Cantilever pouring arching control method for arranging buckle rope steering device on large-span main arch stand column

A control method and cantilever technology, applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of large force, large amount of use, and many anchor points of the buckle cable, so as to reduce anchor points, save consumption, and reduce buckles. Soli's effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

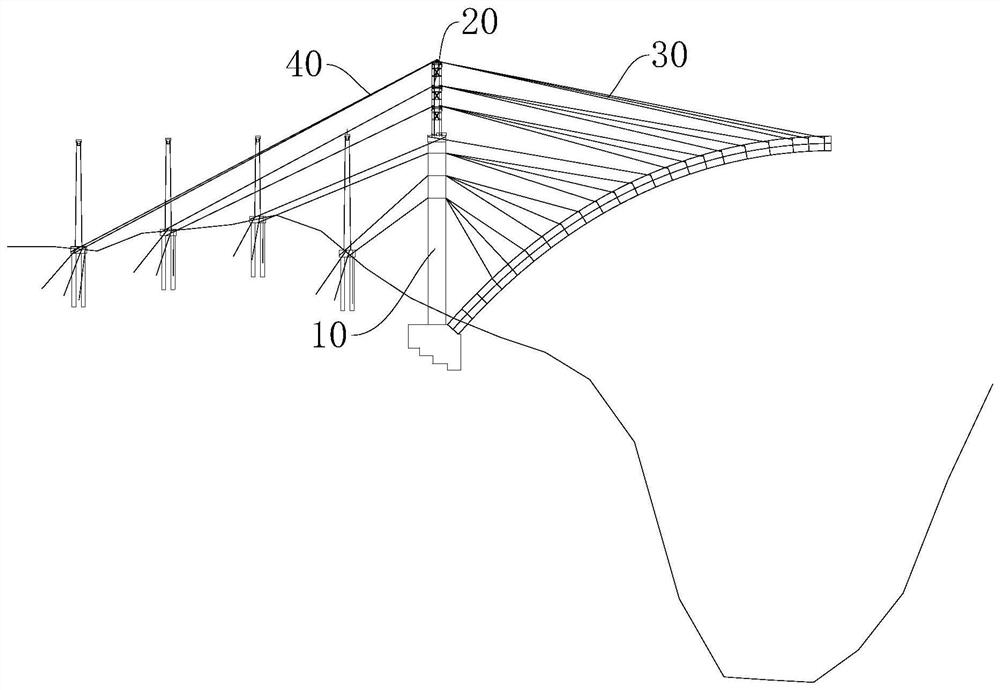

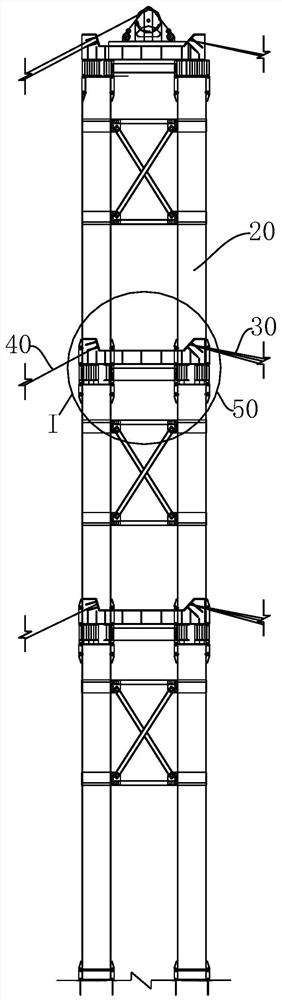

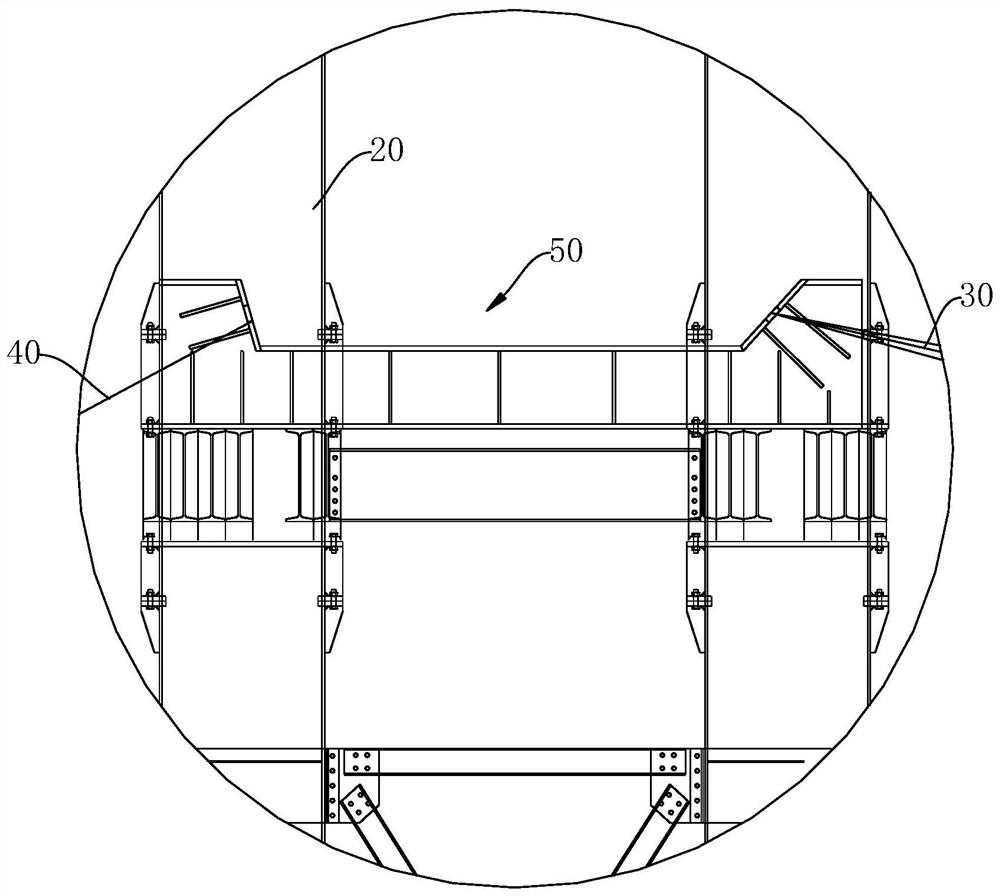

[0044] A kind of cantilever casting arch control method of long-span arch bridge, such as Figure 4-Figure 9 shown, including the following steps:

[0045] Step one, such as Figure 4-Figure 6 , the junction pier 1 is constructed in advance, and the buckle tower 2 is canceled on the top of the junction pier 1. During the construction process, according to the force requirements of the cantilever pouring in the later stage, multiple buckle cable anchor points 11 and anchor cable anchorages are set at different positions of the junction pier 1 pier body. Point 12, the anchorage point 11 of the buckle cable is connected to the buckle cable 3, and the buckle cable 3 is used for the cable-stayed buckle hanging cantilever to pour the main arch segment, the anchor cable anchor point 12 is connected to the anchor cable 4, and the anchor cable 4 is used to balance the force of the buckle tower 2 .

[0046]Step 2: After the construction of the junction pier 1 is completed, the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com