high mud content concrete

A technology for concrete and high mud content, applied in the field of concrete, can solve the problems of not being able to effectively reduce sand with high mud content, unable to meet various needs, single performance of admixtures, etc., achieving good economic and environmental benefits and good weather resistance. , The effect of improving strength and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

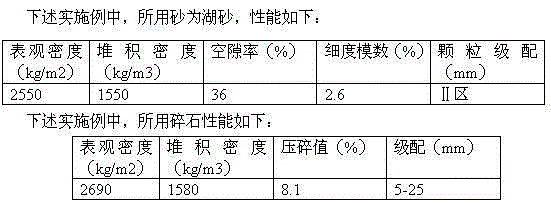

Examples

Embodiment 1

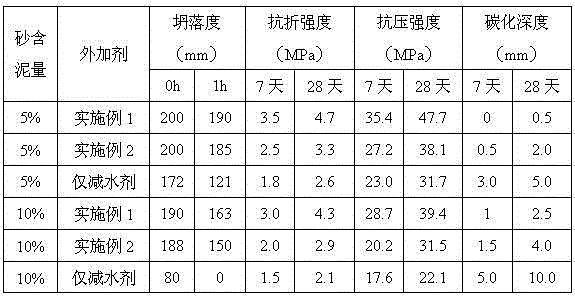

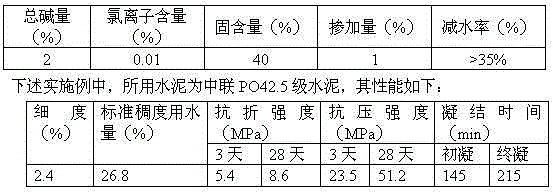

[0030] The formula of the concrete admixture of the present invention is: 45 parts of polycarboxylate water reducer, 16 parts of cellulose grafted chitosan, 16 parts of pretreated flue deposits, 6 parts of silane coupling agent, and 3 parts of polyvinylpyrrolidone , 2 parts of silicon carbide.

[0031] The preparation method is:

[0032] 1. Take the flue sediment, grind the sediment into fine powder, put it into water 4 times the mass of the sediment, ultrasonicate for 30 minutes, then filter and dry to obtain the pretreated flue sediment, which is ready for use.

[0033]2. Preparation of cellulose-grafted chitosan: add cellulose to distilled water, stir to disperse, pass nitrogen gas for 30 minutes to remove oxygen, then add potassium persulfate solution under nitrogen protection, pretreat at 55°C for 2 hours, then add A 1wt% acetic acid solution of chitosan dissolved with a crosslinking agent was reacted at 50°C for 4 hours. After the reaction, water-soluble impurities were...

Embodiment 2

[0036] The formula of the concrete admixture of the present invention is: 40 parts of polycarboxylate water reducer, 20 parts of cellulose grafted chitosan, 15 parts of pretreated flue deposits, 10 parts of silane coupling agent, and 1 part of polyvinylpyrrolidone , 5 parts of silicon carbide. The preparation method is the same as in Example 1.

Embodiment 3

[0038] The formula of the concrete admixture of the present invention is: 50 parts of polycarboxylate water reducer, 15 parts of cellulose grafted chitosan, 20 parts of pretreated flue deposits, 5 parts of silane coupling agent, and 5 parts of polyvinylpyrrolidone , 1 part of silicon carbide. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com