Prestressed light pile for rapidly anchoring emergency bridge inhaul cable and construction method of prestressed light pile

A prestressed, light-weight technology, applied in bridges, sheet pile walls, bridge parts, etc., can solve the problems of increasing the amount of work, prolonging the construction progress, and the weight of steel pipe piles, so as to increase the uplift bearing capacity and improve the uplift resistance. The effect of carrying capacity and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

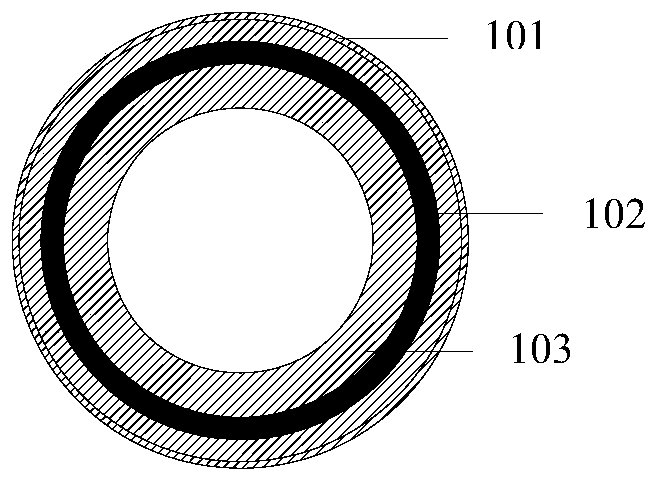

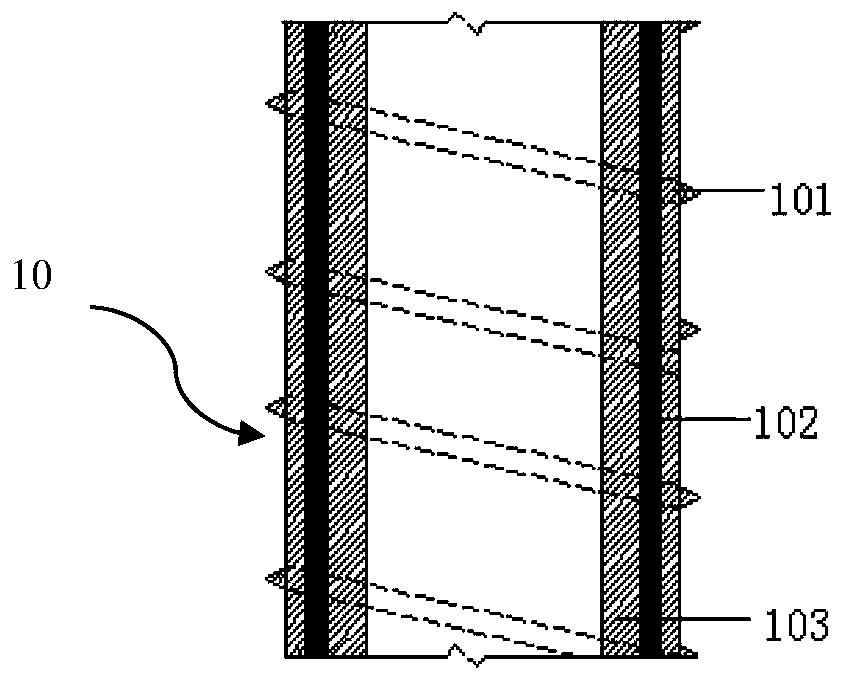

[0027] Such as figure 1 and figure 2 As shown, a prestressed light pile for quickly anchoring emergency bridge cables according to the present invention includes a hollow pile body 10 and a pile cap 20 arranged on the upper end of the pile body 10 and the pile body for interference fit.

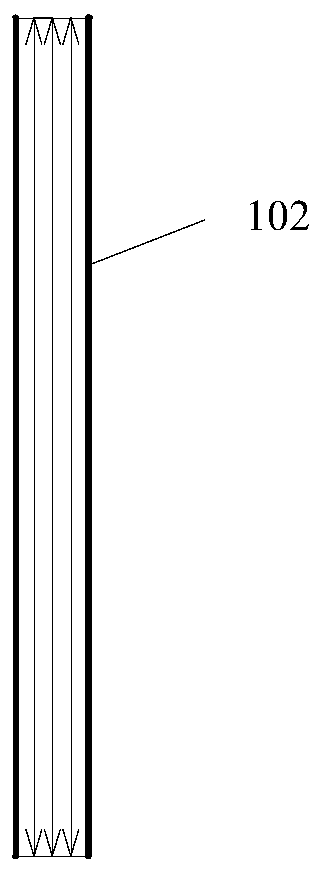

[0028] The pile body 10 is composed of three layers. From the outer layer to the inner layer, it is an outer tube 101, a middle tube 102, and an inner tube 103. The outer tube 101, the middle tube 102, and the inner tube 103 are arranged coaxially. The diameter is equal to the inner diameter of the outer pipe 101, and the outer diameter of the inner pipe 103 is greater than the inner diameter of the middle pipe, so as to realize the interference fit between the inner pipe and the middle pipe.

[0029] The outer tube 101 is a hollow aluminum alloy outer hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com