Space bearing type modular mechanical arm joint and combination thereof

A componentized, robotic arm technology, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of small end load, positioning accuracy control of the end of the manipulator and complicated internal wiring, etc., achieve small size, increase real-time control performance, The effect of high reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

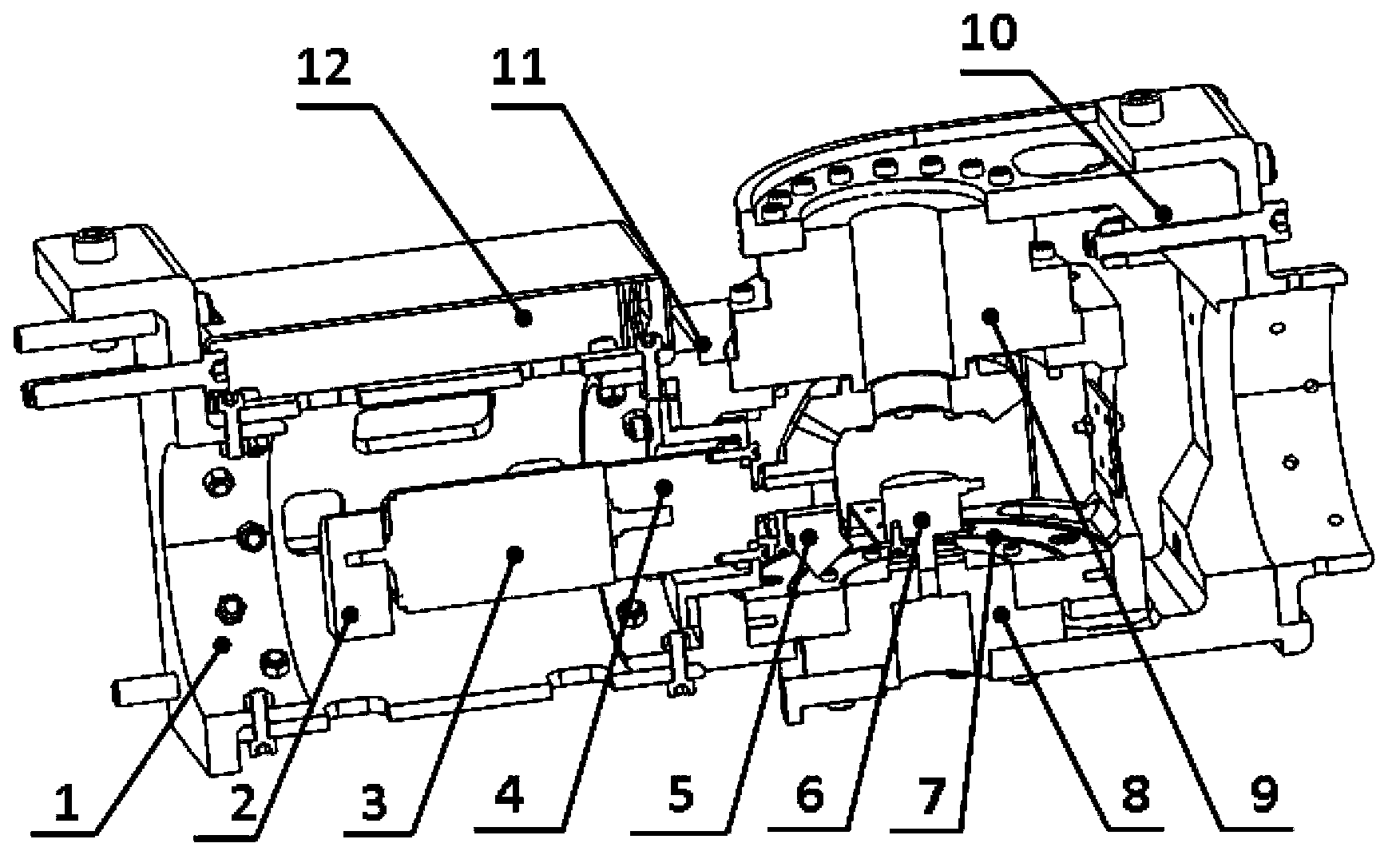

[0029] Such as figure 1 As shown, this embodiment provides a space-bearing componentized mechanical arm joint, including a load-bearing connection mechanism, an incremental encoder, a servo motor, a planetary reduction mechanism, a bevel gear, an absolute encoder, a cross roller bearing, Output shaft, harmonic reducer, rotating load-bearing mechanism, fixed load-bearing mechanism, EtherCAT bus drive, wherein, the load-bearing connection mechanism is fixedly connected to the fixed load-bearing mechanism, and the fixed load-bearing mechanism is connected to the rotating load-bearing mechanism through the harmonic reducer and the cross roller bearing , one end of the servo motor is connected to the incremental encoder, and the other end of the servo motor is connected to the planetary reduction mechanism. The encoder is fixedly connected to the output shaft, and the EtherCAT bus driver is connected with the servo motor to perform servo control on the servo motor.

[0030] Furthe...

Embodiment 2

[0037] This embodiment provides a componentized space-bearing componentized manipulator joint, including a plurality of space-bearing componentized manipulator joints provided in Embodiment 1 that are combined and connected.

[0038] Further, two of the plurality of space-bearing componentized robotic arm joints are fixedly connected by a load-bearing connection mechanism.

[0039]Further, the load-bearing connection mechanism is used to bear the connection strength between two interconnected space-bearing componentized mechanical arm joints, and the length and strength of the load-bearing connection mechanism determine the components of the space-bearing componentized mechanical hip joint. performance.

[0040] Furthermore, the joints of multiple space-bearing componentized manipulators are connected through the EtherCAT bus, which greatly reduces the complexity of wiring in the manipulator and effectively improves the speed of real-time control.

[0041] The course of work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com