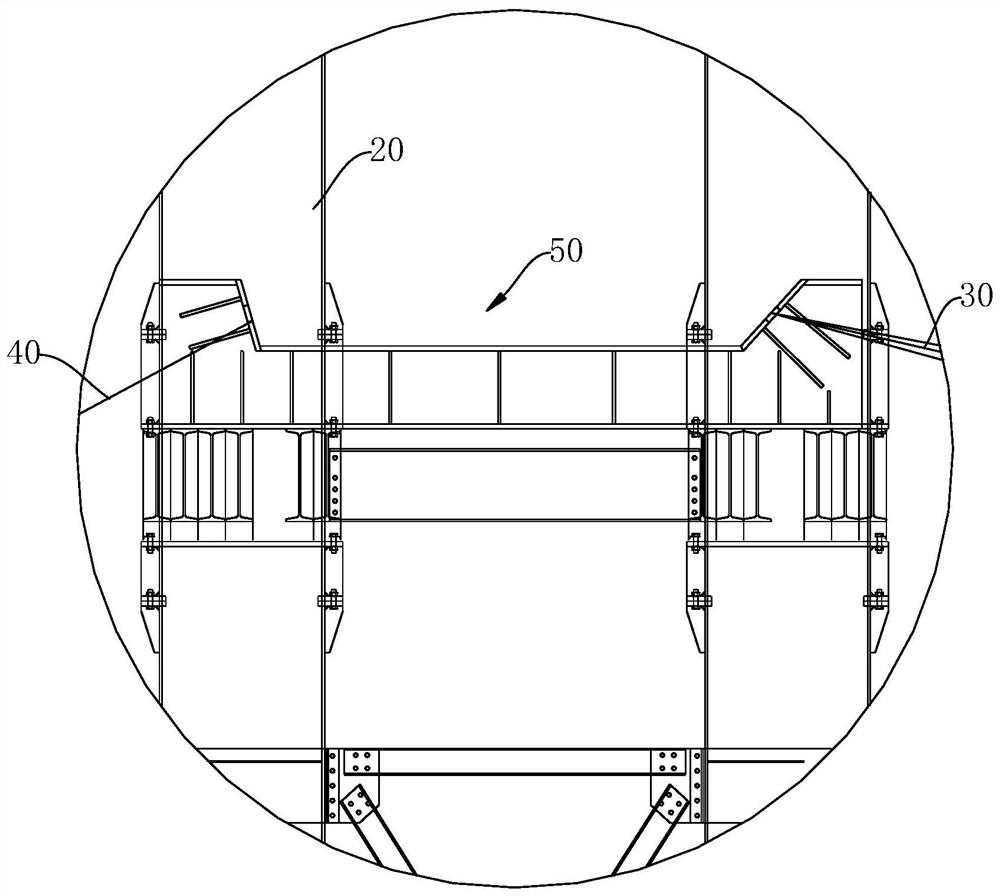

Prestressed light pile for rapidly anchoring emergency bridge inhaul cable and construction method of prestressed light pile

ActiveCN110206021AImprove the pull-out capacityNo loss of tensile capacityBridge structural detailsBulkheads/pilesInterference fitPile cap

The invention discloses a prestressed light pile for rapidly anchoring an emergency bridge inhaul cable and a construction method of the prestressed light pile. The light pile comprises a hollow pilebody and a pile cap which is arranged at the upper end of the pile body and is in interference fit with the pile body, and the pile body is composed of an outer pipe, a middle pipe and an inner pipe.The construction method of the light pile comprises the steps that drilling is conducted, the outer pipe provided with a clamp is inserted into the hole, a spiral drilling machine is moved away, an outer spiral pipe clamp is removed, then the middle pipe and the inner pipe are sequentially driven in, after the inner pipe is driven in, the composite middle pipe expands circumferentially, the outerpipe is forced to extrude rock around the pile, circumferential pre-tightening force is generated, the anti-pulling bearing capacity of the anchoring pile is improved, finally, the prefabricated steelpile cap in interference fit is driven into the inner pipe, and the emergency bridge inhaul cable is anchored on the pile cap. The light pile is made of a light aluminum alloy and a composite, and the transport cost is lowered; and through threads on the composite middle pipe and the outer pipe, the anti-pulling bearing capacity of the pile body and pile-soil is improved, the light pile is drivenin on site and used immediately, and the requirements of an emergency bridge are met.

Owner:HOHAI UNIV

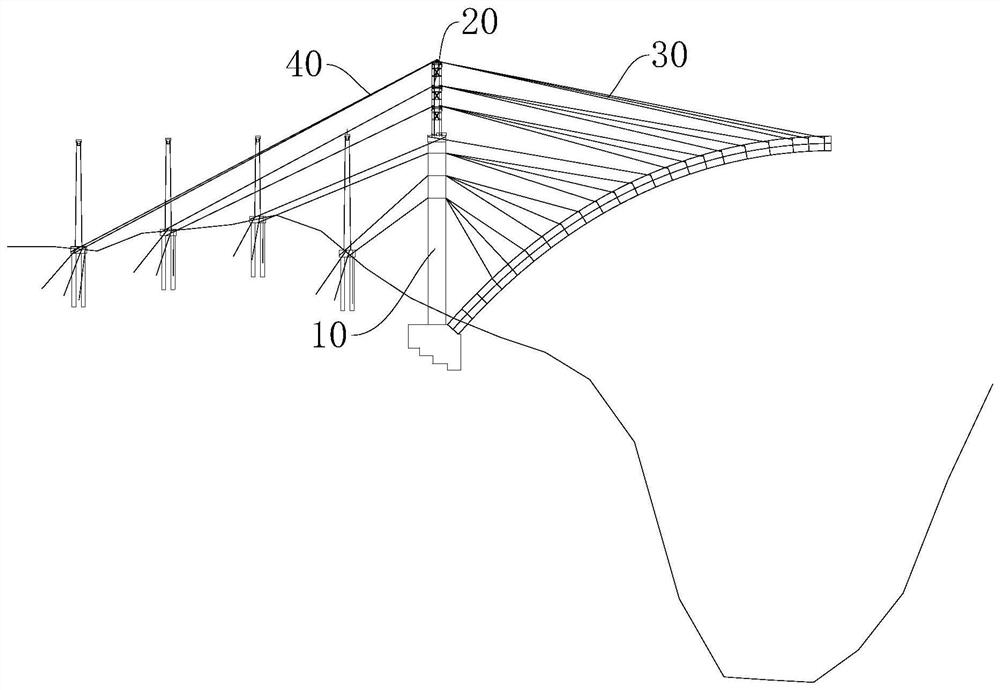

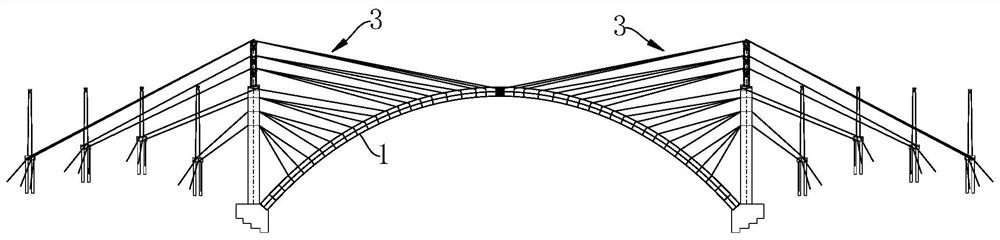

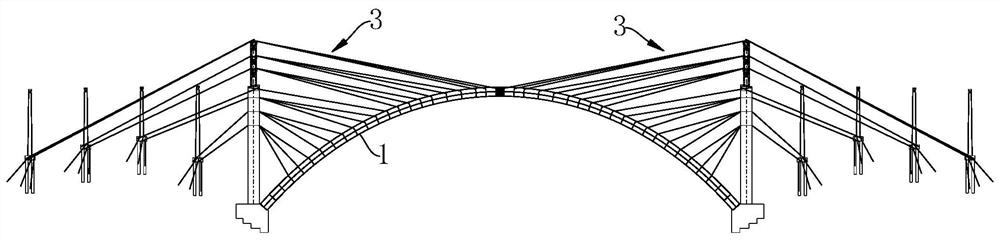

Cantilever pouring arching control method for arranging buckle rope steering device on large-span main arch stand column

ActiveCN111764306ALighten the loadReduce section sizeBridge erection/assemblyArchitectural engineeringTower

The invention relates to the field of arch bridge construction, and particularly relates to a large-span arch bridge cantilever pouring arching control method. The method comprises the steps of firstly, constructing a junction pier, and arranging a plurality of buckle cable anchoring points at different positions on the junction pier according to stress requirements, wherein each buckle cable anchoring point is connected with a buckle cable; constructing arch feet at the left end and the right end of the arch bridge, then sequentially casting each main arch section in a cantilever mode from arch feet at the left end and the right end of the arch bridge, constructing main arch stand columns on one formed main arch section located at the left end of the arch bridge and one formed main arch section located at the right end of the arch bridge respectively in the construction process, arranging buckling towers at the top of the stand columns, and arranging a plurality of steering saddles onthe buckling towers; and anchoring the buckle cable at the buckle cable anchoring point on the junction pier through the steering saddle on the buckling tower, and continuing cantilever pouring of the main arch section till closure. The stability of the buckling tower in the construction process is guaranteed, the construction precision of the arch ring is also guaranteed, and the light-weight trend of the large-span arch bridge construction can be facilitated.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

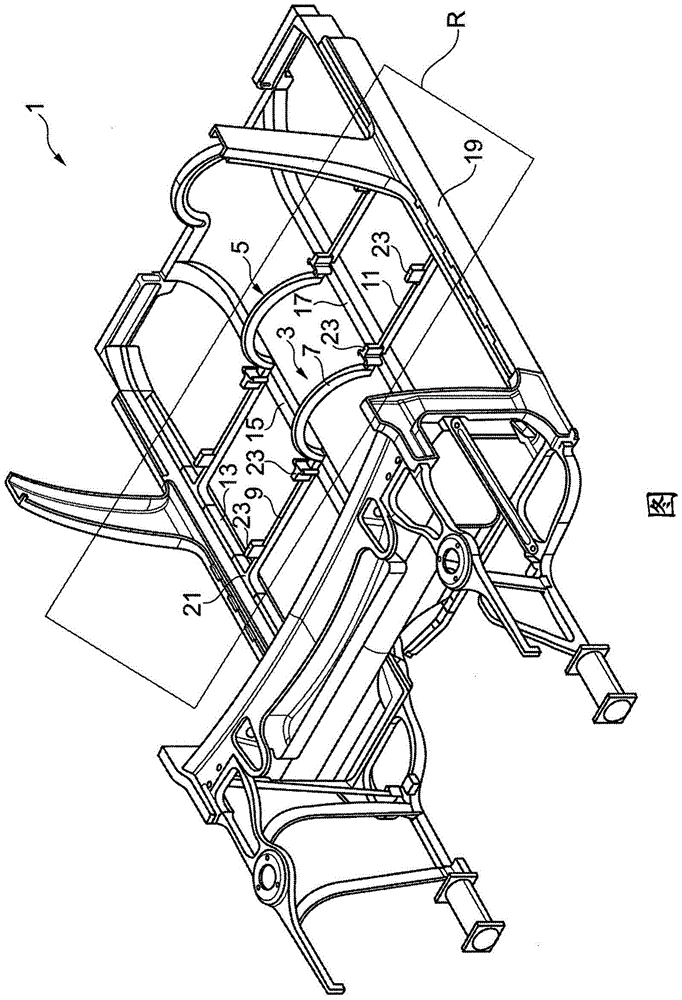

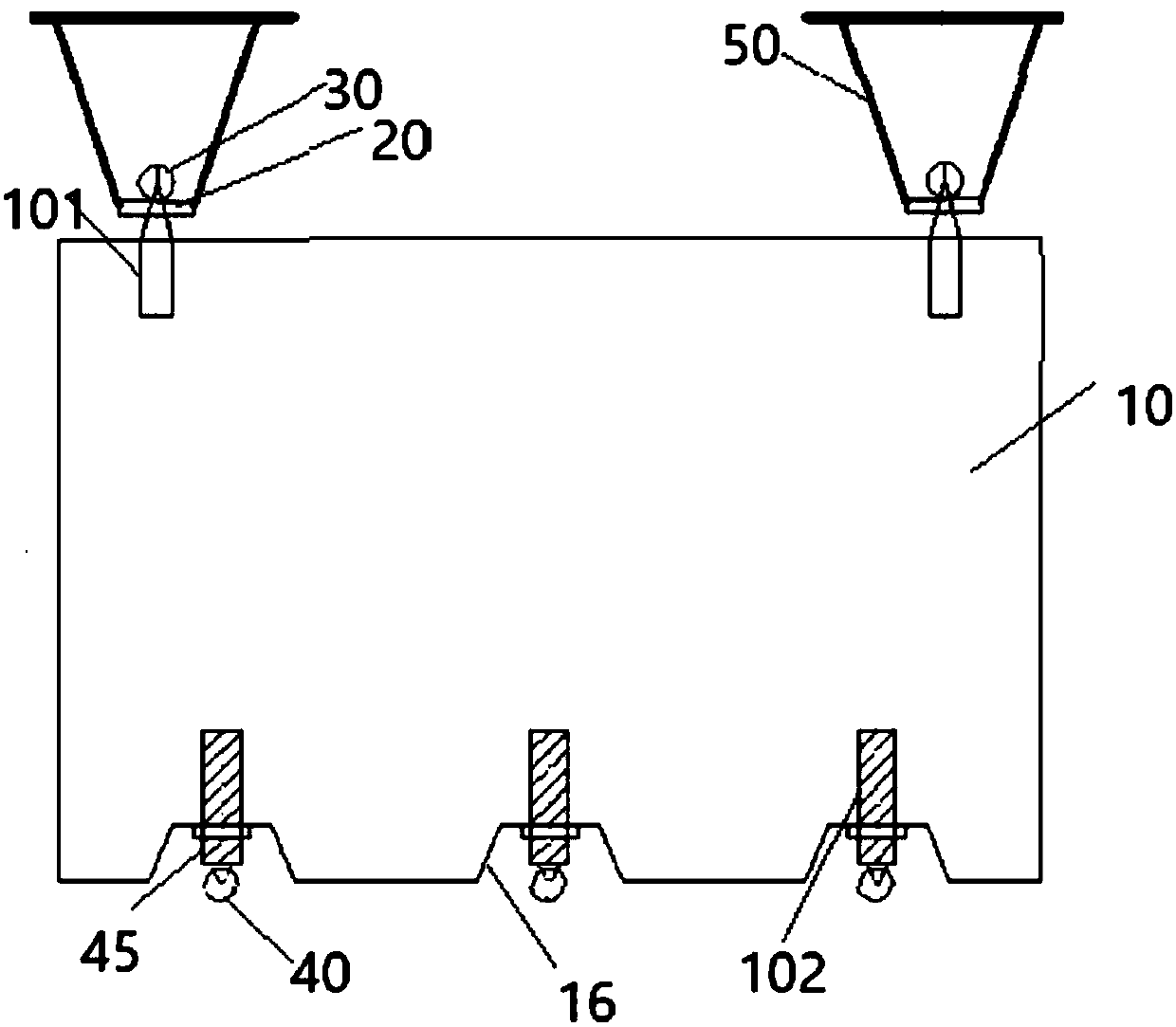

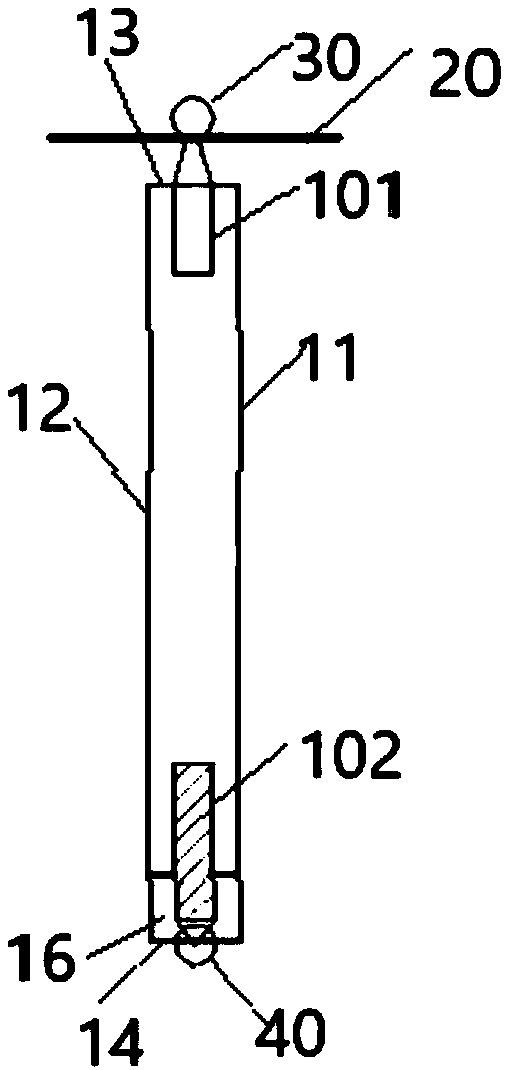

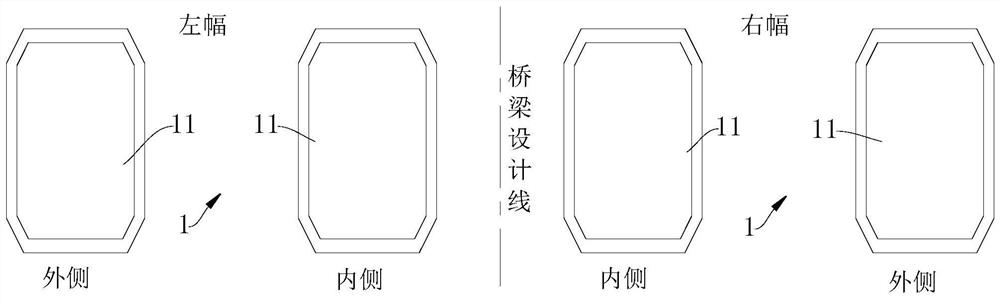

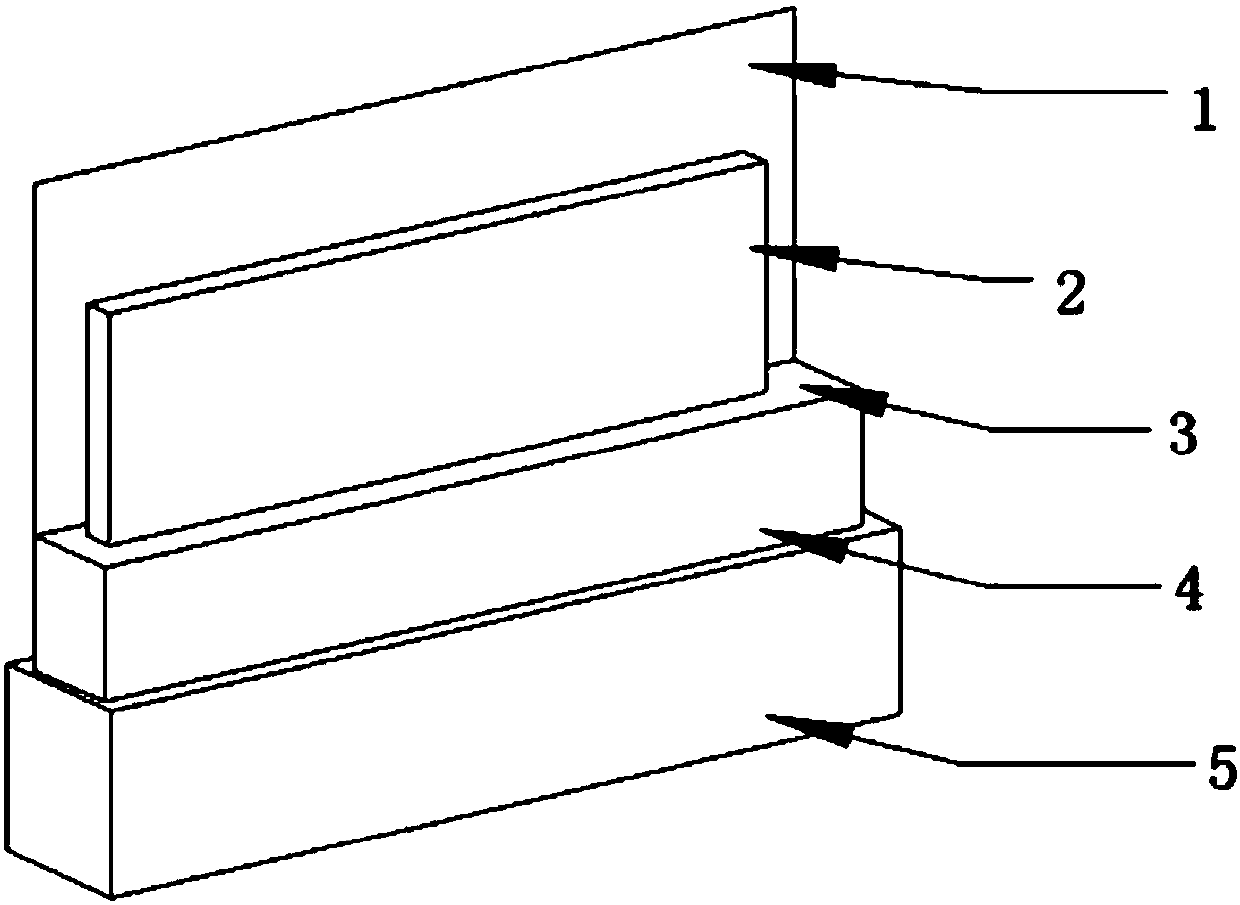

Lightweight movable wall body with gypsum board light-gauge steel frame system

The invention discloses a lightweight movable wall body with a gypsum board light-gauge steel frame system. The lightweight movable wall body with the gypsum board light-gauge steel frame system comprises a movable wall body (10) and at least two guide rails (20) arranged parallel to the top of the movable wall body (10), wherein the movable wall body (10) comprises a frame main body, a first gypsum board (11) and a second gypsum board (12); the first gypsum board (11) and the second gypsum board (12) are used for sealing the frame main body; the frame main body comprises a top plate (13), a bottom plate (14), 3-15 vertical studs and 3-15 horizontal core-through beams; the top plate (13) is provided with at least two universal rolling wheels (30); the at least two universal rolling wheels(30) are separately and correspondingly connected to the at least two guide rails; the universal rolling wheels (30) slide along the guide rails; and the bottom plate (14) is evenly provided with at least three load-bearing rolling wheels (40) at equal intervals.

Owner:肇庆北新建材有限公司

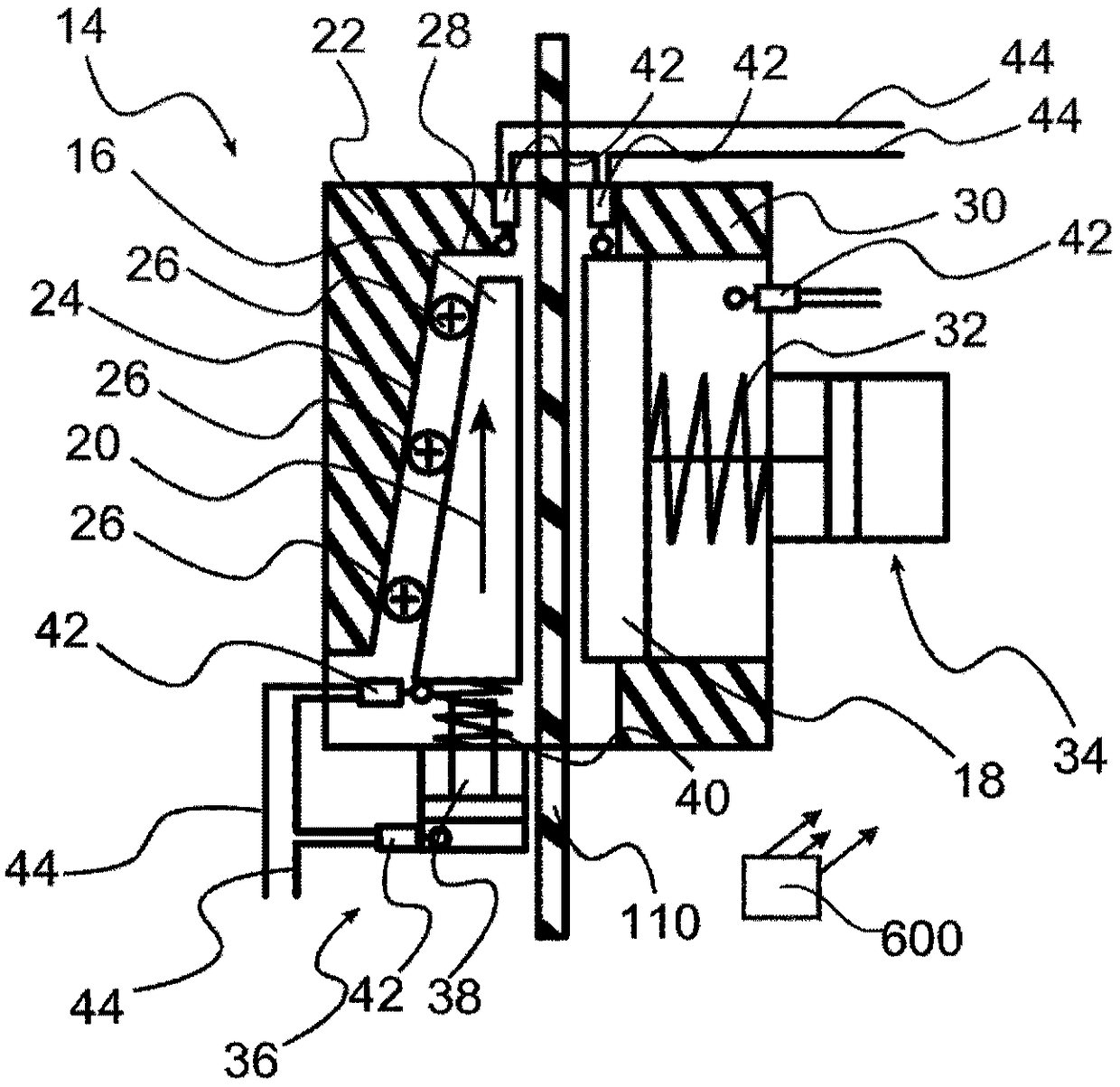

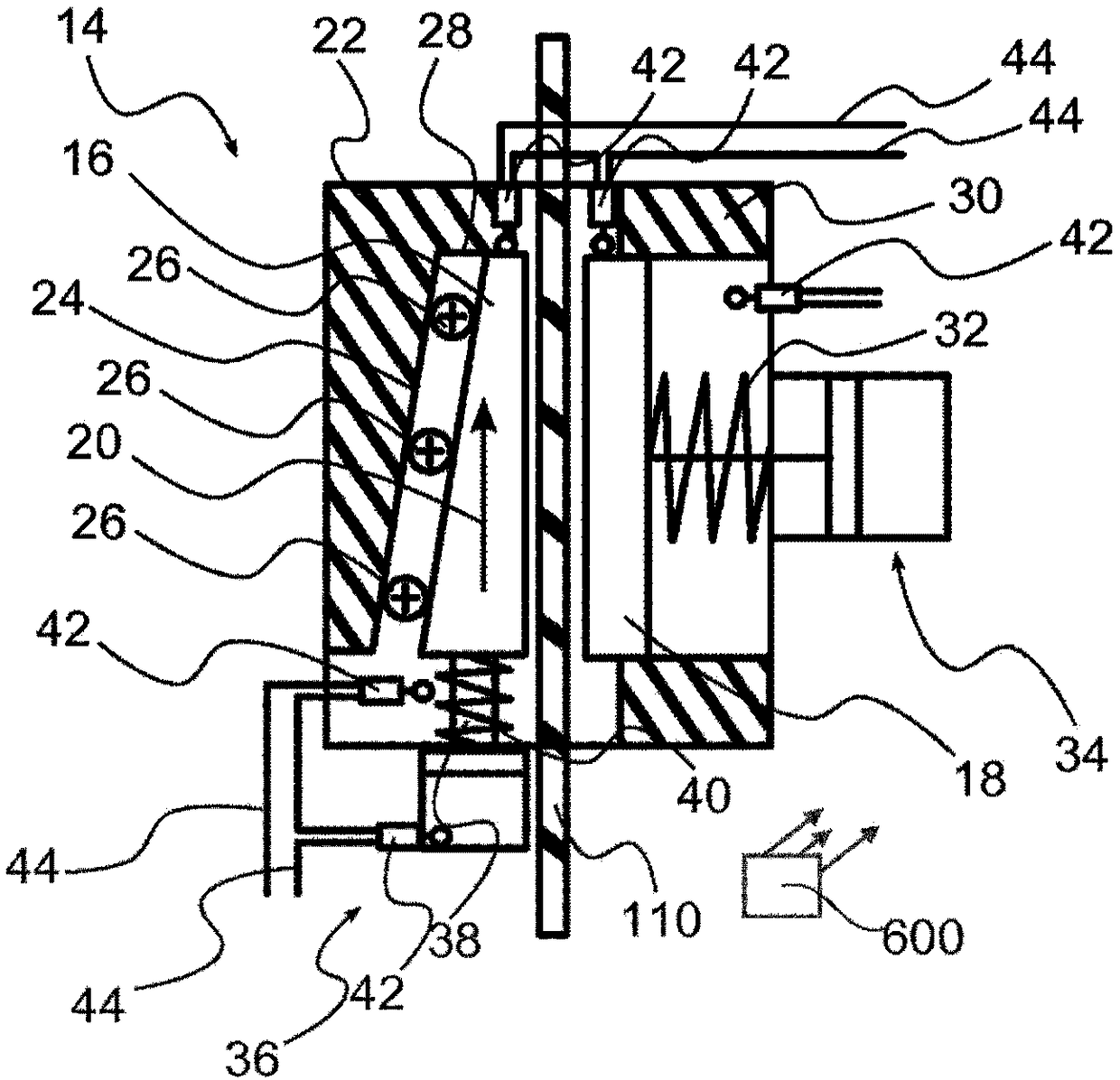

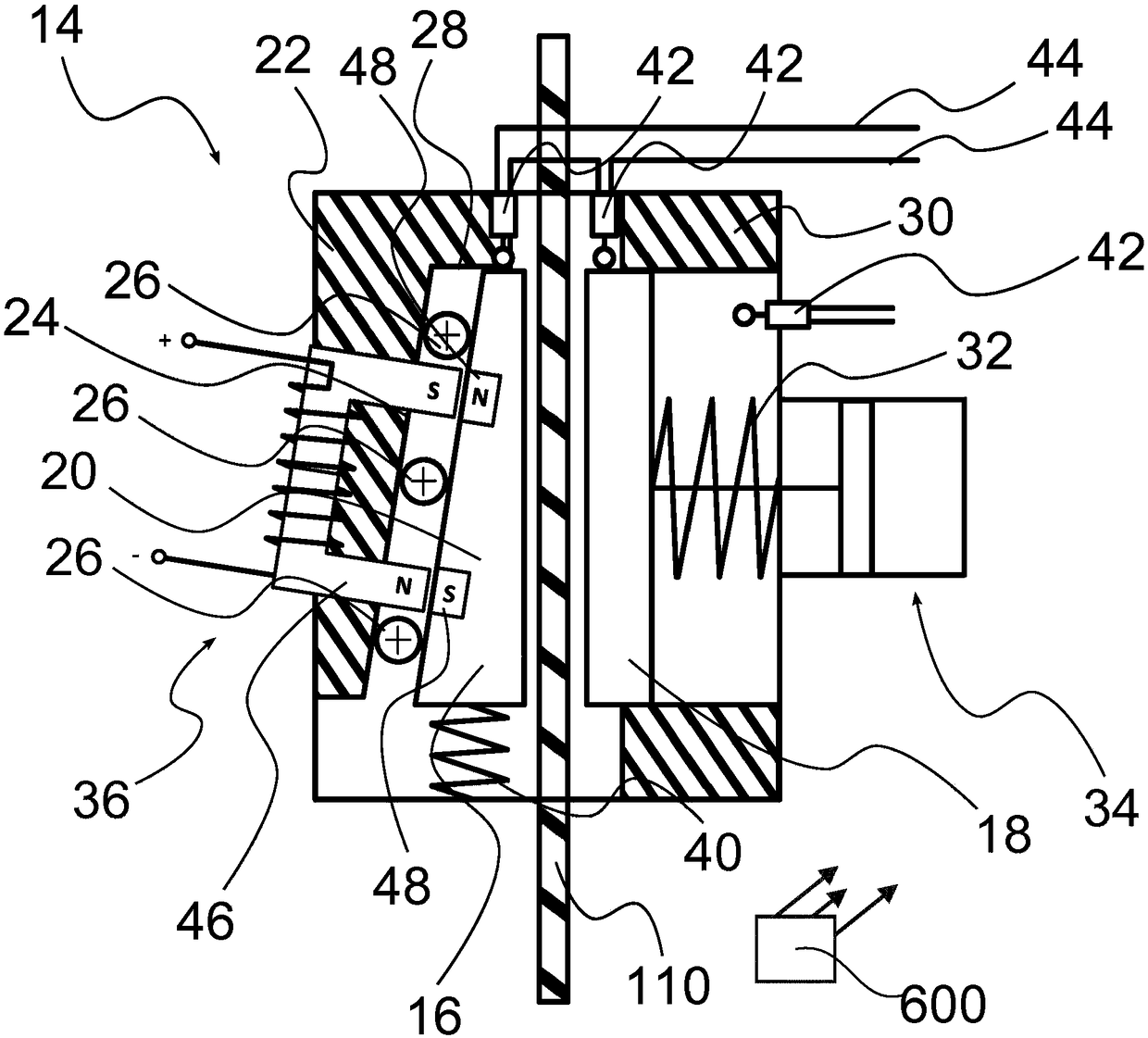

Braking device for a car of a lift system

ActiveCN108473279AEasy to adjustIncrease mobilityElevatorsBuilding liftsControl theoryMechanical engineering

The invention relates to a braking device (14) for a car (200) of a lift system (100), wherein the braking device (14) comprises a first brake pad (16) and a second brake pad (18), which are arrangedopposite one another and accommodate the guide rail (110) between them and deploy a braking effect via a frictional connection when they engage with the guide rail (110). For this purpose, the first brake pad (16) is wedge-shaped and tapers in the direction of a wedge direction (20), wherein the front side of the brake pad facing the guide rail (110) is oriented in parallel to the guide rail (110)and the opposing rear side is inclined according to the wedge shape. In addition, the braking device (14) comprises a brake pad receiving means (22) having a contact surface (24) with an inclinationcorresponding to the wedge-shaped brake pad (16), on which the rear side of the wedge-shaped brake pad (16) rests in a sliding manner. Furthermore, the braking device (14) has a locking device (36) with a first position and a second position, wherein the locking device (36) releases a sliding movement of the wedge-shaped first brake pad (16) against the wedge direction (20) in the first position,and blocks the sliding movement of the wedge-shaped brake pad (16) against the wedge direction (20) in the second position.

Owner:TK ELEVATOR INNOVATION & OPERATIONS GMBH

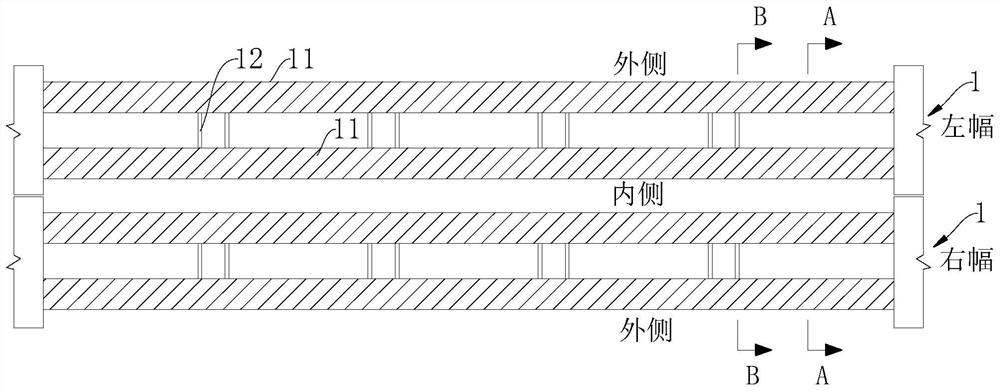

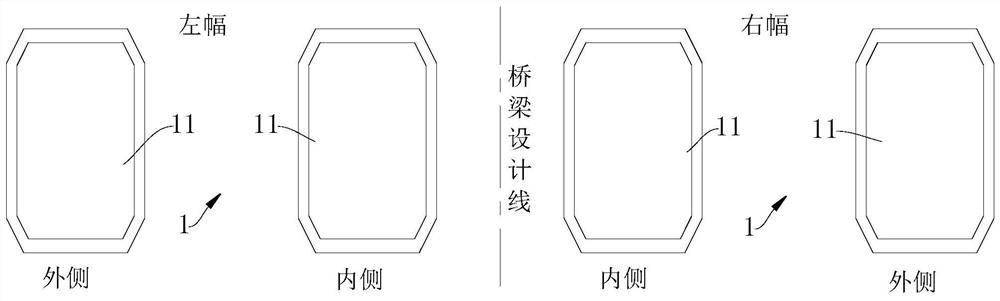

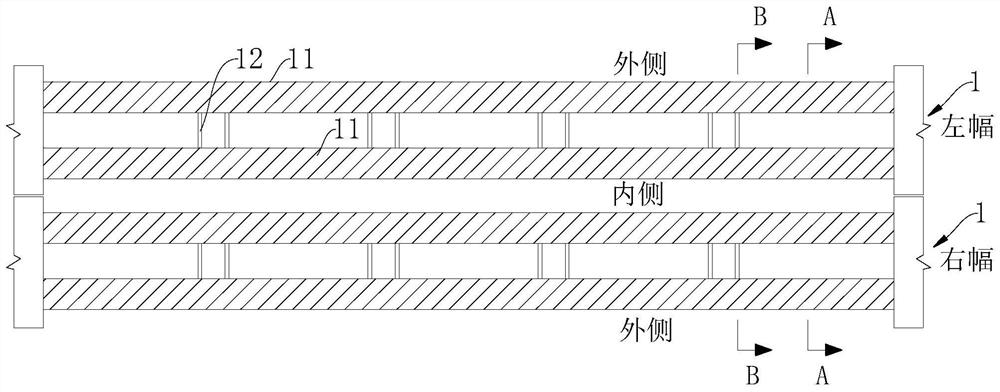

Main arch arching process for synchronous transverse connection of main arch single-rib staggered cantilever pouring

ActiveCN111764305ASmall cross-sectional sizeReduce stressBridge erection/assemblyReinforced concreteArchitectural engineering

The invention relates to the field of reinforced concrete arch bridges, and particularly relates to a main arch arching process of main arch single-rib staggered cantilever pouring. Two single-box-shaped arch ribs are arranged on the left side and the right side of a double-side arch bridge respectively to form arch rings of the left side bridge and the right side bridge respectively; and duringconstruction, the main arch arching process comprises the steps that firstly, the two arch ribs on the inner side of the double-side arch bridge are poured in a cantilever mode till the two arch ribson the inner side are closed; 2, two arch ribs on the outer side of the double-width arch bridge are poured in a cantilever mode till the two arch ribs on the outer side are closed, and arch rings ofthe left side bridge and the right side bridge are formed respectively. The main arch ring comprises the two single-box-shaped arch ribs, the arch ribs in the arch ring are subjected to independent pouring construction, the cross section size of the arch ribs is reduced, the segment pouring weight is small, and the process is suitable for light construction of the large-span arch bridge.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

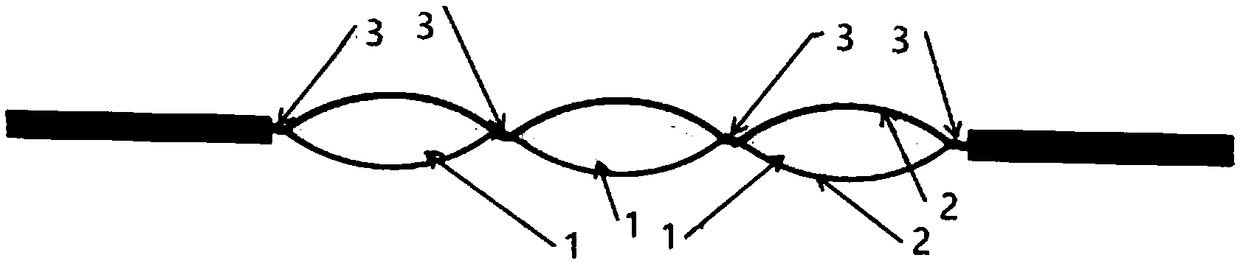

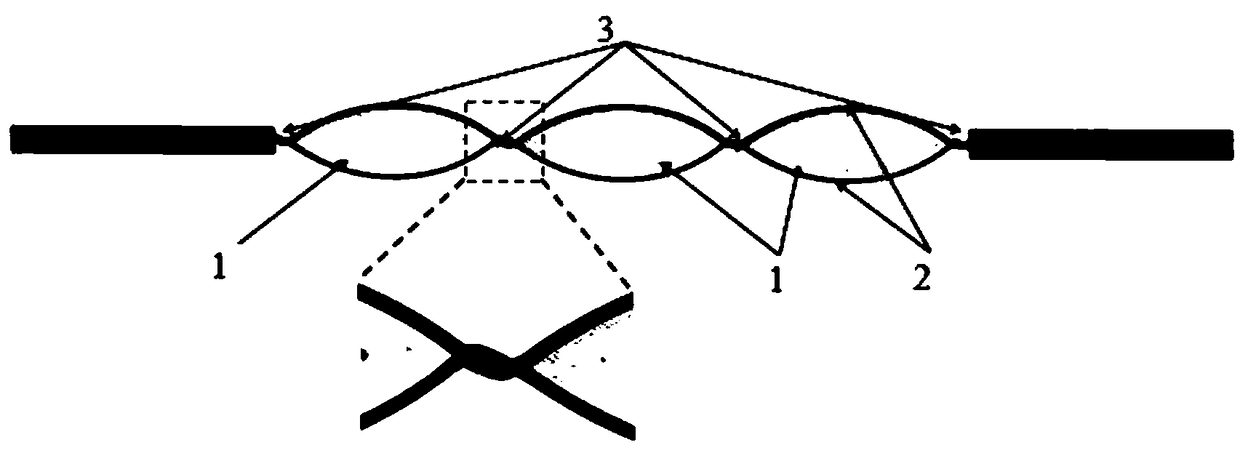

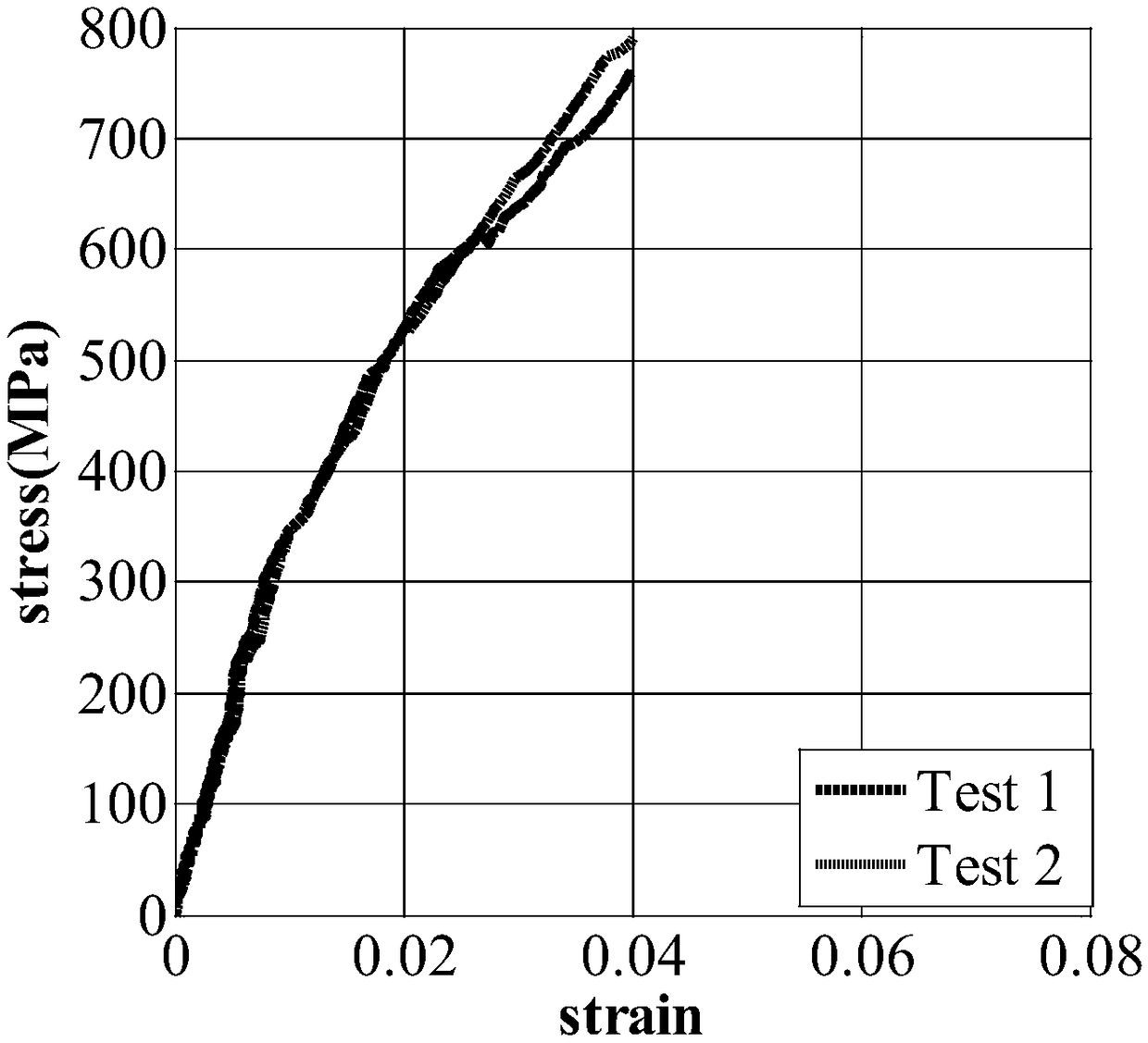

High-strength large deformation carbon fiber composite board and preparation method thereof

InactiveCN109184074ALightweight constructionHigh tensile strengthAdditive manufacturing apparatusConstruction materialEpoxyFiber

The invention discloses a high-strength large deformation carbon fiber composite board and a preparation method thereof. The high-strength and large-deformation carbon fiber composite board is composed of an elliptical core, carbon fiber sheaths and a carbon fiber screw button. The core can be realized by a 3D printer for shaping the carbon fiber sheath to a wave shape, and the elliptical core iswrapped by a plurality of sets of carbon fiber sheaths, each set of carbon fiber sheaths is made of a pair of equal-width carbon fiber strips and bonded to the surface of the core by epoxy resin glue,the pair of carbon fiber sheaths are wound to the carbon fiber screw button at both ends of the core to prevent peeling of the outer edges of the carbon fiber and disengaging between the sheath and the core; finally, the wrapped and wrapped carbon fiber composite structure is soaked in the epoxy resin glue, and the carbon fiber composite board is obtained after curing. The carbon fiber compositeboard materials of the invention are light and high in strength, have large tensile strength and large deformation capability, and the stress / strain property of deformation can be pre-designed by printing the different core structures.

Owner:LANZHOU UNIVERSITY

Indoor floor leveling mortar and construction method thereof

Owner:SHENZHEN GRANDLAND DECORATION GROUP

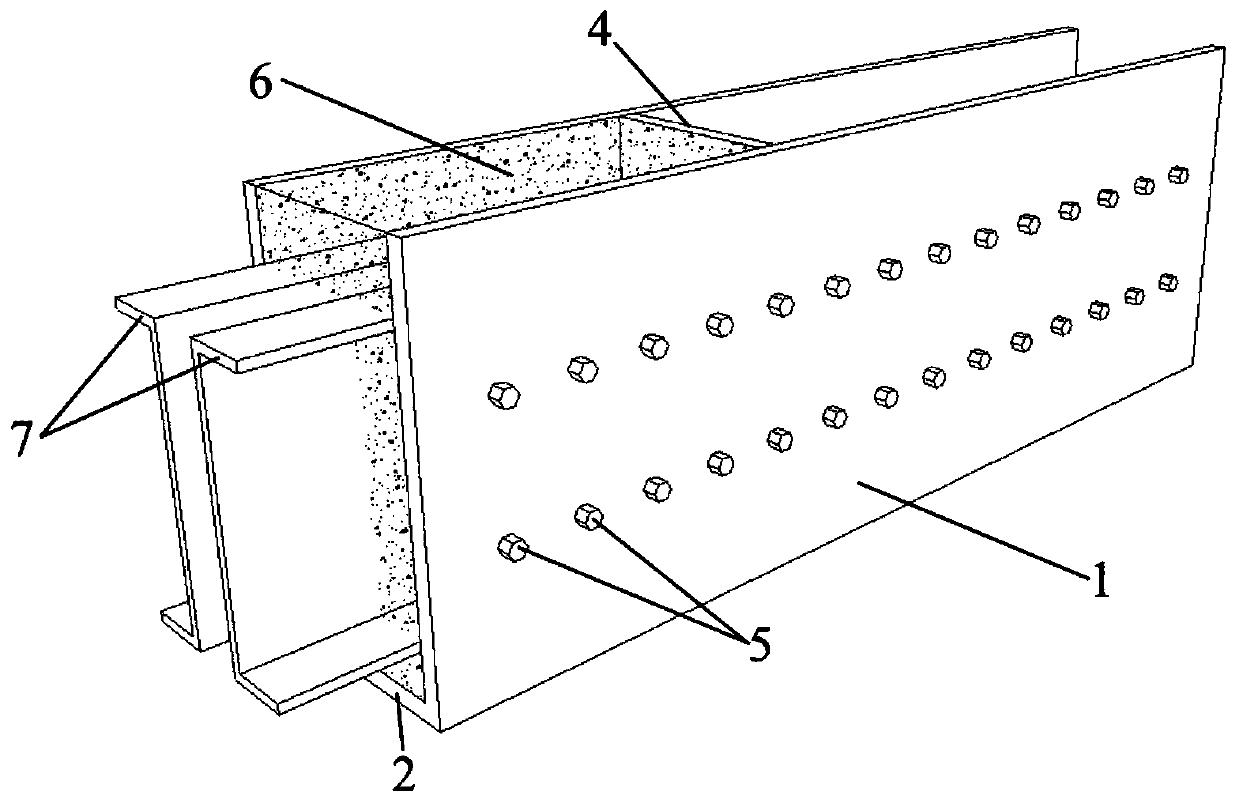

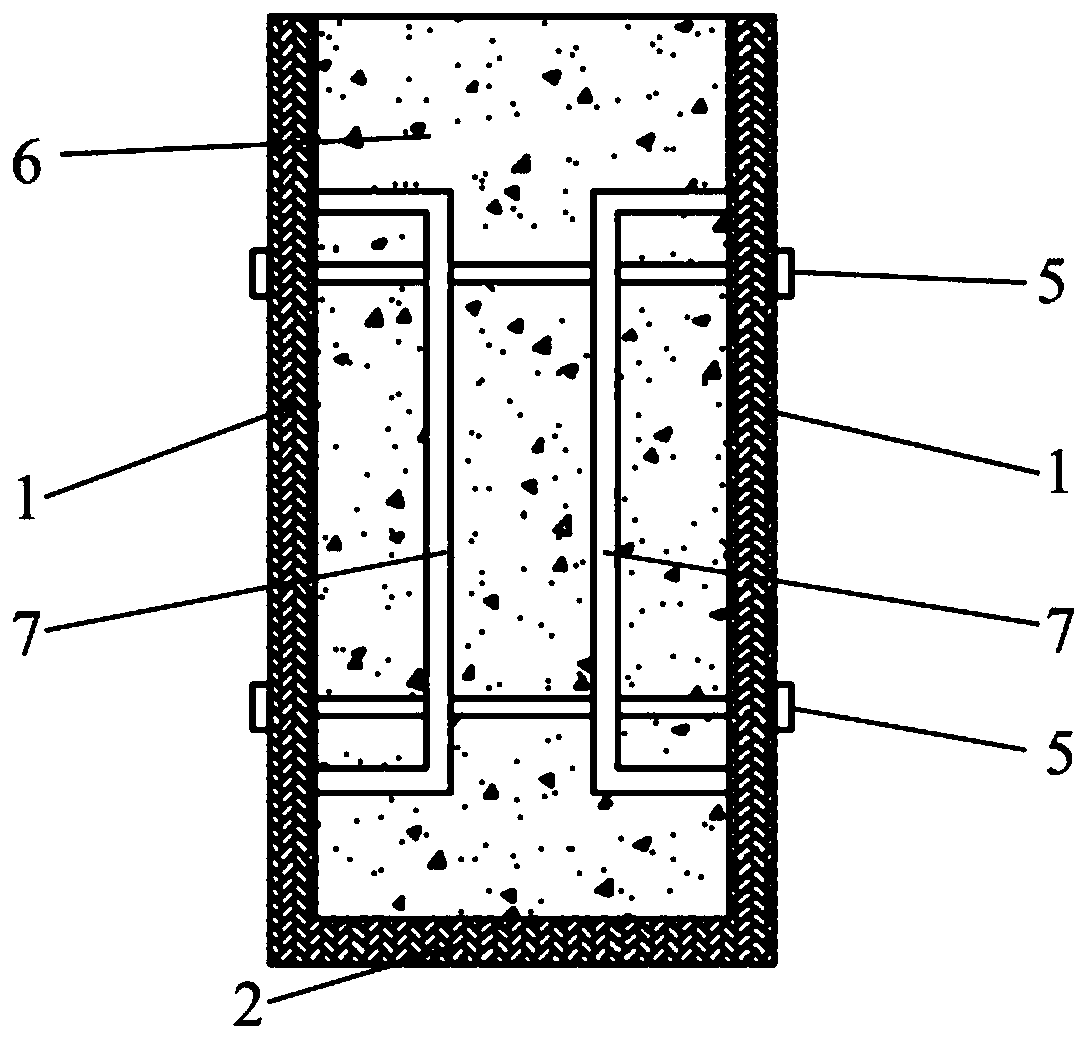

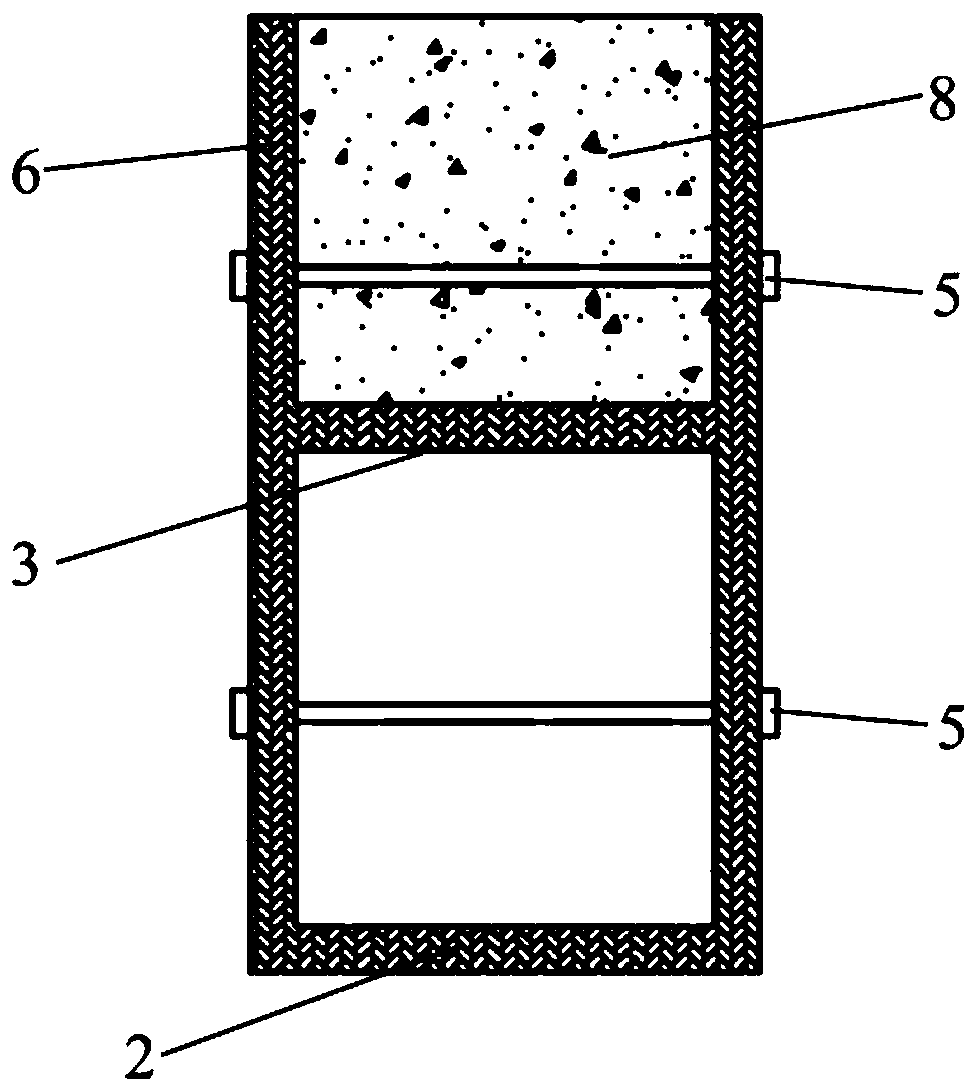

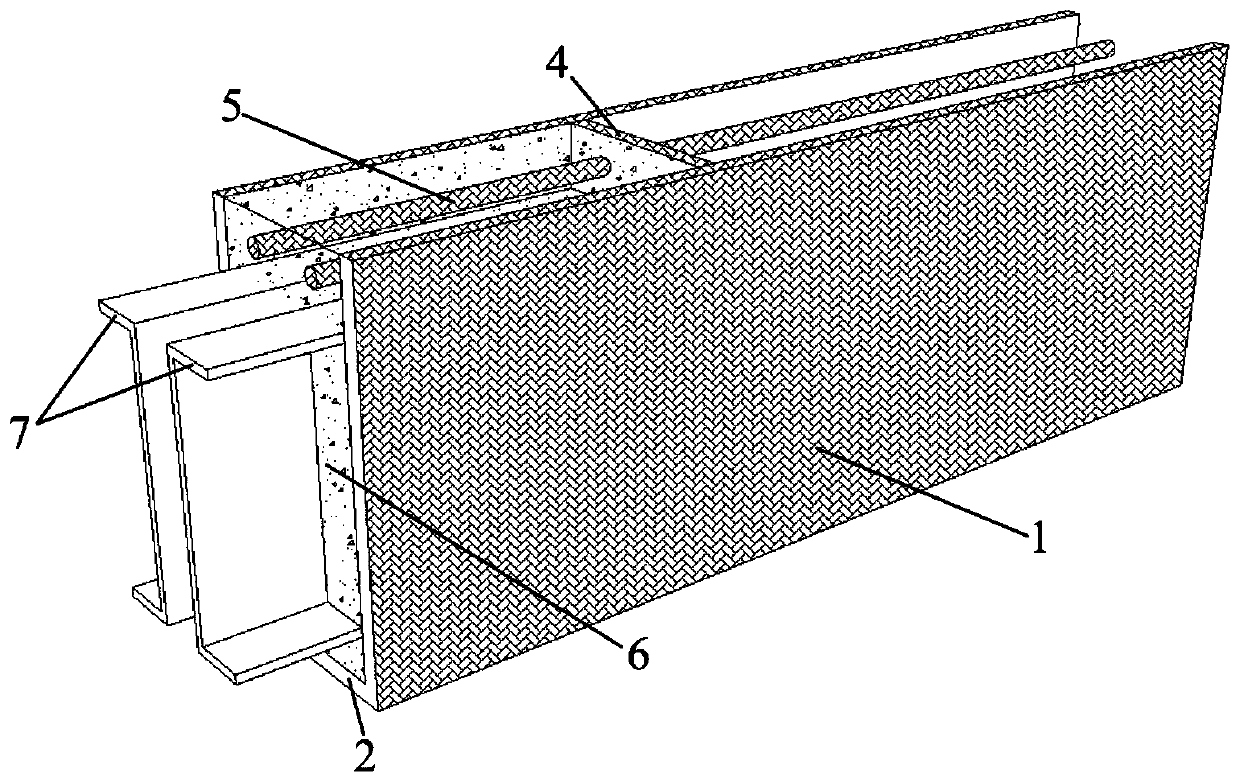

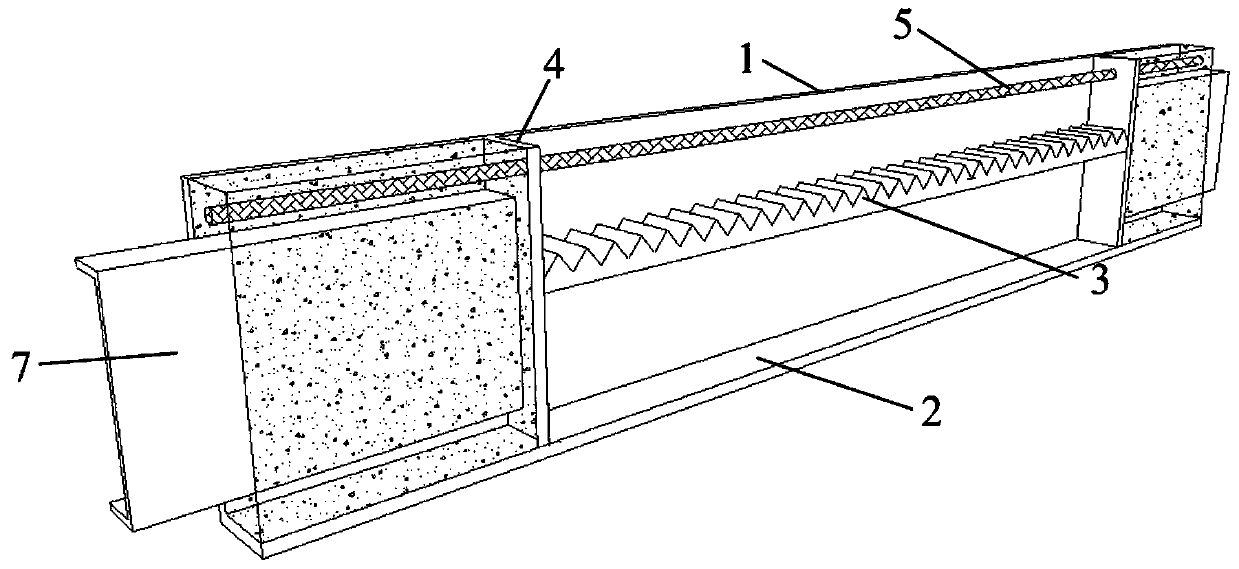

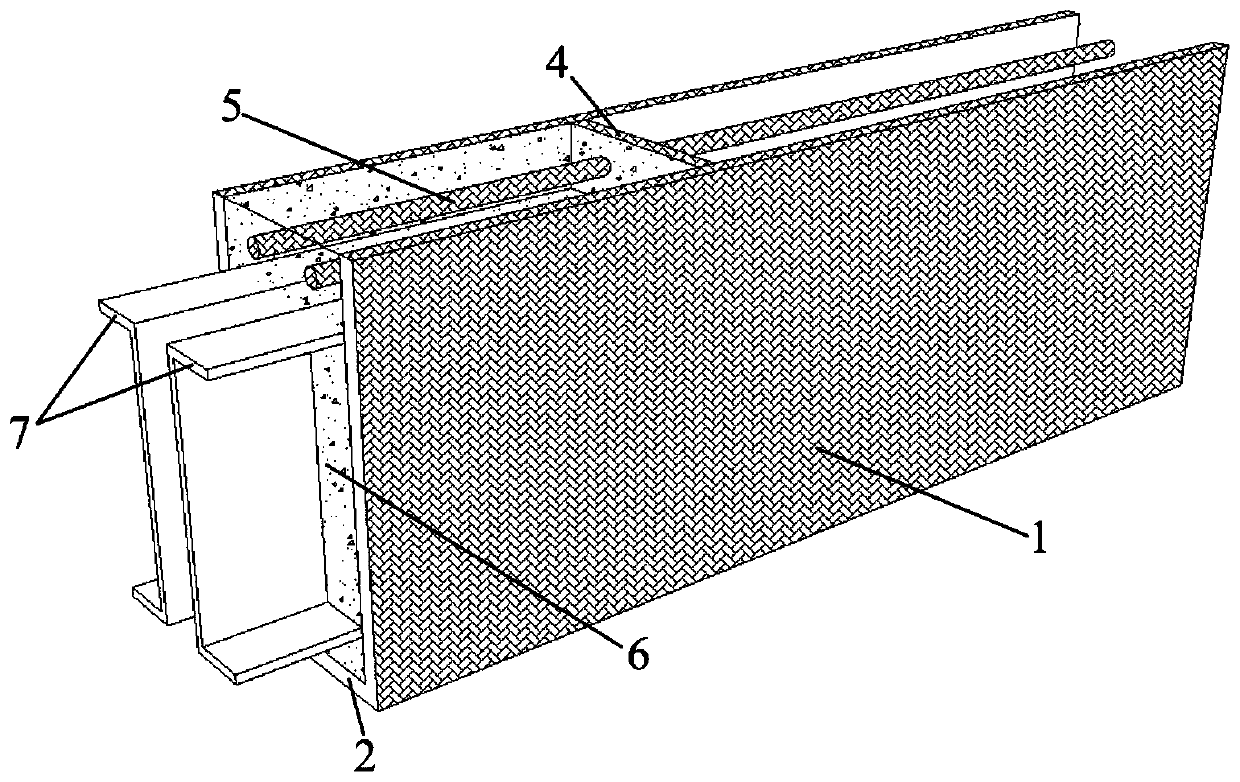

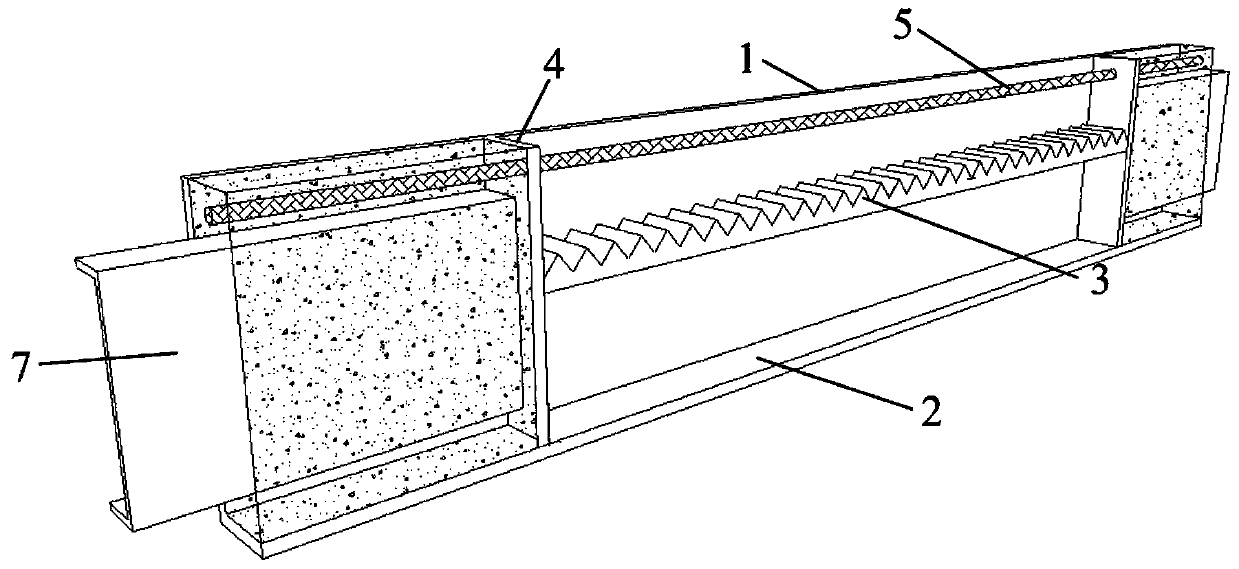

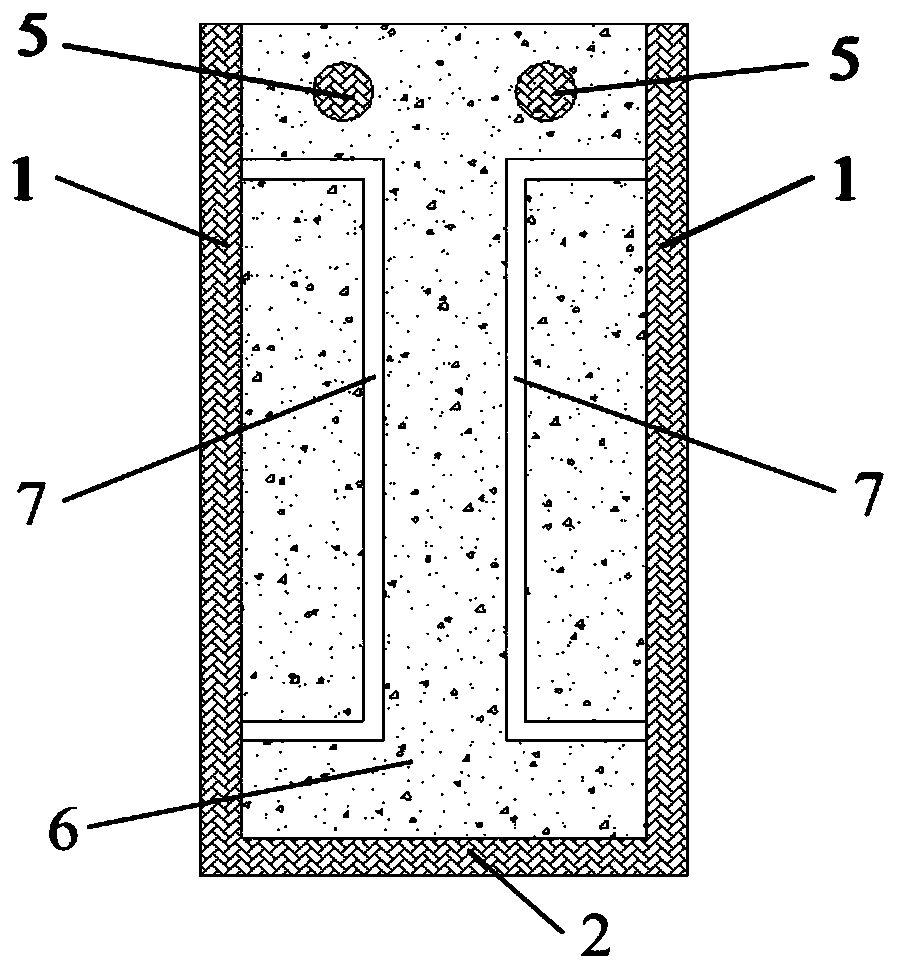

Lightweight fabricated reinforced box-groove-shaped fiber reinforced polymer (FRP) profile and sea sand concrete beam

The invention discloses a lightweight fabricated reinforced box-groove-shaped fiber reinforced polymer (FRP) profile and sea sand concrete beam. The fabricated beam is jointly composed of a middle FRPhollow box-groove section beam section and a pre-poured concrete filled beam section at both ends. The middle FRP hollow box-groove section beam section comprises a lower FRP box chamber and an upperFRP groove, a box-groove partition plate between the lower hollow box chamber and the upper groove adopts an FRP corrugated plate, and corrugations on the plate are used as shear-resisting connectingkeys between an FRP and the concrete. According to the lightweight fabricated reinforced box-groove-shaped FRP profile and sea sand concrete beam, the beam weight is decreased through the two aspectsof materials and structure, transportation is convenient, fast and reliable connection can be achieved with the plate and the column, construction is convenient and fast, good adaptability to severeengineering environments with severe corrosion such as coastal ports is achieved, and the good social and economic benefits and engineering application prospects are achieved.

Owner:WUHAN UNIV

Fabricated box and slot type FRP sectional material light fiber sea sand concrete beam

The invention relates to a fabricated box and slot type FRP sectional material light fiber sea sand concrete beam. A main body of a fabricated beam is constituted by an FRP hollow box and slot sectionbeam section in the middle and precast concrete filled beam sections at the two ends jointly; and the FRP hollow box and slot section beam section in the middle comprises a lower FRP box chamber andan upper FRP slot, an FRP corrugated plate is adopted as a box and slot partition plate between the lower hollow box chamber and the upper slot, and on-plate corrugations are adopted as anti-shear connecting keys between FRP and concrete. According to the main body of the fabricated beam, the self-weight of a beam body is reduced from the two aspects of material and structure, thus transporting isconvenient, the beam can be quickly and reliably connected with the plate and a column, construction is easy, convenient and rapid, good adaptability to the severe engineering environments, with serious corrosivity, such as coastal ports is achieved, and good social and economic benefits and engineering application prospects are achieved.

Owner:WUHAN UNIV

Locking device for vehicle transmission

ActiveCN108368936BReduced wall thicknessReliable deliveryGearing controlMechanical engineeringElectrical and Electronics engineering

Owner:SCHAEFFLER TECH AG & CO KG

Prefabricated box-groove frp profile lightweight fiber sea sand concrete beam

The invention relates to a fabricated box and slot type FRP sectional material light fiber sea sand concrete beam. A main body of a fabricated beam is constituted by an FRP hollow box and slot sectionbeam section in the middle and precast concrete filled beam sections at the two ends jointly; and the FRP hollow box and slot section beam section in the middle comprises a lower FRP box chamber andan upper FRP slot, an FRP corrugated plate is adopted as a box and slot partition plate between the lower hollow box chamber and the upper slot, and on-plate corrugations are adopted as anti-shear connecting keys between FRP and concrete. According to the main body of the fabricated beam, the self-weight of a beam body is reduced from the two aspects of material and structure, thus transporting isconvenient, the beam can be quickly and reliably connected with the plate and a column, construction is easy, convenient and rapid, good adaptability to the severe engineering environments, with serious corrosivity, such as coastal ports is achieved, and good social and economic benefits and engineering application prospects are achieved.

Owner:WUHAN UNIV

Main Arch Forming Technology of Main Arch Single Rib Dislocation Cantilever Casting with Synchronous Transverse Connection

ActiveCN111764305BGuaranteed stabilityGuaranteed carrying capacityBridge erection/assemblyReinforced concreteClassical mechanics

The invention relates to the field of reinforced concrete arch bridges, in particular to a main arch forming process for cantilever pouring of single-rib dislocation of the main arch. Two single-box arch ribs are respectively arranged on the left and right sides of the double-width arch bridge to form the left and right sides The arch ring of the bridge, during construction, includes the following steps: Step 1, cantilever pouring the two arch ribs on the inside of the double-width arch bridge until the two inner arch ribs are closed; Step 2, cantilever pouring the two arch ribs on the outside of the double-width arch bridge until The two outer arch ribs join together to form the arch rings of the left and right bridges respectively. The main arch ring of the present invention includes two single box-shaped arch ribs, and the arch ribs in the arch ring are poured independently, which reduces the cross-sectional size of the arch ribs, and the segmental pouring weight is small, which is suitable for light construction of long-span arch bridges .

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Gear shifting equipment for motor vehicle transmissions

Owner:SCHAEFFLER TECH AG & CO KG

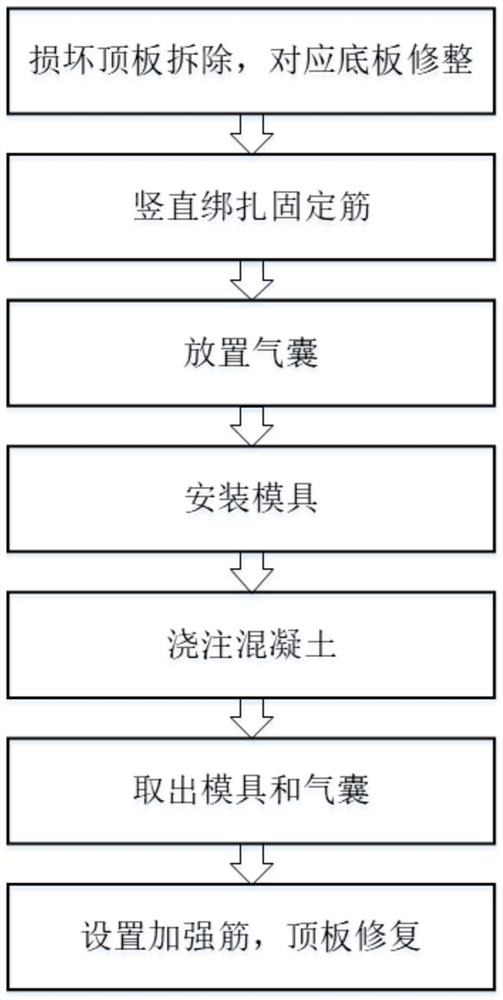

A reinforcement method for hollow slab girder bridge

ActiveCN111172897BMeet the design requirementsEasy to operateBridge erection/assemblyBridge strengtheningBridge engineeringArchitectural engineering

The invention discloses a method for reinforcing a hollow slab girder bridge, which comprises the following steps: step S01, remove the damaged top plate, and repair the corresponding bottom plate, step S02, vertically bind and fix ribs, step S03, vertically place an air bag, step S04, install Mold, step S05, pouring concrete, step S06, taking out the mold and the airbag, step S07, setting reinforcing ribs, and repairing the top surface. Through the above scheme, the invention achieves the purpose of reducing the difficulty of the process and improving the construction safety, and has high practical value and popularization value in the technical field of bridge engineering.

Owner:杜雷

Modular steel frame connecting device and connecting method thereof

ActiveCN106522363BOmit fixed wayReduce on-site construction proceduresBuilding constructionsEngineeringSteel frame

The invention relates to a modular steel frame connection device. the modular steel frame connection device at least comprises a first square steel tubular column and a second square steel tubular column which are internally hollow and are connected through an inner sleeve. The inner sleeve is in clearance fit with the second square steel tubular column. the periphery of the inner sleeve is annularly provided with locating blocks parallel to the column opening of the first square steel tubular column and the column opening of the second square steel tubular column. the modular steel frame connection device further comprises a connection plate provided with an assembly hole matched with the inner sleeve. modular steel frames are connected in an inner sleeve mode, the fixing mode of screws or bolts is omitted, procedures of site construction are omitted, and the construction time is shortened. the modular steel frames and inner sleeves are welded, the firm degree between the frames is enhanced, and risks caused by loosening of the screws or the bolts are avoided. The modular steel frames are partially machined in a factory in advance and then constructed in a construction site, so that the site construction time is shortened greatly, and too many influences on the site environment are avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

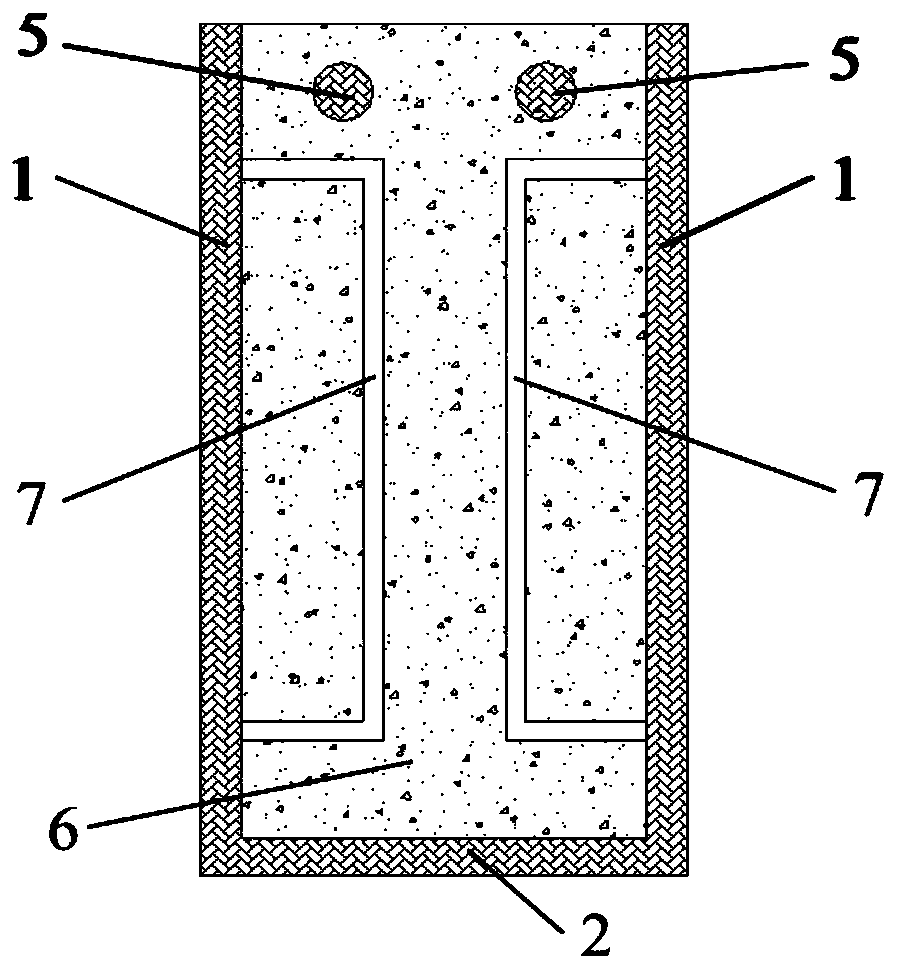

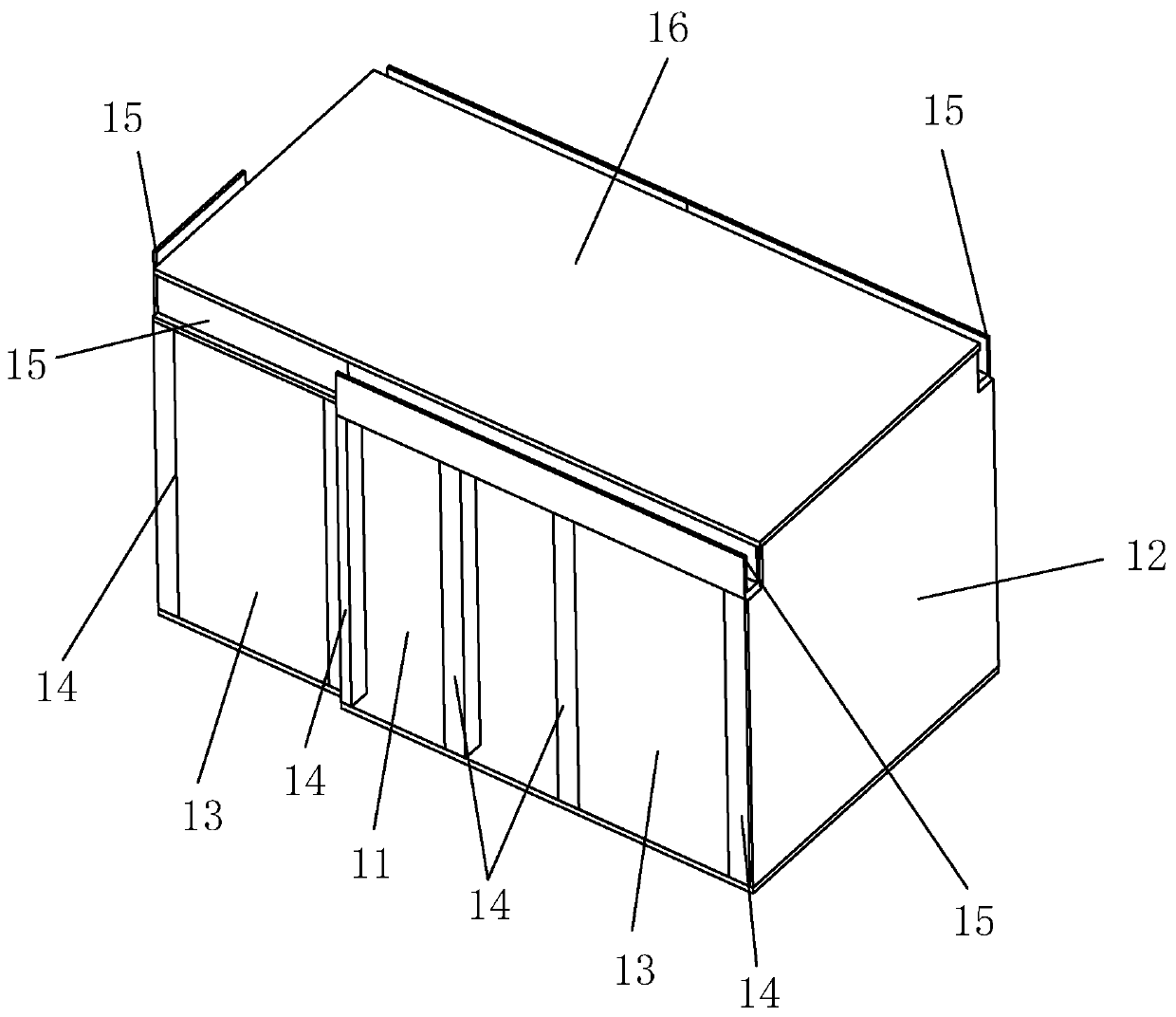

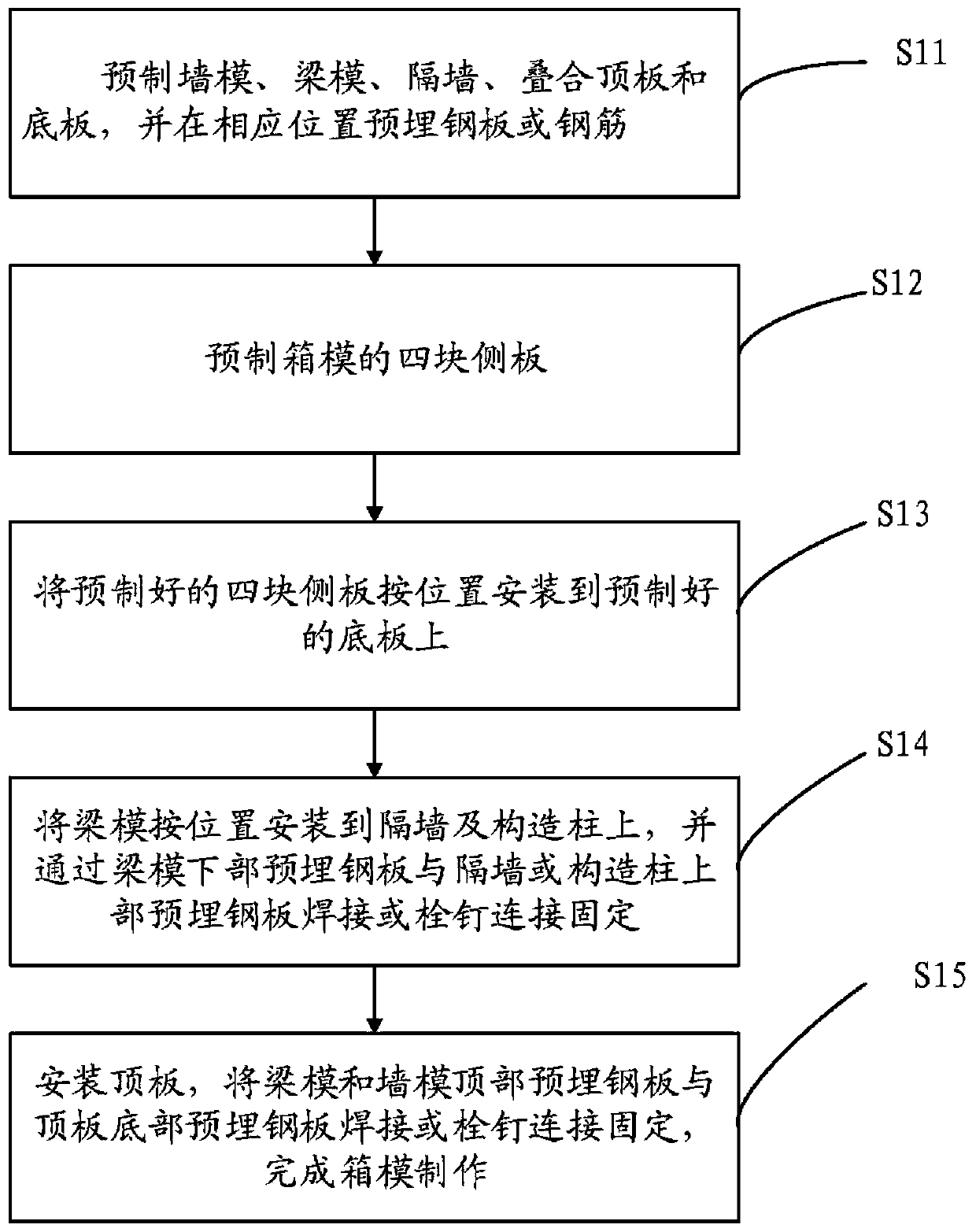

Total-precast concrete building box mold and manufacturing method thereof

InactiveCN110847590AShorten the construction periodLightweight constructionForms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringPrecast concrete

The invention discloses a total-precast concrete building box mold and a manufacturing method thereof. The box mold comprises a precast transverse member and a precast vertical member. The precast transverse member comprises a bottom plate, beam molds and a stacked top plate. The precast vertical member comprises wall molds, partition walls and constructional columns. The wall molds, the partitionwalls and the constructional columns are located above the bottom plate and perpendicularly connected with the bottom plate. The wall molds and the partition walls are connected through the constructional columns. The beam molds are located above the partition walls and the constructional columns. The lower end faces of the beam molds are perpendicularly connected with the partition walls or theconstructional columns. The upper end faces of the beam molds and the upper end faces of the wall molds are located at the same horizontal plane. The stacked top plate is perpendicularly connected tothe tops of the wall molds and the beam molds separately, and embedded steel plates are arranged below the partition walls, below the constructional columns, below the wall molds and above the bottomplate respectively.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

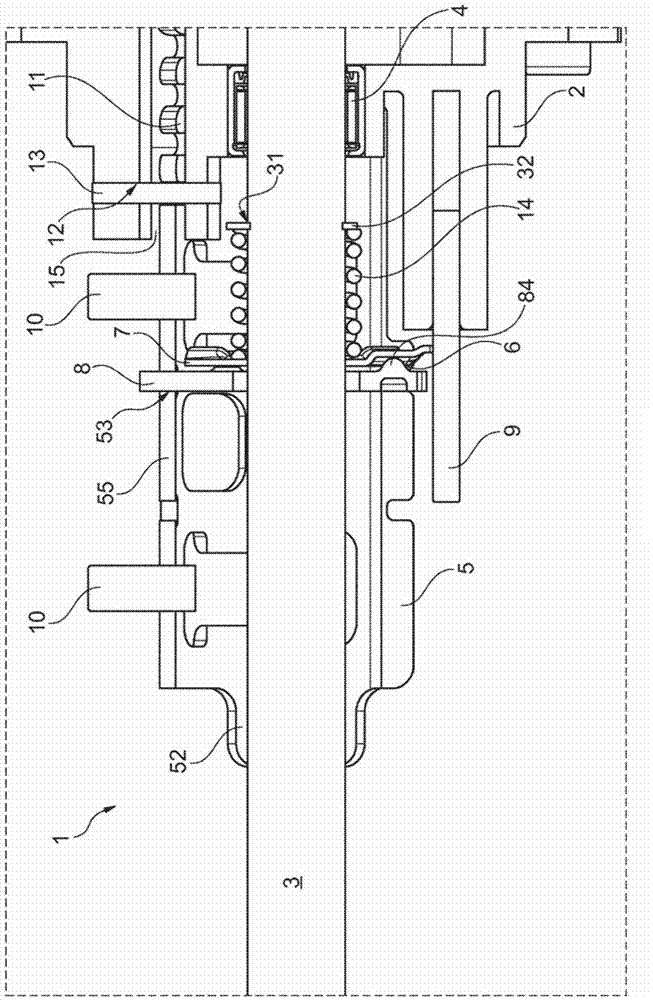

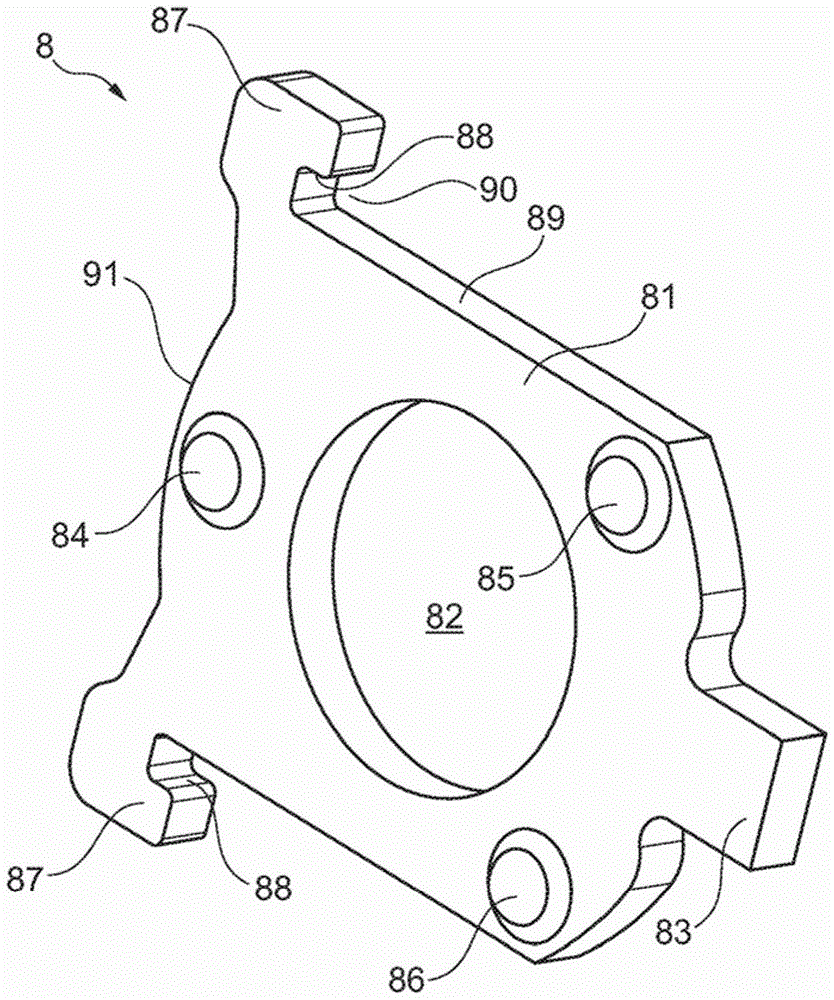

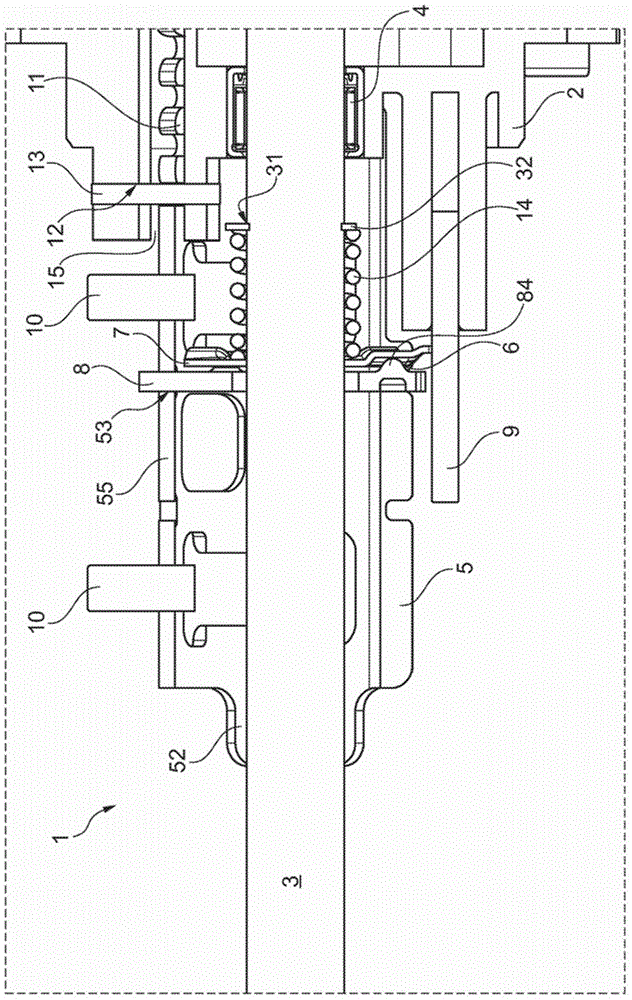

Gear shifting equipment for motor vehicle transmissions

InactiveCN104903625BCompact structureLightweight constructionGearing controlRotational axisEngineering

The invention relates to a shifting device (1) of a motor vehicle change-speed gearbox, comprising a selector shaft (3), a housing part (2) on which said selector shaft (3) can be rotatably mounted, an engaging unit (6) for securing the selected positions, which comprises an engaging contour (74, 75) on a first engaging component (7) and a second engaging component (8) with an engaging element (84, 85, 86). Said components (7, 8) can be moved relative to each other and are locked counter to each other, and the engaging element (84, 85, 86) is pretensioned counter to the engaging contour (74, 75) parallel to the rotational axis.

Owner:SCHAEFFLER TECH AG & CO KG

A kind of derivative product of vacuum insulation panel for interior wall and preparation method thereof

ActiveCN105421602BImprove insulation effectLightweight constructionClimate change adaptationInsulation improvementProtection layerAluminum foil

The invention discloses a vacuum thermal insulation board derivative for an inner wall. The vacuum thermal insulation board derivative is composed of a bonding layer, a thermal insulation layer, a packing layer, a protection layer and a decorative finish layer, the bonding layer is made of aluminum foil, the thermal insulation layer is a vacuum thermal insulation board, the packing layer is made of hard foamed plastic, the protection layer is of a metal frame structure, and the decorative finish layer is made of flame retardant kraft paper. The vacuum thermal insulation board derivative for the inner wall is a material suitable for a thermal insulation system in the inner wall, the vacuum thermal insulation board derivative for the inner wall is good in thermal insulation effect, easy and convenient to construct, short in construction period, high in safety and low in cost, and a series of problems existing in the thermal insulation system of the inner wall are effectively solved.

Owner:CHONGQING ZAISHENG TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com