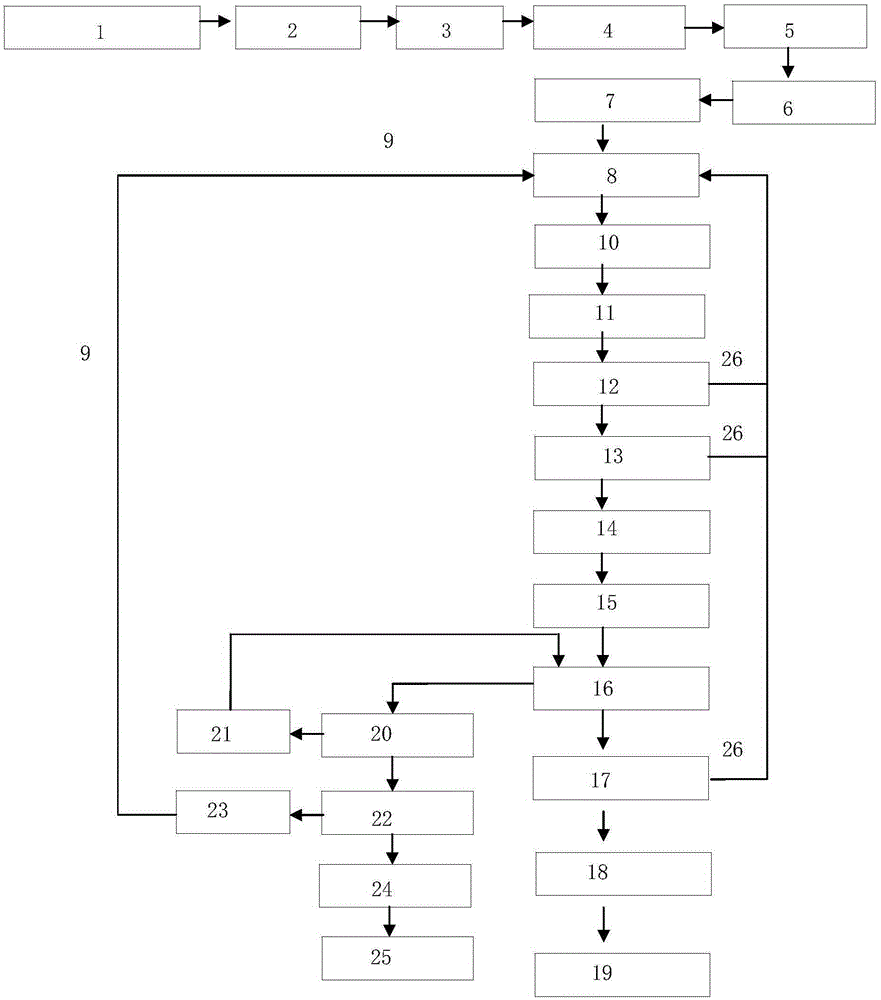

Domestic waste incineration slag crushing, sorting and reuse process

A waste incineration slag and domestic waste incineration technology, which is applied in solid separation, wet separation, grain treatment, etc., can solve the problem of slag accumulation that plagues power plants and other problems, and achieve the effects of saving energy, reducing mud content, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0028] In this embodiment, the gravitational potential energy is used, water is used as the medium and the circulation flow is used to incinerate domestic waste. The equipment in each link of slag treatment: iron remover, hopper, crusher, magnetic separator, jig, screening equipment and slag product collection pool , sedimentation tanks, etc., set vertically from high to low; inject water and waste incineration slag into the crusher to form a material flow, and under the action of material gravity flow, pass through the crusher, jig, and screening equipment to obtain f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com