A reinforcement method for hollow slab girder bridge

A hollow, bottom plate technology, applied in the direction of bridge reinforcement, bridge, bridge construction, etc., can solve the problems of inaccessibility of personnel, low turnover, leakage of formwork, etc., to achieve high practical value and promotion value, sufficient elasticity and flexibility. The effect of good anti-expansion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

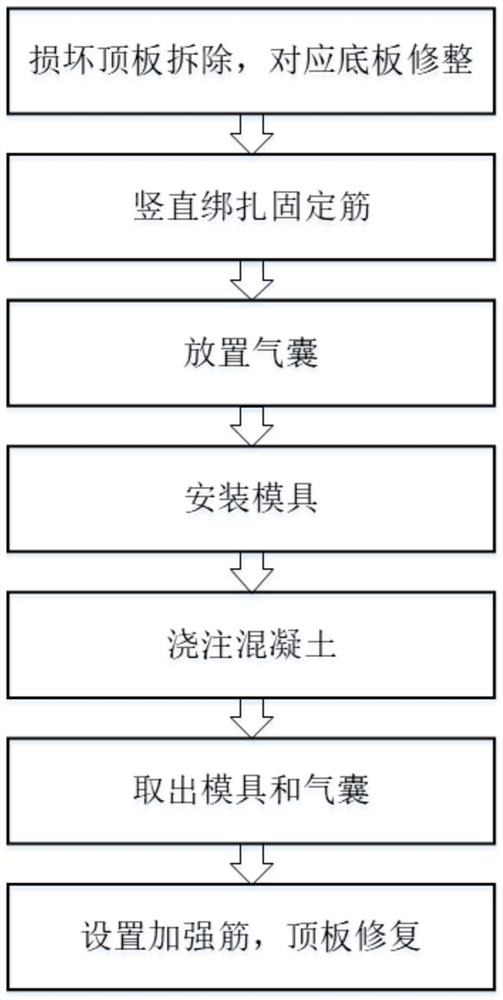

[0030] A kind of reinforcement method of hollow slab girder bridge, the reinforcement method of described hollow slab girder bridge comprises the following steps:

[0031] Step S01, remove the damaged top plate, and repair the corresponding bottom plate: remove the damaged part of the original bridge roof of the hollow slab girder bridge to be reinforced, and repair the surface of the bridge bottom plate corresponding to the damaged top surface;

[0032] Step S02, vertical binding and fixing bars: reserve the size and position of the capsule on the trimmed bottom plate, bind the round anti-floating steel bar on the bottom plate of the bridge body and the vertical bridge body bottom plate, add the capsule positioning steel bar and fastened firmly;

[0033] Step S03, placing the airbag vertically: place the airbag vertically to the reserved position on the upper part of the floor, and inflate the airbag with an air pump;

[0034] Step S04, install the mould: set the side mold t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com