Material composition for preparing brick and prepared brick

A material composition and a technology for bricks, which are used in the field of material compositions for preparing bricks and bricks, can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

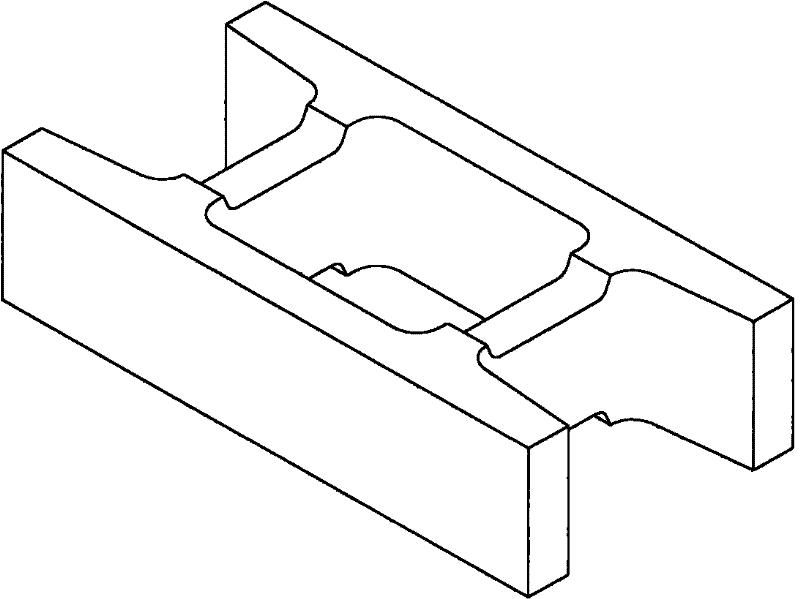

[0028] 100 parts by weight of cement (Tangshan Liujiu Cement Factory, 425), 450 parts by weight of aeolian sand (average particle diameter of 120 microns), 1.2 parts by weight of water reducing agent (Beijing Muhu Additive Co., Ltd., ABS), 1.5 parts by weight of redispersible rubber powder (Shijiazhuang Longrui Building Materials Co., Ltd., LR-80, weight average molecular weight 3500, average particle diameter of 80 microns) and 1.5 parts by weight of glass fiber (length 5 mm, average 10 microns in diameter) are mixed together and introduced into the mold, and cured under the condition of air relative humidity greater than 80, to obtain figure 1 Brick A1 shown.

Embodiment 2

[0030] 100 parts by weight of cement (Tangshan Liujiu Cement Plant, 425), 1200 parts by weight of aeolian sand (average particle diameter of 40 microns), 2 parts by weight of water reducing agent (Beijing Muhu Additive Co., Ltd., ABS), 1 part by weight of redispersible rubber powder (Shijiazhuang Longrui Building Materials Co., Ltd., LR-100, weight average molecular weight 6000, average particle diameter of 180 microns) and 0.5 parts by weight of plant fiber (length 12 mm, average 40 microns in diameter) are mixed together and introduced into the mold, and cured under the condition of air relative humidity greater than 80, to obtain figure 1 Brick A2 shown.

Embodiment 3

[0032] 100 parts by weight of cement (Tangshan Liujiu Cement Factory, 425), 800 parts by weight of aeolian sand (average particle diameter of 40 microns), 1.5 parts by weight of water reducing agent (Beijing Muhu Additive Co., Ltd., ABS), 3 parts by weight of redispersible rubber powder (Shijiazhuang Longrui Building Materials Co., Ltd., LR-80, weight average molecular weight 3500, average particle diameter of 150 microns) and 1 part by weight of synthetic fibers (length 8 mm, average (20 microns in diameter) are mixed together, and introduced into the mold, and cured under the condition of air relative humidity greater than 80 to obtain figure 1 Brick A3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com