PV-led integrated double glass module packaging method

A PV-LED, 1.PV-LED technology, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of LED lamp bead package damage, single application, and affect the quality of components, etc., to achieve structural strength and heat preservation The effect of performance satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

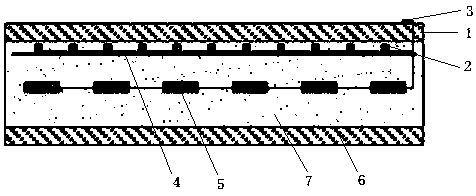

[0032] The PV-LED integrated double-glass component packaging method described in this embodiment includes the following steps:

[0033] (1) Pre-packaged glass-encapsulated LED strips on the back

[0034] a: Choose 5mm back glass, and the specification is 480X560mm, yellow LED light strip as the base material;

[0035] b: Using the glue dropping method, first place the back glass flat on the work surface, use AB glue to fix the LED light strip and the filler made of pvc board together, and then use epoxy glue to put the LED light strip and the filler in the middle Fill the gap, vacuumize for 1 hour, heat and cure under pressure -90kpa, cure at 55°C, bake and cure for 2 hours, and cure the light strip on the back glass;

[0036] (2) PV-LED integrated double glass module packaging

[0037] a: Put the front glass flat on the working table, and then install PVB adhesive film, battery sheet, PVB adhesive film, single-sided fire-resistant phlogopite mica tape, PVB adhesive film, a...

Embodiment 2

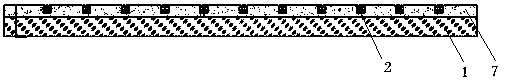

[0040] The PV-LED integrated double-glass component packaging method described in this embodiment includes the following steps:

[0041] (1) Pre-packaged glass-encapsulated LED strips on the back

[0042] a: Choose 3mm back glass, and the specification is 1000x560mm, red LED light strip as the base material;

[0043] b: Using the glue dropping method, first place the back glass flat on the work surface, use AB glue to fix the LED light strip and the filler made of pvc board together, and then use liquid silicone rubber to put the LED light strip and the filler in the middle Fill the gap, evacuate for 0.9 hours, heat and cure at a pressure of -80kpa, cure at a temperature of 50°C, bake and cure for 3 hours, and cure the light strip on the back glass;

[0044] (2) PV-LED integrated double glass module packaging

[0045] a: Place the front glass flat on the worktable, and set POE film, battery sheet, POE film, polyethylene terephthalate, POE film on the front glass in sequence....

Embodiment 3

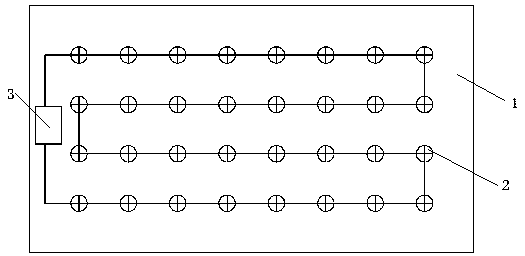

[0048] (1) Pre-encapsulation of glass-encapsulated LED beads on the back

[0049] a: Use 5mm back glass and orange LED lamp beads as the substrate;

[0050] b: Using the glue dropping method, first place the back glass flat on the work surface, use AB glue to fix the LED lamp beads and the filler made of pvc board together, and then use epoxy glue to put the LED lamp beads and the filler in the middle Fill the gap, vacuumize for 0.85 hours, heat and cure at a pressure of -85kpa, cure at a temperature of 50°C, bake and cure for 1.5 hours, and cure the lamp beads on the back glass;

[0051] (2) PV-LED integrated double glass module packaging

[0052] a: Place the front glass flat on the working table, and then install EVA film, battery sheet, EVA film, ethylene-tetrafluoroethylene copolymer, EVA film, and pre-packaged after step (1) on the front glass. The back glass is packaged by lamination method, using the press frame process, the temperature is 135°C for 1500s, the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com