Main arch arching process for synchronous transverse connection of main arch single-rib staggered cantilever pouring

A horizontal connection and cantilever technology, which is applied in the field of reinforced concrete arch bridges, can solve the problem of high mechanical performance requirements for hanging baskets and cable-stayed buckles, large cross-sectional dimensions of single-box double-chamber box-shaped arch ribs, and heavy pouring weight of sections and other issues, to achieve the effect of promoting further development, reducing the weight of pouring sections, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

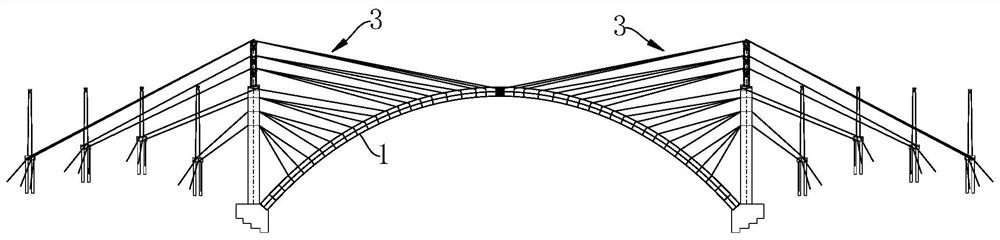

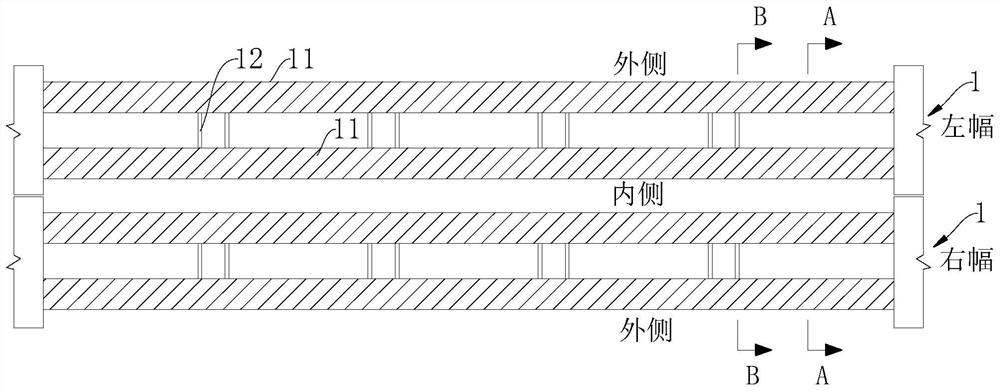

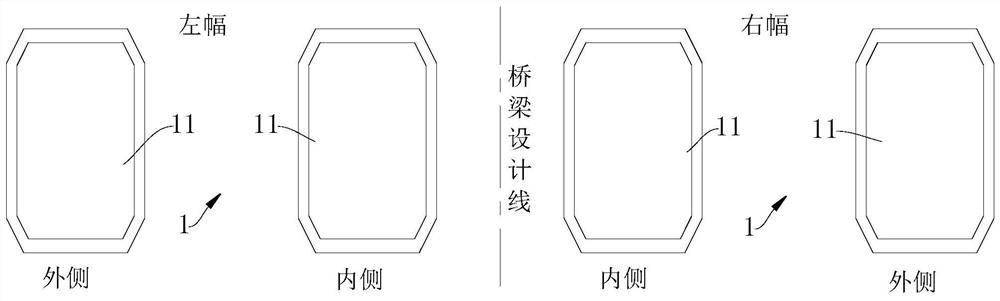

[0048] A main arch forming process of single-rib dislocation cantilever casting of the main arch, such as Figure 1-Figure 10 As shown, for a long-span cantilever cast arch bridge, according to the terrain conditions, except for the arch foot section, which is cast-in-place, the rest of the arch ring sections are constructed by cantilever pouring and cable-stayed buckle-hanging method, and are constructed symmetrically from both sides, as shown in figure 1 shown; for a double arch bridge, such as figure 2 , 3 , 4, two single-box arch ribs 11 are respectively arranged on the left and right sides of the double-width arch bridge to form the arch ring 1, that is, the arch ring 1 adopts the double-box single-chamber cross-section form, and the two arch ribs 11 pass through the intercostal Diaphragm 12 is horizontally connected; during construction, the main arch single-rib dislocation cantilever pouring process is adopted, and a set of cable-stayed buckle hanging system 3 and a s...

Embodiment 2

[0057] Based on Example 1, various methods can be adopted when setting temporary horizontal connection 2 measures, such as Figure 7 , 11 , the top and bottom of the inner arch rib 11 can be provided with section steel 22 respectively, and the section steel 22 at the top and bottom are connected by tie rods 21 to realize the synchronous lateral connection of the left and right inner arch ribs 11 and ensure the lateral stability of the main arch.

Embodiment 3

[0059] Based on Example 1, such as Figure 7 , 12 , 13. According to the needs of the main arch span setting and structural stability, based on the force analysis, it is more convenient to construct under the premise of ensuring the lateral stability of the arch ring. When setting the temporary lateral connection 2 measures, only the inner arch rib Two I-shaped section steels 22 are arranged on the top of 11, and the section steels 22 are transversely connected to the inner arch ribs 11. Specifically, the shaped steel 22 and the arch rib 11 are connected by bolts, and the two shaped steels 22 are connected by a steel plate 23 for further reinforcement; wherein, steel plates 23 can be welded on the upper and lower sides of the shaped steel 22 respectively, and the thickness of the steel plate 23 is 30 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com