Gear shifting equipment for motor vehicle transmissions

A technology for motor vehicles and transmissions, applied in mechanical equipment, components with teeth, transmission control and other directions, can solve the problems of large radial structure space, complex tools, consumption, etc., and achieve the effect of compact structure and saving structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

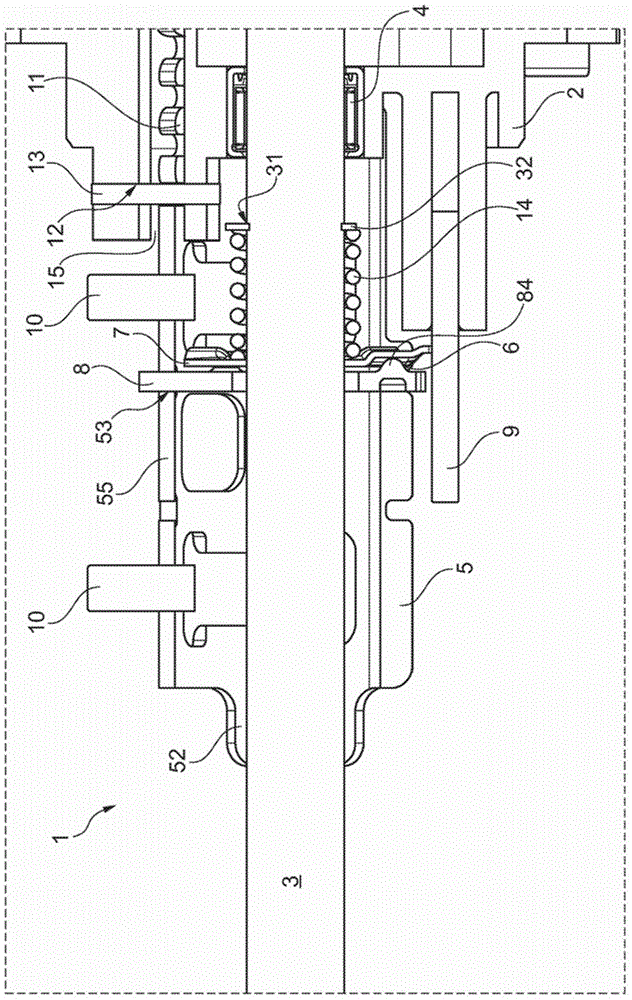

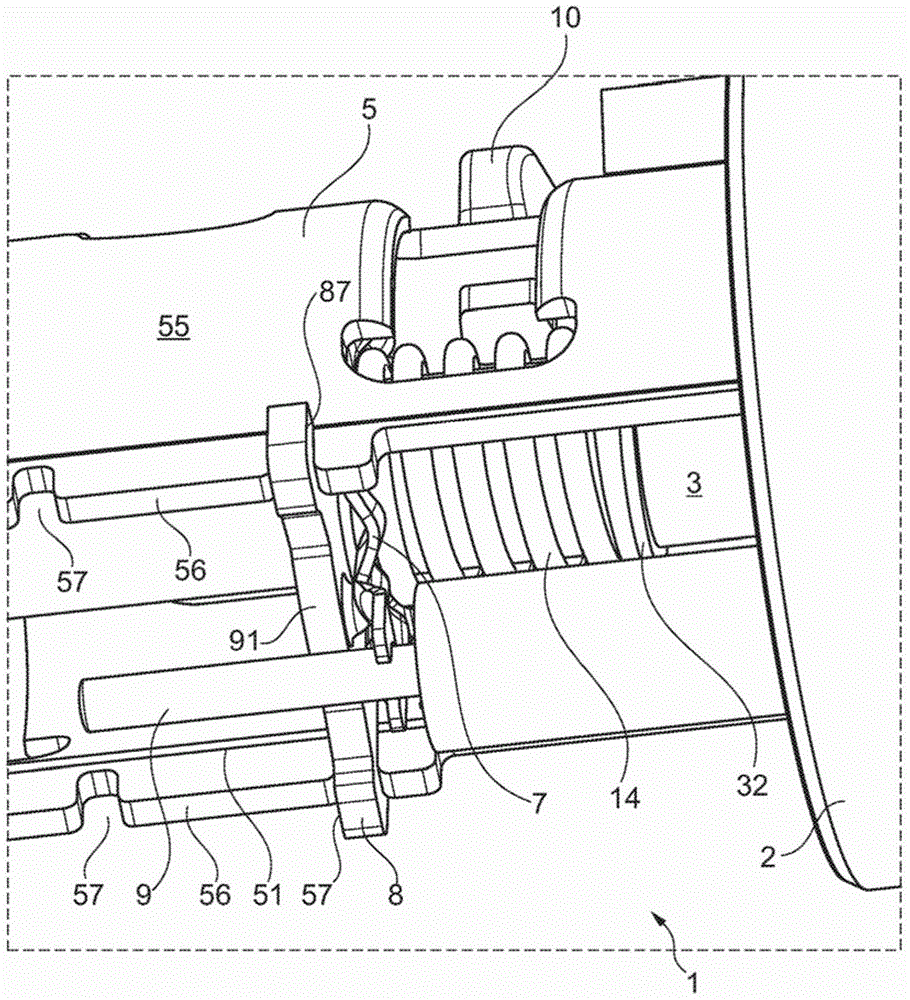

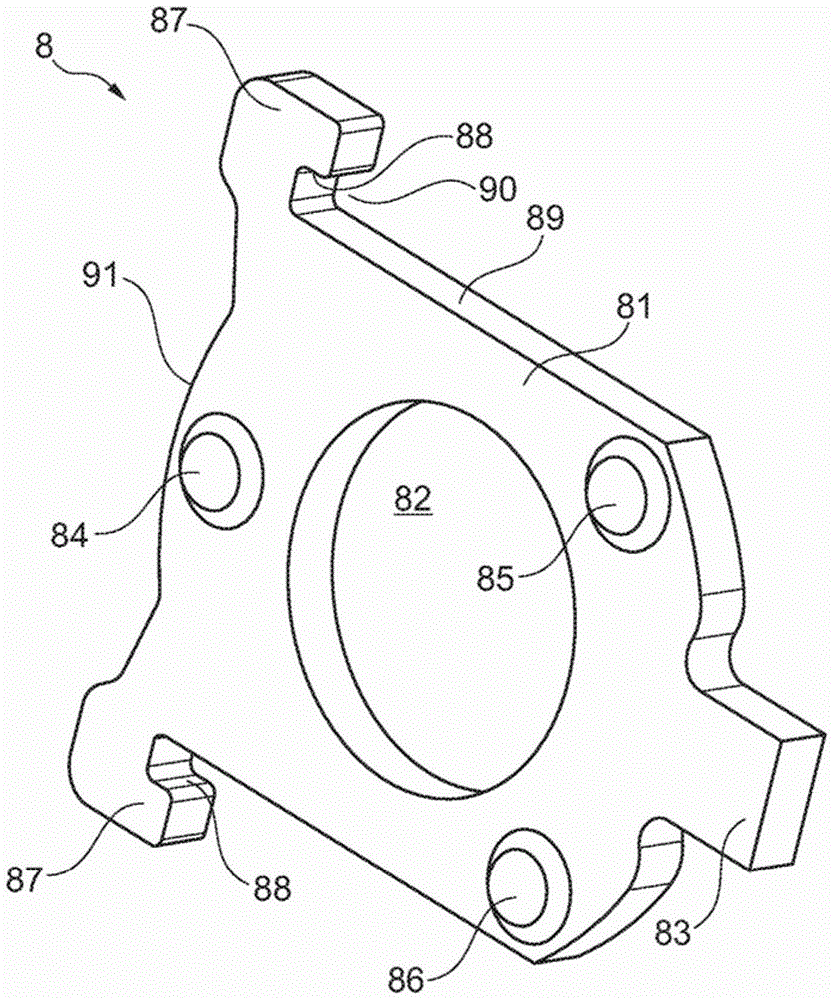

[0029] figure 1 and 2 The shifting device 1 is shown in the form of a shifting dome. The shift dome comprises: a flange-shaped housing part 2, which can be screwed onto a transmission housing not shown further; and a shift shaft 3, which is rotatably mounted on Housing part 2.

[0030] The shifting shaft 3 is mounted in the housing part 2 in a rolling manner via a bearing 4 and is rotatable relative to the housing part 2 . The rotation is introduced via a selector lever, not shown, which is kinematically connected to the selector shaft 3 and which is arranged on the housing 2 . The shift shaft 3 is fixed in the axial direction and cannot move. A low-friction displacement in the (axial) selector direction can thus be dispensed with, so that the bearing 4 is designed to absorb higher forces than a needle bearing.

[0031] The shifting sleeve 5 is arranged on the shifting shaft 3 in a rotationally fixed manner, but axially displaceable relative to one another. The shifting sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com