High-strength large deformation carbon fiber composite board and preparation method thereof

A carbon fiber and large deformation technology, applied in building materials, building components, buildings, etc., can solve the problems of limited use range, lower reliability, etc., and achieve the effect of convenient material source, light weight and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a carbon fiber composite plate with high strength, large deformation and pre-designed deformation performance, which comprises the following steps:

[0027] (1) print an elliptical kernel with a 3D printer;

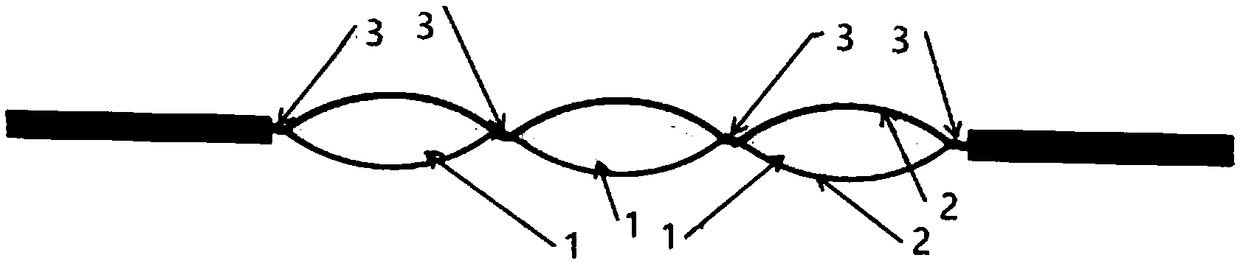

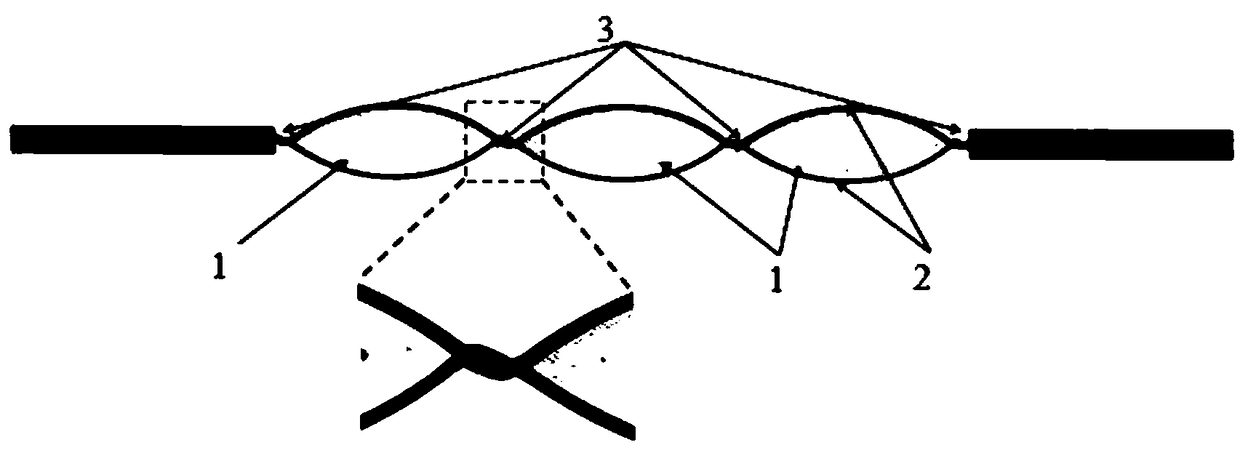

[0028] (2) Multiple groups (two for each group) of carbon fiber strips of equal width are wrapped to wrap the oval inner core, and the oval inner cores are knotted and fixed by twisted carbon fiber turnbuckles;

[0029] (3) Soak the structure wound and wrapped in step (2) in epoxy resin glue for 2-5 minutes, take it out after soaking and put it in a drying oven to cure for 72 hours at 60°C, or cure for a week at room temperature, and the product is ready.

[0030] In the step (3), before the knotted and fixed structure is soaked in epoxy resin glue, the carbon fiber cloths at both ends of the knotted and fixed structure should be fixed to prevent scattering during the soaking process.

[0031] Under the action of tension, the carbon fiber sk...

Embodiment 1

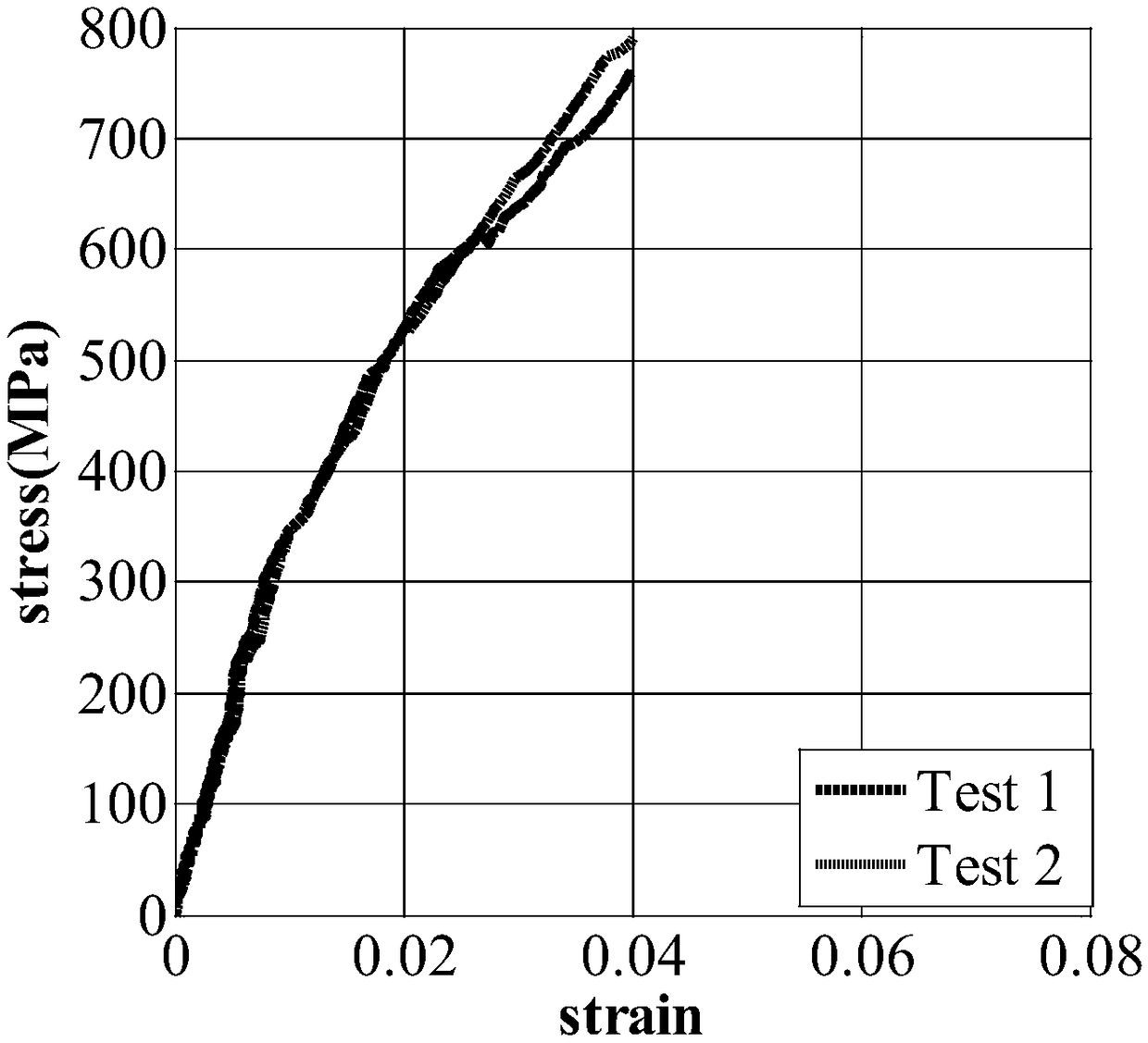

[0033] A carbon fiber composite panel with high strength, large deformation and pre-designed deformation performance, which consists of an elliptical core 1 (the span of the core is 24mm, the height is 4mm, the wall thickness of the core is 2mm, and the thickness of the middle support is 2mm), carbon fiber skin 2 and Composed of carbon fiber turnbuckle 3, the two ends of the oval inner core 1 are connected by carbon fiber turnbuckle 3, and the carbon fiber outer skin 2 is adhered to the upper and lower sides of the oval inner core 1;

[0034] A method for preparing a carbon fiber composite plate with high strength, large deformation and pre-designed deformation performance, which comprises the following steps:

[0035] (1) print an elliptical kernel with a 3D printer;

[0036] (2) Multiple groups (two for each group) of carbon fiber strips of equal width are wrapped to wrap the oval inner core, and the oval inner cores are knotted and fixed by twisted carbon fiber turnbuckles;...

Embodiment 2

[0041] In order to obtain greater deformation capacity, the carbon fiber composite panel is designed to be composed of an elliptical core 1 with a smaller span (the span of the core is 20mm, the height is 4mm, the wall thickness of the core is 2mm, and the thickness of the middle support is 2mm), carbon fiber skin 2 Composed of carbon fiber turnbuckle 3, the two ends of the oval inner core 1 are connected by carbon fiber turnbuckle 3, and the carbon fiber outer skin 2 is adhered to the upper and lower sides of the oval inner core 1;

[0042] A method for preparing a high-strength and large-deformation carbon fiber composite plate, comprising the following steps:

[0043] (1) print the elliptical inner core 1 with a 3D printer;

[0044] (2) Wrap the elliptical inner core 1 with two carbon fiber cloth strips of equal width, and tie the elliptical inner core 1 with a carbon fiber turnbuckle 3 to fix it;

[0045] (3) Soak the knotted and fixed structure in step (2) in epoxy resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com