Vacuum thermal insulation board derivative for inner wall and preparation method of derivative

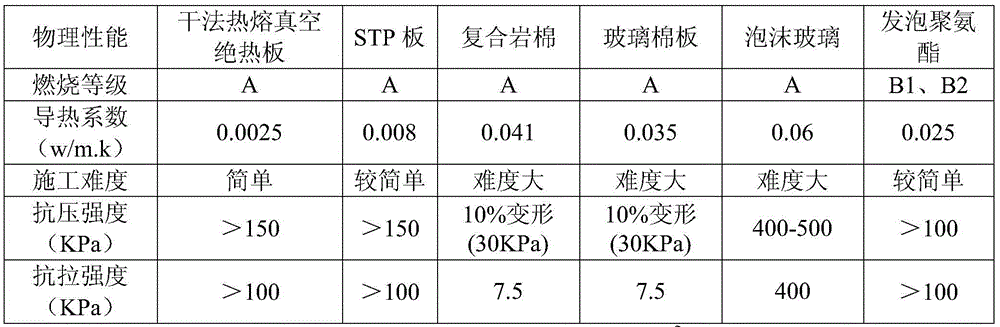

A vacuum insulation and derivative technology, applied in insulation improvement, climate change adaptation, building components, etc., can solve the problems of complex insulation construction methods, climate-affected, low safety, etc., and achieve outstanding energy-saving effect, convenient construction, and water permeability. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

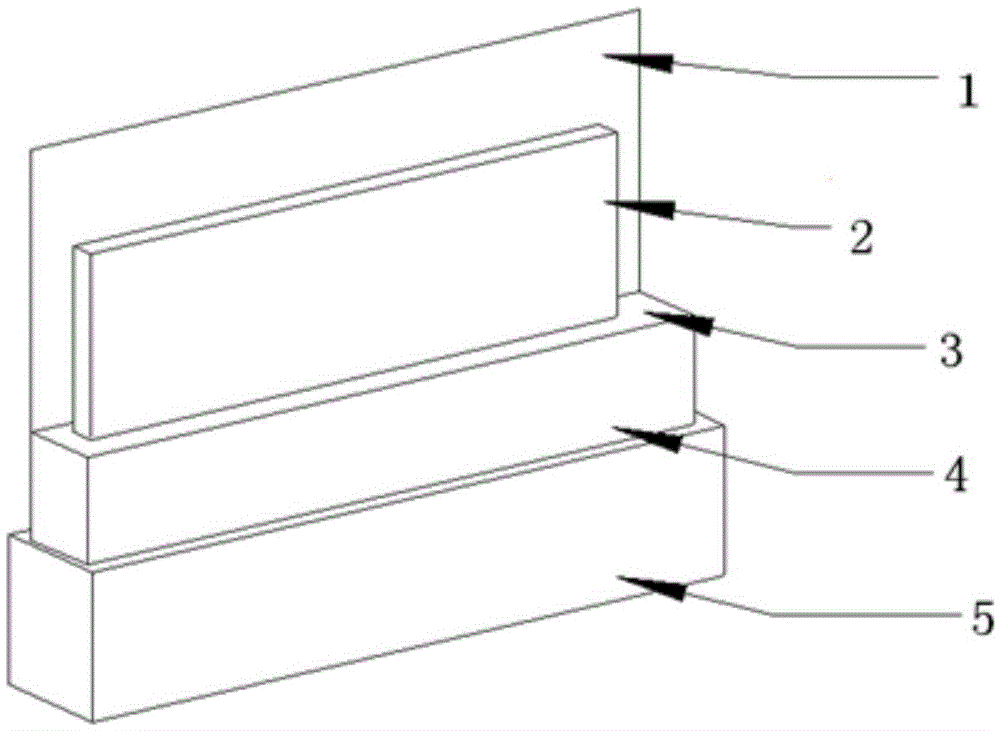

[0024] The specific steps for preparing derivatives of vacuum insulation panels for interior walls are as follows:

[0025] 1. Preparation of ultra-fine glass fiber core material by dry hot melting, with a grammage of 1.96kg / m 2, , the fiber diameter is 2 μm;

[0026] 2. Put the core material into the aluminum alloy multi-layer high barrier film, add getter, and vacuumize to make the thickness reach 8mm;

[0027] 3. Place the vacuum insulation panel prepared in step 2 inside the metal frame, the bonding layer of the metal frame is aluminum foil, and the protective layer is galvanized steel plate. The vacuum insulation panel is close to the adhesive layer, leaving a 5mm gap between the protective layer and the protective layer;

[0028] 4. Fill the gap in the metal frame with rigid polyurethane foam to fix the vacuum insulation panel;

[0029] 5. Adhesive flame-retardant kraft paper on the facing layer, with the glass fiber grid facing inward and the kraft paper facing outwa...

Embodiment 2

[0035] The specific steps for preparing derivatives of vacuum insulation panels for interior walls are as follows:

[0036] 1. Preparation of superfine glass fiber core material by dry hot melting, with a grammage of 1.86kg / m 2 , the fiber diameter is 3 μm;

[0037] 2. Put the core material into the aluminum alloy multi-layer high barrier film, add getter, and vacuumize to make the thickness reach 7mm;

[0038] 3. Place the vacuum insulation panel prepared in step 2 inside the metal frame, the bonding layer of the metal frame is aluminum foil, and the protective layer is galvanized steel plate. The vacuum insulation panel is close to the adhesive layer, leaving a 5mm gap between the protective layer and the protective layer;

[0039] 4. Fill the gap in the metal frame with rigid polyurethane foam to fix the vacuum insulation panel;

[0040] 5. Adhesive flame-retardant kraft paper on the facing layer, with the glass fiber grid facing inward and the kraft paper facing outward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com