Braking device for a car of a lift system

A braking device, lifting system technology, applied in the direction of elevators, transportation and packaging, elevators in buildings, etc., can solve the problems of injury, inapplicability, etc., and achieve the effect of saving space, realizing adjustability, and simple mechanical measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

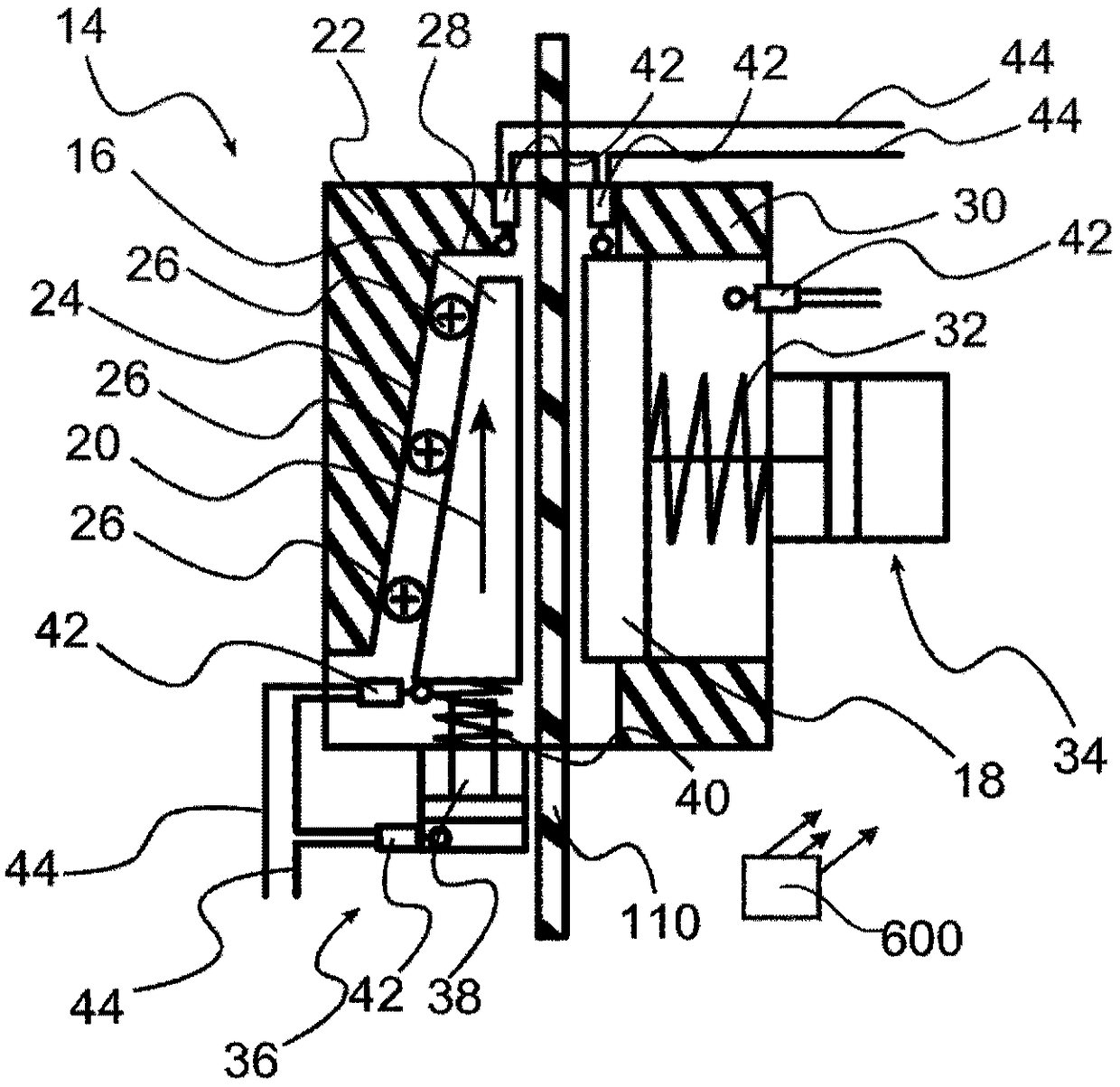

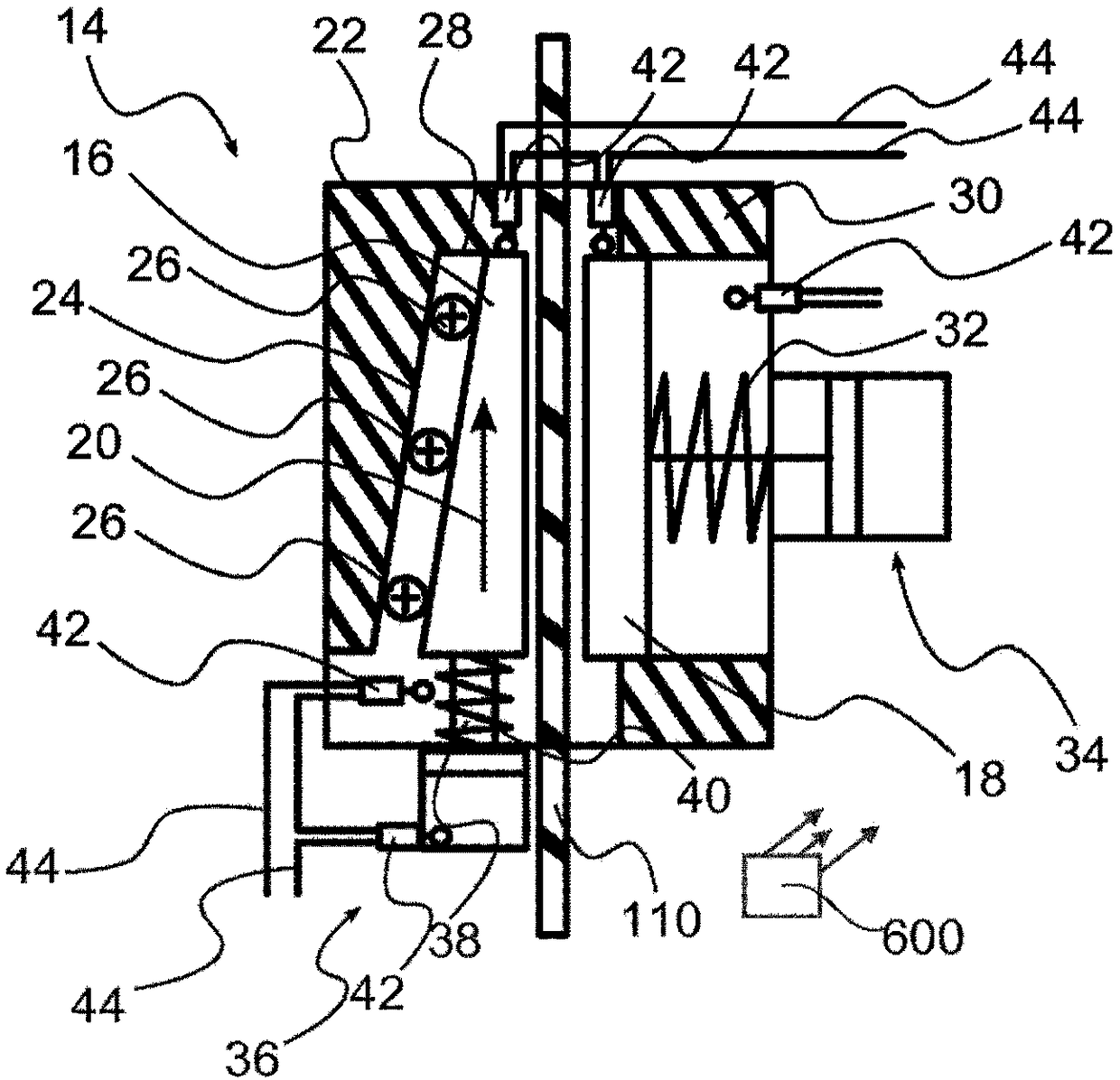

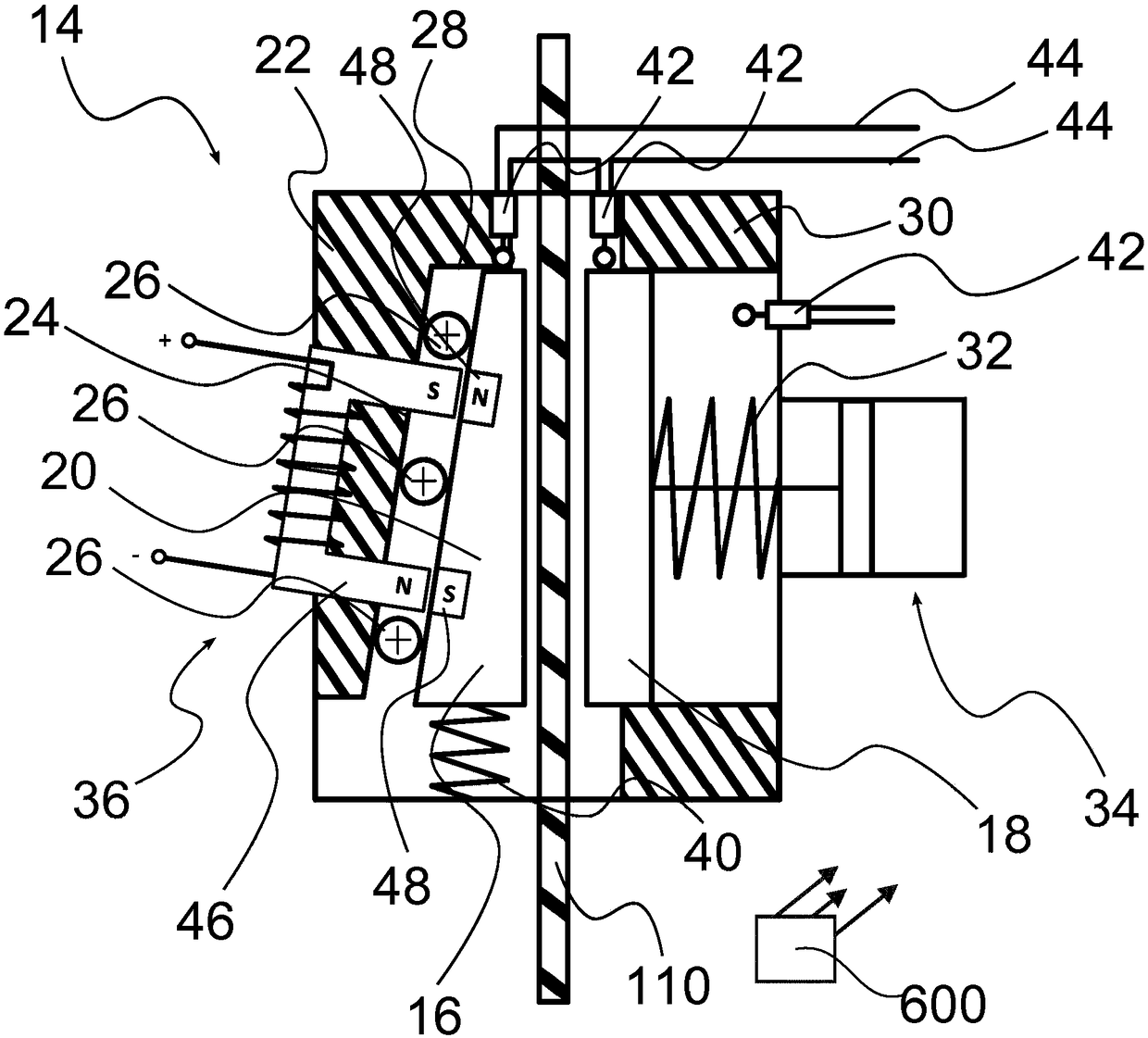

[0035] figure 1 A schematic cross-sectional view of a first embodiment of a braking device 14 for a car of a lifting system according to the present invention is shown. The brake device 14 includes a first brake pad 16 and a second brake pad 18 which are arranged opposite to each other and receive a guide rail 110 therebetween. When the brake device 14 is in the open state, the brake pads 16 and 18 do not engage with the guide rail 110 when the car is traveling, but move in parallel with the guide rail 110 without contact. The first brake pad 16 is realized in a wedge-shaped manner and gradually narrows in the wedging direction 20. The wedging direction 20 is parallel to the main extension direction of the guide rail 110. The first brake pad 16 is oriented such that the front side of the first brake pad 16 facing the guide rail 110 is aligned in parallel with the guide rail 110, and the oppositely arranged rear side is angled corresponding to the wedge shape. In addition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com