Construction structure and construction method of a cast-in-situ box girder prestressed steel tendon

A technology of prestressed steel beam and box girder, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the inability to meet construction conditions, and achieve the effect of simple structure, speeding up the progress of the project, and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

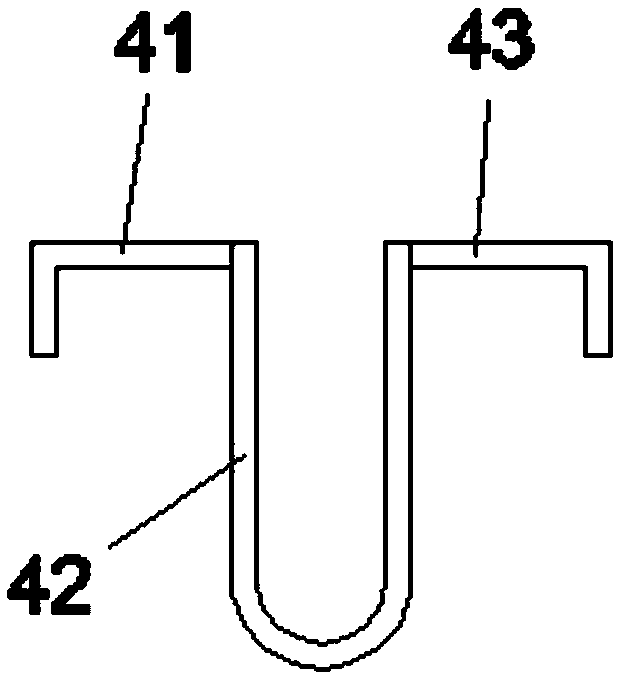

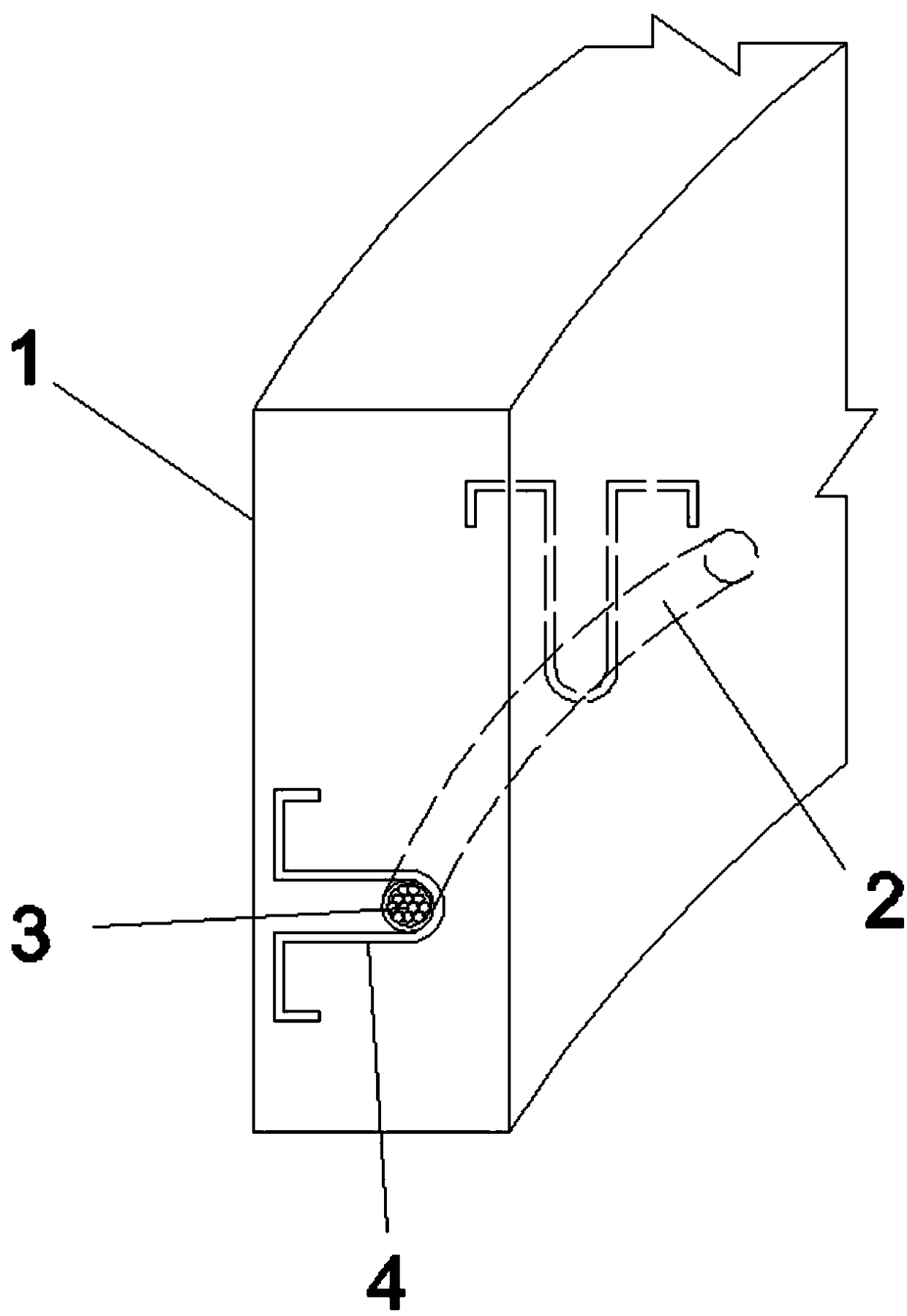

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing, so that those skilled in the art can understand more clearly, as figure 1 and figure 2 As shown, the present invention adopts the following scheme, including the skeleton steel bar 1 of the box girder, and the construction structure also includes a bellows 2, a prestressed steel beam 3, and several limit steel bars 4, and the space limit steel bar 4 is fixed on the frame steel bar 1 Above, the corrugated tube 2 is placed in the limit steel bar 4, and the corrugated tube 2 is set on the prestressed steel beam 3. The limiting steel bar 4 includes a left section 41, a middle section 42 and a right section 43, the left section 41 and the right section 43 are L-shaped, the middle section 42 is U-shaped, and the bellows 2 is located in the middle section 42. The left section 41 and the right section 43 are welded on the skeleton reinforcement 1. The opening direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com