Cross-member for the base region of a motor vehicle body shell structure, a method for producing a cross-member and a motor vehicle body shell structure

A bottom area, motor vehicle technology, applied in the direction of superstructure, substructure, vehicle components, etc., to achieve high stability and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

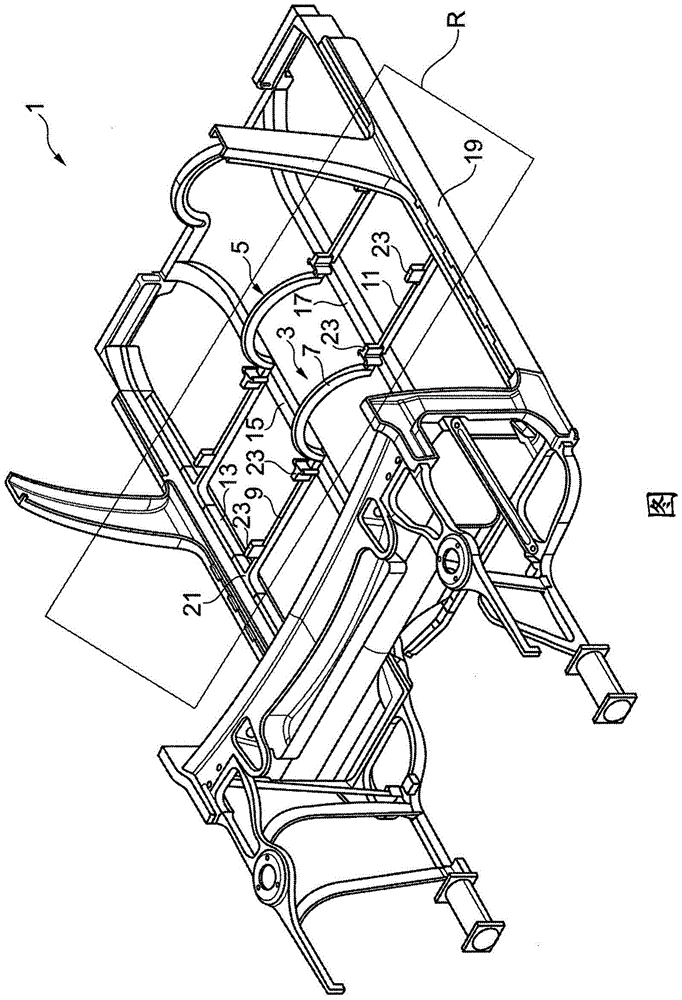

[0028] The drawing shows an exemplary embodiment of a motor vehicle body-in-white structure 1 , the area of the motor-vehicle body-in-white structure 1 being indicated by a rectangle R, within which a first cross member 3 and a second cross member 5 are arranged. In the illustrated exemplary embodiment of the motor vehicle body-in-white structure 1 , the first cross member 3 and the second cross member 5 are designed identically, so only the first cross member 3 will be described in detail below. The design of the first transverse beam 3 also applies to the second transverse beam 5 .

[0029] In a further embodiment of the motor vehicle body-in-white structure 1 two different cross members 3 , 5 or only one cross member or more than two identical or different cross members can be provided.

[0030] The cross member 3 provided for the underbody region of the motor vehicle body-in-white structure 1 has an arcuate middle part 7 which bridges the central tunnel region of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com